What Is Continuous Quality Improvement?

Continuous quality improvement (CQI) is a quality management philosophy that encourages all team members, including board members, volunteers, and employees, to continuously ask what can be done better. CQI builds on existing quality management approaches such as TQM, Lean, and Six Sigma, but emphasizes that internal and external customer satisfaction is paramount, and that problems are caused by processes, not people. Despite CQI’s focus on people, data drives the search for problems and captures improvements. This process is sometimes also called performance and quality improvement (PQI), and involves three main steps: develop, implement, and reflect.

Occasionally, CQI can be considered a part of performance management, which is the long-term evaluation of programs to ensure that they meet goals. Performance management has two parts: CQI, which offers teams the opportunity to test and implement new strategies as they work, in shorter improvement cycles; and process evaluation, which an outside group may conduct by looking at key issues from a systemic perspective. Organizations may also use performance management to encourage team members to participate in improvement efforts.

Origins and Brief History of CQI

The formal pursuit and management of quality in the 20th century traces back to Walter Shewhart’s statistical process control models from the 1920’s and 1930’s. Shewhart demonstrated that employees could track variation in processes and product output on a chart, which allowed them to fine tune work as it was completed. Such activities not only produced superior products, but also empowered employees to learn more about their work and be accountable for it. Shewhart’s student and colleague, W. Edwards Deming further refined the concepts, which eventually found their way into quality management philosophies such as TQM, and then to continuous quality improvement. Here’s a 1994 interview with Dr. Deming on his thoughts about quality and innovation in the workplace.

As one National Institutes of Health article, “Assessing the Impact of Continuous Quality Improvement/Total Quality Management: Concept versus Implementation,” explains:

CQI/TQM differs from the traditional quality assurance in many ways; Among the most important is CQI/TQM's focus on understanding and improving underlying work processes and systems versus the traditional quality assurance emphasis on correcting after-the-fact errors of individuals.

CQI was first used in manufacturing, and Joseph Juran, Brian Joiner, and Philip Crosby expanded the concept to other business areas. By the 1970s, quality management began to move beyond factories to transactional and service fields.

According to Michael Decker, MD in “Beyond Infection Control: The New Hospital Epidemiology,” in health care, quality measurements were originally based on how well an organization followed given standards. As Decker writes:

When a standard was not met, the response was often to seek a miscreant who could be punished for the transaction. Attention was directed almost exclusively to the performance of physicians, with little recognition given to the roles of other participants in the process or to the organization of the process itself. The definition of quality rarely encompassed such considerations as patient satisfaction or the needs of families, employers, or other healthcare providers.

As insurers, government, and other agencies began to demand quantitative proof of quality based on set procedures, it was clear that a new approach was necessary. CQI not only uses data to instruct changes, but also seeks change from within the system and likewise looks for answers from the people in the system. Additionally, in CQI, quality is defined by meeting or exceeding the needs of customers, whether internal or external.

Today, marketing programs teach CQI as part of their curriculum, while social service programs in healthcare, education, facilities management, construction, and transportation use the practice.

What Is CQI in Health Care?

In health care, the continuous quality improvement philosophy came to prominence as those in government and private insurance companies required more evidence of value for money. CQI provides a means to measure consistency and success in private and public hospitals, health programs for specific ailments, and for specific demographics, such as children, seniors, teens, pregnant women, and prison populations.

Beyond controlling costs and justifying expenses, continuous quality improvement in medicine can provide support for excellence in care. For example, the pervasiveness of colorectal cancer demands sound cancer detection methods. Authors of the paper “Quality in the Technical Performance of Colonoscopy and the Continuous Quality Improvement Process for Colonoscopy: Recommendations of the U.S. Multi-Society Task Force on Colorectal Cancer” assert that “Continuous quality improvement is recommended as part of every colonoscopy program.”

What Is a Continuous Quality Improvement Program?

A continuous quality improvement program aims to ensure that all team members, employees, managers, and other stakeholders feel consistently empowered to improve efforts and results.

What Are the Core Principles of CQI?

Organizations and researchers articulate the fundamentals of continuous quality improvement slightly differently, but it generally embodies five principles:

- Look at the system and its processes. Most problems are found in processes, not in people. CQI seeks solutions to produce the best outcome, instead of blaming people for problems that arise. In CQI, problems occur because of poor design, unclear instructions, or poor leadership.

- Use statistical analysis to identify and detail problems and strengths. CQI employs serial experimentation, also called the scientific method. Under this framework, teams manipulate different variables to see what works best. These tests are structured so practitioners can capture results and the chosen course(s) of action.

- Employ cross-functional teams drawn from employees, management, volunteers, board members, and even customers. Quality improvement is the purview of the whole team, not just management.

- Empower all stakeholders to identify problems and opportunities for improvement, and to develop and present solutions.

- Focus on both internal and external customers. Fulfilling the requirements of the customer is paramount.

A commonly recognized problem in any process is variation. Variation in procedures causes variation in outcomes. CQI and all quality management philosophies seek to make processes consistent. When output is consistent, teams can begin to improve processes.

There are other principles that guide continuous quality improvement, as well. Improvement should be part of the culture of the organization and a natural part of how people perform their jobs. Improvement doesn’t only mean success in a one-off project; rather, it is an ongoing effort, concurrent with regular duties. Ongoing efforts also test improvements as they happen, without waiting for a formal evaluation. It is often said that CQI doesn’t follow the adage: If it isn’t broken, don’t fix it. Instead, CQI team members should proactively search for ways to be more efficient and effective.

You can learn more about the core principles in the U.S. by contacting the American Society for Quality (ASQ), American Standards Organization, and the Quality Institute in Healthcare.

Why We Use CQI

A continuous quality improvement approach offers various benefits to organizations. At a minimum, as social service entities and educational institutions shift to outcomes-based models, data-driven efforts that produce measurable results satisfy funding requirements. However, CQI can also provide structural and procedural benefits.

The benefits of CQI include the following:

- Team member accountability

- Creativity and solution creation

- Heightened team member morale

- Improved processes, information management, and documentation

- Greater adaptability to changes

- Tools and methods to monitor program effectiveness

- Opportunities for additional programs and new program modules

Why Do Employees and Others Resist CQI?

Although the principles of CQI may sound inviting, team members may reject improvement initiatives for many reasons. Habits are difficult to adjust, and people often don’t like change. A key word in quality improvement word is continuous. To succeed, the effort must be ongoing and consistent, and that takes additional effort, which team members might resist.

Setting Up a Continuous Quality Improvement Team

Depending on the framework chosen, a team may have specific methodological skills. For example, a Six Sigma implementation may require trained Master Black Belts, Black Belts, and Green Belts to guide and execute research and improvement designs. However, a CQI team should consist of people from the entire organization who are directly involved in its mission. Team members may be administrators, volunteers, board members, customers, or staff members. CQI positions include a chairperson or facilitator, a secretary or scribe, and team members. It can be helpful to build a team with the following skills and designated responsibilities:

- Champion: Selected from within the team, a CQI champion helps to ensure the program receives support within and without the team.

- Program Administrators: CQI administrators should have day-to-day insight into how their organization works. Program administrators should have a sensitivity to when the improvement effort has become a burden, but should also lead the change effort suggested by the CQI process.

- Community Stakeholders: Stakeholders may be internal or external clients who can guide prioritization of CQI program efforts.

- Data Specialist, Program Evaluators: The number crunchers can identify data sources, analyze data, and present results in consumable charts and reports.

- Management: An organization’s management must be committed to the improvement effort, advocate for it to the whole organization, and support efforts by providing time, training, and other necessary resources.

What Are the CQI Methods?

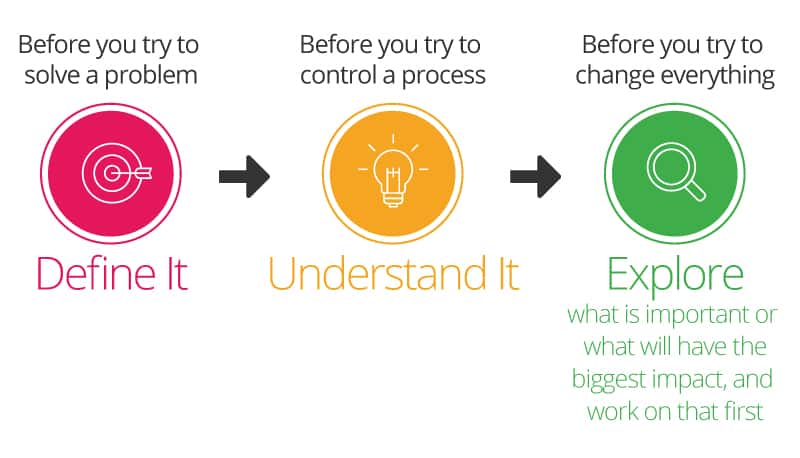

Organizations implementing CQI may choose an existing established quality management method, but effective CQI usually includes some variants of the following core steps:

- Create a Team: Your CQI team should be comprehensive and representative of the organization. Team members need direct knowledge of the work, clients, and system. Team members can be volunteers, employees, directors, managers, or board members.

- Define a Goal: Not every aspect of your enterprise requires tracking and improvement. Consider high-risk or essential aspects of your organization’s activities and study those before you spend time and effort on other aspects.

- Define Customer or Client Needs: Regardless of if your enterprise outputs products or services, the satisfaction and success of customers is critical. While deciding how to serve customers best, also consider what quality means.

- Determine Baseline: What is your starting point? You need this information to help you know whether your efforts are improving the current situation.

- Determine What Success Looks Like: Identify when to stop working on a problem and when to move to the next problem.

- Consider Different Approaches to Reaching the Established Goal: Build your plan of action methodically. Don’t just choose the first idea the group considers.

- Gather and Analyze Data: Numbers and statistics can help with the decision making process and are essential for documenting improvements for certification or funding.

- Use the Scientific Method: Solutions should be tested, refined, implemented, and adjusted as necessary.

- Create Logic Models: Logic models help to connect what you want to achieve to how you’ll achieve it. Logic models work well for demonstrating impact to funders.

- Foster a Learning Culture: Use peer teaching to help individuals build skills and sponsor group classes.

- Sustain Effort: Continuous improvement is not the success of a single project. You can sustain momentum by ensuring that data, evaluations, and procedures are well documented for times of staff transition so they can iterate.

Process Studies and Outcome Studies

In some organizations, improvements are analyzed and tracked through regular process and outcome studies.

- Process Study: Look at the effectiveness of existing processes and ask: How can we improve the facility or processes or procedures? How do we make it more efficient?

- Outcome Study: Evaluate the outcomes of changes. For example, are patients getting the right care? Are they worsening after treatment?

Frameworks

In pursuing improvements, organizations may use an assortment of existing quality assurance methods. Some frameworks are specific to social and health services, while others were developed in manufacturing and have been adopted by different industries and the service sector. Here are a few frameworks to help you accomplish CQI in your organization:

- Getting to Outcomes (GTO): The RAND Corporation, along with the help of the Center for Disease Control, developed this trademarked model to help communities fight assorted addictions among young people. It includes 10 phases: focus, target, adopt, adapt, resources, plan, monitor, evaluate, improve, and sustain. GTO is ideal for both experienced teams and those new to working with quality improvement and outcome evaluation.

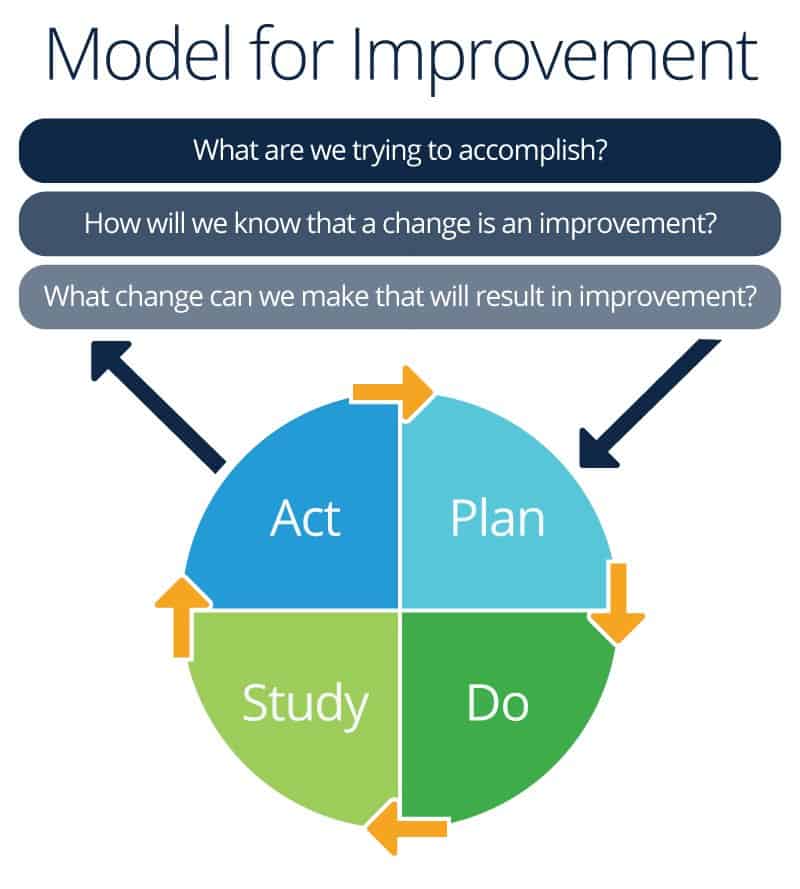

- PDSA/PDCA: Developed by W. Edwards Deming, plan, do, study, act (PDSA) became plan, do, check, act (PDCA), and presents a cyclical model for problem solving. PCSA is an essential element of ISO 9001 and TQM methodologies.

- Model for Improvement: The Institute for Healthcare Improvement Collective created this framework for collaborating across business, government, philanthropy, and social services to address entrenched social problems. Suited to larger organizations, the Improvement Model employs PDSA, plan do study act

- Lean: This method focuses on eliminating waste and redundancy in existing processes, and works well in large organizations.

- Six Sigma: Often employed after a pass with Lean, Six Sigma seeks to find and remove the causes of defects or problems, and variations in process and output. A data-driven methodology, Six Sigma consists of five iterative phases: define, measure, analyze, improve, and control. Six Sigma adapts well to improving processes, such as client intake. The quantitative approach suits situations where you must rigorously document safety and quality.

- Malcolm Baldrige Quality Award Methodology: Organizations often follow Baldrige Award criteria to pursue quality. The Baldrige criteria aim to make strategic changes to an entire organization. Baldrige is a holistic approach and works well for introducing CQI concepts and encouraging a culture of improvement.

Tools for Working with CQI

As with other quality improvement philosophies and methods, tools provide ways to gather information and data, make decisions, track progress, and visualize processes and results. The following are some of the tools you can use through the steps of an improvement effort, sometimes called IADT, which stands for identify, analyze, develop, and track.

Identifying

- Brainstorming allows groups to creatively discover problems and solutions.

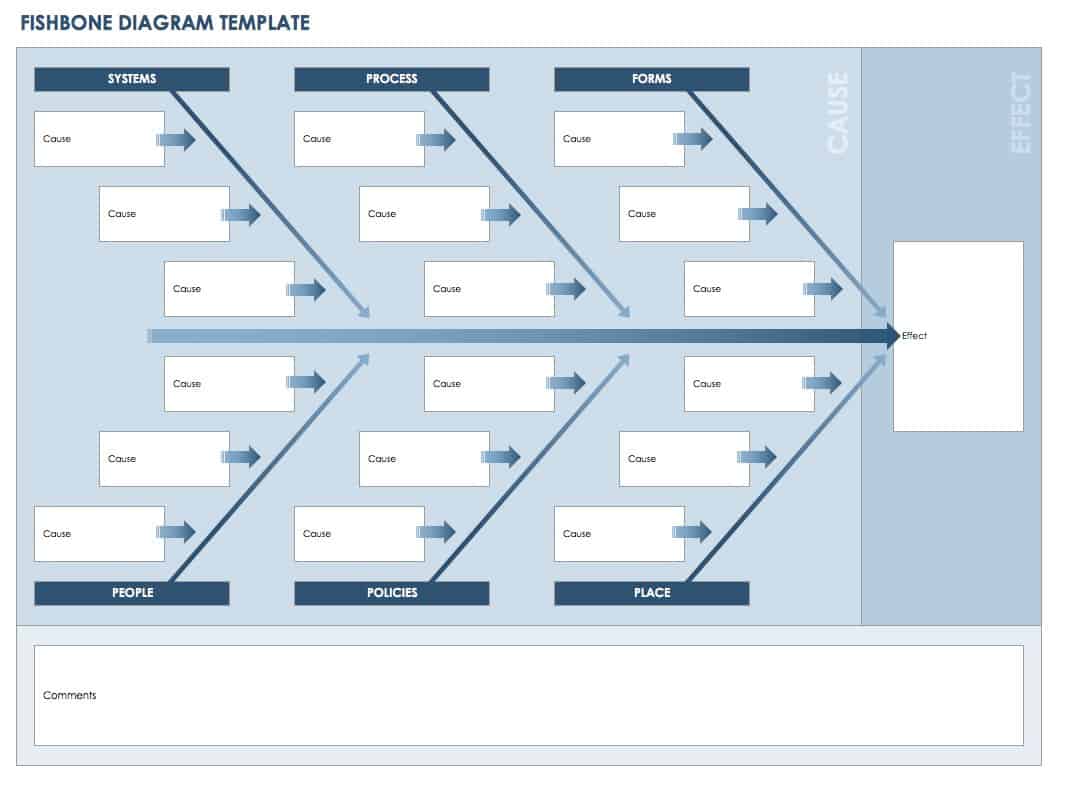

- Ishikawa diagram, also called a fishbone diagram, allows you to graphically display all possible causes of a problem and then group them.

Download Fishbone Diagram Template

Analyzing

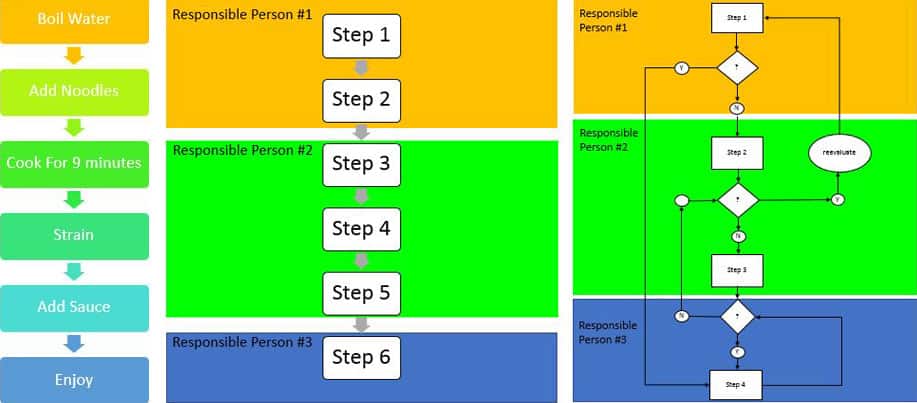

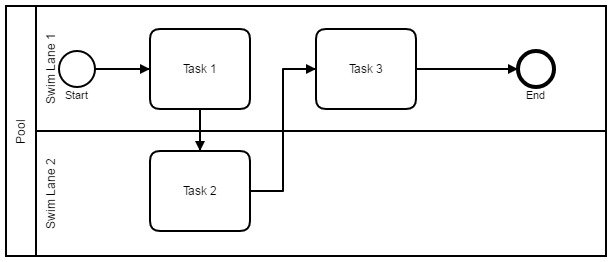

- Flowcharts represent how different elements join and relate to each other in a process.

- Histogram shows how often a problem occurs, and how and where results cluster.

- Check sheets offer a basic way to create and use devices for collecting data.

- Pareto or 80/20 analysis charts are based on the assumption that 80 percent of problems are linked to 20 percent of causes. Pareto analysis helps you identify which problems fall into which categories.

- The Ishikawa diagram is also a useful tool for analyzing problem causes through visual representation.

- Business process mapping or value stream mapping helps to record and analyze the flow of materials or information a process uses. Often business process mapping uses with 5 Whys questioning to determine a processes’ essential steps.

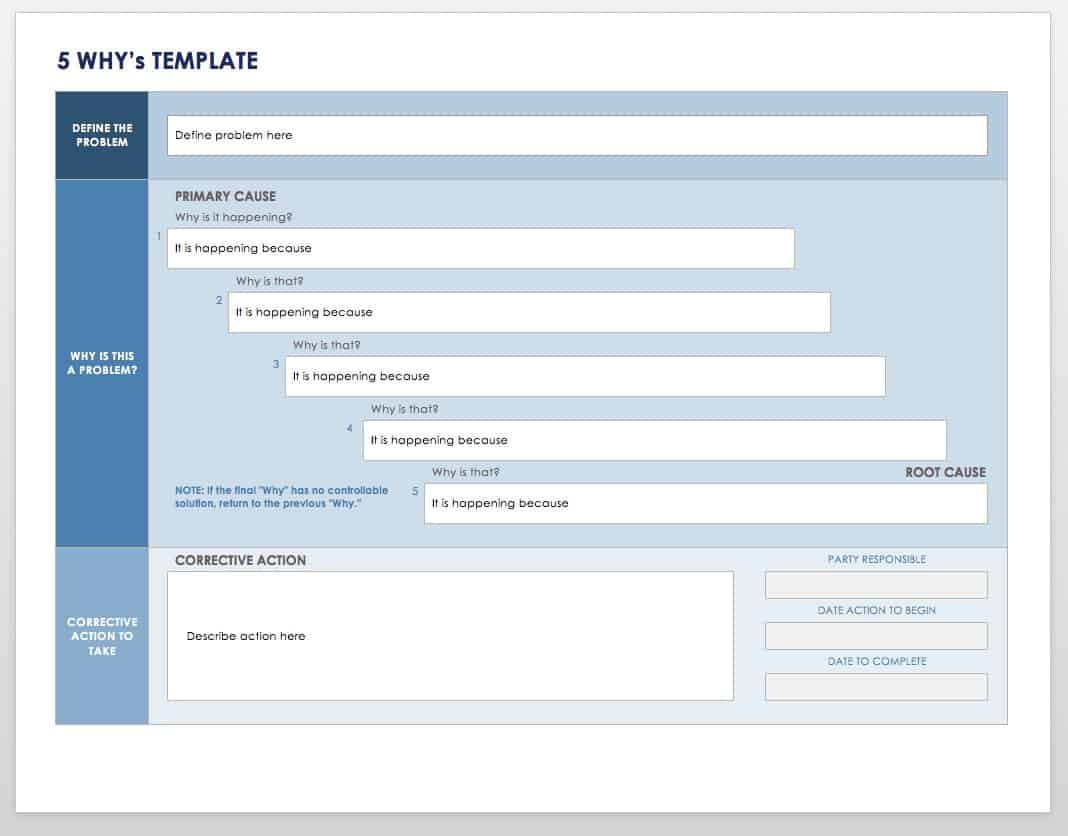

- Group discussions often use the 5 Whys questioning method to discover root causes. You pose a question, and then continue asking why to each successive response.

Download 5 Whys Template

Excel

|

Word

|

PDF

Developing

- Storyboards graphically tell a story. In this case, they can explain how and why improvement is necessary and can provide a reminder for team members of the goal and steps to achieving the goal. A storyboard should be clear and detailed enough to stand on its own without interpretation. Benchmarking uses the information and statistics about comparable organizations to establish standards or benchmarks for attaining quality.

Testing and Implementing

- Gantt charts help to track progress over time and help you visualize the effort applied to individual tasks.

- Storyboards are also useful for mapping the new process and its progress.

- Statistical process charts allow you to track results over time to see if and where outliers appear. These variations may indicate processes that require tuning.

Best Practices for CQI

- Ensure that you have the correct data to address the chosen problem. Data must be accurate, timely, and focussed.

- Measure more than the outcome. It is important to also understand the composition and organization of an entity to understand where problems arise.

- Aggregate data so you and the teams that follow you can understand patterns of input and results.

- Review data collection tools and process for relevance.

- Make time and financial resources available to implement the effort properly. Consider devoting a dedicated team to the initiative.

- Break a large project into smaller ones to maximize opportunities for success and build enthusiasm.

- Define success for a project and understand when it will end so that you can start new projects.

Learning More About Continuous Quality Improvement

Non-profit special interest organizations such as Population Health Improvement Partners offer specific training in continual quality improvement. Training is also available through universities, with online material, workbooks, and via in-person workshops. Other supplementary studies can support the practice of CQI, such as general quality management principle training, problem solving, and team building.

Monitor and Manage Continuous Quality Improvement with Work Management in Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.