What Is Rough-Cut Capacity Planning?

Rough-cut capacity planning (RCCP) is a long-term capacity planning technique. RCCP validates the master production schedule (MPS). The goal is to ensure that companies don’t purchase or release an excess of materials.

It is not uncommon for the MPS to overstate the need for more materials than production can process. Once the RCCP analysis takes place, changes may trickle down to the MPS or available capacity to better balance raw materials, capacity, and demand.

What Is the Difference Between Rough-Cut Capacity Planning and Capacity Planning?

Capacity planning is a process to assess the amount of capacity the shop floor needs to meet the demand for products during a specific time. Capacity planning can be for the long or short term, whereas RCCP is a long-term capacity planning technique.

Capacity planning can help you assess the number of workers, skill sets, machinery, raw materials, suppliers, and resource budget.

What Is the Difference Between Rough-Cut Capacity Planning and Capacity Requirement Planning?

Capacity requirements planning (CRP) is a short-term capacity planning technique that determines whether you have the appropriate capacity to meet the demand for products. As mentioned, RCCP is a long-term planning technique.

RCCP is common in the early MPS planning stage, while CRP occurs at the end of the capacity planning process.

Rough-Cut Capacity Planning Software

Capacity planning software has made short- and long-term capacity planning more manageable and accurate. Before software automation, many companies planned once per year. With capacity planning solutions, companies can plan more frequently.

Traditionally, companies used Excel to perform capacity planning. But this proved difficult for getting a complete look at a company’s product portfolio, multiple locations, and work across teams. With digital innovation, organizations can integrate capacity planning and analysis, as well as ensure that investments in materials and resources align and that plans are optimal and achievable.

Types of Rough-Cut Capacity Planning

Capacity management techniques are for long-, medium-, and short-term planning. Rough-cut capacity planning is a long-term capacity planning technique.

Short-term capacity planning addresses unanticipated increases and decreases in demand. This approach can impact activities over a few days or up to six months. Such short-term planning often results in companies offering employees overtime to handle high product demand.

By contrast, long-term capacity planning looks at the big picture to ensure that the company has enough resources to meet long-term production needs. Long-term capacity planning typically focuses on strategic decisions that impact technology, processes, and locations.

For example, suppose in the short term, overtime does not increase production enough to meet demand. In that case, it might be necessary to add more equipment or facilities in the long term.

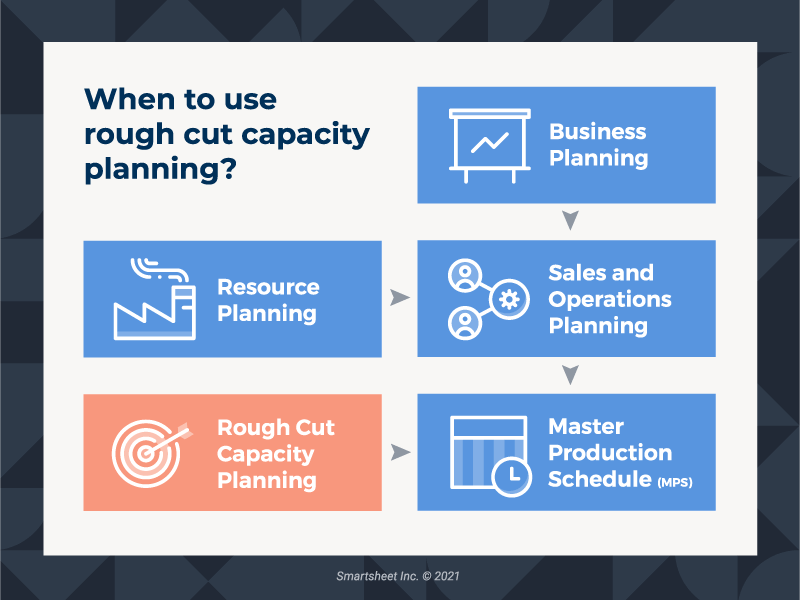

How to Determine When to Use Rough-Cut Capacity Planning

RCCP takes place after the demand planning process and once the master production schedule is complete. At this point, the capacity manager must validate production decisions to meet demand.

As depicted in the diagram below, both the business plan and the sales and operations plan feed into the master production schedule. RCCP takes place after the MPS is complete and might impact changes to the MPS.

Rough-Cut Capacity Planning Methods

Three rough-cut capacity planning methods are available: capacity planning using overall factors (CPOF), capacity bills, and resource profiles.

Capacity Planning Using Overall Factors (CPOF)

Capacity planning using overall factors (CPOF) uses historical data to determine future capacity needs. This simple approach looks at the MPS, the time to produce a product, and workstation data.

According to a research study from the steel industry, Analysis of Production Capacity Planning and Control in Pt. Krakatau Wajatama with Rough Cut Capacity Planning (RCCP), “CPOF estimates work capacity at each work station in each MPS period.”

Capacity Bills

The bill-of-labor (BOLA) or bill-of-capacity approach to capacity planning assesses the number of hours it takes at each workstation to produce a finished product.

The researchers suggest utilizing the bill-of-labor approach for multi product companies. The BOLA approach provides a direct link between the number of hours it takes to develop an individual end product in each workstation to the quantities in the MPS.

Resource Profile Approach

The resource profile approach looks at the time it takes to complete each activity while also including lead time. This approach is more accurate because it goes beyond the workstation hours to consider resource lead times.

The Levels for Calculating RCCP

RCCP can take place at two levels. You use routing-based RCCP when you want to capacity plan by resource. Then use rate-based RCCP to plan by production line.

The output of both routing- and rate-based RCCP is a statement of capacity load ratio. An example formula is as follows:

Capacity load ratio = Required capacity / Available capacity

Routing-Based RCCP

Routing-based RCCP evaluates required and available capacity in hours per week for each resource. This level of RCCP demonstrates your resource availability.

The routing-based RCCP formula is as follows:

Resource capacity load ratio (hours per week) = Resource required capacity (hours per week) / Resource available capacity (hours per week)

Rate-Based RCCP

Rate-based RCCP measures required and available capacity per week per production line. This level of RCCP demonstrates your production line capacity.

The rate-based RCCP formula is as follows:

Production line capacity load ratio (per week) = Production line required capacity (per week) / Production line available capacity (per week)

Rough-Cut Capacity Planning Examples

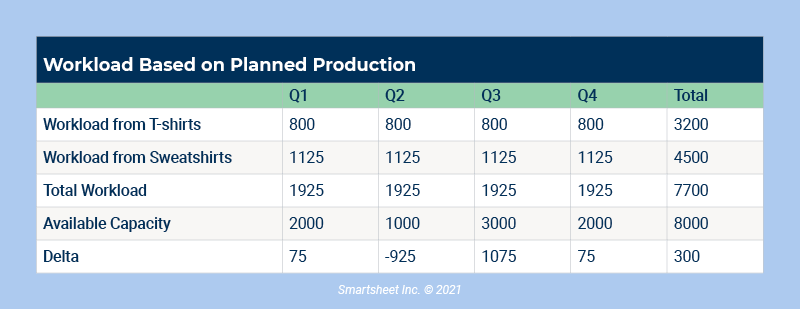

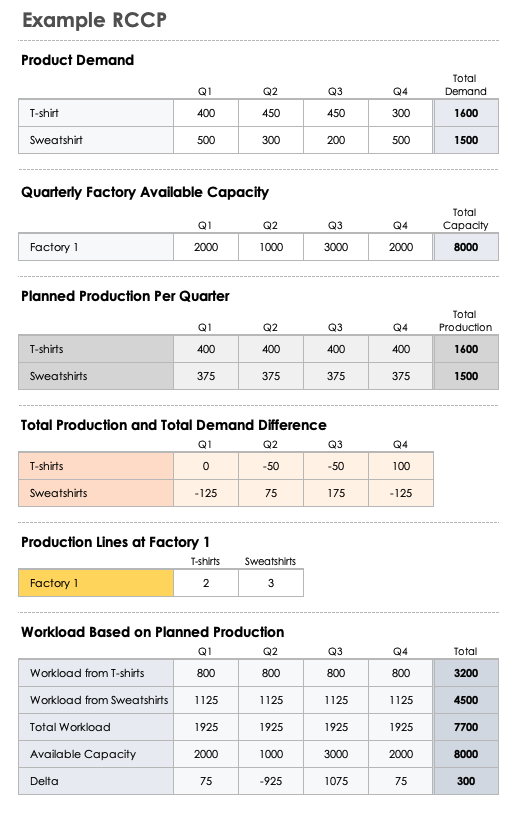

The example below walks through a RCCP scenario at a garment factory. Begin with the demand for each product, the capacity for the factory per quarter, and the number of production lines.

Using the production plan, you will understand gaps in production capacity and make adjustments. In this example, you will see that modifications need to occur to accommodate Q2 demand. The company in this example might be able to shift capacity from Q3 to Q2.

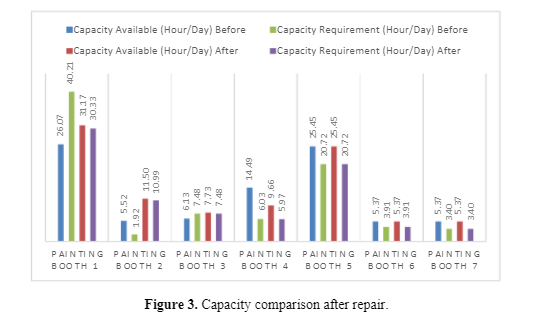

Another example comes from M Sugarindra and R Nurdiansyah at the Department of Industrial Engineering, Universitas Islam Indonesia, Yogyakarta, Indonesia. The study “Production Capacity Optimization with Rough Cut Capacity Planning (RCCP)” demonstrates the improvements to production plans based on the findings of rough-cut capacity planning. In this research paper, the researchers analyzed the production of musical instruments.

According to the study, “The company's success in achieving its goals is the ability to meet demand and provide satisfaction to customers.” Unfortunately, there is an imbalance between capacity available and capacity requirements. The analysis determines that “workload rearrangement must be carried out to distribute labor and increase work hours 90 minutes and 120 minutes so that demand can be fulfilled.”

As presented in the research paper, the graph below shows how redistributing excess workload away from painting booth four and adding overtime helps overcome capacity deficiencies in painting booths one and three.

Rough-Cut Capacity Planning Example for Calculating RCCP

To use this rough-cut capacity planning template, adjust the product demand, capacity, production lines, and production plan to reflect the parameters of your company. This template will help you discover any gaps in capacity.

Download Rough-Cut Capacity Planning Example

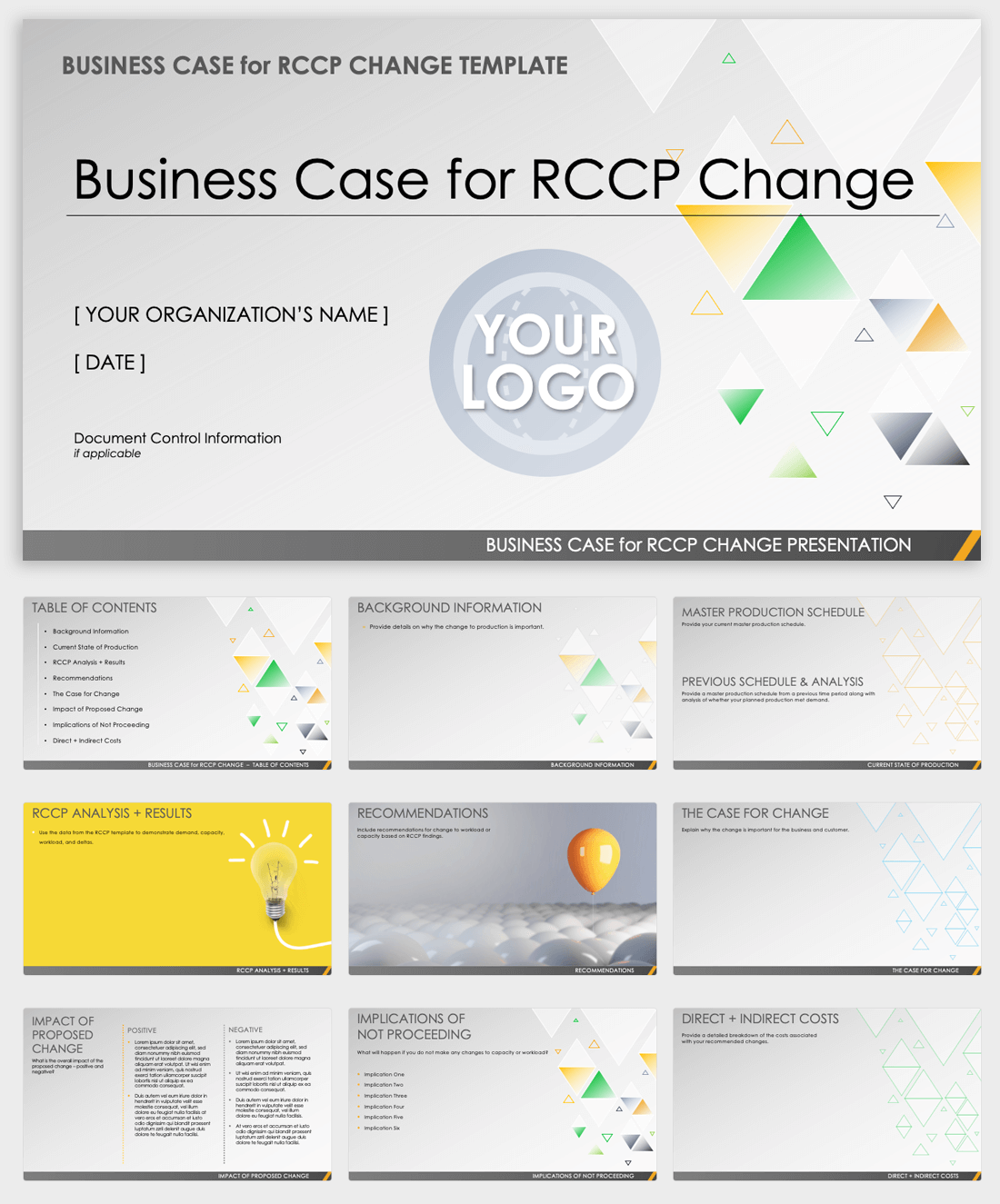

Rough-Cut Capacity Planning Business Case Template

Fill in this PowerPoint presentation to build a business case from the findings of your RCCP analysis. The template will prompt you to include your current state of production, RCCP findings, recommendations, and costs.

Download RCCP Business Case for Change

Rough-Cut Capacity Planning Starter Kit

Use this comprehensive, dynamic set of tools to get started with RCCP. The starter kit includes our RCCP template with predefined formulas, a garment factory example, and a business case presentation template.

Rough-Cut Capacity Planning Tips

Raqeyah Jawad Najy, Industrial Management Researcher, recommends RCCP for validating the MPS. In “Rough Cut Capacity Planning-(RCCP)-(Case Study),” he cites an overstated MPS as the most common problem with MRP-based systems.

“An overstated master production schedule orders more materials than the production resources can complete,” he writes. The main problem with an overstated MPS is that too many materials are purchased and released to the shop. In turn, the shop does not have the capacity to produce the final products from these materials.

An overstated MPS “causes a buildup of queues on the shop floor. Since jobs have to wait to be processed, actual lead times increase, causing ship dates to be missed. As lead times increase, [forecasting] over the planning horizon becomes less accurate.” The most accurate forecasting is done in shorter periods of time. Ultimately, “overstated master production schedules lead to missed due dates.”

Referencing the “Production Capacity Optimization with Rough Cut Capacity Planning (RCCP)” research study mentioned previously, the researchers suggest that “not achieving the production target in the painting department will have a major effect on the delay in sending the piano to the customer.” In this case study, an imbalance exists between the actual production and the production plan, which causes overload. The recommendation, then, is that “production capacity planning needs to be balanced with available production capabilities, both human resource capacity and the machinery capacity used.” When addressing these problems, you must integrate the production plan with the capacity plan.

Benefits of Rough-Cut Capacity Planning

The main benefit of rough-cut capacity planning is achieving a balance between production and demand, which in turn creates customer satisfaction. Other benefits include project, process, and resource management improvements and cost reductions.

Below are some additional benefits to effective rough-cut capacity planning:

- Improved Project Management: RCCP provides visibility into your production plans, which gives your team the ability to prioritize activities and plan projects more efficiently.

- Increased Resource Management Efficiency: Performing RCCP gives you an understanding of the hours spent on a particular product or workstation. This data supports a need to adjust resource capacity with overtime, outsourcing, shift adjustments, or additional workstations.

- Improved Processes: RCCP allows you to easily pinpoint problems or bottlenecks in production lines that you can correct. Doing so will reduce lead time, cut costs, and improve completion rates.

- Greater Understanding on the Impact on Critical Resources: RCCP sheds light on resources, labor, equipment, inventory, and storage that are performing well, as well as those that might be underperforming.

- Insight into Training Demands: RCCP can highlight skill gaps that require training to improve productivity.

Four Rough-Cut Capacity Planning Challenges

Capacity planning is a complicated undertaking. No matter the size or intricacy of a company, four obstacles can impact RCCP: access to data, calculations, communication, and time commitment.

- Data Quality: RCCP depends on data, and much of that data collection requires manual gathering and reconciliation. This results in more time spent finding the data you need than analyzing it. One way to overcome this obstacle is to export data from the appropriate sources and consolidate it into a single solution that allows for dynamic updates. This single source of truth provides a solitary access point to up-to-date information.

- Accurate Calculations: RCCP relies on several calculations that depend on accurate data. Any inaccurate data or calculation error risks creating problems with the entire RCCP process. To reduce the risk of error, maintain all calculations, data, and analytics in a single location.

- Communication: RCCP touches all areas of an organization. Geographical and functional separation adds to the complexity of capacity planning. To overcome any communication issues, choose a single location for planning. This allows for data and analysis transparency, confirmation of data integrity, and cross-departmental conversations.

- Time Commitment: Collecting accurate data, analyzing it, making decisions that impact the organization, and repeating this process regularly is an enormous time commitment. As mentioned earlier, capacity planning solutions automate the data collection and analytics in a single, integrated tool.

Streamline Rough-Cut Capacity Planning with Real-Time Work Management in Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.