2026 OPERATIONAL EXCELLENCE REPORT

Exposing the resilience gap

Efficiency has long been the crown jewel of operational excellence, yet 63% of operational professionals struggle to balance efficiency with the need to adapt to business changes.

Operational excellence now requires efficiency and resilience, but many teams are suffering from years of operational drag caused by fragmented systems, rigid workflows, and disconnected data. In fact, only 8% believe their organizations have achieved it.

The result is a widening operational resilience gap. Organizations are racing to be more adaptive and resilient, but their operational foundations have not kept pace, leaving teams hindered as their infrastructure falls short.

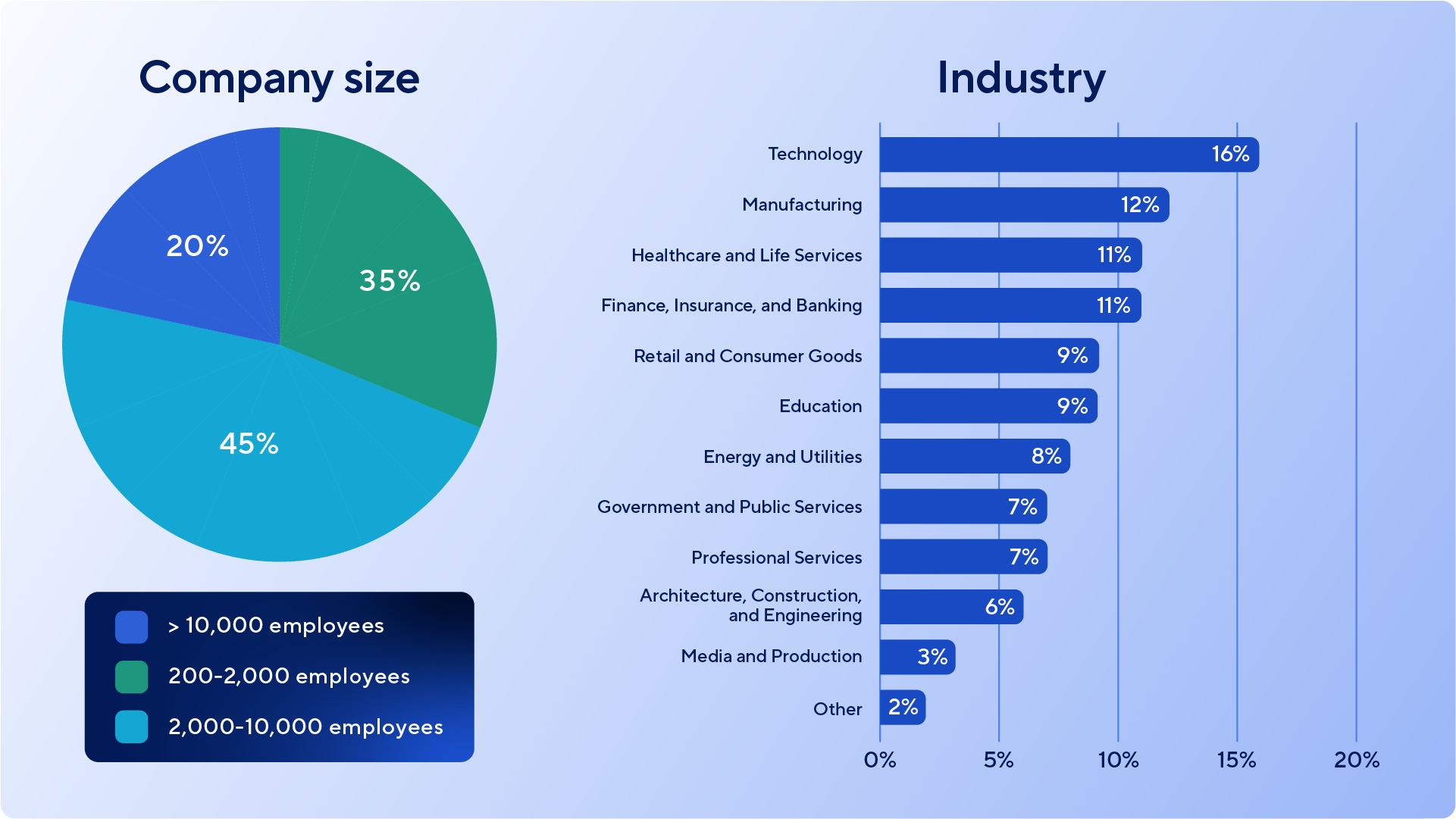

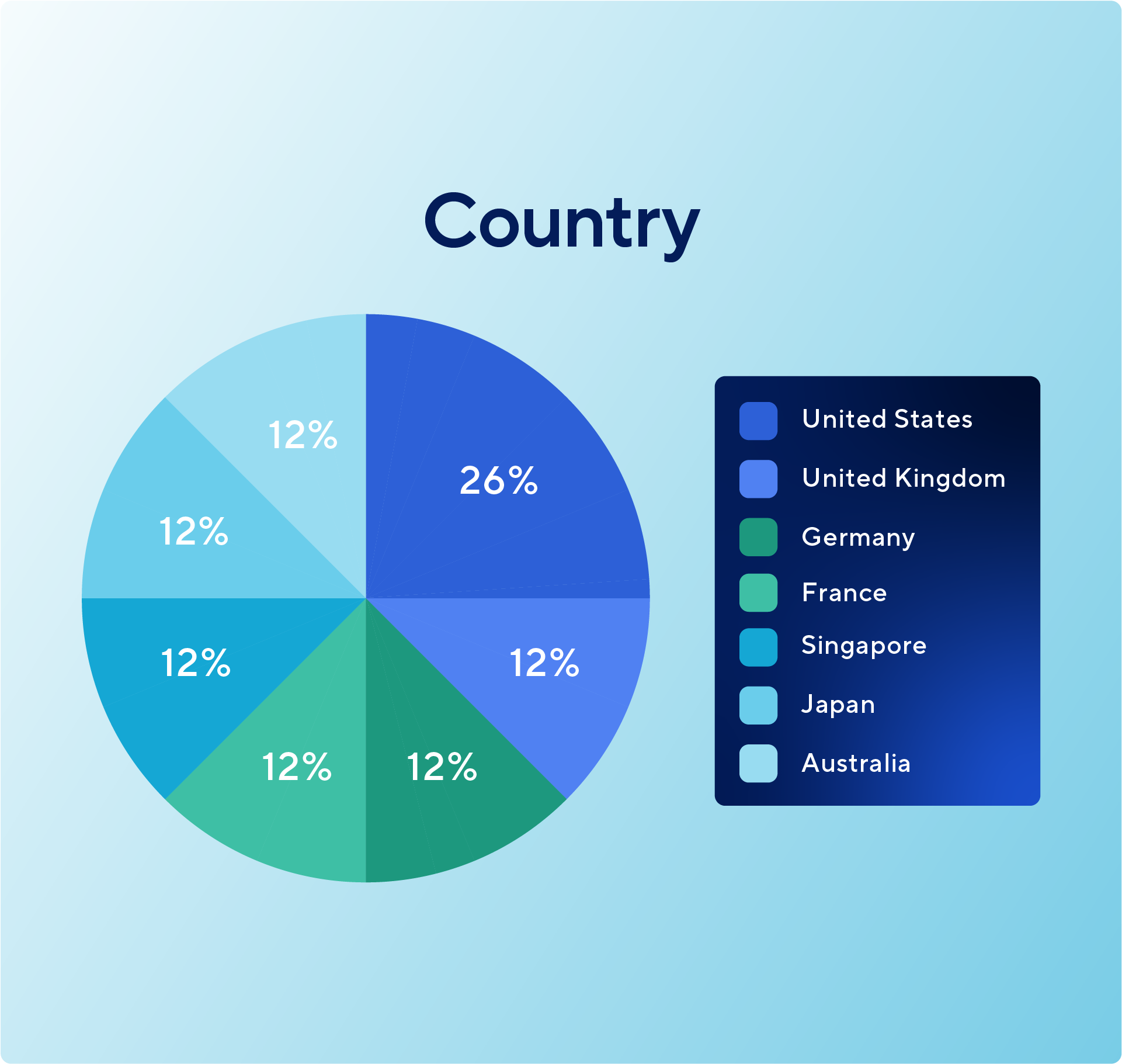

We surveyed 1,550 operations management professionals across the globe to explore this gap, how teams are attempting to solve it, and the tools they need to achieve operational excellence in the era of disruption.

Chapter 1

Efficiency remains a top priority — and a major challenge

Operations leaders rank efficiency as the number one priority for successful operational management. However, they also list it as their second biggest challenge. Nearly all (99%) say they still spend time on repetitive, low-value tasks each week.

Constant pressure to work faster with fewer resources has led teams to build a warchest of point solutions, each one promising to supercharge efficiency in a specific area. Survey respondents reveal the number one way their organizations have enabled operational efficiency in the last year is by investing in more tools and systems.

But, this approach often backfires. Disparate solutions lock teams into rigid, manual workflows while creating information silos that prevent cross-functional visibility and agile, informed decision making.

Chapter 2

Operational drag hurts organization resilience

Almost all (99.6%) operational leaders say business changes require them to shift priorities. Some 14% say this happens “constantly,” while 46% say it occurs “frequently,” making it clear that operational excellence also requires resilience — not to simply absorb disruptions, but to respond proactively and purposefully when disruption occurs.

Yet, 71% of respondents agree that the friction from fragmented tools and rigid, manual processes creates operational drag that slows down their ability to quickly and creatively address business challenges and opportunities. In addition, while 97% say it’s important for operational management tools to provide full visibility into work being done across the entire organization, a whopping 61% admit they lack “full visibility” into this work.

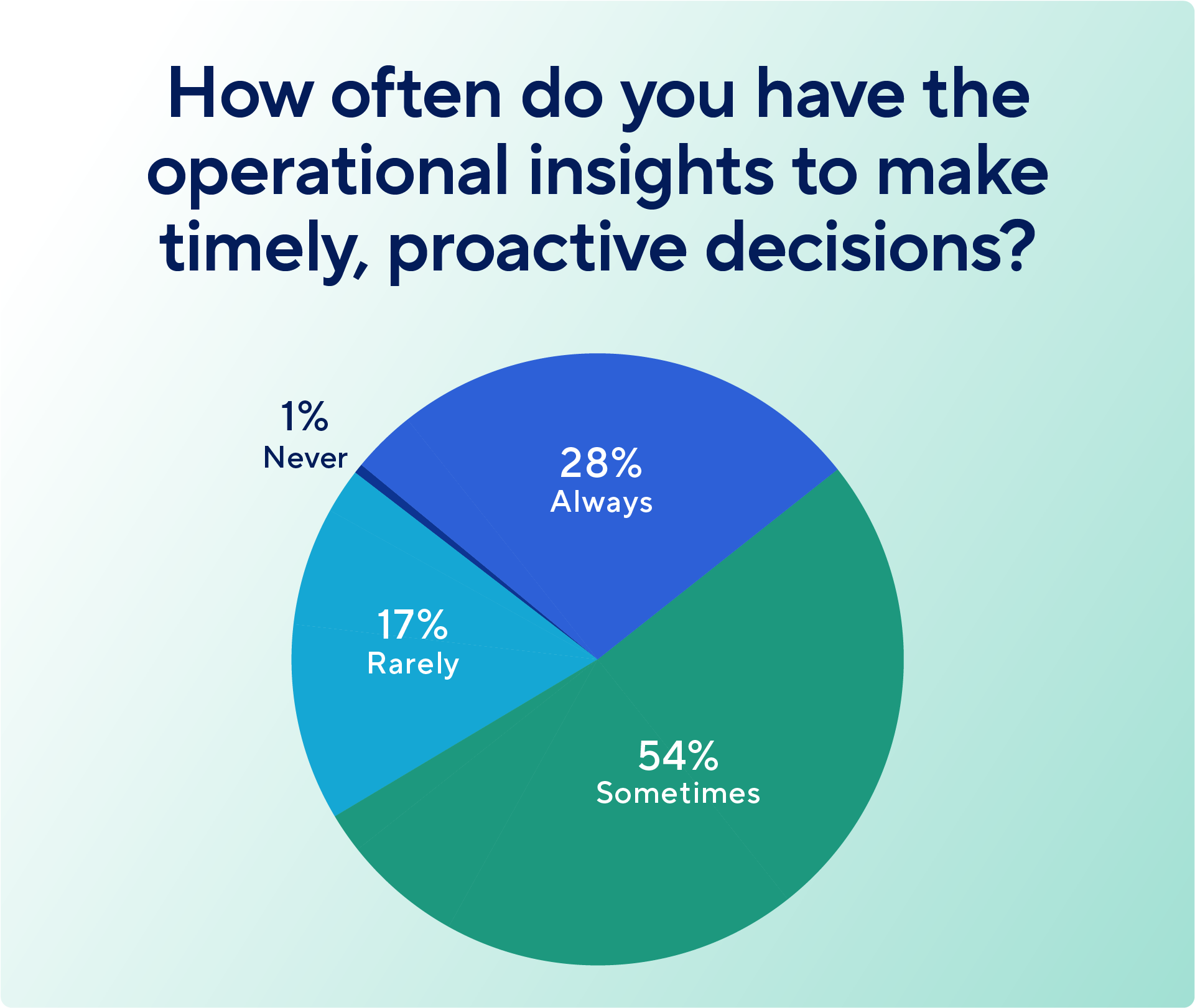

It makes sense, then, that only 28% of operational leaders say they “always” have access to the right operational data and insights they need to anticipate disruptions and make timely, informed decisions. When operational data, workflows, and decisions are connected, leaders can anticipate disruptions instead of reacting to them.

Chapter 3

Welcome to the widening operational resilience gap

Operational leaders are expected to do more work and change direction faster than ever before, yet their operational systems, data, and workflows remain too fragmented to support that pace. As a result, organizations struggle to get a clear view of objectives or performance because their operational foundation cannot keep up with their goals.

Case in point: 76% of operations professionals say their organization relies on workarounds because their tools and processes can’t flex with changing priorities. Each workaround adds complexity, slows execution, and pushes teams further from true operational resilience.

With 63% struggling to balance efficiency and resilience — and just 8% believing they’ve achieved operational excellence — the resilience gap continues to widen.

Ready to transform your operations?

CHapter 4

AI offers a promising solution

To help strike this balance, teams are turning to AI to improve efficiency and create the visibility needed to drive resilient decision making. Most (94%) say they currently use AI tools for operational management.

These include general purpose generative AI (GenAI) applications capable of creating content and recommending process optimizations (e.g. ChatGPT and Claude), as well as specialty GenAI features built into operations management tools to automate repetitive tasks and streamline workflows. A surprising 31% say they’ve even begun using AI agents to autonomously approve and trigger actions.

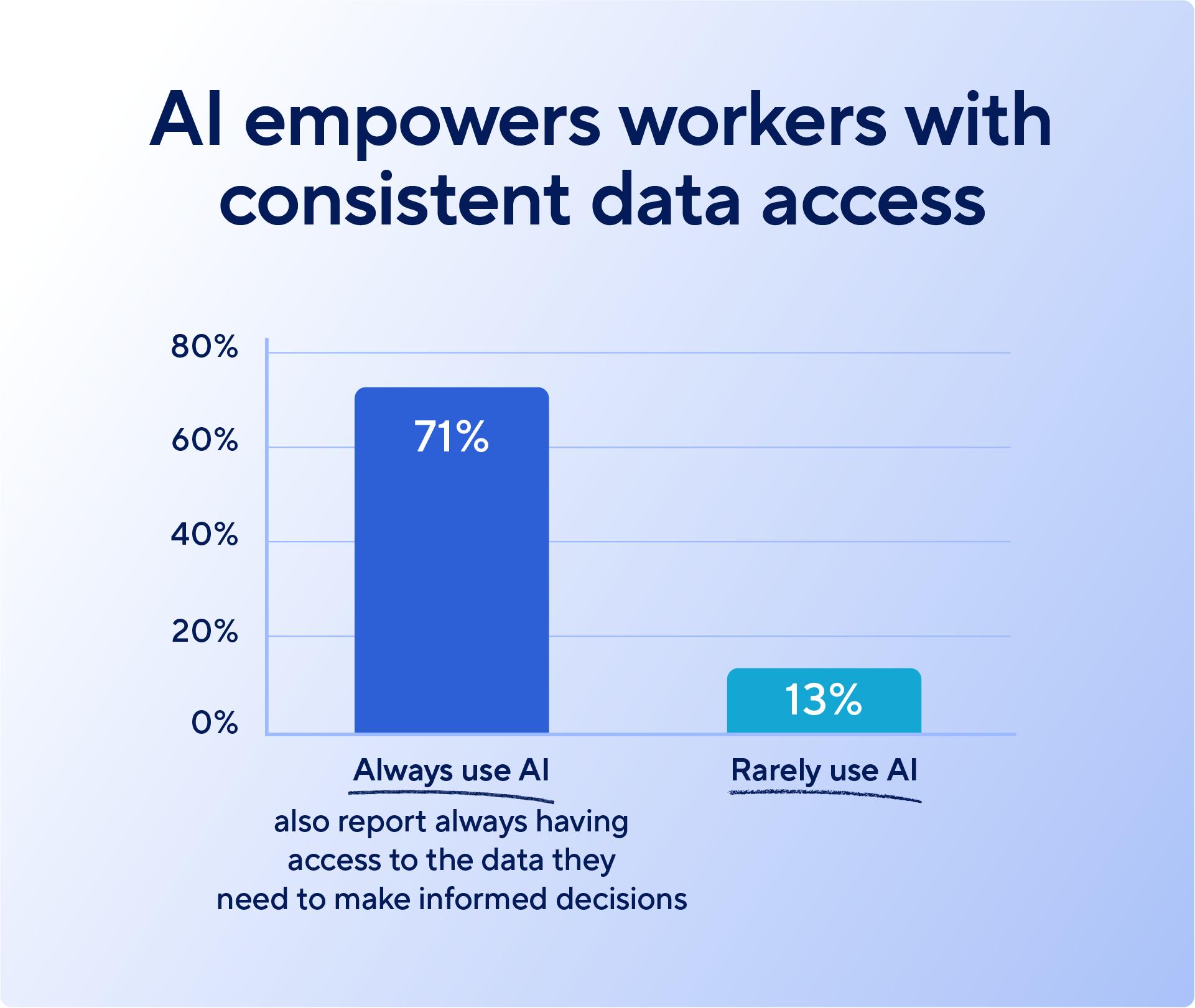

AI’s biggest strength is its ability to aggregate, organize, and analyze data across systems. That’s why 71% of survey respondents who say they “always” use AI also report “always” having access to the data they need to make informed decisions, compared to just 13% of those who “rarely” use AI.

CHapter 5

…and creates new challenges

AI can also create additional silos and even new risks without proper organizational implementation, orchestration, and oversight.

First, AI adoption is uneven, with over half of respondents (58%) “rarely” or “occasionally” using this technology, exacerbating existing tool sprawl and knowledge gaps.

Second, 87% believe that AI still needs human input to deliver what they need. Teams run the risk of overly relying on this still-evolving technology, resulting in inaccurate insights and misguided decisions. Lack of proper, standardized training means inconsistent, ineffective usage for many.

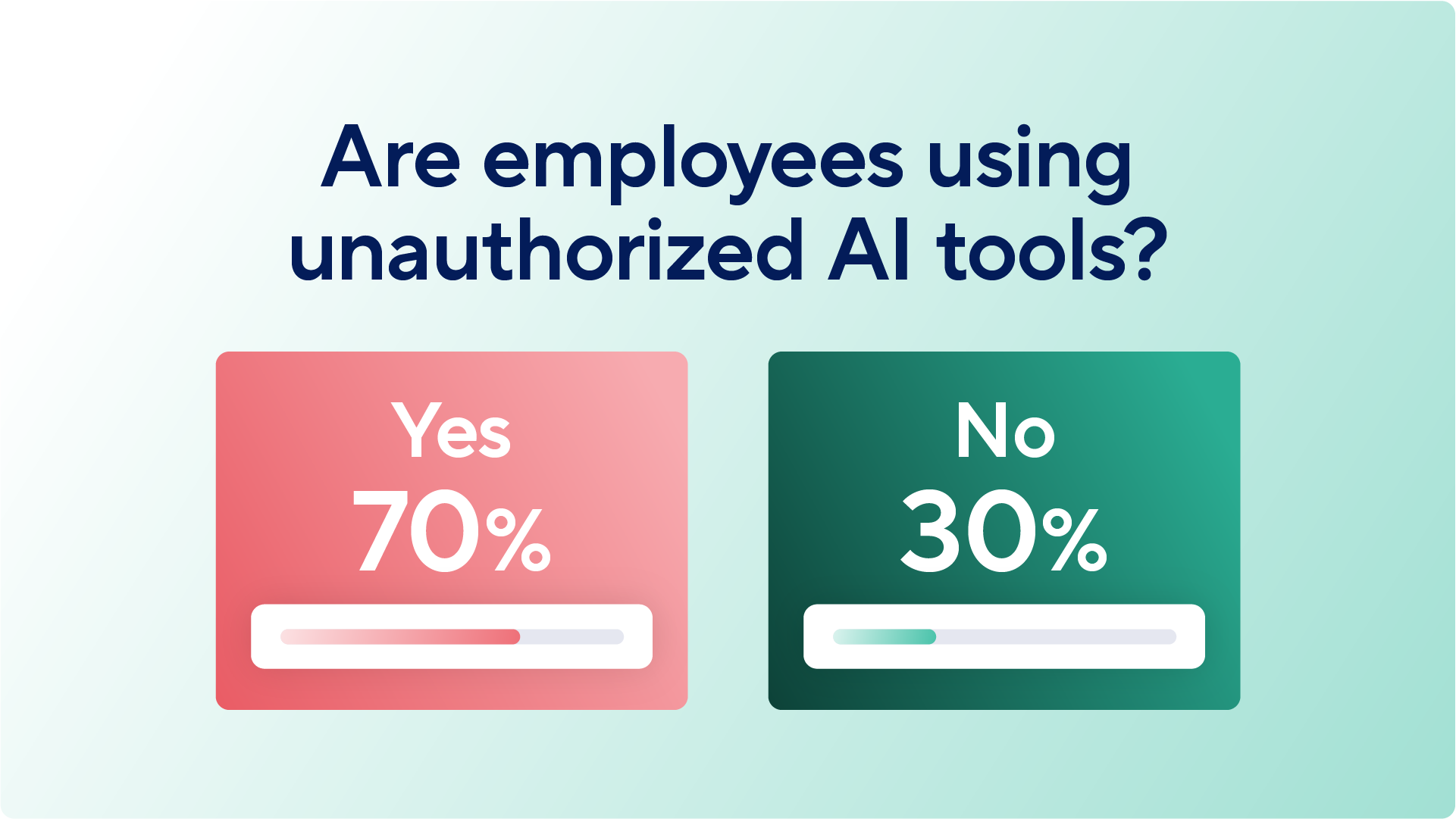

Finally, just 26% of operations professionals say their companies have fully documented and strictly enforced AI governance policies in place, but 70% of respondents admit employees use AI tools not covered by corporate policy. This mismatch between governance and usage creates an unpredictable AI environment — one where teams rely on tools the organization can’t properly oversee or secure.

CHapter 6

Operations managers crave flexibility

Survey respondents’ experimentation with AI reflects a deeper need: operational tools that combine standardization with flexibility. When asked what would bring them closer to operational excellence, operations managers ranked “standardized processes that allow for flexibility where needed” as the top option.

Repeatability is the linchpin of efficiency, so it should come as no surprise that just 13% of respondents say their operations management tools are “extremely flexible.” Many organizations end up compensating with workarounds, a clear sign of the resilience gap at the heart of the disconnected work crisis. This reinforces the need for tools that can flex with real-world change.

Conclusion

Bridge the gap: Intelligent Work Management

Modern teams shouldn’t have to choose between standardizing routine, repeatable processes and having flexibility to quickly and creatively adapt to evolving business strategies. But more fragmented point solutions and random acts of AI only contribute to the operational drag and poor visibility weighing them down.

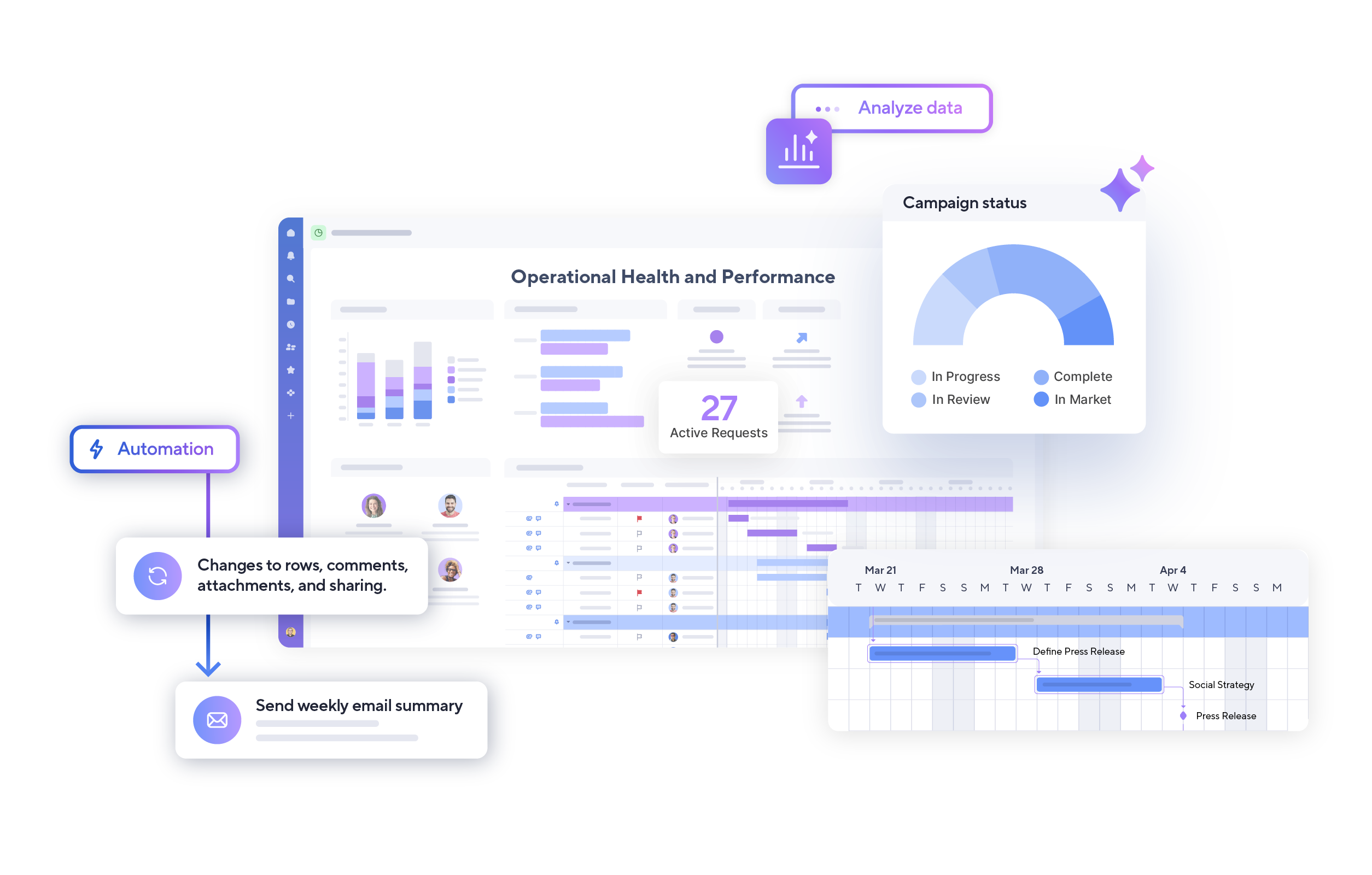

Most organizations don’t need another tool. They need an operational layer that connects their people, data, and workflows into a system that adapts as fast as their business does. Enter Intelligent Work Management.

An Intelligent Work Management platform acts as the connective tissue enterprises require, accelerating work velocity, closing the resilience gap through intelligent automation, and empowering teams to drive meaningful business impact. Smartsheet leads this category, providing the visibility, flexibility, and governed automation operations teams need to achieve scalable, resilient performance.

Ready to turn your operations into a strategic advantage?

Discover how Fortune 500 leaders achieve operational excellence through Intelligent Work Management, uniting people, data, and AI to optimize resource utilization, streamline end-to-end workflows, and accelerate business impact.

RESEARCH Methodology

Survey details

Smartsheet partnered with Dimensional Research to conduct a global online survey with a total of 1,550 operational management professionals from the United States, the United Kingdom, Germany, France, Singapore, Japan, and Australia. All participants had responsibilities for operations management and included a mix of ages, job levels, job functions, company sizes, and industries. The survey was fielded in September and October 2025.