Deeper Definitions: What Does Operations Management Mean?

Operations management refers to the activities involved in overseeing the process of creating goods and providing services, including resources, technology, people, and products. These elements must be well managed in order for the business to remain competitive.

As we define operations management more fully, we consider these foundations of OM:

- Planning: Operations managers must constantly forecast, plan, and adjust to optimize processes based on conditions.

- Process: Production of goods or services requires having strong, repeatable processes.

- Efficiency: Managers must troubleshoot bottlenecks, inadequate resources, and downtimes to create optimal efficiency.

- Cost Control: Production is typically a major part of a company’s cost structure, and you must manage it wisely.

- Quality: Good quality control is necessary to maintain customer satisfaction and the company’s reputation. Companies can greatly suffer without it.

- Continuous Improvement: To remain competitive, companies need to have processes in place to consistently seek better ways of doing things.

- Technology: Underlying all of these foundations is technology. Well-used technology keeps a company ahead of the curve.

- Profitability: Executed properly, all of the above foundations lead to a strong bottom line.

Project Management Guide

Your one-stop shop for everything project management

Ready to get more out of your project management efforts? Visit our comprehensive project management guide for tips, best practices, and free resources to manage your work more effectively.

The History of Operations Management

Operations management dates back to 5000 B.C. with the Sumerians, who tracked inventories, transactions, and taxes, and has evolved into modern day services like overnight and same-day deliveries. We’ve listed some notable historical highlights below:

- The Industrial Revolution (1760s to early 1800s) ushered in the foundations of division of labor and interchangeable parts, keys to efficient production. Eli Whitney, inventor of the cotton gin, also manufactured 10,000 muskets by using the concept of interchangeable parts.

- In 1883, Frederick Winslow Taylor used the stopwatch method to time tasks for complex jobs. This became key for studying efficiency and productivity.

- In about 1912, Frank and Lillian Gilbreth laid the foundation for predetermined motion time systems (PMTS), which predict the time it takes to complete tasks.

- In 1913, Henry Ford’s first moving assembly line started rolling, cutting production time for a car from 12 hours to less than three.

- In post-World War II Japan, Toyota developed just-in-time production (JIT), later called the Toyota Production System. The company designed it to eliminate waste and increase productivity and quality.

- In 1971, FedEx started overnight package deliveries. Nowadays, Amazon even offers same-day delivery on orders.

The Importance of Operations Management

Operations management serves as an organization’s engine room, and plans and drives manufacturing and services. Operations managers maximize efficiency, productivity, and profit, which are vital to a company’s growth, survival, and competitive edge.

Most companies have an operations department with many employees and a large budget. Forbes magazine reported in 2011 that three-quarters of CEOs come from an operations background, which shows the importance of understanding how a company functions.

We can also see the importance of operations management in these aspects of a company’s success:

- Customer service

- Product or service quality

- Correctly-functioning processes

- Market competitiveness

- Technological advances

- Profitability

It’s no exaggeration to say everything depends on operations.

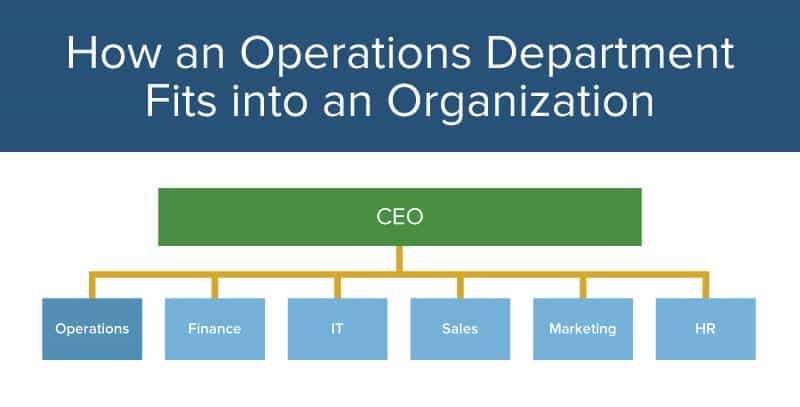

The Relationship of Operations Management to Other Departments

Operations managers facilitate cooperation between departments and ensure that department and company goals are aligned, and to standardize logistical approaches to budget and project constraints. Operations teams must collaborate with all other departments to be effective.

Operations Management Strategies

Operations managers are deeply involved in strategy, in addition to their daily production roles. From designing and testing processes to facilitating interdepartmental collaboration, we have outlined some key strategy and tactics points below:

- Data Use: Analytics are essential for strong planning, adjustments, and decision making. Two common types are efficiency metrics and effectiveness metrics.

- Inventory Analysis: To manage inventory in the supply chain, ABC analysis (also called Pareto analysis) comes into play. This method divides inventory into three categories: A, B, and C. Category A has the highest value and tightest controls, and Category C has the lowest value and loosest controls.

- Data Challenges: Data is often siloed, which makes it difficult to compare. But newer systems and setups make this process easier and help analysts and managers to examine data in new, helpful ways.

- Process Design: Researching, forecasting, and developing a sound process takes expertise and energy, but the results can be lasting.

- Forecasting and Goal Setting: The best forecasting often combines a look at historical data with an analysis of changing conditions.

- Collaboration Among Departments: With good communication and collaboration, operations management can work effectively with finance, sales, marketing, human resources, and other departments.

- Being Green: Ecological soundness has become a strategic and legal necessity at companies nowadays, especially in manufacturing.

- Managing People: With all the advancements in machinery and technology, people remain critical to the equation, though often in different types of jobs.

Levels of Operations Management

Operations management includes three levels: strategic, tactical, and operational. The strategic level defines company goals, and the tactical level outlines a plan to implement that strategy. The operations level contains the daily operations required to produce the desired outcome.

Principles of Operations Management

There are many widely accepted principles of operations management. Most experts advise a focus on organization, risk management, and adaptation. We’ve outlined two prominent lists of principles by experts below:

Randall Schaefer, CPIM, described The 10 Principles of Operations Management at his presentation at the 2007 conference of the American Production and Inventory Control Society (APICS).

- Reality: There is no universal solution to the problems in your business.

- Organization: You must organize all aspects of production into a coherent whole.

- Fundamentals: Adhere to fundamentals, such as accurate inventory records.

- Accountability: People try harder when they’re held accountable.

- Variance: Variance is part of every process.

- Causality: Problems are often symptoms. Get to the root cause.

- Managed Passion: People with a passion for their jobs will drive your company.

- Humility: You don’t have to know everything.

- Success: Define success, and change with the market.

- Change: Every manufacturing solution is temporary.

Another set of operations management principles comes from author Dr. Richard Schonberger. His 16 principles are:

- Team up with customers. Know what they buy and use.

- Engage in continual, rapid improvement.

- Maintain a unified purpose. Involve employees in strategy.

- Know the competition.

- Focus.

- Organize resources.

- Invest in HR.

- Maintain equipment.

- Use the simplest, best equipment.

- Minimize human error.

- Cut times. Shorten the product path to the customer.

- Cut setup.

- Pull the system. Improve the workflow and cut the waste by producing on demand.

- Employ total quality control.

- Fix root causes.

- Manage visibility. Let the market know about your achievements.

Types of Production and Production Systems

You can categorize production and production systems in several ways, including by technical elements, processes, or lead time. Most modern production systems are software-based, meaning that planning, scheduling, and inventory control systems and processes are managed by software.

- Technical Elements: This includes machines, tools, and organizational behavior, such as people, division of labor, and information flow.

- Process Production versus Parts Production: Process production means the product undergoes a physical-chemical transformation, such as paper or cement. Parts production means parts are made and assembled into a product.

- Lead time: Categories include purchase to order, make to order, assemble to order, and make to stock.

The Biggest Operations Management Challenges

Some of the biggest operations management challenges include acquiring and maintaining the right workforce and the right technology. We’ve asked our experts to weigh in on some other common challenges below:

David Shelton: COO of healthcare service company PatientMatters lists these challenges: “Staffing: I'm convinced your staffing determines your success. A mixture of new employees combined with seasoned experts allows your operation to maintain stability while training staff, expanding sales opportunities, and identifying new solutions to existing problems. Technology: Whether a service provider or manufacturer, new technology and your ability to understand and react to internal data will dictate your operational success. Growth: Do you have the materials, vendor relationships, and labor to keep pace with your sales team and market demands?"

Tips for Good Operations Management

Operations management is concerned with the quality of a company’s technology and people. Our experts provide their best tips for how to maintain quality resources to ensure efficient and effective operations management:

- Keep Current on Innovation Trends: “Take the time to listen to suggestions of tech-savvy employees; only use technology that is simple to use and engaging for employees at every skill level,” suggests Tsidon. “Invest in educating managers and employees on the goals of implementing new systems, and make sure to build in rewards so that everyone is motivated to learn and use new technology.”

- Encourage Effective Communication: “Make sure that you communicate processes, rules, and policies to everyone. Have a smart marketing plan and be up to date. Pattern your marketing plan after whatever is on trend. Do it as soon as possible, and use that concrete plan with a timeline until a new trend arrives. Have weekly reports of everything about the company. Then, from there, manage everything based on the needs of each category,” says Jing.

- Collect Data Electronically: “Having team members write down their processing numbers for data collection can lead to inaccurate data and [will] not give you the results you need to run your operations efficiently,” explains Leonard. “Use report dashboards and rely on data and analytics. Determine what information you need to run your business, measure it, and use analysis to augment your process and continually improve your operations. Be customer-focused: Design your processes with the end customer in mind. Think about what they see as value and what they’re willing to pay for, as well as how quickly they expect to get results.”

- Listen to Your Teams: “Field-level employees, internal sales, and vendors have invaluable information and know what is going on with your product or services and the competition,” notes Shelton. “Measure and analyze. We are constantly examining our internal processing times and employee performance and measuring success rates. Measuring your internal performance allows you to exceed customer demand. Expand your network. Managers from competitive firms change jobs. A friendly relationship can become a key alliance. Vendor partnerships in developing new products or services allow you to grow your operations while controlling costs. Joint ventures that benefit both parties can substantially increase your knowledge base while increasing your speed to market.”

- Slow Down: “It’s important to consider the side effects of each decision and how you relay communication to the team,” advises Wilhelmi. “People tend to like working for (and have higher engagement with) leaders who maintain a level head and aren’t too quick to pass judgment. Be proactive and strategic. It’s important that leaders aren’t reacting all day. The constant reactionary environment can turn great leaders into fire chasers, which tends to devolve their communication. Stay focused on the numbers. If something isn’t working as it should, it’s better to focus on the measurable data than on the emotion of disappointment or the result. When you can tweak a process and measure it along the way, you remove the subjectivity and remain objective.”

- Assign an Internal Owner: Make sure every project has an internal owner, or it can go off track,” says Wiegand. “Understand the key performance indicators that will drive the business. Just because you can measure it doesn’t mean it matters. Protect the data. Operations managers have to safeguard the info. Consider leveraging infrastructure as a service, with hosting, security, and redundancy built-in.”

- Keep Up With Your Field: “Read a lot. Learn a lot. If you’re a logistics manager, connect with your tech people,” suggests Lowe, Jr.

Current Trends in Operations Management

The field of operations management has evolved over time to keep pace with technology and human behavior. From Lean manufacturing to sustainability, we’ve outlined some current and existing trends for operations managers:

- Business Process Reengineering (BPR): BPR helps companies revamp their organizations from the ground up by reorganizing and reassigning processes to better align with company goals.

- Lean Manufacturing: Lean, Six Sigma, and Agile are disciplines focused on efficient, adaptable production. They continue to be mainstay approaches.

- Reconfigurable Manufacturing Systems: These systems are designed to be flexible and adaptable to sudden market changes.

- Behavioral Operations Management: This approach focuses on human behavior as it relates to operations management.

- Sustainability: This approach highlights maintaining ecologically-minded practices under changing laws.

Expert Opinions on Operations Management Trends

Most experts agree that computers and tech are at the center of operations management. We’ve gathered expert observations of current operations management trends, from data visualization and forecasting to further trends, below:

- Data Visualization: “The key trend that I see is companies combining data visualization with key performance indicators to create real-time monitoring and management systems,” says Tsidon.

- Automation: “I see firms moving toward technology to solve the mundane, time- consuming, and error-prone tasks that inhibit operations teams from providing the best service to customers,” Leonard notes.

- Trend Forecasting: “How can you incorporate internal and external data to make decisions that are ahead of the curve?” asks Shelton. “The best sports analogy I know is ‘Skate where the puck is going.’ We've got to be planning ahead in order to anticipate customer needs and beat our competitors; managing resources and minimizing waste. Both product and service organizations wrestle with maximizing resources (materials or staff) to produce the best product for the consumer.”

- Collaboration: “I see operations management becoming more closely aligned with human resources as companies are increasingly aware of how important their culture and human capital are as they relate to operations and engagement,” observes Wilhelmi.

- Location Technology: “With hyper-accurate location services, one trend is using that technology for real-time alerts, such as for a dementia patient wandering off,” says Wiegand.

- Use of the Internet: “Internet shopping continues to be a big trend, involving pretty much any product, including food. Amazon sends some products within a few hours of being ordered. You better be able to match that. You have to be able to meet tighter inventories, such as just-in-time (JIT) stocking, with some food staples, such as bread and eggs, arriving two or three times per day,” notes Lowe, Jr.

What Is the Future for Operations Management?

The future of operations management can be inferred from its past. While no one can know for sure, our experts anticipate a future of ever-increasing data and technology, including self-drive vehicles and the automation of low-skilled jobs.

- Automation: “With increasing automation will come sweeping organizational change,” Tsidon says. “Operations are going to reduce hierarchy and make management easier, so, while many are concerned about the loss of low-level jobs, I see that there will be a sweeping change at every level, including upper management. Previous positions that needed highly skilled workers will no longer exist because artificial intelligence will provide better results without human error. In the future, the most valuable management skills will be the ability to combine data analysis with emotional intelligence. This is something that no algorithm can replace and that will be more crucial than ever.”

- Remote Management: “The future will bring remotely-handled operations management. Nowadays, there's nothing a remote worker cannot do. It is possible, and it will be the next trend,” predicts Jing.

- May Require a Technical Background: “I envision operations management becoming a high-tech position, requiring a highly analytical skill set and product-focused mindset,” says Leonard. “With Amazon delivering packages on the same day, customers are coming to expect instantaneous results, and, to maintain competitiveness, operations needs to drive toward that type of success.”

- Larger Focus on Quality Labor: “There are opportunities presented by technology to build or service faster, better, and cheaper. It’s critical to utilize technology, interpret data, source new materials, and identify talented labor. You must confront labor challenges and build a better workforce. How do you better utilize your labor force? Improved recruiting techniques allow you to draw in new labor, but how can you also better train existing staff to advance within the organization? This is a key area we are focusing on. We strongly believe we have an obligation to train our existing team to grow and advance internally,” explains Shelton.

- Human Resources: “The future of operations management is sliding toward creating data (so it can be measured and studied from an objective position) around the culture of a company’s human operations. Dozens of reports have come out in the past few years that are confirming that lack of engagement by employees leads to a substantial loss of productivity — or worse, high turnover. In the truest sense, it’s the operations manager’s responsibility to maximize their operations. The better your culture, the better your operations,” observes Wilhelmi.

- Location Based Services: “The future will include location-aware devices and smart buildings that will maintain themselves,” predicts Wiegand. “For example, an elevator could know that it needs service work through data inputs and could initiate the repair as part of a structured workflow. There will be greater use of artificial intelligence to recognize a problem and start a workflow. There will also be greater use of predictive analytics. Moreover, you’ll see greater protection of proprietary data, especially if problems result from data being too available. Finally, you’ll find greater gender equality in operations management. We certainly have great female leaders in operations today. That diversity brings a lot of value.”

Other Resources for Operations Management

- American Production and Inventory Control Society (APICS)

- Journal of Operations Management

- Professor Gad Allon's online course, Northwestern University

- Wharton online course

- University of Illinois online course

- Introducing Operations Management

Effectively Manage Operations with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.