What Is Six Sigma?

When practiced well, Six Sigma can be a powerful tool. As consultant Jennifer Williams says, “I have not found an industry that could not benefit from Six Sigma.”

Six Sigma is a set of methods and tools for business process improvement and quality management. Six Sigma aims to improve quality by finding defects, determining their cause, and improving processes to increase the repeatability and accuracy of process results. By improving efficiency and decreasing defects, the quality and timeliness of product delivery improves, and with it, ideally, employee enthusiasm and confidence--and the company’s bottom line.

With the aim of achieving near perfect ouput, Six Sigma employs statistical methods to detect problems and improve processes. Data-driven improvement projects are executed with specific steps in a defined sequence and with specific improvement goals in mind, called value targets. Teams with in-depth knowledge of the Six Sigma methodology are established to sponsor, manage, and complete the project.

“Six Sigma is a methodology and set of tools that help us measure what we do and then improve what we do. It really can work in any industry and in any type of business because everywhere we have a process, we can study it, measure it, and try to make it better,” says Kimberly McAdams, a Six Sigma Master Black Belt and Principal with FireFly Consulting.

This popular methodology, which gained a foothold in American business in the 1980s, is now a worldwide practice. Proponents of Six Sigma tout its advantages, including reduced waste, improved understanding of customer requirements, reduced production time, and a cost savings of up to 50 percent.

What Is Lean Six Sigma?

A variation on the Six Sigma framework marries Lean Management principles with Six Sigma methodologies. Lean Management seeks to reduce waste and thereby production cycle time, whereas Six Sigma focuses on reducing variation among deliverables. As some see it, Six Sigma focuses on finding and fixing defects after the fact, while Lean tries to prevent defects from occurring in the first place. At its best implementation, Lean is introduced first to increase efficiency, and then Six Sigma methods are applied for fine-tuning. Manufacturing, healthcare, finance, IT, and other fields use Lean Six Sigma.

Sermin Vanderbilt is Founder of Lean and Six Sigma World Conference and President of the American Quality Institute. According to her, “Six Sigma is getting it right every time or most of the time, 99.9 percent of the time. Almost every organization does need Six Sigma. Six Sigma is about accuracy. Lean is about cutting the costs, cutting time, so they go hand in hand.”

In short, what is Six Sigma? In the words of perhaps its most famous proponents, Jack Welch, “Six Sigma is a quality program that, when all is said and done, improves your customer’s experience, lowers your costs, and builds better leaders.”

Project Management Guide

Your one-stop shop for everything project management

Ready to get more out of your project management efforts? Visit our comprehensive project management guide for tips, best practices, and free resources to manage your work more effectively.

History of Six Sigma

Although the term sigma (with a lowercase s) was used as far back as the 1920s in statistical process control, Motorola first named Six Sigma as a quality goal in 1984. The previous 60 years of quality improvement theory, including Total Quality Management and Zero Defects helped develop the formal methods known today.

Over time, Motorola realized that they could apply many of the tools and methods used to achieve fewer defects in parts manufacturing to other aspects of business. In the years that followed, other large companies such as Allied Signal also adopted the methodology. But Six Sigma attained true star status in the late 1990’s when GE’s chairman and CEO, Jack Welch, proclaimed phenomenal savings as a result of of Six Sigma.

ISO (International Organization for Standardization) published its first certification for Six Sigma in 2011, but no single governing Six Sigma organization publishes the definitive body of knowledge. Companies, institutions of higher learning, and consulting companies may offer standards and training that differ slightly.

The 2000s saw Lean Manufacturing, with an emphasis on reducing waste and improving process flow, combined with Six Sigma principles to form Lean Six Sigma. This framework offers organizations methodologies for streamlining processes and then detecting and removing defects and inefficiencies.

Six Sigma: What’s In a Name?

Six Sigma derives from statistical process modeling in manufacturing. A sigma is a measure of standard deviation, abbreviated as small s, or the Greek letter, σ. Something that is within +/-6s, Six Sigma, from the centerline of a control chart was created by a process that is considered well controlled. In other words, there is little deviation from the standard and is within tolerance. Six Sigma is sometimes written as 6σ. Motorola trademarked the name in the 1990s with capital letters.

Six Sigma Processes

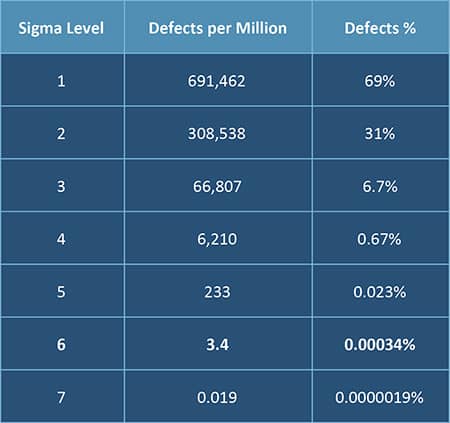

In practical terms, a Six Sigma process produces 99.99966% of all deliverables, called opportunities, free of defects. Essentially, the process produces 3.4 defects per million opportunities (DPMO). You can also think of Sigma levels as how far a process or deliverable deviates from perfection. An important concept is to think of sigma defects as not meeting customer expectations. Aiming for Six Sigma level, you have a high probability of producing items that are well within specification. Several Sigma levels exist, each of which indicates the number of allowed defects per million and thus the level of maturity of a process, as is indicated in the table that follows.

Some theoreticians also consider that processes deteriorate over time in a 1.5 Sigma shift. Statistically, this means that the process will deviate 1.5 Sigma from the centerline of a control chart.

What Are the Benefits of Six Sigma?

As a new methodology, Six Sigma focussed on measurable goals, especially financial goals. You can achieve the goals through data-driven decisions, based on statistical processes, and not hypotheses.

“Control charts have been around for almost 100 years, but being able to take a methodology, really define a problem up front, find what a customer needs, and then start using these business and statistical tools to really dig in, that’s what helped Six Sigma become so powerful,” says McAdams.

Indeed, many companies credit Six Sigma with earning them substantial savings. For example, Motorola touts a savings of $17 billion. Although the initial results of work with Six Sigma at GE were less promising, between 1995 and 2000, Six Sigma processes are said to have saved the company $12 billion. Over 50 percent of Fortune 500 companies use Six Sigma and credit the methodology with savings of over $400 billion in the past two decades.

Six Sigma is usually a practice that large corporations use, and some consider that the methodology requires significant adaptation for small organizations. In addition, formal certification may be prohibitively expensive for small companies, especially for more advanced certifications.

However, experts also see the advantages of Six Sigma for all organizations. “I would say that smaller companies need Lean and Six Sigma more than larger companies because they need to be so much more competitive to stay in business,” asserts Vanderbilt.

Although Six Sigma did originate in manufacturing, business and service industries have also realized its benefits as well. “What makes it a little more challenging sometimes, is that we can’t visualize the virtual, electronic processes, and so actually, in the end, the tools become even more important in that environment,” says McAdams. In manufacturing, you can go to the production floor and view the assembly line and time the processes. “A lot of our processes in the business world are happening over email and other electronic communications. But in some cases, it actually makes it easier to time, if we have good data coming from those systems.”

Williams adds that if you started out practicing Six Sigma in manufacturing, applying it to non-manufacturing, such as finance, requires some adjustments in thinking. Instead of putting a part down a conveyer belt, it’s handing off information from one department to another department or within the same department. “It’s following that value stream and seeing where the bottlenecks are, seeing the delays, and asking are we waiting? Is there overproduction? Are we over processing. We still can tie those quality improvement concepts to information or data.” Further, she adds, “I have not found an industry that could not benefit from Six Sigma.”

What Are the Six Sigma Principles?

Depending on where you look, you’ll find some slight variation on Six Sigma principles. In general, these are the thoughts that guide the approach.

- Continuous efforts to achieve stable and predictable process results are crucial to business success.

- Manufacturing and business processes have characteristics that can be defined, measured, analyzed, improved, and controlled (see DMAIC below).

- Achieving sustained quality improvement requires commitment from the entire organization, including and perhaps especially upper and middle management.

- All processes can be defined and analyzed in detail, and therefore improved: if you control the inputs, you can control the outputs.

- Continual evaluation is crucial. Stop what you’re doing and consider what went right or wrong.

- Eliminating variation saves money and reduces defect

The Six Sigma Methodologies

The principles of Six Sigma are executed through methodologies, or roadmaps to improvement, like a workflow. Two main methodologies are DMAIC and DMADV.

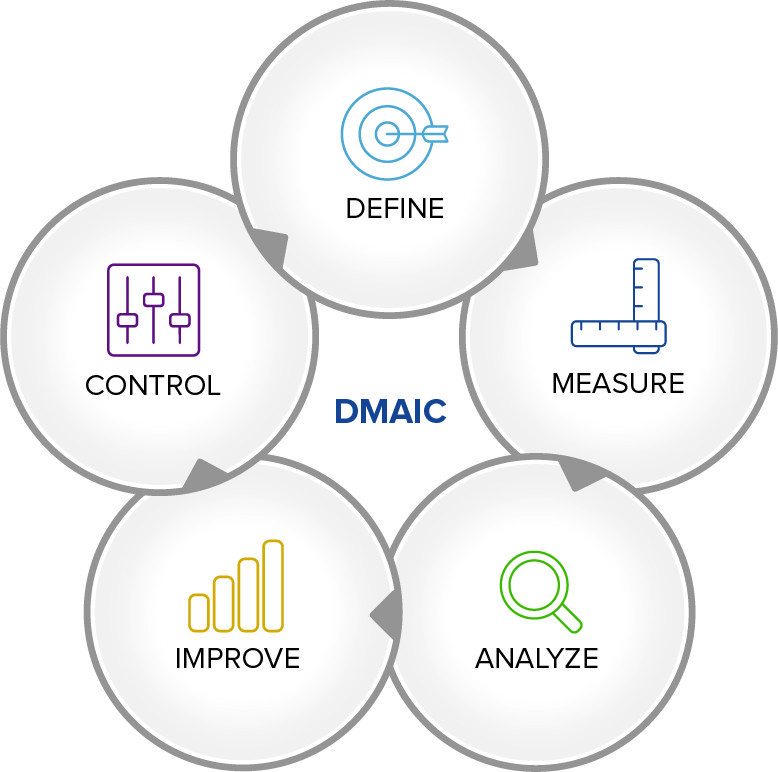

DMAIC, pronounced duh-may-ick, focuses on incrementally improving existing processes. It is the most widely known methodology and the one most associated with Six Sigma. Here’s a breakdown of the acronym:

D: Define customer needs, requirements, and project goals.

M: Measure the key aspects of the current process. According to McAdams, “This is when you start to understand your process and collect data on it.”

A: Analyze data. “You really dig into what types of errors occur and where they occur so you can target the big ones. It’s always looking at that 80/20 rule. Let’s see if we can find 20 percent of the reasons that give us 80 percent of the defects and let us reduce those,” says McAdams.

I: Improve processes. Test and verify that the improvements work.

C: Control future implementations of the processes to ensure that errors don’t creep in again.

Download DMAIC Roadmap Template

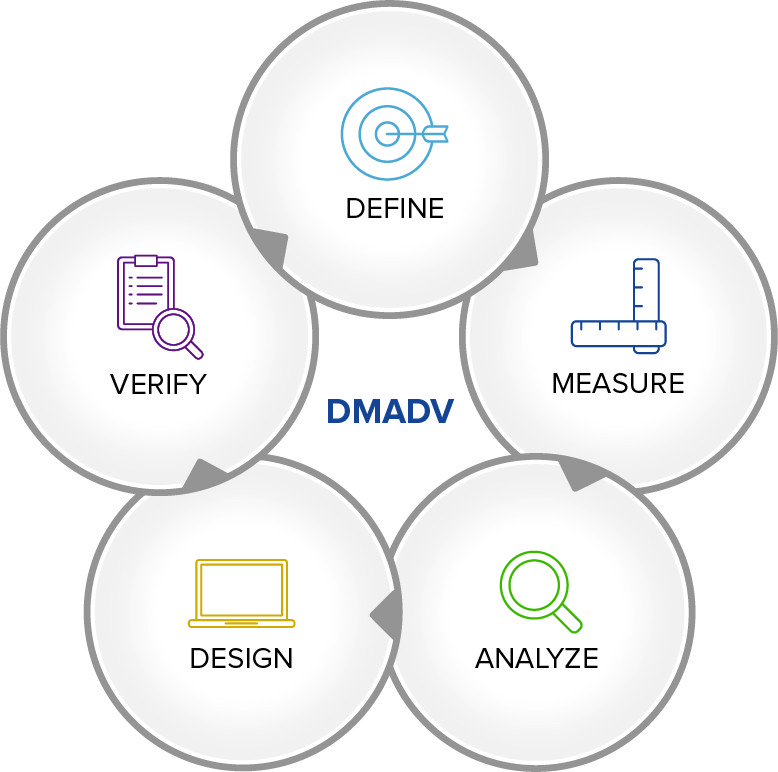

DMADV, pronounced duh-mad-v, focuses on optimizing new products or processes to Six Sigma standards. Here’s a breakdown of the acronym:

D: Define customer or company goals.

M: Measure CTQs (characteristics that are Critical To Quality), measure product capabilities, production process capability, and risks.

A: Analyze data from your measurements.

D: Design the new process based on the analysis in the previous step.

V: Verify the design through a pilot run, implement the new process, and hand off to the process owner.

Download DMADV Roadmap Template

An emerging methodology, particularly associated with Lean Six Sigma, is DFSS (Design for Six Sigma), with an emphasis on determining from the beginning what the customer wants and ensuring that defects and inefficiencies are anticipated and eliminated at the design phase of a process.

Analysis Tools

During the phases of these methodologies, Six Sigma practitioners use various existing tools to measure and analyze process and outcomes. A partial list of the most mentioned tools is as follows:

- Control charts

- 5 Whys

- Root Cause Analysis

- CTQ Tree (Critical to Quality)

- Statistical process control

- Process mapping

- ANOVA gauge R&R (analysis of variance gauge repeatability and reproducibility)

- Pareto charts

- Value Stream Mapping

- Business Process Mapping or Checksheet

- Cause and effects diagram or fishbone diagram or Ishikawa diagram

- Taguchi method

Who Makes It Happen? The Belts of Six Sigma

Execution of the Six Sigma methods relies on a team of trained practitioners sourced from throughout the company hierarchy. Management aligns the right projects with the right people and ensures that they can achieve goals and sustain success. The production team employs the methods to create a good result, and all participants must have Six Sigma training. Six Sigma borrows from the martial arts the concepts of belts to designate a level of methodological mastery.

- Executive Leadership: The CEO and other executive staff establish the vision for the Six Sigma implementation at the organization level, and support management.

- Champions: The executive leadership from upper management selects the Champions. They ensure that all departments in an organization work together to implement Six Sigma, and to mentor Black Belts.

- Master Black Belts: Champions select the Master Black Belts, who advise on Six Sigma practice for programs. Master Black Belts also train and mentor Black Belts and Green Belts, and identify potential Six Sigma projects for the company.

- Black Belts: Master Black Belts supervise Black Belts, who are responsible for executing the Six Sigma methodology for specific projects. Their sole focus is the statistical analysis and the correct execution of Six Sigma methodology.

- Green Belts: Guided by Black Belts, Green belts are employees who implement Six Sigma recommendations as part of their regular duties. They may also lead projects part of the time.

- Yellow Belts: Yellow Belts have a basic knowledge of Six Sigma, but they may be either new to the methodology or need only a basic understanding as, for example, a Champion or an Executive. Yellow Belts may participate in projects by finishing such tasks as creating process maps, and working on smaller improvement efforts within larger projects.

- White Belts: New to Six Sigma concepts, White Belt certification takes only a few hours, and typically does not include testing.

Training and Certifications for Six Sigma Belts

Many training organizations offer Six Sigma certification, although no one official body of training knowledge or certification exists. Different schools and individual companies may offer their own variations. Some training institutions and consultancies do band together to provide a version that they accept. The Council for Six Sigma Certification, for example, accredits Six Sigma trainers to guarantee their curriculum meets a basic standard. The International Association for Six Sigma Certification (IASSC) provides certifications for Lean Six Sigma.

Training can be in a classroom, onsite, self-paced, online, or a combination of all. Certificates are awarded upon successful completion of a written exam, which may be taken online or on paper.

Aside from being a workplace requirement, a Six Sigma certification presents well on a resume, and can garner as much in salary as an MBA. Learn more about Six Sigma certifications by reading What You Need to Know About Six Sigma Certifications and Belts.

Formal training may not be necessary. “You don’t need the Belts to implement it,” says Sermin. “You just need to have the philosophy and the belief that you need Lean and Six Sigma to be competitive.” Training can be as simple as reading a basic Six Sigma book and deciding to focus on efficiency and to trim waste.

Six Sigma Glossary

Here are some common terms beyond those already mentioned in this article that all Six Sigma practitioners use.

5 Whys - An information gathering technique for exploring cause and effect.

7 Wastes - A Japanese concept describing how a business might waste resources. It is described by the acronym TIMWOOD, which stands for Transportation, Inventory, Motion, Waiting, Overprocessing, Overproduction, and Defects.

Acceptance, and Acceptable Quality Level (AQL) - This term refers to the acceptance of the product as meeting quality standards, or acceptance, or agreement with, a proposed action.

Activity Report - A report that tracks tasks, responsibilities, schedules, and duration.

Affinity Diagram - A diagram that captures the result of brainstorming activities, often used during the Improve phase of Six Sigma.

Analysis - A review and study of the data captured during the Measure phase.

ANOVA, ANCOVA, MANOVA, MANCOVA - The advanced statistical methods for comparing data.

Balanced Scorecard- A tool for aligning strategic elements and communicating strategy to the company.

Black Noise/White Noise - Elements that are always unpredictable and elements that are unpredictable, but will be eliminated with further information, respectively.

Business Improvement Campaign - An endeavour to improve processes throughout a company, not just on the manufacturing floor.

Business Process Management - An endeavour to improve workflow and flexibility throughout a company.

Cause-Effect Diagram - An Ishikawa diagram or fishbone diagram.

Checksheet - Also referred to as a frequency distribution or frequency distribution analysis. A tool held over from Total Quality Management. A simple chart used for collecting data over time in many instances to learn where problems occur. This chart helps to show the larger pattern of behavior, rather than making assumptions about the circumstances in which problems occurred.

Critical To Quality (CTQ) - An essential element that contributes to the success or quality in a process.

Defect - A failure to meet customer specifications or expectations, a failure within a process, or a physical defect.

Design For Six Sigma (DFSS) - Along with DMADV, DFSS focuses on listening to the customer to get the processes right before defects occur.

Define, Measure, Analyse Improve, Control, Improve (DMAIC) - The Six Sigma methodology for finding and fixing defects in a process.

Define, Measure, Analyze, Design, Verify (DMADV) - Similar to DFSS.

DPMO - An acronym that stands for Defects Per Million Opportunities.

Just-In-Time (JIT) - Just-In-Time is a production method that aims to minimize stock levels by producing products just in time for customer purchase.

Kaizen - A Japanese philosophy focusing on continuous improvement of process and people. The concept also influences Lean Thinking.

Materials Requirements Planning (MRP) - A methodology for optimizing material levels with production and delivery schedules.

Pareto - An analysis that looks for the 20 percent of activities that generate 80 percent of the benefits, or the 20 percent of problems that cause 80 percent of waste.

Plan, Do, Check, Act (PDCA) - The Total Quality Management method, and the precursor to DMAIC. Acknowledged as a foundational method in ISO 9000.

Process - Describes a workflow, or describes how Six Sigma is implemented.

Process Mapping - Including flow charting and value stream mapping, this is the process of creating a graphical representation of how things work

QxA=E - Quality multiplied by acceptance equals effectiveness. This equation originated in the Six Sigma program at GE.

Soft Skills - People skills, rather than statistical or process skills. The ability to influence people, build teams, communicate, empathize, and so forth.

Stakeholder - Internal and external customers, team members implementing a Six Sigma process and solution.

Tollgates - The review periods between Six Sigma stages.

Total Quality Management (TQM) - One of the original management systems, TQM teaches that every employee, management to janitor, is responsible for quality deliverables and a quality work experience.

X's/Big X's - The possible causes of the problem or the big Y.

Y's/Big Y's - The little aspects of a solution that serve the big Y, or main customer requirement.

Value Target - The financial goal for a Six Sigma project

Criticisms of Six Sigma

Nothing is perfect and Six Sigma has come under various criticisms. Some criticize what they see as the Black Belt industry, wherein it’s all too easy for anyone to hang up a shingle and start selling training and certifications. Others, such as the quality guru Joseph Juran felt that Six Sigma was, in effect, old wine in new bottles, that the principles were old and had simply been repackaged with fancy belts for certifications.

McAdams says that nothing is a panacea and success derives from a good implementation. “Just like any business methodology it’s sometimes practiced well and sometimes not so well. What it doesn’t really do, is fix the business strategy. A good strategy still needs to be in place. But the data that you can get from a good Six Sigma program and good projects can help you focus a business strategy. But, no, it’s not the end-all solution to saving a business.”

How Six Sigma Practitioners Use Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.