What Is Value Chain Analysis? Porter’s Concept of Value Chain Analysis

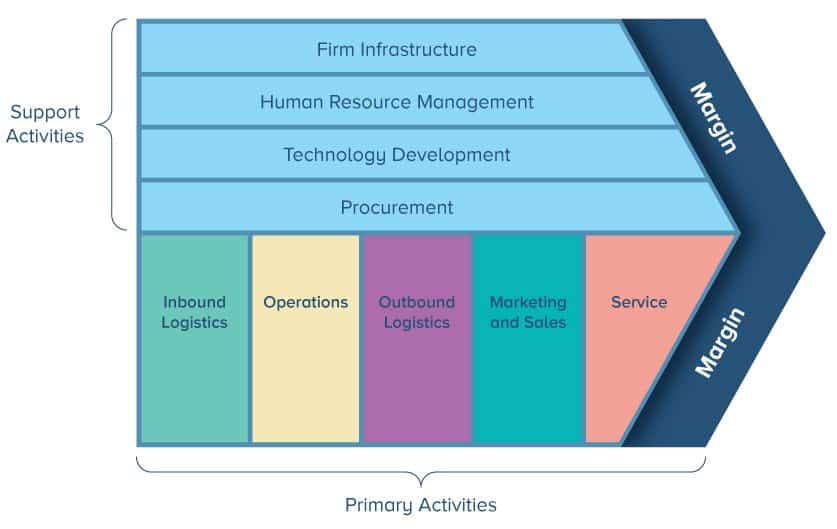

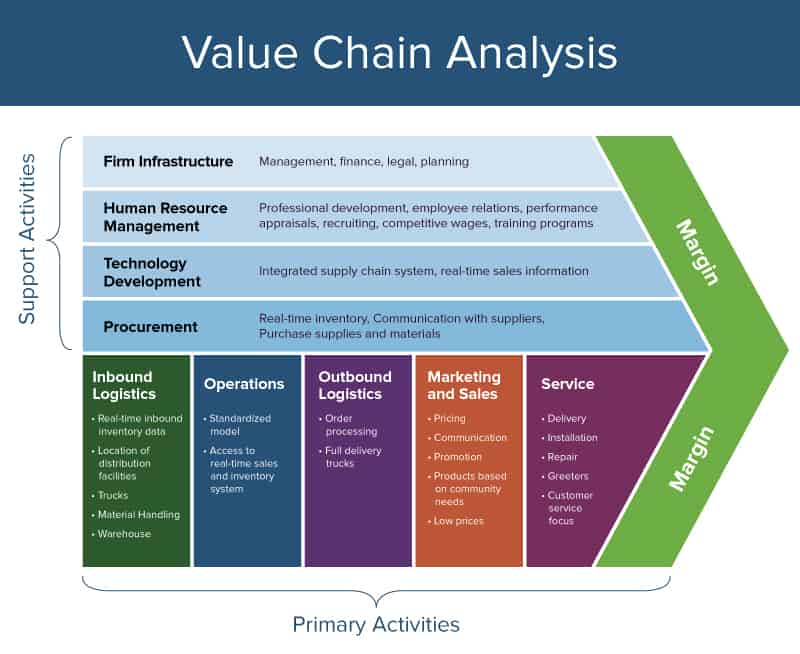

Value chain analysis focuses on analyzing the internal activities of a business in an effort to understand costs, locate the activities that add the most value, and differentiate from the competition. To develop an analysis, Porter's model outlines primary business functions as the basic areas and activities of inbound logistics, operations, outbound logistics, marketing and sales, and service. The model also identifies the discrete tasks found in the important support activities of firm infrastructure, human resources management, technology, and procurement.

The overall goal of value chain analysis it to identify areas and activities that will benefit from change in order to improve profitability and efficiency. For more on Porter’s value chain model and a detailed description of the goals, functions, and tasks of a value chain, read The Art of Value Chain Analysis. Here you will learn about Porter’s primary and supporting value chain activities and how to apply value chain analysis to your business.

What are the Cost Drivers of Value Chain Analysis?

Cost advantage results from a reduction in costs associated with activities in a value chain. After the value chain has been defined, it’s important to associate costs to the activities and then make adjustments for efficiency. Porter’s 10 cost drivers are factors that can impact the cost of an activity. An organization can aim to control these cost drivers in order to improve efficiency, add value, and differentiate.

- Economies of scale

- Learning and spillovers

- Pattern of capacity utilization

- Linkages

- Interrelationships

- Integration

- Timing

- Organization policies

- Location

- Institutional factors

Value chain analysis is more than a straightforward cost-to-profit model. It expands on the principles of economies of scale and capacity. There are limits to lowering costs and increasing capacity that can inhibit business growth. Value chain analysis stresses that competitive differentiation can also focus on the perceived value to the customer that justifies a product's price tag. Finding these perceived values could mean the difference between getting a consumer to spend three dollars on a cup of Starbuck's coffee rather than one dollar on a competitor's discount brand.

Who Uses Value Chain Analysis?

The management and analysis of value chains are becoming both industry specific and increasingly global, taking into account fast-changing markets, adjustments necessitated by new technologies, delivery methods, trade and government involvement, and fast-paced and fickle consumer demands. Add to that the global value chain's emphasis on sustainability, as well as its goal to expand the economic prospects of the world's poorest nations by fostering partnerships (especially in the agri-business sector). An example of this is discussed in the December 2009 briefing paper, Upgrading Along Value Chains: Strategies for Poverty Reduction in Latin America by Jonathan Mitchell, Christopher Coles, and Jodie Keane. In both micro and macro-change management strategies, business leaders continue to successfully implement Porter’s deceptively simple value chain framework.

The reason for this continued success is that Porter's framework is, first and foremost, a general model. It is not meant to be a standalone, rigid framework that creates barriers between functions or gives equal weight to every task that brings a product or service to market. Various departments, including human resources, marketing, sales, and operations utilize value chain analysis. Similarly, a wide variety of industries such as enterprise, manufacturing, retail, service, and technology, in addition to governments and their agencies, successfully adapt the basic value chain concept, and understand that not all functions or activities need to receive the same level of scrutiny.

For example, the Department of Defense (DOD) has a design-chain operations reference (DCOR) that cites little need to spend time or resources analyzing marketing and sales activities in their overall value chain. Although this is probably an accurate and reasonable evaluation for the DOD’s purposes, it’s one that few other enterprises are likely to echo.

Therefore, the first order of any value chain strategy is to identify the important tasks and functions necessary to deliver your product or service. Once you identify value activities, you can then focus analysis on where you can add value and discover areas for optimization, differentiation, or cost efficiency. When you complete these aspects of analysis, you’re ready to put together a plan for changes.

Examples of Value Chain Analysis by Industry

For now and into the near future, value chains are a useful management strategy for many different industries. However, as industries become more global, more cooperative, and more socially aware, they’ve come to perceive value chains differently based on their specific needs. Companies like FedEx see the future as a circular chain that values renewability. The World Bank, the United Nations Conference on Trade Development, and the International Crops Institute for the Semi-Arid Tropics all use global value chains to foster international cooperation to assist the world's poorest countries.

Companies that depend on global resources are developing initiatives to support global value chains by working with governments, United Nations partners, and economic aid organizations. In fact, in December of 2015, twenty value chain experts from various organizations, including OECD, FAP, ILO, UNIDO, WFP, WTO, ACID/VOCA, and GIZ, gathered for the “Inclusive and Sustainable Value Chain Development” meeting in Vienna, Austria, to discuss inclusive and sustainable agriculture value chains.

As one of the biggest purchasers of cocoa in the world, Nestlé has developed the "Every Woman, Every Child Initiative." To improve company value, they have committed to providing expertise, sustainable solutions, and social improvements, especially in the area of child labor. A number of companies create partnerships to provide opportunities for overseas development assistance through the development of agri-food value chains, such as those in the macadamia industry in Kenya, the sweet sorghum by-products in India, and the seed nut harvests in Uganda. These initiatives advocate a greatly expanded view of the value chain called collaborative value networks.

Additional examples include:

- Food and Beverage: Selecting and sourcing high-quality coffee beans, developing loyalty through excellent customer service, and aggressively marketing their brand were key elements in Starbucks’ creation of a unique identity and a robust competitive edge. Rather than focusing on premium pricing, Pizza Hut outpaced the competition by offering fast delivery of a less expensive product.

- Delivery Service: To increase market share and brand loyalty, FedEx's value chain emphasizes and invests in employee development through excellent human resources initiatives and infrastructure improvements.

- Retail: Walmart is constantly performing value chain analysis in order to keep costs low for their customers. From regularly evaluating suppliers and integrating in-store and online shopping experiences to remaining innovative in order to differentiate, Walmart is driven by their commitment to helping people save money.

Implementing and Using Value Chain Analysis

Porter’s generic strategies — so named because they can be administered to products or services in all industries — act as a starting point, not an absolute, step-by-step guide. However, Porter’s generic model identifies three general steps in value chain analysis: the initial evaluation of tasks, the location of areas of cross-functionality, and the discovery of dynamic areas of opportunity. For extensive strategies and actionable guidance to support or begin a process of value chain management, consult Michael Porter's book, Competitive Advantage.

Additionally, to help manage and fulfill the strategies of Porter’s model, there are numerous templates, articles, online courses, and other roadmaps available to develop goals, strategies, and methods of value chain analysis. Many present industry-specific insight, models, and assistance.

For example, approaches that focus on discovering cost advantages and disadvantages include:

- Identifying primary and supporting activities

- Rating the importance of each activity in providing value to the product or service

- Identifying the cost drivers that cause a change in the activity cost

- Identifying linkages and dependencies

- Identifying cost reduction and value improvement opportunities

Approaches with a focus on finding differentiation include:

- Identifying activities that create value for your customers

- Identifying differentiation activities that improve customer value

- Identifying the best opportunity for differentiation

Value chain analysis as a tool also concentrates on finding activity links or, as Porter called them, bridges between both the primary and secondary functions of a department, business unit, or enterprise. Although the model is clear in defining general, discrete functions, there are numerous areas of interactions and cross-functionality that can identify cost opportunities, areas of greater efficiencies, and methods to distinguish a brand.

Factors that can influence the value you provide include finding and utilizing the right people, motivating the team, remaining relevant, incorporating technology, and listening to customer feedback.

When analyzing the value chain, it is important to include many stakeholders, and to study the entire market to find areas for competitive opportunities. It is also vital to provide clarity and information, and to define goals. There are thousands of activities varying in importance in the primary and supporting areas of the chain, and opportunities are discovered through cooperative research and analysis, brainstorming, surveying, and observation.

Advantages of Value Chain Analysis

The advantages of value chain analysis can be seen by breaking product and service activities into smaller pieces in an effort to fully understand the associated costs and areas of differentiation. With value chain analysis, you can easily identify those activities where you can quickly reduce cost, optimize effort, eliminate waste, and increase profitability.

Analyzing activities also gives insights into elements that bring greater value to the end user. Some of the resulting activities may be as simple as negotiating with suppliers on raw material cost, focusing on end-user experiences that are enhanced by new communication or customer service experiences, and identifying activities that are better served by outsourcing — those that are not a core competency, result in process improvements, or are less expensive when performed by external suppliers. It is common practice for organizations of all sizes and in all industry verticals to outsource to strategic partners.

A company may choose to design a product or service, but use an outsourced provider to build or manufacture the product. When deciding to outsource, it’s important to consider whether the end customer will have a concern with the company outsourcing the specific activity, whether outsourcing impacts delivery time, and of course, the associated costs. In addition to negotiations, creating a better experience, and finding opportunities to outsource, analysis may also advocate the need for greater or more expensive resources that increase product value, develop loyalty, or create differentiation from your competition.

Disadvantages of Value Chain Analysis

Value chain analysis is no simple feat. Some of the difficulties involve gathering data (which can be labor and time-intensive), identifying the tasks or functions that can add perceived or real value, and developing and deploying the plan. Additionally, it is not always easy to find appropriate information in order to break your value chain down into primary and supporting activities.

Value Chain Analysis Tips

When implementing value chain analysis, questions of how to identify the relevant tasks, pinpoint areas for cost versus benefit, and locate the best strategies can be arduous for an in-house committee or a project manager. Here are some tips to overcoming these challenges:

- Involve your team in identifying and analyzing activities. Your results will be more thorough than if you attempt to identify them on your own.

- Obtain customer feedback on your results from a trustworthy, well-known customer.

- Decide whether you are trying to reduce costs or differentiate.

Ms. Roberts shares the following pointers on how to make value chains more efficient:

- “Minimize any and all waiting time. Don’t look at your timeline linearly, i.e., one task at a time. Instead, identify tasks you can start simultaneously based on dependencies. This can really help optimize your schedule.

- Standardize whenever possible. Is there a repeatable task that your company duplicates in numerous projects or jobs? If so, find the most optimal approach for that task and standardize it. This will increase efficiency substantially.

- Allow for wiggle room. If you plan for too tight of a timeline, you’ll run into problems. Build in time that allows you to react to uncontrollable interruptions; that is, make a contingency plan. If you don’t need it, great. If you do, it’s better to have planned for unforeseen delays.

- Communicate your timeline to stakeholders. I recommend clearly organized Gantt charts. Communicating these with clients and managers demonstrates organization and dependability. Update your timeline with the progress you’ve made as you move forward. This will help you build trust."

Today’s Impact on Value Chain Analysis

Many companies manage both physical and virtual value chains. The differences in approaches are best illustrated by comparing the consumer experiences of utilizing the services of a brick and mortar bank and those of online banking. Customer service experiences, infrastructure and technology needs, and personnel and training are a few of the many factors to consider when analyzing and adapting these value chains.

In reimagining the basic value chain, you should also study rapid technological advances. The Consumer Goods Forum Board findings recognize that the consumer is now more involved in product development. And, as society onboards new and unknown technologies, value chains need to be continuously reengineered. Societal questions about increased urbanization, the rapid rise of online shopping, and the changing expectations of the consumer are all considerations as valuable as the cost of raw materials, warehousing, and the delivery of any product or service. As companies adapt the basic value chain to the 21st century, many look at this methodology as a journey of transformation rather than a destination. As such, value chain analysis will continue to be a relevant and useful tool to develop and maintain a sustainable, competitive advantage.

Create A Collaborative Value Chain Analysis with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.