What Is Six Sigma?

Six Sigma is a set of methods and tools to improve business processes. The practice provides a data-driven, statistical approach to identifying defects, determining their causes, and improving the process to avoid continuous create errors and defects. Based on the past 60-plus years of quality improvement methods, Six Sigma was formalized in the 1980s for use in manufacturing. Since then it has become widely used throughout finance, healthcare, IT, the military, and more. In the 2000s, a new approach called Lean Six Sigma was formulated, which combined the Lean principles with Six Sigma to reduce variation, defects, and waste.

With Six Sigma, a team trained in the use of analysis tools and Six Sigma methodology researches and implements improvements. This task training leads to certification and a belt to indicate a level of proficiency.

Project Management Guide

Your one-stop shop for everything project management

Ready to get more out of your project management efforts? Visit our comprehensive project management guide for tips, best practices, and free resources to manage your work more effectively.

What Is Six Sigma Certification?

Certification proves to employers that you have a standard set of skills based on one of the Six Sigma bodies of knowledge. Companies often sponsor individual candidates for outside training, or they provide customized, in-house training to standardize team members’ knowledge baseline.

Certification can offer many advantages to individuals and companies, but it can also pose some difficulties:

Certification Pros for the Individual:

- Show proficiency in Six Sigma subject matter

- Improve chances of promotion

- Gain hands-on experience in quality management

- Increase attractiveness to potential employers

- Increase your salary

- Employment at biggest companies in the world

- Nurture your managerial and leadership abilities

- Transfer skills across industries

Certification Pros for Companies:

- Helps organization eliminate errors and waste

- Ensures better customer relations through efficiency

- Aids with Business Process Improvement (BPI)

- Sustains quality improvements in organizations

- Measures and quantifies financial benefits

- Ensures compliance

- Organizations that successfully implement the Six Sigma culture are some of the most highly touted in the world, with the highest customer loyalty ratings and one-tenth the typical organization’s cost of poor quality.

Certification Cons for Individuals and Companies:

- Certification, including training and examination fees, can be expensive, especially for individuals

- Small companies may not require practitioners to have certification

- Subject matter expertise and education may be enough

“Six Sigma helps in a career, especially if you’re going into a managerial position. It’s also helpful for a person who may be an individual contributor, but they’re empowered to make suggestions or present ideas on improvement,” says Jennifer Williams, a Lean master Black Belt and President and CEO of Integrity Business Consulting. “It helps put the data behind your recommendation. You say, This is where the baseline is today and we’re trying to get here, if we make those changes.”

Not everyone believes that formal certification is essential to success with Six Sigma. “You don’t have to have a black belt, or a master black belt to be qualified to implement Six Sigma,” says Sermin Vanderbilt, Founder of Lean and Six Sigma World Conference and President of the American Quality Institute. “Of course having those certifications can give you added benefits, but it should not be viewed as essential to implementing Lean and Six Sigma.” She thinks that very small companies can implement Six Sigma practices just as well, if one of the principals has a solid, basic engineering or technical degree. “To get you going, take any basic book about lean and Six Sigma or supply chain management, that should be sufficient for most small companies. It’s about asking, what can you do to make your processes more efficient.”

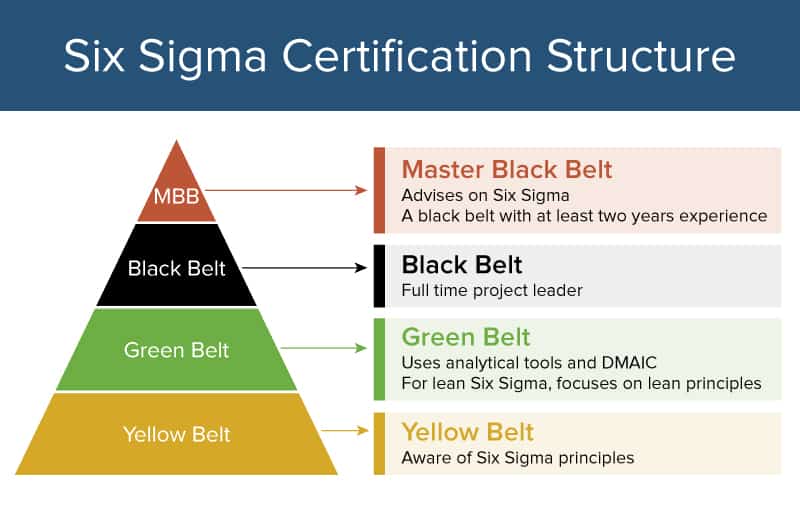

The Six Sigma Belts

As discussed earlier, trained teams in many different kinds of organizations implement Six Sigma principles and methodologies. As in martial arts, belts designate levels of training and experience. Here’s an overview:

- Executive Leadership: The CEO and other executive staff establish the vision for the Six Sigma implementation. They support management and are considered sponsors of initiatives. Executives may take orange belt training to familiarize themselves with Six Sigma.

- Champions: The executive leadership selects champions from upper management. Champions ensure that all departments in an organization work together to implement Six Sigma, and also to mentor Black Belts. They are also considered project sponsors. A Champion may be a Master Black Belt, but they may also simply sit in Orange Belt training or take one of the few Champion level course offerings.

- Master Black Belts: Champions select Master Black Belts, whose sole job is to advise on Six Sigma practice throughout the organization. People with a Master Black Belt identify potential Six Sigma projects for the company. Usually with project management experience, Master Black Belts have considerable opportunity to move between industries. Lean Six Sigma Master Black Belts are known as senseis. Training and courses can cost thousands of dollars.

- Black Belts: Master Black Belts supervise Black Belts, who execute the Six Sigma methodology for specific Six Sigma projects. Black Belts lead projects full-time, and their sole focus is statistical analysis using commonly accepted analytical tools and correct execution of the five phases of Six Sigma methodology. Black Belts have the opportunity to move between industries.

To embark on certification training, Black Belts are often expected to demonstrate leadership ability. The required training and math can be complex, and courses can cost thousands of dollars.

- Green Belts: Black Belts guide Green Belts are employees whose regular duties include implementing Six Sigma recommendations. Green Belts may analyze and solve process problems using recognized Six Sigma analysis tools, and may also lead projects part-time.

Some training organizations put restrictions on who qualifies for Green Belt training. For instance, you may need to have participated in a Six Sigma project previously, or spent a minimum number of years working in process improvement. You may also need to be a full-time employee or a full-time, paid intern. You are almost always required to show evidence of practical project work or make a presentation of a project to a certification committee.

For custom training, Green and Black belt training may be taught together so that team members can work from a common baseline of understanding.

- Yellow Belts: With a basic knowledge of Six Sigma, Yellow Belts participate in projects by creating process maps, and by managing smaller improvement efforts within larger projects. Some programs have Yellow Belts focus on design, measure, and control aspects of process improvement.

Testing is only theoretical and consists of multiple choice questions. Test fees range from as low as $50 to between $250 and $400. ASQ provides discounts to members.

- Orange Belts: Not widely offered in training organizations, Orange Belts enter training at an introductory level. Orange Belts largely represent specialized areas that a company may not feel is well represented by other belts.

Testing may include only theoretical topics and consist of multiple choice questions. Test prices range from around $250 to $400.

- White Belts: This level is a new Six Sigma concept and is not offered by every organization or training firm. Instead, the White Belt simply familiarizes employees and managers with Six Sigma and functions as a potential recruitment phase for future Six Sigma practitioners. White belts are not certified by IASSC.

The test may cost around $100, although in some cases is offered for free on-demand.

Lean Six Sigma

Some training organizations offer separate training for each Lean belt, particularly Lean Green and Lean Black Belts. Others offer regular belts, and then augment with Lean training. Lean includes sensei, a role similar to a Six Sigma Master Black Belt but that functions more as an advisory consultant rather than a manager.

Doing the Math

The power of Six Sigma is it’s foundation in statistics, which can provide impartial views into what’s happening in a business. A candidate with previous statistical training may find courses easier, but anyone who applies themselves can achieve a good grasp of Six Sigma’s statistical tools.

Job Titles and Companies That Use Six Sigma Skills

Many different companies have jobs that use Six Sigma skills. Some job titles include:

- Assistant plant manager

- Business improvement advisor

- Director of operational excellence

- Improvement advisor

- Manufacturing engineer

- Regional facilities manager

Additionally, many companies across industries use Six Sigma practices. These include:

- ADT Security

- Amazon

- Bank of America

- Quest Diagnostics

- Rolls Royce

- United Health Group

Does It Pay to Get Six Sigma Certification?

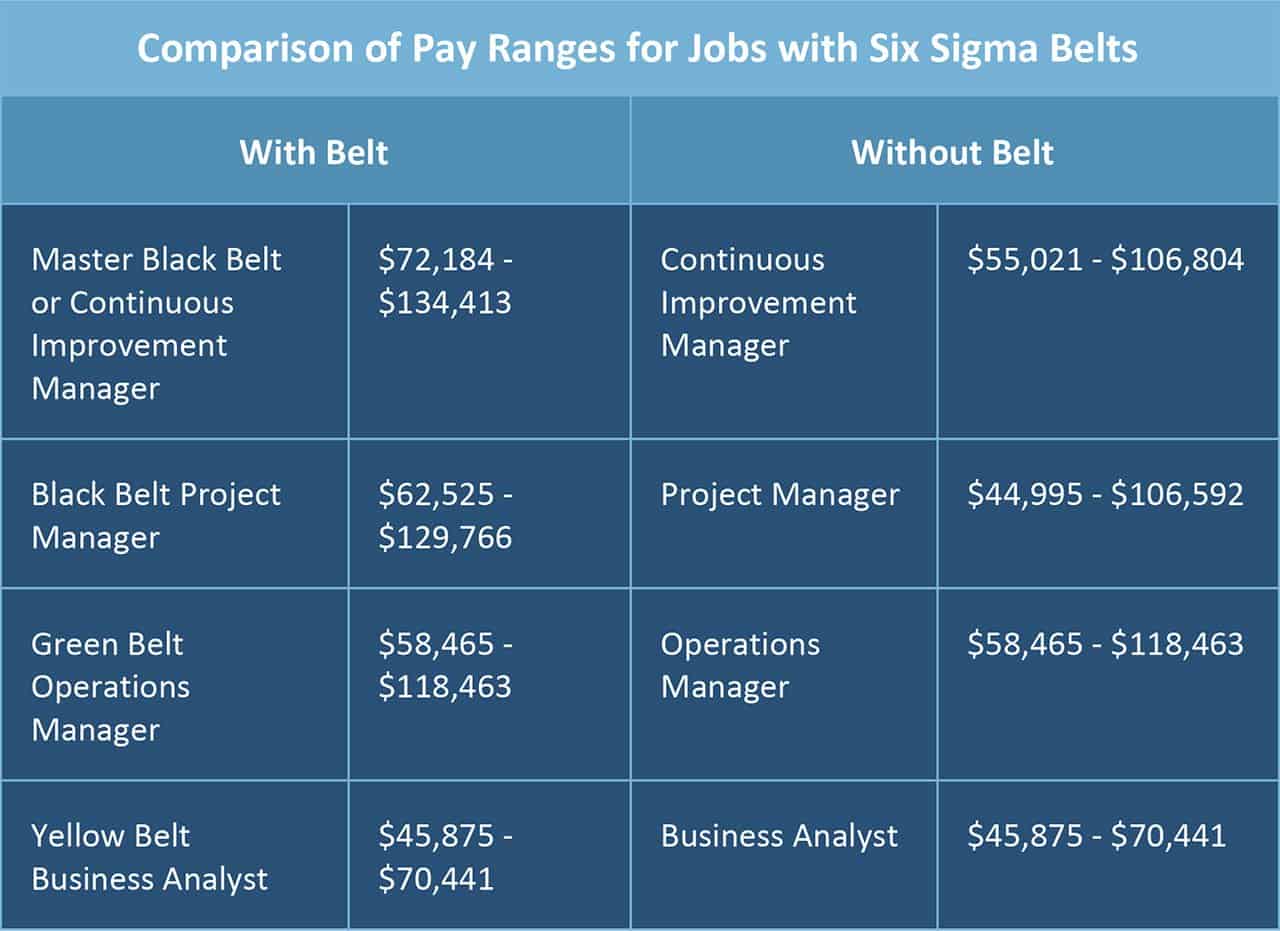

Certification bodies and training organizations claim that certification can increase pay, potentially earning certificate holders as much as those with an MBA. Payscale.com results show a lower pay range for the same job title without certification.

How to Acquire a Six Sigma Certification

You now know what role Six Sigma belts play in a company and how much people with belts get paid. But what else should you consider before embarking on certification?

“If you’re considering certification, you want to know that this is definitely something you’re interested in continuing on with because once you get trained and you don’t use it you kind of lose it,” advises Williams.

Prerequisites

White, Yellow, Orange, and Green belts usually have no prerequisites. Black Belts typically require a Green Belt, although some candidates with previous process improvement experience go straight into Black Belt training. Master Black Belts require a Black Belt.

However, considerations go beyond certificates, statistics, and class time. Williams says that project management experience and skills are essential. “If you are unable to communicate properly or successfully, or even to influence others, you will fail,” says Williams. “It does not matter how much you can do hypothesis testing, or any of the different types of analysis - if you don’t know how to leverage those softer skills or gain those softer skills, it will be very difficult to be a practitioner.”

Training Length

Black Belt: 75 - 80 hours of class time.

Green Belt: Length of training spans from 35 - 100 hours, and may include assignments.

Yellow Belt: Training and curriculum are much shorter, ranging from as little as seven hours to as long as two days.

Orange Belt: Curriculum is usually limited, and can last only seven hours.

White Belt: Certification training takes as few as two hours, and typically does not include a testing component.

Format for Certification

Some companies offer their own training customized to meet their circumstances. Companies may also pay for employees to attend training offered by outside companies. Finally, individuals may also choose to enroll in private training.

Training is available in a variety of formats. On-demand video is one option, and is sometimes combined with interactive exercises and scheduled virtual forums. Students and instructors communicate through email, VOIP conferences, and remote whiteboards. Other options include in-class training that may offer online exercises and communication.

Body of Knowledge

Certain fundamental principles are common to all Six Sigma training, but no single, agreed-upon body of knowledge exists. That said, many use the ASQ Body of Knowledge. Specific application can vary between instructing bodies, and some material is proprietary.

Some organizations offer separate Lean Six Sigma training. The ASQ offers coursework for Six Sigma, but refers students to the Society of Manufacturing Engineers for Lean certification.

Because curriculum is not necessarily applicable in every situation, some articles assert that students should to choose a program based on where they wish to work. Vanderbilt disagrees. “A Green Belt should be a Green Belt,” she says.

Curriculum and Course Requirements

Course materials include lectures and readings. In addition to the Body of Knowledge, instructors may assign other articles and books as supplemental resources. For higher belts, you may be required to do a project, or submit a work project and defend it to a panel (similar to presenting a thesis in school).

Course costs can range from a few hundred dollars (for White, Orange, and Yellow Belts) to several thousand dollars (for Black and Master Black Belt).

Certification Exam

One criteria common to all belts, except perhaps white, is a certification test. “If you’ve gone through a standard, reputable training program, then the tests are generally fairly straightforward,” says Kimberly McAdams, a Master Black Belt and Principal at Firefly Consulting.

Tests are held fairly frequently throughout the year, but you must register in advance. Some tests are available everyday on-demand. You must also take the exam within a certain period after completing training. There is also an exam fee that you will have to pay each time you take the exam.

Exams are multiple choice, may be taken online or in person (note that online exams may have more questions), and are usually timed. If you complete training online, you may still choose an in-person exam, depending on the school. Sample practice examples are available online and from training organizations.

For White, Yellow, and Orange Belts, the closed book exams are one hour and contain about 50 questions. For Green Belt and above, the exams contain 60-plus questions to be completed in three to four hours. While the exams are open book, notes may be limited to approved books or notes. You may also be able to use a laptop with mathematical software to make calculations. During in-class exams, you may be required to show your notes to the exam proctor.

You may pay for and take a recertification exam every few years.

Types of Questions

Exam questions test your knowledge of statistical analysis and Six Sigma principles. The examples below were taken here from sample exams posted on the Six Sigma study support site Six Sigma Study Guide.

- Statistical process control (SPC) is best defined as the use of…?

- Which of the following control charts is used to monitor discrete data?

- The following chart was developed by a Six Sigma team to measure reactions on two different products. In this chart, temperature represents the …?

Projects

As part of their certification, Green and Black Belts are required to complete at least one improvement project in their workplace, and either provide evidence of its completion or present and defend the project to a panel.

Similarly, Black Belts use Six Sigma 100 percent of the time and also complete a project related to their work.

Cost

Training and certification can be expensive. As Williams advises, seek certification only if you know you will use the training in your current or future job. The cost alone also suggests not doing so just to add letters behind your name.

Training costs for White, Yellow, and Orange Belts are usually well under $500. For Green Belts and above, costs increase dramatically. A Green Belt ranges from around $1,500 for about 35 hours of online training to $3,000 for eight days of in-class training. In-class Black Belt training can cost as much as $8,000, and expect to pay over $10,000 for a Master Black Belt.

Who Certifies the Six Sigma Certifications?

The Council for Six Sigma Certification describes itself as the “Official Industry Standard of Six Sigma Accreditation for Six Sigma training providers.” Basically, training providers who agree to contribute to and recognize the standards set by the council can then indicate that their practices are acknowledged by the Council as meeting an agreed standard. Their curriculum meets a minimum level for covering Six Sigma Body of Knowledge and certification testing is approved as meeting a baseline for proficiency. They do not provide training or certification, but list preferred providers.

The ASQ, “the champions of quality,” offers certification in Six Sigma Black, Green, and Yellow Belts, among other certifications.

The International Association for Six Sigma Certification (IASSC) focuses on supporting Lean Six Sigma certifications and trainer accreditations. The organization publishes the Universally Accepted Lean Six Sigma Body of Knowledge.

How Six Sigma Practitioners Get Optimal Results Using Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.