What Is a Vendor Scorecard?

A vendor scorecard (also called a supplier scorecard or supplier management scorecard) is a business tool that enables vendor performance monitoring and ensures you are maintaining a beneficial relationship with your vendors. Vendor scorecards also allow you to access insights for improvement.

You can develop scorecards using basic spreadsheets or take advantage of vendor management system (VMS) software, which large organizations with many complex vendor relationships usually prefer. Across all industries, vendor scorecards support strategic supplier relationship management (SRM). To learn more about managing your supplier relationships, check out “The Definitive Guide to Managing Vendor Relationships.”

Although each scorecard differ in its specifics, vendor scorecard development commonly involves the following four process steps:

- Identify KPIs: Decide which performance metrics you will use to conclusively decide whether or not your organization is achieving key business objectives.

- Define Metrics: Pinpoint the vendor performance data that you need to track on an ongoing basis.

- Weight Metrics: Some metrics will be more critical than others. Score metrics based on their importance to your organizational success and how they support your KPIs.

- Assess Rankings: Stakeholders can see how vendors are performing based on three types of assessments: analyzing metric data results and the weighting of those results; determining the areas in which a vendor requires improvements; and deciding if you should reconsider a partnership.

You may use multiple different types of scorecards to evaluate different vendors. As Gerard Blokdyk, CEO of The Art of Service and author of over 50 books, including Effective Vendor Management: A Complete Guide (2020 Edition), notes, “Companies take advantage of different types of scorecards to measure specific kinds of vendor performance… Design your scorecards thoughtfully to ensure that a vendor meets your defined needs.”

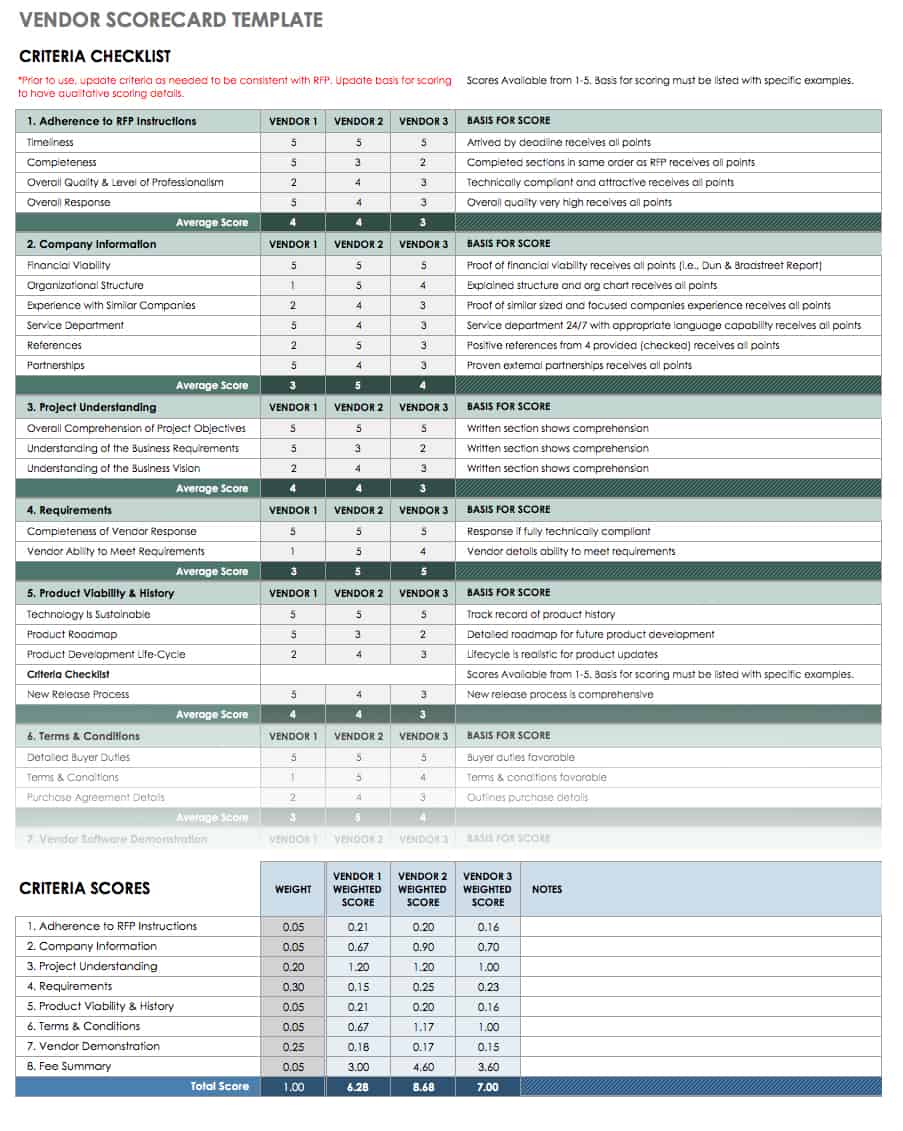

Vendor Assessment and Scorecard Template

Use this Excel scorecard to make an initial vendor selection, to compare multiple vendors, and to evaluate a single vendor on an ongoing basis. This template conveniently compiles data, so you can apply a weighted score approach and make evidence-based decisions. This spreadsheet makes it easy to edit and add the metrics that matter most to your business.

IT Vendor Scorecards

In organizations with multiple or complex IT vendor relationships, managers use IT vendor scorecards to organize and evaluate metrics specific to IT suppliers and processes. This type of scorecard allows managers to cut costs, mitigate risk, and drive continuous improvement.

Today, nearly every business in the world relies on IT in order to run efficiently. The larger or more multinational a company is, the greater its reliance on IT vendors. Effective IT is integral to business success, so carefully managing IT vendor relationships (which can often be quite costly) is vital to profitability and operational functionality.

IT managers need to gauge how well new technologies will serve business goals. In order to do this accurately, carefully assess the metrics and criteria that you’ve added to the vendor IT scorecard. Following this pragmatic approach regarding IT purchasing or outsourcing will help you forestall potential risk.

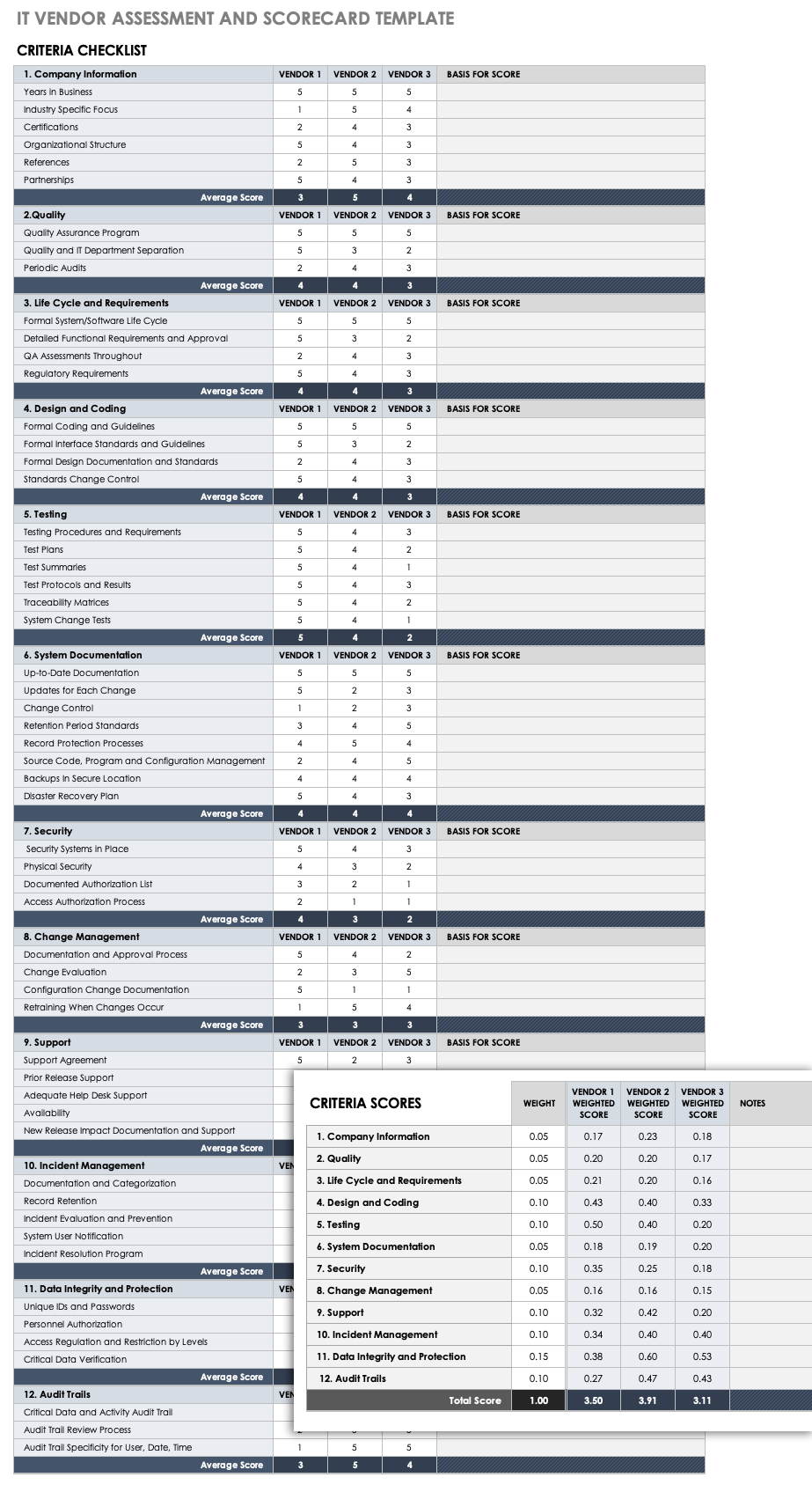

IT Vendor Assessment and Scorecard Template

Because the services IT vendors provide often give them access to sensitive company information, they constitute a special supplier category. Vetting these particular vendors calls for a high level of scrutiny. To keep IT vendor assessments on track and maintain the ability to make apples-to-apples comparisons, use the categories built into this IT vendor risk assessment and scorecard template. You can also add categories that are more relevant to your organization.

Download IT Vendor Risk Assessment and Scorecard Template - Excel

Vendor Risk Scorecards

Use vendor risk scorecards to make a purchasing decision or to monitor ongoing engagements. These scorecards allow you to quantify the potential downside of IT and other high-risk suppliers who may disrupt or otherwise negatively impact your business.

A high-risk vendor may have access to sensitive information — such as an individual’s healthcare data, intellectual property, or financial records — and consequently pose high financial, compliance, or operational risks or the threat of reputational damage. To assess the risk of a vendor, organizations generally categorize a third party’s scorecard metrics as high, medium, or low risk. To learn more about supplier risk mitigation, refer to the “Definitive Guide to Vendor Risk Management.”

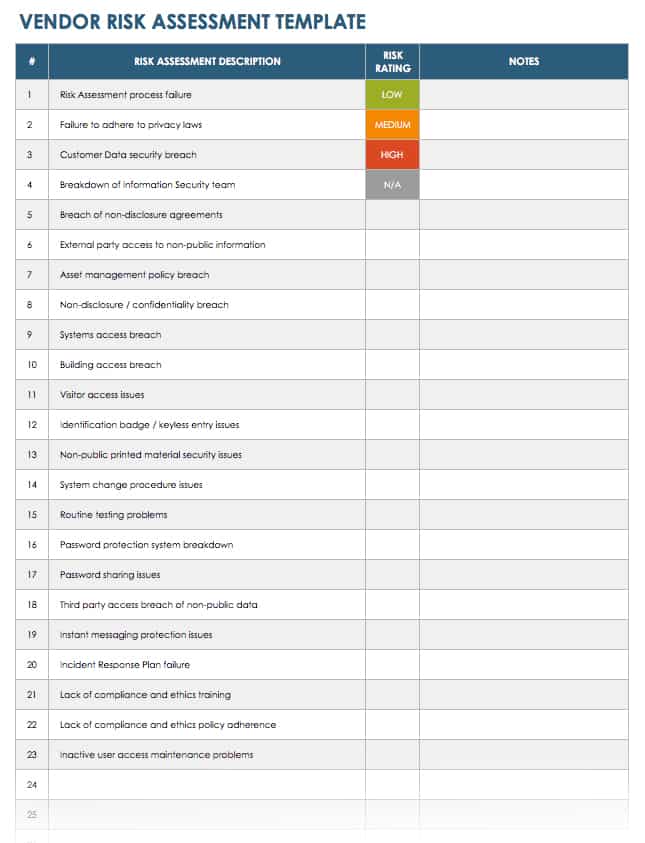

Vendor Risk Assessment and Scorecard Template

As part of your company’s due diligence, this Excel template helps pinpoint and assess potential risks before you hire a vendor. Once you identify those risks, you can decide if a vendor meets your standards; you can also ask a vendor to remove a risk that you consider unacceptably high. This vendor risk assessment template presents a series of questions that you can adjust to suit your specific situation. To facilitate decision making, the template also provides a space to assign risk.

Download the Vendor Risk Assessment Template

Vendor Scorecards as a Strategic Tool

Vendor scorecards that focus on meeting strategic goals like KPIs can form a competitive advantage for organizations that use them to manage multiple suppliers and complex domestic and international supply chains.

Suman Sarkar, Partner at 3S Consulting and author of The Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive World, sees the power of solid supplier relationships as uniquely tied to organizational success in a global economy.

“Most successful companies acknowledge the importance of suppliers to their success — from driving innovation and managing operations to improving efficiency,” Sarkar emphasizes. “Scorecards are a good way to hold suppliers accountable and track their progress toward achieving business results.”

Sarkar cites Steve Jobs as someone who understood the importance of managing vendor relationships and the company’s supply chain: “When Steve Jobs returned to Apple to turn it around, his three goals were as follows: One, improve the product pipeline; two, improve marketing; and three, transform the supply chain.” The results speak for themselves.

The Art of Service’s Blokdyk sees vendor scorecards as a critical component of optimal strategic planning and management: “A successful organization’s vendor scorecard is often a balanced scorecard that measures and tracks vendor performance on various levels related to organizational strategy.” To learn more about balanced scorecards and the importance of tracking leading and lagging indicators in order to move the business forward, read “Everything You Need to Know about the Balanced Scorecard.”

Vendor scorecards can serve as a strategic tool by virtue of their very existence. The Hawthorne effect states that when people (in this case, vendors) know they are being observed, they modify their behavior. In other words, when vendors are aware of scorecard monitoring, they do their best to adapt or change their actions to meet expectations and gain approval.

Self-Assessment and Vendor Scorecard Creation

It can often be difficult to determine the ideal KPIs and metrics for your company. If you’re experiencing such a challenge, conduct a thorough self-assessment with internal stakeholders to determine your goals.

“It’s important to do a self-assessment (that is, to ask the right questions) before you design your scorecard,” says Blokdyk, who consults with clients to probe company goals and issues. “The first goal is to build a vendor scorecard using a rational process design. Then, use the scorecard to quickly review existing operations. Such a review will serve as a starting point for a gap analysis, which will help you understand goals and what you need to improve.”

Blokdyk uses seven dimensions, and each dimension can include a few hundred guided questions. The answers to these questions auto-generate RACI scorecard diagrams, along with action steps. The scorecard points out which areas require attention.

While your team may not generate hundreds of questions, these steps will help you and your internal stakeholders create a roadmap to establish strategic goals and corresponding metrics.

Here are the questions to use for the seven areas of self-assessment:

- Recognize: What is of value to our business? What are our unfavorable problems or symptoms?

- Define: What are the needs and objectives of our business?

- Measure: How do we currently manage vendors and their performance? What is the current performance data and what does it reveal?

- Analyze: What do our current findings reveal? What are the causes, assumptions, and hypotheses to help explain our current situation?

- Improve: How can we improve processes and implementation? What are the practical solutions?

- Control: How can we control deliverables and results? How do we maintain performance and correct possible complications?

- Sustain: How can we sustain practices in the future? How do we retain the benefits of improved business processes?

Once you’ve identified the appropriate vendor scorecard strategy and associated metrics for your organization, use them to build your custom scorecard.

Vendor Scorecard Metrics

Vendor scorecard metrics are measurable statistics that provide hard data about a supplier’s performance. Whether you are comparing prospective vendors or evaluating current suppliers, you can capture and use this information to quantify and simplify your evaluation and decision-making processes.

“A scorecard should include quality and quantity or volume measures,” says 3S Consulting’s Sarkar. “For example, concerning outsourced payables services, the number of errors would represent a quality measure and the volume of transactions would represent a quantity measure. Most companies do a good job on the quantity measure, but don’t spend enough time thinking through quality measures.”

Sarkar adds, “The best way to create quality metrics for scorecards is to have a discussion with stakeholders about their business objectives and about how a supplier can help them achieve those. The scorecard should act as an incentive, rather than a penalty, for suppliers.”

Here are some basic metrics to consider as you begin or redesign your scorecard:

Vendor Scorecard Metrics Checklist

Quality

- Has low error, mistake, material, or performance issues

- Aligns with a certified testing lab or other oversight bodies

- Has an internal, pre-ship quality control system

Delivery

- Demonstrates appropriate lead times and on-time delivery

- Offers a flexible delivery schedule when necessary

- Provides proper and accurate delivery receipts and reporting

- Identifies packages or other deliverables correctly

- Provides appropriate packing materials

Contract Agreement

- Complies with all agreement terms

Compliance

- Complies with U.S. Customs & Border Protection requirements

- Takes environmental responsibility/engages in ethical sourcing

- Follows a social responsibility program

- Complies with specified requirements for product safety that apply to your organization

- Complies with security standards

- Complies with legal requirements

Service

- The fill rate stock availability meets demand without backorders, stockouts, or lost sales

- Provides real-time inventory status

- Provides excellent lead times

- Sends alerts about issues or concerns in a timely manner

- Holds backorders and out of stock at a minimum

- Advises about production status

- Provides prompt and accurate technical assistance

- Supplies prompt replacement of rejected or defective product

- Handles complaints efficiently and correctly

Costs/Pricing

- Offers the lowest (or a lower) cost option

- Offers a competitive cost of goods

- Communicates price increases in advance

- Suggests cost-reduction ideas

Finance/Accounting

- Sends invoices in a timely manner

- Sends clear invoices

- Issues asset chargebacks

- Provides clear payment terms

- Invoices accurately

- Issues credit promptly

Equations to Determine Specific Metrics

To quantify vendor performance, many organizations develop equations to generate hard data. Here are a few examples to help with your scoring efforts:

- Quantity:

- Monthly Quantity Rejected ÷ Monthly Quantity Delivered = Total Monthly Deliveries

- Rolling Quarterly Quantity Rejected ÷ Rolling Quarterly Quantity Delivered = Total Rolling Quarter Deliveries

- Lead Time:

- Real Lead Time - Starting Lead Time = Amount of Improvement

“A strong financial performance, often the top scorecard perspective for most companies, is the result of strong performance in all the other scorecard perspectives,” says Blokdyk.

Vendor Scorecard Criteria

Sometimes, using qualitative assessments to evaluate vendors can be more challenging than using strict quantitative measures. But, qualitative measures can also increase your chances for success. As competition accelerates, businesses may be vulnerable if they favor quantitative measures like cost cutting over qualitative ones, like innovation or other soft considerations.

Gary Gustafson, President of G-Force Consulting and a writer, says, “I've been developing supply chains in the power sports industry (e.g., motorcycle, ATV, and snowmobile manufacturers) for more than 20 years, and I'm amazed that many of the same metrics are still in use.

“Why is there no supplier metric for innovation that includes the input of the relevant original equipment manufacturer’s (OEM’s) engineering group?” Adjusting this metric in this way makes it adaptable. “A supplier looking to elevate its score or a buyer looking to preserve its contract can game more antiquated metrics, like year-over-year (YOY) cost reduction and on-time delivery.”

Gustafson stresses that long-term thinking is the way to go: “Not thinking strategically hinders innovation and obscures larger opportunities. When companies operate in the short term, buyers (who have the incentive to maintain the status quo or merely generate an incremental improvement) turn away opportunities; others simply leave those opportunities off the table.”

Gustafson emphasizes the need to view innovation as a critical scorecard criterion: “If you chain a supplier to a buyer who is non-technical, you may place established suppliers at a disadvantage concerning introducing new design ideas to an OEM.”

Use this list to add to your scorecard or to begin discussions about criteria that works for your company:

Vendor Criteria Checklist

Strategic Capabilities

- Business value proposition

- Strong R&D team

- Supplier financial health assessment

- Vertical integration of supply chain capabilities

- Policies in effect throughout supply chain

- Weekly saving of backordered dollars and units for products

Responsiveness and Creativity

- Continuous improvement orientation

- Tracking of new product development

- New product development and innovation

- Cost-saving ideas and opportunities

A focus on cost metrics and finite saving goals often hurts business prospects. “In my industry, it’s often the case that innovation is the biggest contribution a supplier makes to an OEM. But, that innovation may be stillborn at the OEM, because the commodity manager didn’t have the metrics-based incentive to draw innovative ideas from their suppliers (while still respecting intellectual property). Keeping the pipeline full of new supplier-driven innovations should be just as important as PPM (parts per million), cost reduction, and other metrics,” Gustafson points out.

Essential Vendor Scorecard KPIs

A vendor key performance indicator is a measurable value that demonstrates how effectively vendor performance is propelling a company to meet its strategic business objectives.

“If you design a vendor scorecard that leverages the service-level agreements (SLA) that you include in a contract, then you should have well-defined KPIs,” Sarkar says. Your company’s KPIs will vary depending on the nature of your business objectives and how you measure them.”

Sumari provides an example of an SLA/KPI: “For instance, a transportation vendor that wants to furnish its client’s employees with excellent transportation service would compose an SLA stating that drivers should provide exceptional customer service and maintain a safe driving record. After all, the driver is the first and last person that an employee interacts with on a daily basis.

“To measure how well the transportation provider is performing in these respects, namely, customer service and safety, you would design KPIs that incorporate client feedback on the following: the driver’s overall behavior, their level of informativeness, and their degree of helpfulness. You would use these metrics in addition to the driver’s driving and accident records. You would then translate these KPIs into a scorecard that measures performance on a monthly basis.”

Here are the essential KPIs to consider as you build your vendor scorecard:

- Number of Vendors: Track your level of dependence on specific vendors and eliminate redundancies.

- Rate of Compliance: How well do vendors fulfill company, safety, or statutory requirements?

- Cycle Time for Purchase Orders: Understand lag times and how they impact your business.

- Vendor Availability: Measure a vendor’s on-demand response capacity and its ability to scale based on the needs of your company and customers.

- Product Defect Rates: Determine your current levels and breaking point to measure defect percentages.

- Error Rates: Track how often a vendor delivers incorrect products or services.

- Materials Defects: Make sure the vendor uses the proper grade and value regarding production.

- Competitive Lead Times: Understand the total time it takes to fulfill an order.

- Purchase Order Cost: Control the internal costs you incur with each purchase.

- Reduction of Procurement Cost: Use accumulated data to avoid potential extra costs in the future.

- Procurement ROI: Determine the return on investment of a particular vendor.

- Continuous Improvement: Determine a vendor’s level of dedication to incremental or breakthrough improvement.

For more information and expert advice on how to identify KPIs and other measures of success, read “Essential Guide for Defining Business Dashboard Metrics.”

Weighting the Metrics

Weighting or assigning value to vendor scorecard metrics is the act of assessing the impact of each measure on the overall business. You can determine weights according to a metric’s consequence to cost, risk, customers, business units, business relationships, and organizational success.

“Weights depend on your business objectives and should provide an incentive for suppliers to deliver on aspects that are important to your company,” Sarkar advises. “Weights provide company leadership and suppliers with a quick snapshot on steps to take to resolve any performance issues.”

Blokdyk notes that weights are subjective: “If you as a client value completing your project on time more than keeping to a budget, you can overspend and still consider your effort a success — particularly if you weight the criteria in your vendor scorecard accordingly. If you want your vendor management program to add value to your organization, make sure that your vendor evaluation looks beyond the requirements of a standard or regulation.”

“Weighting or magnifying operational successes and failures actually takes place outside of the typical supplier scorecard. For example, you acknowledge a supplier's competence by awarding a new program. You handle a supplier-originated recall with penalties,” finds Gustafson, based on his power sports industry experience.

Gustafson offers a weighting scenario based on percentage and illustrates how it can change over time, depending on business conditions:

“On the supplier scorecard, a typical starting point might be allocating 30 percent to cost performance, 30 percent to quality, 20 percent to on-time delivery, and 20 percent to innovation. Each of these four categories will include some performance measurements that feed into them.

“From year to year, an organization can change how they weight these four categories. In a year when a company faces financial headwinds, it may shift a higher percentage of its overall grade to YOY cost reductions. In a fast-paced innovation environment, you can weight the scorecard more toward new product ideas or improvements.”

Vendor Scorecard Best Practices

Blokdyk says, “Vendor scorecards that you develop using best practices provide a framework for managing your business. They do this by translating high-level strategies into operational objectives and communicating those objectives in measurements and goals that every stakeholder can understand.”

Vendor Scorecard Best Practices from the Experts:

Here are some indispensable tips from the vendor scorecard experts:

- Move the Goalpost Regularly: “Establish achievable KPIs; set yearly and quarterly objectives while you keep thinking outside the box; and develop and implement new ideas that set expectations,” suggests Blokdyk.

- Think Collaboration: Working with vendors in the spirit of collaboration paves the way to company success. All of our experts agreed that the scorecard should act as an incentive, rather than a penalty, for suppliers. Blokdyk recommends the following: “Evaluate performance against mutually agreed-upon or accepted criteria, and talk through solutions with current vendors before you move to suppliers who will need onboarding.”

- Make Sure to Do Quality Measures: “Most companies do a good job on the quantity measure, but don’t spend enough time thinking through quality measures. For example, concerning outsourced payables services, the number of errors would represent a quality measure, and the volume of transactions would represent a quantity measure,” says 3S Consulting’s Sarkar. “After a discussion with a vendor, you can make relevant additions to the scorecard.”

- Keep It Simple: Your scorecard should be easy to use. Stick to primary goals and objectives and make scorecard information brief and easy to digest. Add features like color-coding to flag action items or to get a quick sense of a KPI’s status.

- Involve Stakeholders: As you develop or refine your vendor scorecard, include cross-functional involvement from all affected departments across your organization.

- Have Milestones: In order to meet your business goals, synchronize your KPIs with your set of benchmarks and corresponding timeline.

- Look at Linking Incentives and Penalties: While all of our experts thought punitive measures were counterproductive to supporting partnerships, you can consider providing bonuses or financial hits based on metrics. “Be sure to invite the suppliers who are earning the highest scorecard grades to bid on new programs. Do it even if your buyer or commodity manager isn't sure that these particular suppliers offer a best-in-class solution. There must be some reward for high grades beyond just a trophy,” recommends Gustafson.

- Clarify Your Process: Set standards concerning what should take place when performance is unacceptable and how you should handle grievances. “Have a clear process; a supplier should be able to contest elements of a scorecard without recrimination. Leaving the commodity manager both to score the suppliers and to handle their grievances is like having the fox guard the henhouse. For example, if your commodity manager's request (let’s say, for an engineering hold) caused a supplier to miss a shipment, there should be a clear path to rectify the issue in the supplier’s favor,” Gustafson advises

- Define Expectations: A well-designed scorecard clearly defines and communicates expectations. It tells you precisely what constitutes good, merely acceptable, mediocre, or poor vendor performance.

- Consistently Perform Measurements and Schedule Audits: Vendor assessment isn’t a one-and-done process. Make your vendors aware that measurements are ongoing and that you’ll be conducting audits on a regular schedule with all of your contracted suppliers.

- Capture Data: Think about what you want to accomplish with the data you collect. You should be able to slice the data by date, category, vendor, style, and item. Collect purchase order and delivery data from your order management system to enable both detailed and big picture insights.

- Compare Vendors: Comparing one vendor to another to obtain critical data makes it easy to select new vendors or rethink current vendor performance.

- Survey All Stakeholders: Ask employees who work closely with or rely on a supplier about that particular vendor’s performance. See if your in-house opinions reflect your data and vendor assessments.

- Plan for the (Tech) Future: Blokdyk sees artificial intelligence (AI) making inroads into vendor management best practices. For example, AI speeds database population and offers real-time alerts about issues that need human attention. “AI-powered business intelligence is the future of vendor management and is already in use in industries like aerospace and healthcare,” says Blokdyk. “It can also provide your organization with an edge over competitors who are unable to access your strategic information.”

How to Approach a Vendor about a Scorecard

If scorecards are new to your company and your vendor relationships, facilitate optimal working relationships and results by bringing your vendors into the process early and positioning the change as a partnership. For the best results at each stage of the process, do the following:

- Before Implementation: Casually discuss scorecards with your suppliers prior to implementation.

- Orientation: Provide formal notice explaining the program, KPIs, and metrics.

- Vendor Meeting: Set up meetings to discuss any questions your suppliers may have.

- Rollout: Do a soft deployment to work out issues. Also, check in frequently with vendors to see how the new standards are working for them and how they feel about their scoring.

Ultimately, it’s all about engaging with suppliers. Work together to measure progress and check in at regular intervals — quarterly, monthly, or even weekly if need be.

Why Use a Vendor Scorecard?

Scorecards offer an objective method for measuring vendor performance. Vendor scorecards strengthen relationships, lower costs, reduce errors, and serve as a mutually beneficial vehicle for continuous improvement.

The major benefits of vendor scorecards include the following:

- Clarity: Metrics and other KPIs qualify and quantify how your organization defines itself, conveying the trends most relevant to your company. Design a scorecard that balances and reflects the broader role of a partnership. Manage vendor concerns that organizations place too much emphasis on short-term financial and budgetary issues. Your scorecard should demonstrate your commitment to social responsibility by incorporating environmental and social governance elements.

- Objectivity: According to G-Force Consulting’s Gustafson, “Supplier scorecards provide an objective, data-driven analysis of supplier performance, which helps remove mistakes or personal biases from the process of managing the supply chain. A corporation must have an objective way to evaluate supplier performance. Scorecards give suppliers a level playing field for judging both their own performance over time as well as that of other suppliers in the same space.”

- Specificity: “Not only do scorecards provide the obvious benefits of an analytical tool, but they also offer the advantage of self-evaluation; the very process of customizing your scorecards to your business’s particular needs provides invaluable lessons. Vendor scorecard solutions give you the means to manage, monitor, and maintain growth strategies by supplying the right level of detail at the right time to the right people,” says The Art of Service’s Blokdyk.

- Tracking and Benchmarking: Scorecards track whether suppliers are meeting their SLAs and act as a tool for benchmarking vendor performance. “The measures on the vendor scorecard ensure a balance between external measures (i.e., concerning shareholders and customers) and internal measures (i.e., concerning critical business processes, innovation, and learning). These measures also follow growth over time,” says Blokdyk.

- Negotiation Support: The data you gather from scorecards provides a stable, evidence-based platform for new or ongoing negotiations with current or future vendors.

- Decision Making and Consensus Support: Scorecards allow you to visualize data in order to drive corrective management and simplify the decision-making process for individual managers or teams.

- Supplier Justification: With a single or related set of scorecard documents, you can quickly evaluate whether a supplier is an asset or a liability to your company.

- Improved Partnerships: The transparency of vendor scorecards facilitates communication and understanding between all stakeholders. You should use scorecards on an ongoing basis, both internally and externally (i.e., with suppliers). Blokdyk recommends using scorecards in quarterly, monthly, or even weekly reviews, depending on your business priorities: “Don’t treat a vendor scorecard as a stand-alone tool. You must use it as an integral part of standard operating procedures or formal vendor reviews. Otherwise, you won’t extract its full value.”

Blokdyk summarizes the cumulative effect of “using the business-specific customized vendor scorecard: It empowers your staff, accesses critical information quickly, performs management activities more efficiently and effectively, and provides reporting and analytics that are critical to your business.”

For more information on vendor and contract management, see the “Vendor & Contract Management Solution Guide.”

Improve Vendor Management with Real-Time Work Management in Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.