What Is Vendor Performance Management?

Vendor performance management (VPM), also known as supplier performance management (SPM), is the practice of monitoring and analyzing your vendors’ quality, performance, and reliability.

Gerard Blokdyk is the author of over 50 business management books, including Effective Vendor Management: A Complete Guide (2020 Edition) and the CEO of The Art of Service. He says that VPM is about taking control: “With data-informed insights, you can determine if the organization is working to plan or will adversely impact, operations.”

Valid information on vendor performance is best derived from a vendor performance management framework that organizes requirements, collects current data (reviews it against past data), and assesses workflow patterns against your company’s strategic and tactical plans.

To learn the most useful ways to maximize the value and opportunities of your company’s vendor partnerships, refer to our Peak Performance Guide to Vendor Management. Read our tutorial on how to build your vendor management process to create an effective management operation custom-designed for your organization.

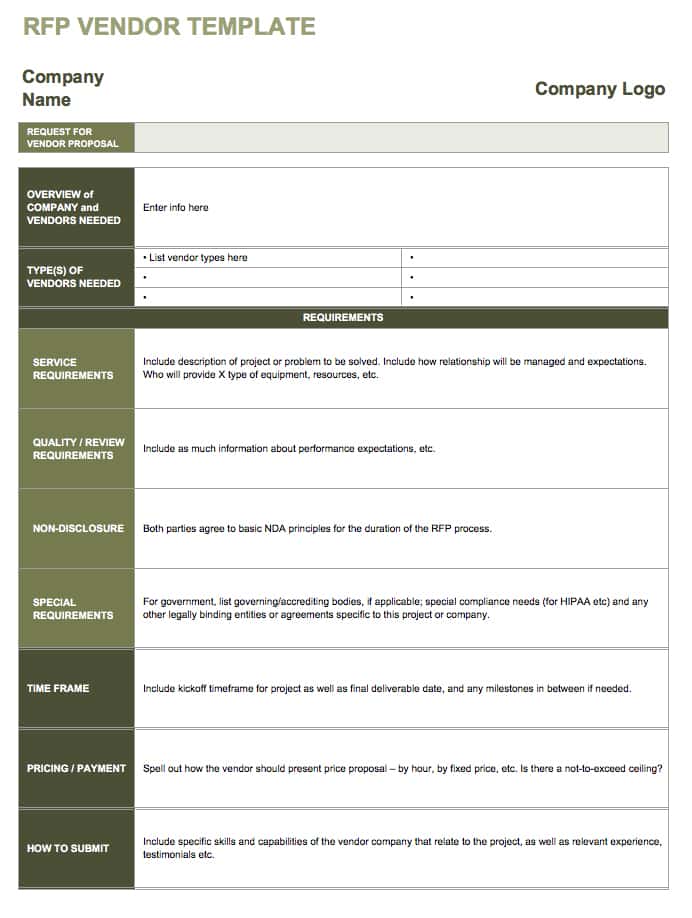

RFP Vendor Template

A thorough request for proposal (RFP) fosters clear communication, builds successful relationships, and provides a way for both parties to track how they've performed and where they fail, meet, or exceed performance expectations. Using an RFP template allows you to specify vendor performance requirements for proposals or projects, so everyone is on the same page at the outset.

Download RFP Vendor Template

Templates make tracking every phase of your vendor relationship easier. Download free tools by reading “13 Free Vendor Templates.”

The Role of the Vendor Performance Management Process in Your Organization

Vendor performance management transforms vendor relationships from ‘old school’ purchasing into a strategic methodology. Use data, accountability, and insights to gain control and get a competitive advantage as you align with company strategy and build lasting value.

All vendor relationships should be contract-based, but the addition of a Service Level Agreement (SLA) makes sense for vendors who provide mission-critical products or services. An SLA should clearly state responsibilities, expectations, metrics, frequency, and timing. That way, if issues arise, there’s an objective metric to assess compliance.

There’s no one-size-fits-all pattern for contracts, SLAs, or vendor performance management. To get started or refine your vendor programs, read our guide to vendor management programs.

Risk Management: A Principal Vendor Performance Management Benefit

Risk management is a core competency that organizations must have in order to be successful over time, and is also a principal benefit of VPM. Vendor dealings pose potential damage to your company and can affect finances, production, reputation, cybersecurity, and other risks.

Ignoring vendor performance management is like driving without a map. It’s important to know which vendors pose the most significant risk and rank them accordingly (all vendors pose some type of risk).

“When you look at a vendor in manufacturing, you have to consider what their participation means to the whole system and understand the potential risks if there are defects or failures,” says Jon M. Quigley, author and Value Transformation, LLC principal. “You can determine quality levels based on significant issues like safety. For example, if you’re building airplanes, a chair cushion zipper sticking isn’t a make-or-break situation, but a lack of quality in landing tires isn’t acceptable, ever.”

Quigley asserts, “You can never get to zero risk, but you can verify, monitor, and manage at the right cadence to mitigate them.”

Cybersecurity is one of the most recent and prevalent risks to organizations of all kinds. Hackers are continually finding new ways to steal data, making an initial performance assessment almost immediately outdated. Review technology vendors or vendors with access to your systems on an ongoing basis.

To understand the different risk levels and how to control them, read “The Definitive Guide to Vendor Risk Management Strategy” and our ultimate guide to enterprise risk management.

More Benefits of Vendor Performance Management

As organizations focus on core competencies and outsource more work to remain competitive, success relies on vendors. The main benefit of methodological vendor performance management is that both parties continue to improve for the life of their business commitment.

Advantages of Vendor Performance Management

Vendor challenges rarely stem from a single issue, and problems are usually interrelated. Methodical oversight of vendors benefit your organization and give you greater authority over the following:

- Multiple Vendors: The vendor base of many organizations is increasing, thanks to globalization, growing supply chain complexity, and increased scale of operations. A well-structured vendor performance management process allows you to manage more vendors simultaneously through their entire engagement lifecycle.

- Costs: Closer scrutiny of all vendors, invoicing, and tracking contract stipulations and SLAs results in fewer problems and lower spending levels.

- Quality: Managing performance, identifying performance gaps, and agreeing to meet needed performance levels improve quality and products. VPM best practices also help you identify cost savings opportunities and directly impact your bottom line.

- Root Causes: With a VPM system in place, you will have data and information readily available to pinpoint root causes of problems with vendors or their products. You can remediate issues with the vendor and prevent downtime quickly.

- Streamlining: Having control over all aspects of a product or service reduces the time spent in all areas, from inventory costs and stock levels to time to delivery, and even communication. Additionally, when you don’t need to replace existing relationships because you’re working closely with vetted and supervised vendors, you save on money and downtime.

- Compliance: Using the vendor performance management framework and tools to facilitate oversight, you can determine that vendors meet or exceed contract terms and SLAs.

- Value Measurement: You need to know how vendors perform because your company performance relies on them. Using key performance indicators (KPIs) to measure supplier performance allows you to assess the value your vendors create.

- Collaboration: When you collaborate and involve vendors to achieve requirements, you build trusting, long-lasting relationships. Collaborating with vendors makes them understand your business needs and consider mutually beneficial innovation and strategies.

- Continuous Improvement: VPM flags issues and provides an opportunity to remedy them and make positive changes. Once you have evaluated vendors and identified areas for improvement, formulate vendor development programs that improve their performance and cater to longterm, crucial requirements.

Putting a formal VPM program into place often makes the difference between lackluster and outstanding company performance. Find out how to make vendors your most significant asset by reading our guide to vendor management programs.

Tips and Best Practices for Measuring Vendor Performance

The following tips and best practices will help you impose discipline around decision making and interactions with vendors. Maintaining a high-level perspective while focusing on details and human factors will improve your performance, relationships, and reputation.

- Set Standards: Commit standards and program plans in writing, and establish criteria to assess the performance of approved vendors. Apply these steps equally to all: Set improvement goals and a clear, written plan to achieve them.

- Do Your Research: Talk to the people in your company who deal with the vendor. If you are rebooting your vendor performance management process, ask for historical data on vendors. Meet with vendors in person — preferably where they do business — so you can see how they operate.

- Communicate and Maintain Relationships: Keep vendors in the loop and ask for feedback regularly. Keep the lines of communication open by talking or using messaging, meeting, or collaboration tools. Develop and sustain long-standing relationships with company-approved vendors, particularly those ranked at the strategic and tactical level. Share data and performance information across your company, especially with those who use the products or services your vendors provide.

- Never Stop Monitoring: Measure and monitor progress based on value metrics. Undergo regular program reviews and suggest improvements. Monitor sales trends continuously to determine which products are more popular than others. Use technologies specifically designed to gather vendor performance data to streamline the process.

To learn more about fostering relationships with vendors, review our vendor management best practices guide.

Which Vendors Should You Monitor for Performance?

“You should monitor all vendors for performance,” says Value Transformation’s Quigley. “However, the level of scrutiny varies depending on how new the relationship is, how crucial the items or services are to operations, and cost.”

Quigley recommends monitoring new vendors at all value levels more frequently. The goals of keeping an eye on vendors are to ensure they’re performing based on contractual agreements, mitigate problems early, and build the relationship based on mutual trust and communication. For tips and tools to help get started on the right foot with your vendors, read “How to Streamline Supplier and Vendor Onboarding: Best Practices, Process Flows, and Checklists.”

Vendor Ranking, Performance Tracking, and Frequency

Rank vendors into four value categories. Start with a list of the most strategic vendors (usually about 10), and then add more vendors in descending value as tactical, operational, and commodity vendors.

Organizations rarely have adequate human resources to monitor vendors equally, so ranking them is crucial. Risk is tied to value in determining rank.

“To perform control assessments for your third parties, acknowledge and weigh risk and value posed to your organization appropriately and realistically, based on data,” emphasizes The Art of Service’s Blokdyk. “Use this [finding], combined with experience in vendor performance management, vendor relationship management, contract management, and a drive for continuous improvement and managing results through facilitation, to determine the frequency of monitoring for each vendor.”

Value Based Vendor Performance Oversight

This type of value-based performance ranking provides a guideline, but monitoring rankings and performance can change. “I often change metrics as the project moves along in a manufacturing setting. For example, as you move from the design phase to staging to production, the value, risk, and scrutiny shifts as you move closer to shipping the final product. A specific part and its vendor, once used, may move lower in the rankings as production phases progress,” shares Quigley.

How to Measure and Track Vendor Performance

In order to correctly measure and track vendor performance, you need to put the right team in charge, select the right tools, and decide which KPIs are most appropriate.

VPM Teams, Tools and Methods, and Metrics

Answering the following questions will help you organize your vendor performance management program:

- Who Should Be in Charge?

“Establish the right team with an internal search for the best candidates in-house to individually manage or, better yet, create a [designated] VPM team,” saysBlokdijk. “If no one in-house has the necessary skill set, you may need a consultant to get the process started and then establish a training course.” - What Tools and Methods Should We Use?

“MS Project can be useful, and I use it often for large manufacturing projects,” Quigley states. “Excel, dashboards, and balanced scorecards work too.” You’ll find more information on the difference between balanced scorecards and dashboard tools below. - What Metrics Should We Put In Place?

Metrics that matter are clearly defined, measurable, and stipulated. The most common measurements are based on vendor management key performance indicators (KPIs) that are tied to overall company goals.

To learn more about the vendor management process and how KPIs pave the way for smoother performance, read our guide on the vendor management process.

Examples of Vendor Performance Management KPIs to Measure

Design vendor management KPIs to suit your industry, specific business, and business units. In addition, you should develop KPIs around your specific needs, including applicable risk, relationship, cost management, delivery, and quality.

One of the temptations and potential downfalls of the vendor performance management process is having too many KPIs. There is no set number of KPIs to track, but it’s a good idea to keep the number low, so it’s possible to monitor and act on your findings.

Examples of Vendor Performance Management KPIs

Here are some general examples of VPM KPIs to monitor:

| Risk & Compliance |

|

| Cost |

|

| Quality |

|

| Delivery |

|

| Relationship |

|

Vendor Performance KPI Examples in Specific Manufacturing Industries

Here is a sampling of some KPIs that apply to specific industries:

| Industry | KPI |

|---|---|

| Aerospace | Cost of Goods (COGS) Sold as a Percentage of Revenue: Inefficiencies can drive COGS to unmanageable levels and reduce sales. Exposure to financial risks may prevent the company from paying its liabilities on time. Customer Order Cycle Time in Days: This refers to the average cycle time (in days) between customer order placement and delivery to the customer for primary products. Time lost is money lost when margins are slim. Dock-to-Stock Cycle Time in Hours for Vendor Deliveries: This metric measures the productivity and speed for stocking. Minimizing these timeframes reduces issues that can occur further down the supply chain to increase on-time shipments and customer satisfaction. Costs of Production Material Handling Damage as a Percentage of Total Material Costs: High failure rates suggest insufficient product packaging, too many material touchpoints, improper use of packaging or transporting equipment, etc. Defects are costly when you need to replace damaged raw materials. It also slows down cycle times for manufacturing and deliveries and increases backorders and stock-outs (inventory exhaustion). |

| Apparel | Factory Efficiency Percentage: If materials or sub-vendors can no longer produce more goods without lowering the production levels of another garment, company production will fail to meet demand and will jeopardize the purchasing company. Man to Machine Ratio: This is the total workforce in a factory compared to the total number of sewing machines in operation. Man to machine ratio widely varies depending on the type of apparel manufacturer, but the goal is to keep the number even and all operations working at maximum capacity. Cut to Ship Ratio: This provides a bird's eye view of the entire system and efficiency snapshot. The goal is to have a low percentage of garments lost or rejected (such as two percent of total production). Order to Ship Ratio: This is the ratio of orders shipped for immediate delivery to orders booked for future delivery and billed. It is used to help measure a company's efficiency and identify potential problems in internal and external supply chains. On-Time Delivery Rate: This is the ratio of customer ordered apparel lines shipped on or before the requested delivery dates. Repeat business and customer satisfaction are highly correlated to this KPI. |

| Food Industry | Number of Non-Compliance Events: Food products of all kinds are subject to high inspection levels by internal supervisors and government inspectors. Products rejected for safety and spoilage reasons result in lost revenue, reputational issues, and potential shutdowns. Total Capacity per Product line: This metric shows the number of units produced based on technology and human capital, without considering sales forecasts. Throughput (Total Quantity Manufactured by Product:) This KPI shows each product’s units manufactured over a specified period of time. Product categories can have different metric units: weight, volumes, packs, bottles, etc. Margin per Unit: This shows the net earnings per unit, after deducting fixed and variable expenditures. |

| Pharmaceuticals | R&D Expense per New Drug Developed: High R&D expenses drive up product prices, make them difficult to sell, and expose the company to reputational and financial risks. Takt Time: A Takt-time diagram identifies production bottlenecks and shows where you can reorganize production for greater efficiency or to improve products. Pharmaceutical manufacturers find applying the Takt-time analysis is exceptionally challenging and therefore valued. Vendor-Enabled Innovation: Pharma companies value ways vendors can devise new ways to lower costs and support first-to-market measures and new product introductions. Vendor Transparency: Pharma companies want and need to know the details about their vendor’s supply chains. Material traceability and sub-supplier information are essential to ongoing production and legal reporting. |

Vendor Performance Management KPI Best Practices

In order to improve overall vendor performance management, you should develop KPI best practices that align with the goals of your specific business. However, some strategies apply universally, including specificity, communication, realistic expectations, and ongoing realignment.

- Aim for Specificity: “Garbage in garbage out — your vendors’ performance is only as good as the information provided and the expectations set,” The Art of Service’s Blokdyk points out. “Give your vendor the information necessary to do the job.”

- Link Vendor Performance to Other Factors: “Link your performance management and incentive systems to your risk management practices,” says Blokdyk.

- Be Realistic: Choose measurements that are defined, realistic, and achievable. Many vendors never hit the service level agreement details because the contract was written with impossible metrics and set the vendor up for failure.

- Set Minimum Performance Level Specifications: “There is usually a floor on minimum acceptable performance, which you should know and share,” says Quigley. The level depends on different factors, such as tolerances in areas that don’t affect safety or product performance. For example, a threshold could define paint thickness on a meter or a 24-hour slip in delivery that doesn’t affect overall production.

- Review and Realign Regularly: As conditions change, the business matures, and priorities shift, KPIs should change as well. Typically, KPIs change once a year, depending on the company’s nature. This especially affects industries that are driven by trends, like apparel, gaming, or cosmetics.

For more ways to refine your vendor’s performance and management practice, read vendor management best practices guide.

Verifiable Data Is Fundamental to Effective Vendor Performance Management

“It isn’t just about collecting data,” says Value Transformation’s Quigley. “It’s the ability to verify it. If you can’t prove the source of your data, then you can’t validate your conclusions or work from a basis of trust with your vendors.”

Blokdyk agrees, “There is one red through-line across all industries, and that is data management. Are the vendor’s management information systems adequate? For example, customer data protection, access methods, reporting, performance monitoring and reporting, and scalability need to be reliable.”

Data drives final decisions on how well the vendor performs, from delivery to quality measures to cost. When you communicate with the vendor to review results, refer to the contract language or SLA specifics to either acknowledge good results or use it as a basis for improvement discussions. If issues are ongoing, you can use the SLA as a grounds for termination.

An Aerospace Manufacturing Case Study: Data Use to Track Defects in First Pass Yield

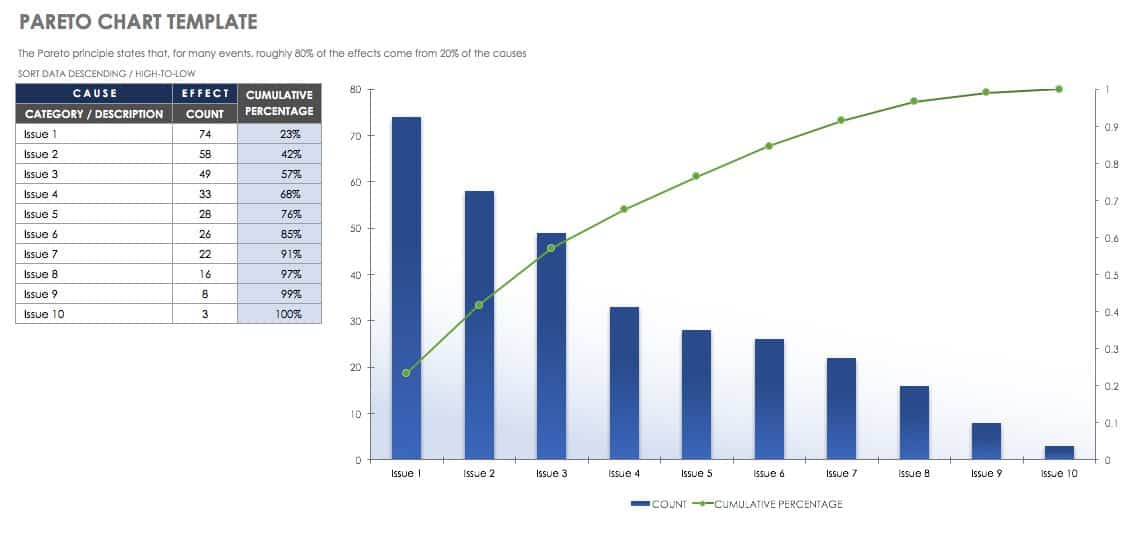

Graphic courtesy of Jon Quigly of ValueTransformation

ValueTransformation’s Quigley shares a data analysis performed during aerospace production while supervising a vendor’s production of a part to determine first pass yield, which is an indicator of the line’s production and quality performance.

- Pinpoint Defects: “The Pareto chart reveals the manufacturing defects that lead to waste and consequent yield. Based on the data, to make improvements to the system, we should start with [so-called] ‘waves’ and ‘chips’ and ‘cracks.’ These three defects represent 80 percent of the reasons for the scrap and reduction in the first-pass yield. Based on the data, we don’t know the why, but we do know where the difficulties lie.”

- Adjust for Maximum Performance: “The next step is to explore and experiment with the system and do some root cause analysis. Once the root causes are determined and system adjustments made, we’ll see a reduction of total scrap and first-pass yield, which is the goal. Those elements to the right of ‘crack’ are now fodder for further exploration and experimentation to reduce those defects. This approach continues until we adjust the system for maximum performance.”

- Find Data Prioritization Alternatives: Quigley points out another aspect of how to prioritize types of data. “The customer may not be equally impacted by defects. We can look at the failure rate in each category. Suppose the ‘chip’ unit failure cost was one-and-a-half times the failure cost of the ‘waves,’ and though the ‘chip’ defect is a little less than the ‘wave’ failures, the cost for that defect is much more substantial. That means we would prioritize that defect. Another way to analyze in that case could be to create the chart using dollar amounts rather than defects.”

The Pareto chart in the case study is manufacturing-centric. These analysis charts can also track vendor performance for hardware, software, or other items to facilitate continuous improvement demands.

Pareto Chart Template

Use this Pareto analysis template to assess your vendor performance data to determine the frequency of process defects or problems. The template provides a standard Pareto diagram, with a bar chart to represent the issues to study and a line graph to show the cumulative number of occurrences.

Balanced Scorecard vs. Dashboard Tools for Vendor Performance Management

You can use a balanced scorecard (BSC) or a dashboard to track KPIs for optimal vendor performance management. Balanced scorecards emphasize global business objectives linked to KPIs, while dashboards focus on operational metrics and monitoring processes.

Balanced scorecards and dashboards provide different insights and benefits, so it isn’t necessarily a balanced scorecard versus dashboard competition. In fact, you can use both tools in tandem to track progress and reach your goals on a large and smaller scale.

Balanced Scorecards for VPM Offer Big Picture, 3D Insights

A balanced scorecard is a reporting tool that details performance management measures. With a BSC, you can describe and measure your company strategy (around a significant effort like improving customer satisfaction worldwide), and then track how you achieve results using KPIs. BSCs provide a big-picture, qualitative, 3D view that defines measures at a specific level based on your selected metrics. Find more best practices and free vendor scorecards to download.

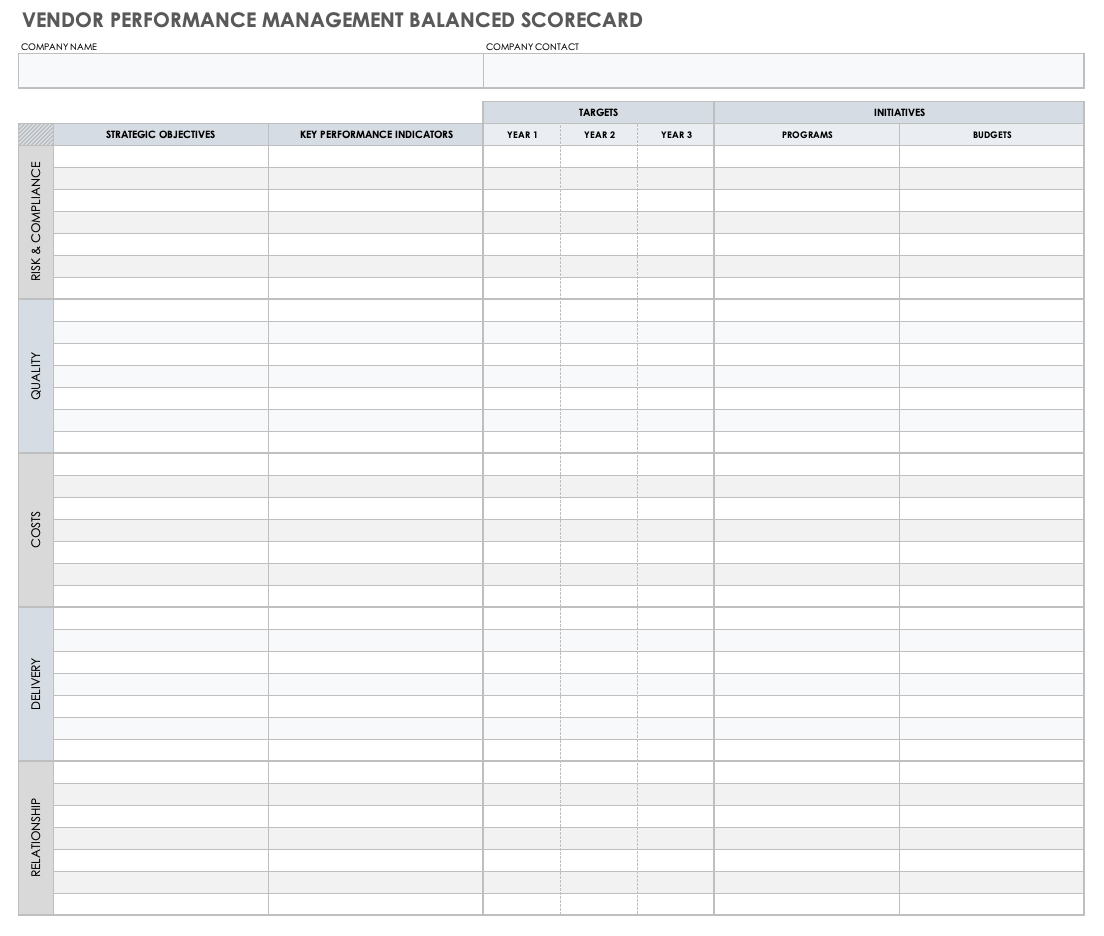

Vendor Performance Managed Balanced Scorecard Template

With this template, you can hover over each cell for instructions on how to use this vendor performance balanced scorecard. The scorecard features an easy-to-read, customizable layout in Excel. Enter objectives, KPIs, targets, and initiatives in each of the four perspectives and related budget information.

Download Basic Vendor Performance Managed Balanced Scorecard Template - Excel

Dashboards for Vendor Performance Management for a 2-D, Quantitative View of KPIs

A dashboard is a business intelligence tool for visualizing large data sets, and is useful for tracking specific KPIs. For example, you could use a dashboard to report the number of factory injuries to the Occupational Safety and Health Administration (OSHA), inbound calls to your call center at specific times, or error rates in your apparel manufacturing facility.

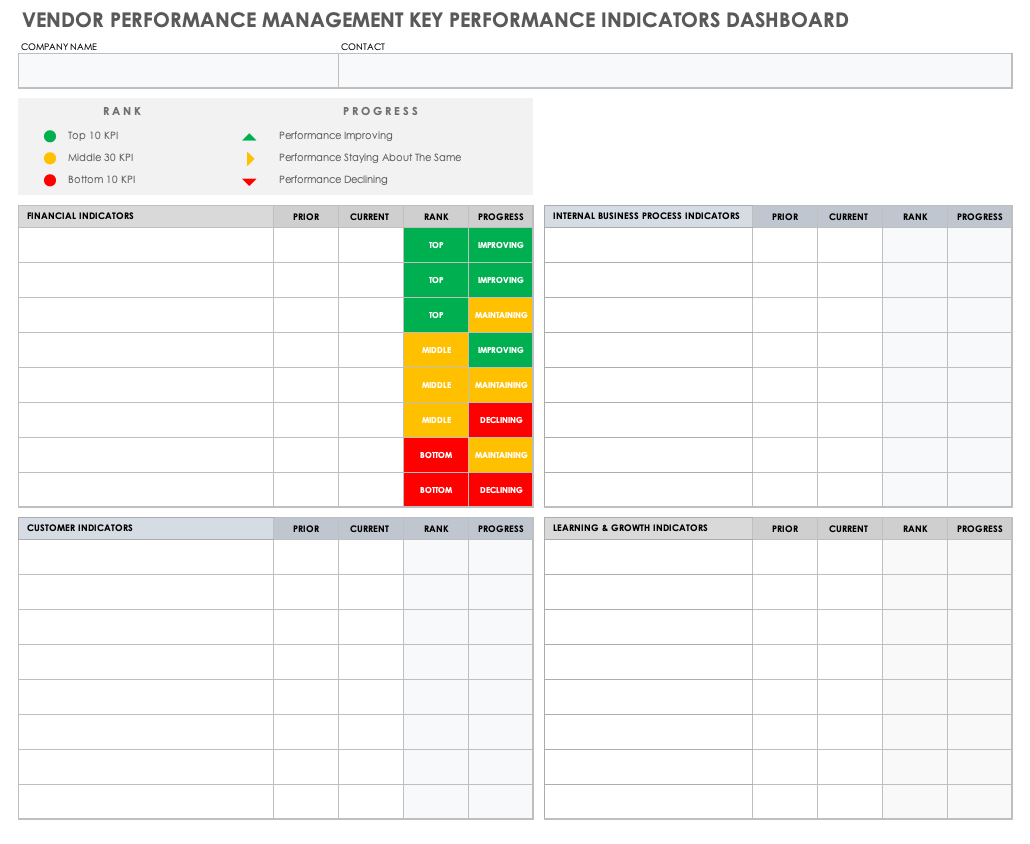

Vendor Performance Management Key Performance Indicators Dashboard Template

Use this template as a shareable document to track your company KPIs, hold all the major perspectives, and customize fields to fit your VPM framework. The template also provides an easy way to mark the importance of individual KPIs and how well your organization achieves its metrics.

Download Vendor Performance Management KPI Dashboard Template - Excel

How Technology Facilitates Vendor Performance Management

VPM technology provides many capabilities, including customizable scorecards, multiple programs, reports, configurable participation access to vendors, and a simplified way to perform regular reviews and suggest improvements.

The use of technology facilitates VPM to capture data, provide analysis, and display results in an easy-to-digest format. Software solutions provide the simplest and most efficient way to measure and monitor progress according to determined value metrics, as well as to scale efforts when necessary.

Learn more about all the many aspects of VPM solutions in our definitive guide to vendor management.”

Improve Vendor Performance Management with Real-Time Work Management in Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.