What Are Barcodes?

Barcodes are a visual representation of numbers, letters, and symbols. The characters are encoded in black and white areas.

Barcodes are easy to create. They can be made in Excel, Word, or nearly any PC or Mac application that allows you to change fonts; via online barcode generators; or via dedicated inventory management programs. Learn more about creating a barcode in Excel.

How Do Barcodes Work?

Businesses use barcode inventory management systems to assign a number to each product they sell. They can associate several data points to the number, including the supplier, product dimensions, weight, and even variable data, such as how many are in stock.

Barcodes can also be assigned to locations, such as a bin on a shelf in a warehouse or stockroom. When a product is placed in the location, a worker can scan both the product and the location codes, and the inventory system will record the location data.

You can think of a barcode as you would the license plate on a car. ABC123 (an example plate number) has no real connection to what make, model, or year a car is or who owns it. However, the number is stored in a database and refers to your car’s registration information (including your name and address), any outstanding tickets, and more. Likewise, when you scan a barcode on an item in a business’s warehouse, you’ll receive information on the product itself, whether it’s red XL t-shirt or a replacement piston for a tugboat engine.

Understanding and Mastering Barcode Inventory Control

Barcodes systems are great tools for inventory management and control. They can speed up the process of both shipping and receiving goods, ensure a more accurate count of what’s on hand, and reduce costs. By printing and scanning barcodes, an organization can track everything that comes into or out of a warehouse or stockroom. Larger businesses can track inventory across multiple locations, with immediate updates to a database, so anyone in the company can know what’s in stock anywhere in the world.

What Is the Difference Between UPC and SKU?

UPC (Universal Product Code) and SKU (Stock Keeping Unit) are terms used in retail. While both UPCs and SKUs are generally barcodes, they serve different purposes.

UPCs are coordinated through an organization called GS1 (GS stands for global standard). By working through a centralized organization, manufacturers and vendors can sell their products in many places, including online. Customers and potential customers can use the UPC to research and compare product prices across websites. No other company can use the UPC for their product (this helps to protect the brand).

The UPC standard includes a manufacturer code, a product code, and a check digit (which helps verify that the code was scanned correctly).

A SKU is internal to a company and helps companies keep tabs on items in stock from the moment they are received until they are sold. Because SKUs are internal, companies don’t register them with a central organization. Businesses can use UPCs as SKUs, but internal SKUs offer more flexibility. Organizations can create them manually (by entering the required numbers into a barcode creation tool) or automatically by using a software package.

| UPC | SKU | |

|---|---|---|

| Registration | Manufacturers register with GS1 and are assigned a company prefix for use in their UPCs | N/A |

| Encoding scheme | UPC-A is the most common encoding scheme in North America, EAN-13 in the rest of the world | Varies, but Code 39 is the most common |

| Creation | Using a GS1-assigned company prefix, manufacturers add a product number, and then calculate the check digit, which creates the final UPC | Companies can assign any set of characters (numeric, alphanumeric, section, etc.) as a SKU |

| Length | UPC is 12 characters, EAN is 13; there are variations and add-ons for certain situations | No prescribed length, but generally 8 characters |

How Do You Read a Barcode?

The ambitious among us could learn to read a barcode by eye, but it makes more sense to use a scanner. Below are a few facts about scanners:

- The most common type of scanner is the laser scanner.

- Linear imagers take a photo of the barcode, then analyze the image. This only works on 1D barcodes.

- 2D area imagers are similar to linear images, but can also read 2D and stacked barcodes.

- You can also use smartphones (or other mobile computers) as scanners with certain apps.

1D Barcodes

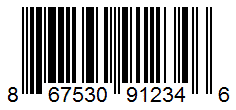

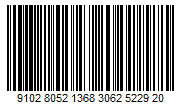

Data in 1D barcodes is encoded in vertical lines and spaces that vary in thickness. You can find 1D barcodes on almost every manufactured product in existence, as well as on shipping labels. The encoded data sometimes appears above or below a 1D barcode.

There are a number of different 1D barcode encoding schemes. Some include numbers only, while others also include letters and punctuation. Common codes include the following:

- UPC-A: Standard UPC, it encodes 12 numeric characters.

- UPC-E: A version of UPC that has six digits for use when there is limited space to print the barcode.

- UPC-2: A two-digit addition to UPC that allows periodicals and magazines to indicate the edition or issue.

- UPC-5: A five-digit addition to UPC that allows book publishers to indicate the suggested retail price.

- EAN-13: EAN (European Article Number) is a type of UPC that originated in the EU. It uses 13 digits.

- Code 39: The most popular non-UPC barcode. It encodes numbers, letters, and some punctuation.

- Code 93: A version of Code 39 that allows for higher-density printing.

- EAN-128: An alphanumeric code most often used on shipping labels.

- Interleaved 2 of 5: A nine-digit numeric code used on rolls of film and on shipping cartons.

- USPS IMB: IMB (Intelligent Mail Barcode) is a proprietary, variable-length alphanumeric code used by the United States Postal Service for sorting and routing mail.

2D Barcodes

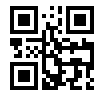

Data in a 2D barcode is encoded in pixelated dots or shapes (usually in a square or rectangle, rather than in vertical lines). Compared to 1D barcodes, 2D barcodes can encode more data — as such, 1D barcodes are often only a reference to product information records stored in a database, whereas you may not need to link 2D barcodes to a database.

Most 2D barcodes have features (like the squares in the three corners of a QR code) that help orient the scanner; therefore 2D barcodes are also called matrix barcodes. Examples include the following:

- QR Code: The most common type of 2D barcode, QR (Quick Response) is often used to open a website or an app when scanned with a mobile phone. QR is a matrix and can contain over 7,000 characters.

- PDF417: Used for transit passes, state-issued IDs, and U.S. postage (from vendors like Stamps.com), PDF417 (Portable Data File) is a stacked code and can contain about 800 characters. PDF417 is not related to PDF documents.

- GS1 Databar: This is stacked variation of EAS used when there is limited space for a barcode to be printed. It can contain 14 characters and was formerly known as RSS-14 (Reduced Space Symbology).

- Data Matrix: Similar in appearance to QR codes, data matrix is often used to mark small electronic parts (it can be read at a small scale) and on food packaging labels. It’s a matrix code that can contain about 2,300 characters.

- Aztec: Aztec is commonly used for transit tickets. The name was chosen because the central portion (for scanner orientation) resembles a satellite view of a step pyramid. It’s a matrix code that can contain about 3,800 characters.

- MaxiCode: Originated by UPS, MaxiCode is a matrix code that can store about 90 characters, but they can be chained in a series of up to eight codes. It uses hexagonal dots rather than the squares seen in most other matrix codes.

How Do Barcode Scanners Work?

Barcodes scanners are tools that attach to a computer or smartphone, and are pointed at a barcode to read and decode the information stored in them. A barcode scanner can be fixed (like at store checkout kiosks) or handheld (like at rental car agencies).

A scanner shines a light (usually a laser or LED) that’s reflected back; white spaces reflect better than black. The scanner also has a sensor that reads the pattern of reflected and nonreflected lights, which is translated into a series of binary digits. The scanner sends the digits to the computer, which decodes them into the string of characters that were originally encoded.

Because there are different schemes for encoding characters, the software has to know which scheme was originally used.

How to Use Barcodes in Inventory Management

In the following sections, you’ll learn how implementing a barcode system can aid in your inventory management efforts.

How to Use Barcodes for Your Business’s Stock

Using barcodes in your organization is not as simple as printing a bunch of stickers and slapping them on products. You’ll need to do some planning and figure out their impact. Below are some key points to consider:

- The barcoding process need to be scalable, so it can keep up with growth.

- A standardized pattern of codes for various products would be a smart move. For example, all clothing barcodes could start with 1, shirts could have 1 as the second digit, and pants could have 2.

- Label items at the quantity they are sold (piece, box, pallet, etc.).

- Ideally, the barcode system will interface with your existing accounting system. This will reduce the need for file transfers and manual processes.

- Eric Woods is a warehouse, process, barcode, and mobile application troubleshooter at Legacy2Mobile. “Accounting is tied to inventory control — obviously accounting needs to know when goods are received and when goods ship out. Inventory control has to work with this accounting package that then helps narrow the field,” he says.

How to Implement a Barcode System

First, assess your current inventory management processes. Doing so may uncover problems that need to be fixed before implementing a change. Eric Woods says, “If we're not doing barcoding, we're doing clipboard and pen, and we're losing inventory. The inventory counts don't match what we see in the warehouse, and there are all kinds of issues. We don't have products to fulfill this order today. I thought we did. The system says we did.

“The problem may very well be a process problem. In my work, part of what we do is walk through the process, through each step that has to happen for a product to be received. Invariably, that reveals either inconsistency, inefficiency, or glaring areas that can allow error,” he says.

Next, verify that the hardware and software you are considering work together; some combinations integrate better than others.

Additionally, note that some barcode ending schemes can be read from longer distances. Determine if this might be a concern for your operation.

You may be able to use supplier’s codes, but they may not be the best option. You can work with suppliers to see if they can add your barcodes before they ship to you. Woods advises, “Let's say you have a new supplier who ships something and has some random barcode on the box, but it doesn't really mean anything about what’s in the box. Hopefully you can put some pressure back on the supplier to change it, so you're able to use a barcode that's been generated by somebody else to track a product that's coming in.”

Components of a Barcode System

In addition to a software package, you’ll need to invest in a few more items to complete your barcode system.

- Barcode printers to print tags for items:

- Standard office printers and labels are OK, but the printouts are more likely to smear.

- Thermal printers are cheaper and last longer. Woods says, “You're going to need either a thermal transfer printer or a direct thermal printer to print barcodes.”

- You’ll also need to buy a supply of labels compatible with the printer you choose.

- Barcode scanners to read the barcodes:

- Wireless scanners are good for real-time entry management and for mobile scanning.

- Wireless scanners can store data internally or on a memory card, or connect via Bluetooth/Wi-Fi/cellular.

- Some handheld USB scanners can be plugged into a computer or mobile phone.

- Wireless scanners need to be recharged periodically.

- Wired scanners are cheaper but need to be near an outlet, so they aren’t portable.

- If the work environment requires a ruggedized scanner, that will add to the cost.

How to Use a Barcode Scanner for Inventory Management

A barcode scanner is only one piece of a robust inventory management system. Software and a barcode printer are other key components. To learn more about how the system works, check out this section.

Inventory Management with QR Codes

QR codes are a great way to encode a lot of information into a small physical area without having to pull up a database to get information about the product (this is especially helpful if your warehouse doesn’t have Wi-Fi). But if any information changes, all existing QR codes will be outdated and require adjustments. For example, if you include the shelving location for a widget and then move the item — or if information about the price changes — all existing QR codes would have to be replaced.

You should examine your business processes, supply chain, and other factors to make sure the benefits of using QR codes outweigh the deterrents.

How Expensive Is an Inventory Management System?

As with most purchases, the cost of an inventory management system varies based on need. Make sure that whatever you buy will not only meet your current needs, but also serve projected future needs.

Some software vendors, including TradeGecko and NetSuite, offer a monthly or yearly subscription model, and the cost can vary based on usage, the size of the business, or the features needed. Some vendors provide free options and free trials.

Other vendors, like Gigatrak, sell the software. The cost varies based on the vendor.

There are also open source options, such as ABC Inventory and Fakturama, that may be free.

You can use Excel to track inventory if the program interfaces with the scanner. Add formulas to notify you in the case of duplicates, low counts, and unknown barcodes.

In addition to the software, you will also need to purchase scanners, barcode printers, and possibly other hardware.

Due to the number of variables involved, it’s difficult to give a price range, but businesses of all sizes and needs have many options available. Eric Woods says, “The low-end cost is around $1,000, and that gets you a self-contained inventory control system.” The caveat: Self-contained systems may not easily interface with other software.

From there, Woods adds, “We move up to about $5,000. Some of the nicer inventory control packages that interface (for instance) with QuickBooks, like Fishbowl, are $4,000 or $5,000.”

What Are the Different Types of Inventory Control Systems?

Inventory control systems can support a number of business philosophies, including FIFO (first in, first out) and LIFO (last in, first out). You can also categorize inventory control systems by what they do, including the following:

- Mail tracking

- Shipping, receiving, and counting inventory/product shipments

- Order management/fulfillment

- Warehouse management

- Manufacturing management

- Stockroom management

- Time and attendance tracking

- Asset tracking (computers, printers, and mobile devices assigned to employees)

- Field service management (tracking parts used in the field)

- Consumables tracking

The main types of inventory control systems are classified by when they reconcile the data they receive:

- Periodic inventory systems: These systems help an organization maintain a regular manual count of stock, parts, or ingredients to verify what they have on hand, and then enter that into the system. The time period for the manual count can be weekly, monthly, quarterly, or yearly.

- Perpetual inventory systems: These systems keep a real-time running tally of stock, parts, or ingredients as they are used/sold or brought in.

Examples of Inventory Management and Control Systems

There are a number of different inventory systems available. The list below is just a sampling and by no means a complete list.

- Fishbowl

- Wasp

- BarTender

- Label Matrix

- asap systems

- system_id

- Finale Inventory

- Quickbooks/Intuit

- Sortly

- Inventory Now

- Stock control

- Goods order inventory

- SOS inventory

- OnShelf

- JumpStock

- Business Inventory

- Canvas

- myStock Inventory Management

- Simple Inventory Control

- Cashier Live

- Rapid Inventory

- topShelf Mobile Inventory

- Inventory Droid

- barcode eXpress Pro

- On hand

- ComputerEase Inventory Control

- Inventory Scanner

- SphereWMS

- Scan to Spreadsheet

- GoCodes

- MobileFrame

- 2B-inventory

- Apptivo

- RIO Inventory

- Stock controller

- Inventory Counter

- Instant Inventory

- Spreadsheet & Inventory Pro

- Industrial IT Inventory Management

- AsCount

- Inventory Management

- StockZure Inventory Management

- SAP Inventory Manager Mobile App

- Odoo

Benefits of Using Barcodes for Inventory Control

Properly implemented, a barcode system can improve inventory management and contribute to business growth. For example, Eric Wood notes improved turnaround times on orders: “How can we get stuff out of here faster? How can we fulfill orders the same day? How can we fulfill orders in the same order that we get them? Barcodes will be a critical part of that.”

Barcode systems can also help provide the following:

- Increased efficiency and productivity by reduction of manual entry

- Improved accuracy of inventory counts

- Increased cost effectiveness by simplifying processes

- Real-time reporting and more accurate data analysis

- Notifications when inventory hits a threshold

- Streamlined reordering and purchasing processes

- Improved loss security

- Process can be made more adaptable and versatile

- Less reliance on paper

A barcode system can also help an organization improve performance of the following key tasks:

- Real-time data

- Lot and date code tracking

- Shipping and receiving

- Retail process integration

- Connection to protect catalog and inventory system

- Order packaging

- Photos of items

- Sort, filter, and search

- History tracking

- Report creation

- Location tracking

- CMS and sales integration

- Vendors and purchase order tracking

- Lot and serial number tracking

- Business operation tracking

The History of Barcodes

In 1948, Bernard Silver (then a graduate student at Drexel University) heard the president of a supermarket chain discussing his desire to implement a system to automatically read product information, rather than having checkers manually enter prices into a cash register. Silver brought in a friend, Norman Joseph Woodland, to work on the idea. They first tried creating a system that used ultraviolet ink, which showed some promise but turned out not to be workable.

Woodland went off on his own and created the idea of a barcode after drawing lines in the sand inspired by Morse code; dots became thin lines, dashes became thick lines. He then turned the lines into concentric circles to allow omnidirectional scanning.

In 1949, Woodland and Silver applied for a patent. It was issued in 1952, and it covered both the linear and circular versions.

Barcodes were first used in 1961 by a railroad to identify cars while they were in motion, then spread to toll bridges, and finally inventory control.

The UPC was proposed in the 1960s and first tested in 1972 at a store in Cincinnati, using a circular code; the results from this test showed that vertical bars worked better. The first commercial scanning system was installed at a store in Troy, Ohio, in 1974.

The U.S. Department of Defense implemented a barcode inventory control system (using Code 39) in 1981; all vendors had to mark any products sold to the DoD with a barcode. This helped push them into more common use for inventory control.

Build a Powerful Inventory Management System with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.