What Is a Construction Plan? Definition, Uses, and History

Construction plans differ from maps, which cover much larger areas and have much larger scale ratios. Rather, a typical construction plan depicts only one structure and its parts or sections. By changing perspectives and details, it can do so in a number of ways.

Construction drawings also fill an important role in the overall construction planning process. Building departments and local governments must review plans before they will issue construction or renovation permits. Planners estimate building material and labor costs based on plans. In the pre-construction planning and scheduling phase, contractors use plans to create work breakdowns and schedule construction tasks. Once construction gets underway, drawings guide the work.

As physicist John Swain writes for the Boston Globe, blueprints originated after an 1861 discovery by French chemist Alphonse Louis Poitevin. He found that the chemical ferro-gallate, derived from gum, could permanently turn a vivid shade of blue when exposed to strong light. To create a blueprint, one would first place the translucent paper of an architectural drawing over paper coated with unexposed ferro-gallate. Then, they would expose the paper layering to strong natural light. As light passed through the translucent top sheet, turning the ferro-gallate sheet beneath it blue (except for where the drawn lines on the top sheet prevented light from passing through to the bottom sheet), the chemical combination would reproduce a complex, finely detailed drawing in minutes.

This process was called contact printing, and the result was a blueprint: a white-lined, blue sheet of paper that formed a drawing. Blueprints cost a fraction of the money and time that other contemporary reproduction techniques did, so they quickly gained popularity among not only architects, but also scientists and artists who wanted to quickly reproduce complex diagrams.

True blueprints fell out of use in the 1950s. The name stuck, however, and today we continue to call complex design drawings blueprints. Of course, since the mid 20th century, architectural drawings have undergone several evolutions. With CAD (computer-aided design) software, we can now easily visualize them in 3D with varying levels of detail and from a variety of perspectives.

CAD software simplifies the architect’s work considerably. Blueprints’ background color made them very difficult to write on, and it’s much easier to make design changes digitally rather than on paper.

Though modern construction plans vary greatly in scale and complexity, representing everything from small residential to large commercial projects, all construction plans comprise the same essential elements. All buildings, no matter how complex, consist of structural components, mechanical systems, and finishes.

A construction plan will provide the same kind of information regardless of the size or complexity of a project. For example, a floor plan will provide a bird’s eye view of room dimensions and installations regardless of whether it’s drawn for an apartment or a convenience store, and a mechanical plan might detail mechanical systems for either a kitchen or a laboratory. If you can read one, you can read the other; only the level of complexity will vary.

Construction plans are different from a construction company’s business plans, which tell little about specific construction projects and more about how a company wants to develop its business. Construction plans also differ from specifications: A construction plan tells you what you will build, while specifications tell you how you build it.

Specifications will include information on materials you use, installation techniques, and quality standards. While most designers and architects will follow these methods for presenting information, others will annotate specs on construction plans, so the difference isn’t always clear cut. If the information in the specifications conflicts with that of the plans, the usual practice is to follow the specs over the plan.

General contractors, subcontractors, and tradesmen must have a deep knowledge of plan reading, and owners of large commercial projects will want to understand at least the broad strokes of a plan. Small project owners have an advantage if they are familiar with construction plans because they can understand exactly what the builders are going to be build. If you’re a homeowner and you don’t understand the architect or designer depicts the project, ask them so you’re on the same page before construction gets underway.

In fact, the professionals at HomeBuildingSmart recommend that you familiarize yourself with house plans before beginning a construction project, so you know what your tastes are and can provide useful input as the architect creates your construction plan. Remember, you can modify plans, but you can’t undo construction. So, iron out the details while they’re still only on paper.

Blueprints can seem arcane when you’re starting out, but with practice, reading them will get easier. So, if you’re a project owner, don’t shy away from construction plans: Make sure you understand what’s going on with your project.

Construction Plans: A Foundation Document in the Construction Process

Home owners who want to build new houses generally start with rough ideas of their desired home structures and layouts. They may select an architect or designer to draft the house for them. (The National Council of Building Designer Certification program offers advice on how to evaluate designers for residential projects.) Ideally, homeowners provide input as the architect draws up a set of plans until they reach a solution that satisfies everyone.

Once the plans are ready, the homeowner will seek a contractor to build the house. Some contractors don’t actually perform construction work themselves, but rather delegate it to subcontractors and tradesmen (though this is unusual for smaller projects). The builders will need a variety of construction plans to bring the architect’s ideas to life.

Regardless of the size of the project, construction almost always proceeds systematically. The first stage, planning, is generally a conversation among project owners and stakeholders who decide what objectives the project should achieve, whether they are achievable, and how and when they will be met.

During the design stage, the project owner or client works with the architect to come up with a finalized building design that is buildable and meets the client’s requirements. The level of collaboration here varies from project to project.

This stage is followed by pre-construction, when planners, contractors, and inspectors examine the design for constructability and value - therefore, this phase may result in changes to the plans. Contractors also bid for the project during this phase. Once you sign with a contractor, the builders procure materials, resources, labor, and expertise for the project.

Construction is usually the longest phase of any building project. General contractors, subcontractors, and tradesmen work to bring the architect’s plans to life. When construction is complete, the building goes through commissioning, which is the process of making sure that everything works as it should before people occupy the building.

You define many construction project types by end use, but projects are broadly classified as either residential or commercial. Residential refers to relatively small projects that builders complete for homeowners, and commercial acts as an umbrella term for anything from warehouses to hospitals.

However, builders may categorize projects even more narrowly, and some architects, engineers, and contractors specialize in particular niche areas, such as commercial (office buildings), education (schools), healthcare (hospitals), civil (highways and bridges), retail (stores), or industrial (factories, distribution centers) structures.

No two projects are exactly the same, even though there is a large degree of repeatability - the replication of a proven construction model - in some projects.

Because every project is unique, planning needs to be specific and tailored to the circumstances. Designers customize residential projects, for instance, to meet a variety of individual needs, such as the number of rooms, bathrooms, garage bays, and stories. The project planner must take into account the space available and decide how to make the house’s exterior fit the owner’s taste and the neighborhood. The designer must also make the internal layout fit the structural elements, architectural style, and intended usage patterns.

For home sites that don’t pose special challenges, such as slope or space restrictions, owners may want to save money by using stock plans. Rather than designing a custom plan for a specific owner and site, architects design stock plans for flexibility and to appeal to a wide variety of tastes. Stock plan companies sell the same basic plan over and over - they sometimes include slight modifications to fit an owner’s needs, but the degree of individualization is very limited.

Stages in Designing and Drafting Construction Plans

Architects iterate custom plans several times during the design process. The American Institute of Architects divides the design process for any construction project into five phases, and includes plan revision in the first three phases, and sometimes the fourth as well.

The first stage, schematic design, involves creating multiple preliminary designs based on the project owner’s requests and the site. Usually, the designer prepares two or three of these preliminary designs, and the owner picks the one they like best as a starting point for modification. A rough cost estimate is also attached to each design.

The design development phase is a back-and-forth discussion between the architect and project owner as they attempt to reach a consensus over the project design. This phase is followed by the construction documents phase, when the architect uses the agreed-upon design to create a set of precise construction plans and detailed specifications. The contractor will use these for bidding and to apply for construction permits.

Project stakeholders may consider the building’s design and construction documents finalized by the end of the third stage, but it’s not unusual for contractors to suggest design amendments during the fourth stage, bidding. This stage can be part of a process called value engineering, the attempt to increase the value-to-cost ratio of a structure. Value engineering seldom results in major changes, but in some cases, it may necessitate updating or resubmitting the permit application. The last phase, construction administration, involves the architect’s oversight of the construction process to make sure everything is going according to plan.

The project’s rules, as stated in the specifications, contract, conditions, and special conditions, govern the construction process. The specifications cover materials, installation techniques, and quality standards. The contract and all conditions are collectively referred to as the project contract. They delineate the roles and responsibilities of both the project owner or client and the contractor.

The specifications and project contract form the basis of the contractor-client relationship. Therefore, it’s not surprising that the highest numbers of construction disputes worldwide are directly related to contractual issues.

According to design and consultancy firm Arcadis’ Global Construction Disputes Report for 2016, the leading cause for contract disputes was a failure to properly administer the contract, followed by poorly drafted or incomplete and unsubstantiated claims, errors, or omissions in the contract,

incomplete design information or employers requirements, or the parties’ failure to understand or comply with the contract.

In North America, the average time to dispute resolution was about 13.5 months in 2015 - this illustrates the need for clarity and thoroughness in construction plans, specifications, and contracts if a building project is to proceed smoothly.

How Construction Plans Fit into Construction Planning

Construction plans are part of the construction planning process, which is one stage of the construction project management lifecycle. Before we go into more detail on construction plans, however, let’s recap the main principles of construction project management.

Construction planning involves defining all the steps involved in building a structure, splitting and arranging these into a logically ordered series of performable tasks, and then deciding what’s necessary (people, equipment, and materials) to complete each task successfully.

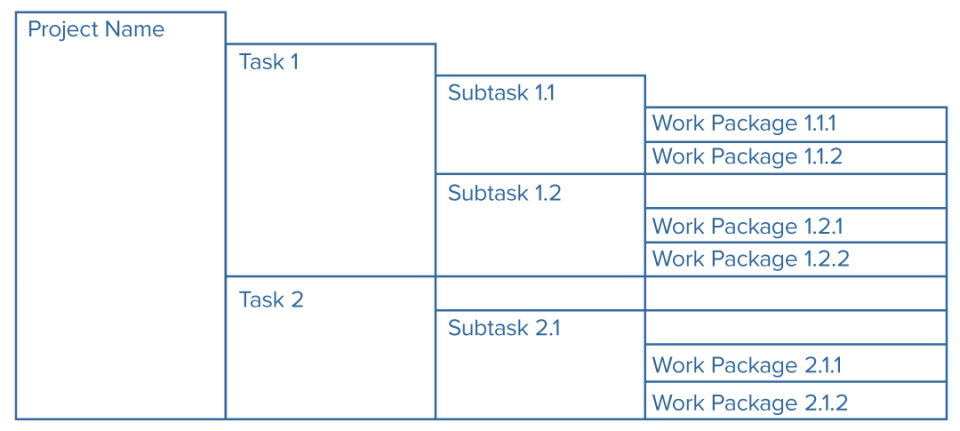

A construction plan is a prerequisite here, since you’ll need to know what you’re building before you can define all the necessary steps. A work breakdown structure, a diagram that depicts all deliverables, represents the project work in a hierarchy of work packages that each comprise a series of tasks. Laying bathroom tiles is an example of a project deliverable: It would comprise tasks like applying cement, placing tiles, and grouting.

The complete work breakdown structure is the basis of the project schedule, which tells you when each task should start and end in order for the building to be ready on time. To arrive at the schedule, construction planners determine task durations and establish the precedence relationships between tasks.

Task durations are the lengths of time required to complete each task, and are determined by a number of factors. Some of these factors are controllable (for example, the number of personnel or the type and availability of equipment needed to complete a task) and some are uncontrollable (the fact that cement must dry for several hours before the next process can happen, regardless of the resources available). Experienced builders estimate task durations based on how long it took them to do similar tasks in prior projects. Often, planners will use statistical techniques, such as program evaluation and review technique (PERT) to estimate the time required to complete a task.

Precedence relationships are the logical order in which you will complete tasks. A combination of basic job logic — figuring out what must happen before, during, and after performing a specific task — and physical or practical constraints determine precedence relationships. Builders have an intuitive understanding of job logic: You have to lay the bricks before you can paint the walls.

Other constraints that can be hard to see in advance may affect task execution. For example, it may appear that the cabinetry team and the painting team can work simultaneously, except that the space is too small for all the workers.

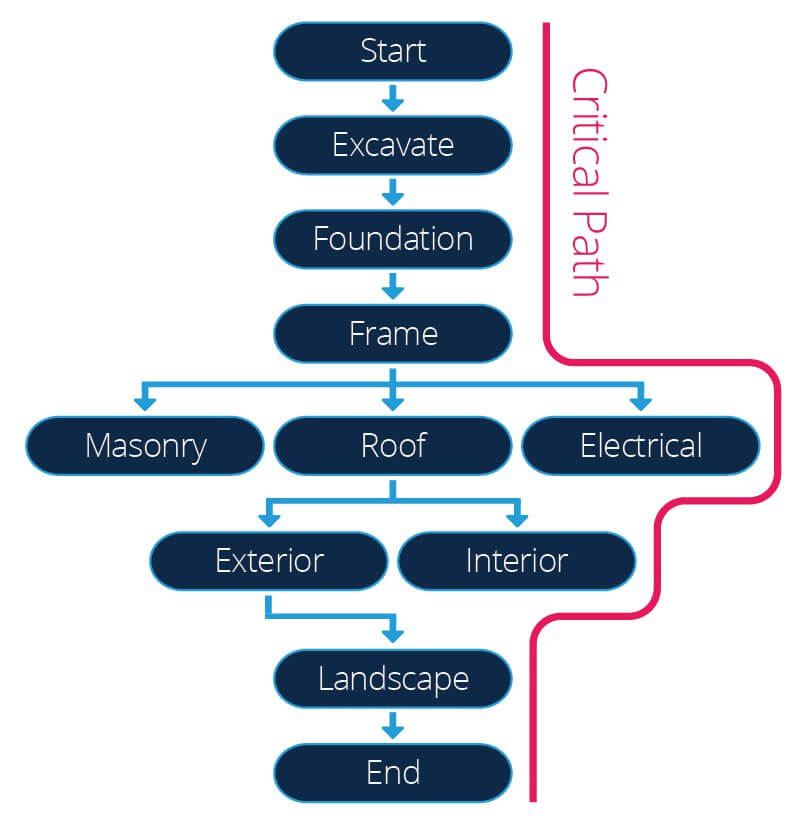

Once you determine task durations and precedence relationships, you can create a precedence network. A precedence network is a visual representation of all project tasks that you arrange in logical order. Nodes, or hollow circles, represent activities that contain written task durations, and arrows between nodes represent the order in which you perform tasks.

The precedence network drives scheduling with a technique called the critical path method (CPM). The CPM establishes the early and late start and end dates for tasks — that is, when you can (or must) start and finish them in order to complete the project on time. It also identifies the project’s critical path, a sequence of activities for which any delay will push back the project’s completion date.

Since all of these activities follow from the work breakdown structure, you can clearly see the importance of construction plans to the planning and scheduling of a building project.

Construction Drawings Help Planners Make Key Building Decisions

Blueprints also shape other important decisions, such as the choice of technology and construction methods for a project. Builders assess the scale not only of the project as a whole, but also of specific components of the project, such as building materials and their position within the structure. This process allows contractors and construction planners to figure out what kind of equipment and construction techniques they’ll use.

For example, a construction planner might ask whether a project requires a cement mixer truck or simply a wheel-based cement mixer. And, once the crew mixes the cement, do they need to pump the mixture to the higher levels of the structure, or can they transfer it by pulley or even manually?

Blueprints also make it easy to check if the structure conforms with building rules and codes and if it’s ready for building departments to issue permits for new and renovated structures. Most jurisdictions have building departments or councils that must issue permits for new construction or renovation projects before the construction work can begin.

For example, inspectors will check whether buildings have adequate fire protection and safely positioned windows, include enough parking, and many other details. Project owners seeking a building permit communicate these details by submitting the blueprints for review. Government permit departments will pore over the plans and check for compliance with building rules and codes before giving construction the permission to break ground.

Plan Specifications and the Construction Estimating Process

Earlier, we touched on specifications and how they’re different from construction plans. Builders use a standardized coding system, such as MasterFormat, to simplify specifications and make it easy for all participants to communicate requirements. MasterFormat, developed by the U.S. Construction Specifications Institute (CSI) and Construction Specifications of Canada, comprises 50 major divisions of construction information for commercial and institutional projects.

In this coding system, you identify each work product with a series of numbers that describes the major category and subcategory, and the type of work involved. For example, masonry is in division 04, and the clay unit masonry is in subgroup 21. Brick masonry gets MasterFormat number 04 21 13, which you would use on the construction plan.

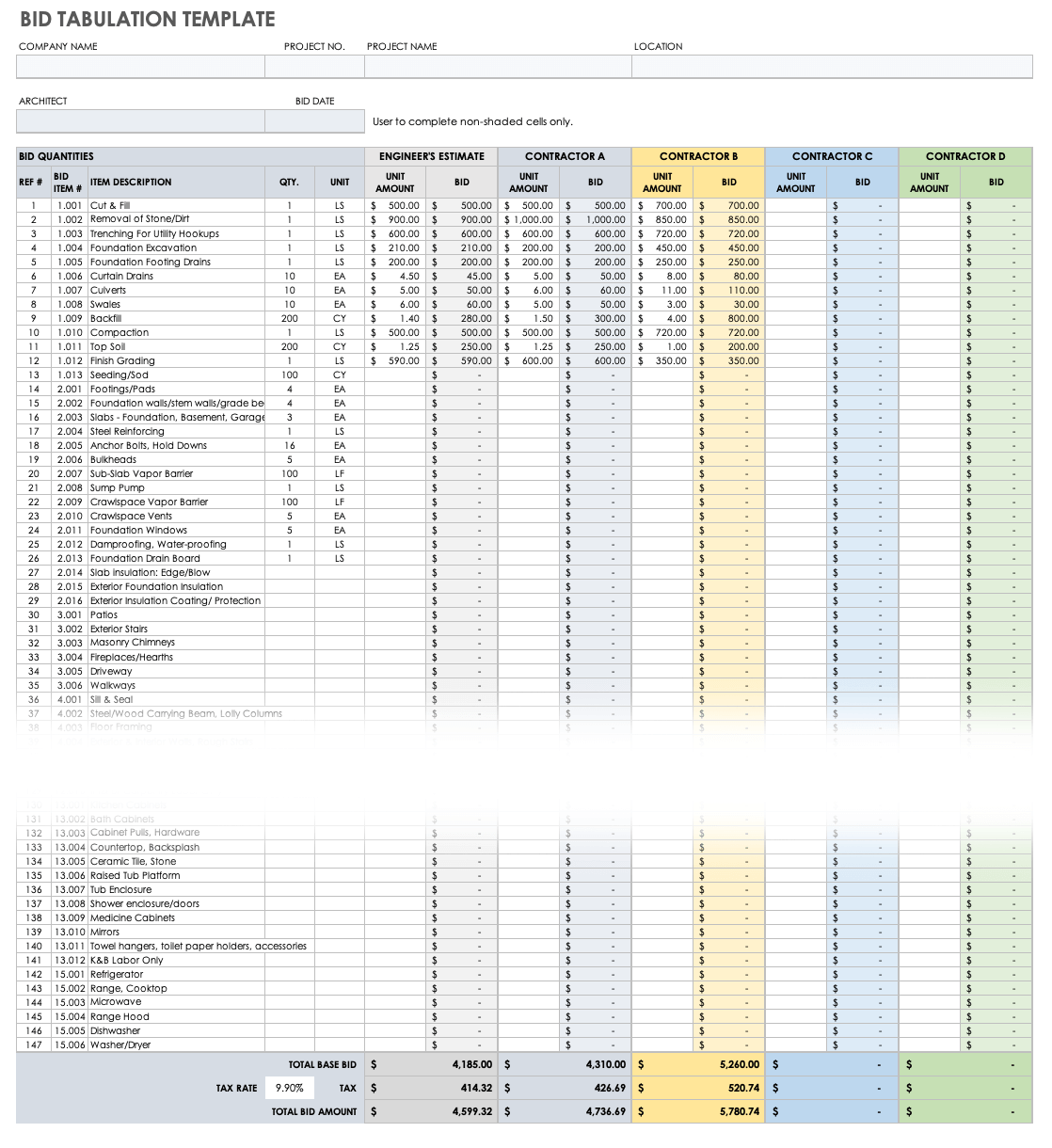

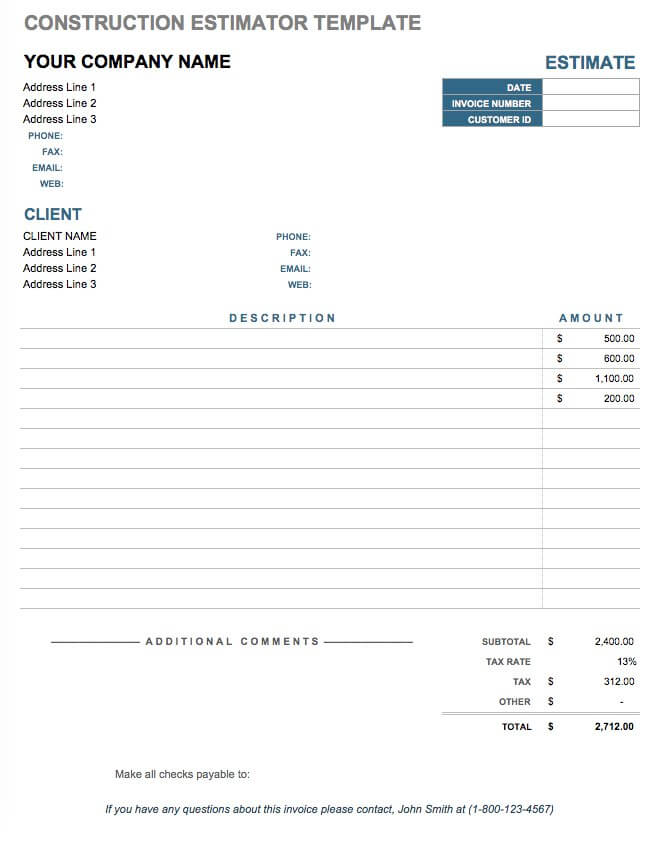

Construction plans help builders estimate costs, especially during the early stages of a project when contractors are preparing bids. To arrive at a cost estimate, you use a technique called quantity takeoff and prepare a document called the bill of quantities.

The quantity takeoff calculates the materials you need in a construction project. Its name derives from the expression “taking off,” and it lists material quantities from the construction drawings and specifications. You list, for example, how much wood you require for an activity, and then you multiply that amount by how many times that activity occurs during construction.

The quantity takeoff is a fairly specialized operation performed by an estimator who can both read blueprints and quantify all costs for work tasks without overlooking anything or double counting. Pinpointing costs is tricky - even for someone who can read blueprints - because architects vary in how clearly they enumerate all dimensions on construction plans. A cost estimator or quantity surveyor typically performs the quantity takeoff.

Use this quantity takeoff worksheet to get a sense of the process.

Download Quantity Takeoff Worksheet for Construction

The bill of quantities lists the material quantities from the quantity takeoff, and contractors use this to determine their expenses on materials and labor for the project. This calculation enables them to bid accurately. The bill looks like an extensive table of itemized costs: The scope of each item is described in some detail and accompanied by the number of units of each item (in terms of area, length, volume, or other dimensions as appropriate), the cost per unit, and the resulting total cost of that item. The bill of quantities also includes so-called contingency costs for unforeseen expenditures and waste costs and materials prone to breakage or wastage. Since the bill of quantities is an exhaustive document, you only prepare it once you have a completed and finalized set of construction plans.

Download Bid Tabulation Template

Download Construction Estimator Template

Working with Construction Plans

Paper construction plans are large (about 24 by 36 inches) and consist of several pages. To start working with these documents, you’ll first need to clear a workspace where you can fully unfold the plans. Also, remember that paper plans tear and fade easily, and they deteriorate if they get wet. They’re very expensive to produce and cost hundreds of dollars to replace, so make sure you’re using them and storing them carefully.

You can easily feel overwhelmed by the sheer size and amount of detail on the plans, so the first step in working with them is to relax. Unlike books, plans do not have a single starting place. Focus your attention on one corner, and then work your way across. Good plans show a lot of detail and are highly accurate.

Next, figure out what kind of plan you’re looking at: Is the perspective bird’s eye or side on? Is this a full view or a section? If it’s a section, which area does it pertain to?

Next, check the scale. The scale is the ratio between a construction component’s dimensions on the drawing and its actual dimensions. Architects use scales with fractions, such as 1/8 inch equals 1 foot, while engineers use whole-integer scales, such as 1 inch equals 100 feet. You use architectural scales in plans for buildings, and engineering scales in plans for other construction projects, such as roads or dams. This guide from the U.S. Fire Administration is a good primer on how to select the correct scale and accurately interpret the dimensions.

If the architect possesses written dimensions for the plan, use those instead of measuring the dimensions with a ruler. According to a U.S. Navy blueprint reading and sketching course, paper will stretch or shrink over time, which can make dimensions bigger or smaller than you intended.

You might also run across amended plans with written dimensions that don’t correspond to those suggested by the scale. Sometimes, in the revision process, you miss details. Cross reference the dimensions you computed using a ruler and blueprint scales with those you’ve detailed explicitly on the drawing to see whether they agree. Also, try comparing different plans with elevations to see whether the dimensions add up. If you are measuring dimensions using the ruler and scale, remember to check whether someone reduced the drawings themselves during reproduction.

Since scaled dimensions aren’t always accurate, an architect, engineer, or contractor should never rely on construction plan scales to calculate dimensions. Instead, use the dimensions written explicitly on the plans - if these are unavailable, contact the architect to obtain missing dimensions.

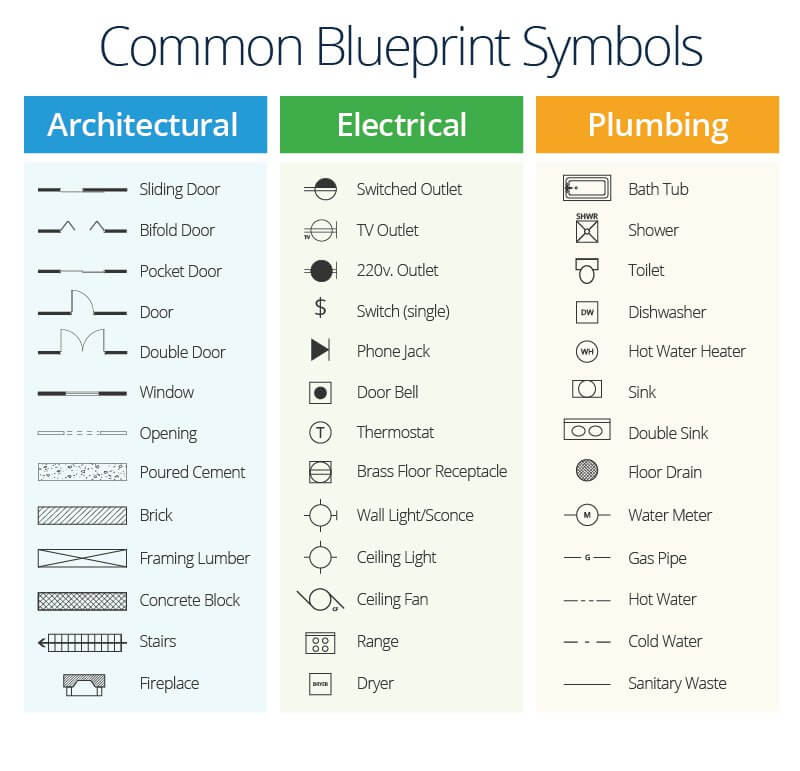

Construction plans feature symbols that represent components of the completed structure. For complex projects, architects may use hundreds of abbreviations and symbols. These represent all the structural components, down to nine different symbols for nine different types of doors. The symbols are mostly standardized, but architects have latitude to use their own symbols. Either way, the plan will feature a key explaining what the symbols mean. In addition, the architect will depict elements, like stonework, using simple graphics. If you want to brush up on blueprint symbols before you get your hands on a set of plans, check out these free resources that HousePlanHelper.com offers.

On your plan, you’ll notice several different types of lines. These lines indicate everything from the visible and invisible sides of objects to the dimensions and center axes of objects. Figure 1-3 in this Army Carpentry Field Manual details all the types of lines you’ll see in architectural drawings as well as what they mean.

The General Order of Drawings in a Set of Construction Plans

A set of plans for a single residential project can include dozens of separate drawings (in some cases, there might be more than 100). There’s no standard practice for how many drawings a set of plans will include: It depends on the project, the architect’s preferred level of detail, and the customs of the architect’s office. Quickly scan the entire set of plans before you start, so you know what the architect has included.

The topmost sheet is the cover sheet. It includes the date, the name and location of the project, and the architect’s name, address, and contact information. The cover sheet may also feature an architect’s rendering of the completed structure.

In many states, applying for a construction permit requires an architect or engineer to stamp the drawings. Stamped plans bear the seal of a registered and licensed engineer or architect. The professional applies the seal with an ink stamp that shows the person’s name, state, license number, credential, and expiration date for their license.

After the cover sheet comes a plan index, which lists all the drawings contained in the set. It also contains a list of commonly used abbreviations, a scale bar that indicates the plan scale, and design notes if needed.

Typically, the architect will identify each drawing with a letter and number. The letter denotes the plan series: A for architectural plans, S for structural engineering plans, E for electrical plans, M for mechanical plans, and P for plumbing plans. The number refers to a specific plan type. (For example, A2 plans are site plans, A3 plans are floor plans, and A5 plans are roof plans.) If the structure has multiple levels, the designer will add additional numbers. Each architectural firm uses their own plan-numbering conventions.

The typical order of drawings after the cover sheet and plan index is as follows:

- G for General Sheets: Cover sheet, plan index, and location plans

- A for Site and Architectural Plans: Floor plans, ceiling plans, roof plans, elevations, sections, wall sections, and others, depending on the architect’s chosen level of detail

- S for Structural Engineering: Framing plans for foundations, floors, and roofs

- E, M, and P for Electrical, Mechanical, and Plumbing Components (though small residential plans may not feature these)

- Finish Schedule and the Door and Window Schedule: Door, window, and other interior types and finishes

- Specifications: Detailed descriptions of the materials (though these may also be appended to the A-series architectural plans)

The level of detail (LOD) is proportional to the number of plans in the set and determined by the architect on a project-by-project basis. The architect is responsible for making sure the structure’s occupants and users are safe, so they generally choose to include more detail rather than less. There’s also a growing trend for architects to include more details to make it easier for contractors during bidding and construction. If the architect repeats a detail or dimension on multiple floors, they may note that it is “typical at all floors” instead of detailing it on each drawing. It is the contractor’s responsibility to make sure they include these repeated details in their estimates.

Each drawing will also feature a title block in the lower-right corner, which lists the name of the specific drawing, the drawing number, the name of the party who prepared the drawing, the date, the record of approval, and the scale. Architects may create their drawings on gridded sheets to make pinpointing the location of various construction components easier if people are viewing the sheets simultaneously from remote locations.

If you’ve revised a drawing, you’ll also include a revision block (usually in the top-right corner of the drawing but sometimes as part of the title block). Check the revision block to make sure you’re looking at the latest approved drawing. A numbered bubble indicates a revision on a drawing. In a corner of the drawing, you provide a record of revision dates and descriptions with corresponding numbers, usually in easily recognizable shapes, such as a triangle or octagon. If you make revisions, a good practice is to insert the new sheet in front of the sheet you’re changing. You can fold the old sheet in on itself and tape it closed. Mark the sheet number “void.”

You’ll also hear references to two other types of drawings: redline drawings and as-built drawings. Redline drawings, so named because you draw them in red over the original construction plans, indicate where the actual constructed structure differs from the original plan and typically indicate only minor changes. As-built drawings incorporate the changes from redline drawings, in effect making them official and depicting the final structure as built.

No set of drawings is ever perfect, and there will be discrepancies between different plans that feature the same structural components. To shift responsibility for these discrepancies onto the builder, the architect will typically specify that the contractor follow the highest standard of quantity or quality in case of conflicting information.

Additional Plans for Steel Construction

The construction plans for a steel structure will typically feature other drawings in addition to the general plans, which depict the main members of the steel structure, detail their size and material, and show their position relative to each other.

Fabrication drawings detail the size, shape, and material for each member of the structure as well as the ways in which each member connects or attaches to other members. You use the fabrication drawings to procure the required materials for construction.

Erection drawings show the placement of members in the final structure, and usually detail their weights. You design these mainly to aid fieldwork.

Falsework drawings show any supportive structures that you will need to temporarily erect around the main structure.

Construction Plans for Different Building Parts

Let’s delve into each plan type in detail. For a look at the construction plans for a typical residential project, check out what the firm Donald A. Gardner Architects provides in one of its house plan sets.

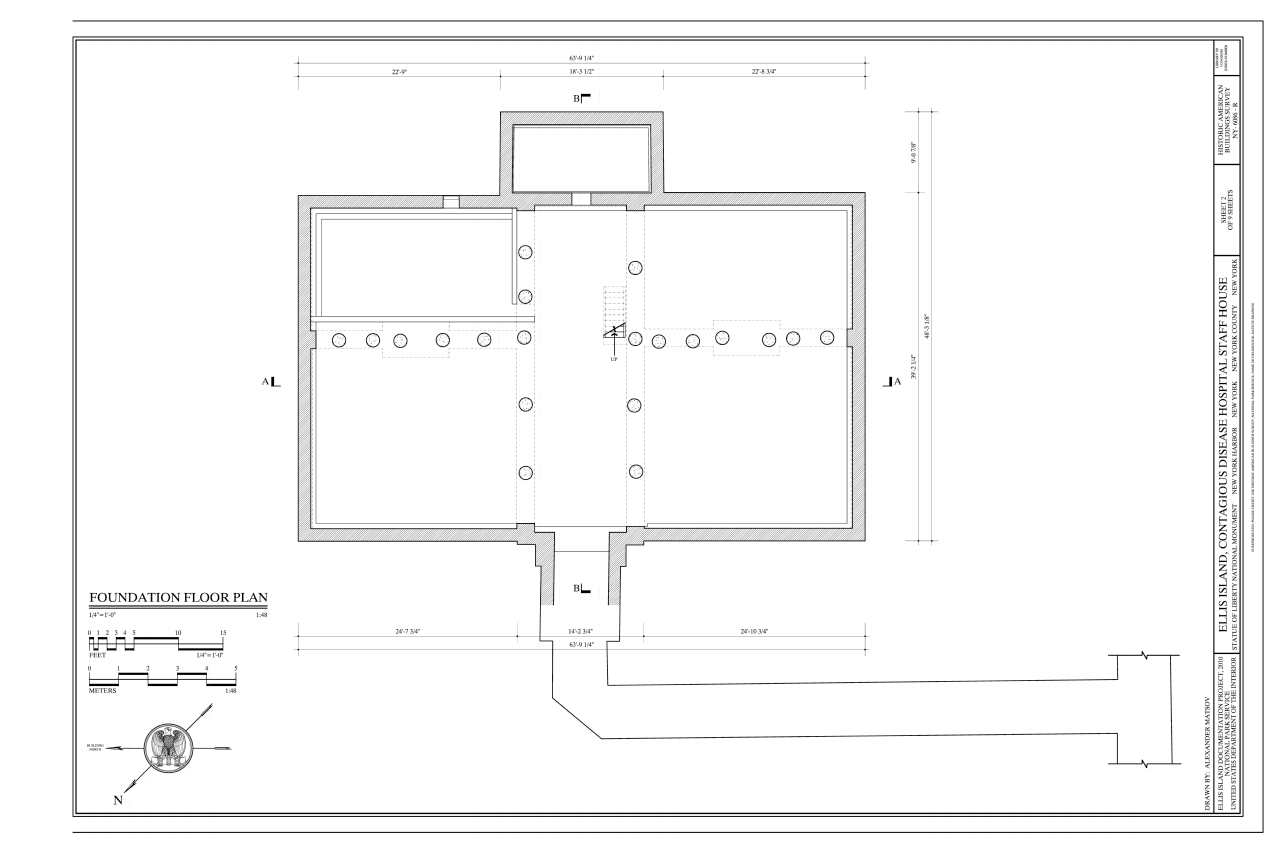

Foundation plans are a type of structural engineering plan. They can also refer to subfloor plans or, in some cases, basement floor plans. They show the sizes, shapes, thicknesses, configurations, and elevations of foundation walls and footings, including interior load-bearing walls and exterior post footings. Foundation plans will also show the positioning of reinforcing bars and the connections and attachments via anchor bolts or weld plates between the foundation’s structural members. These plans delineate excavated and unexcavated areas of the foundation.

A footing schedule accompanies the foundation plan. It lists and describes all the footings upon which the structure will rest. Typically, there will be extensive notes that explain how you reinforce structural members and define the concrete break strength requirements. The notes will also describe how you test the strength of the structure.

Framing plans are another type of structural engineering plan. They detail the structural members that constitute the building’s framework: the size and positions of beams that appear in plans, and the joist and rafter space, layout, and size. Framing plans help builders lay out roof, floor, and ceiling structures.

A framing plan for a roof will show the various elements of the roof’s structure, including dormers, hips, valleys, drains, and any equipment mounted on the roof. It also shows the roof pitch. Pre-engineered floor and roof systems are also available. If you use these, the manufacturer must provide engineering information to the builders, and building inspectors will probably want to review the plan before issuing a permit.

Floor plans are architectural plans that show the layout of each level of the structure. The drafter shows the layout from an overhead perspective that omits the roof and any upper floors. The floor plans illustrate the configuration of internal walls, doors, windows, and wall insets, such as fireplaces and chimneys. They also indicate the placement of permanent fixtures, such as bathrooms, major appliances, and internal structures (stairways or elevators).

Each floor will have a floor plan that includes a description of the intended uses of rooms or other internal spaces. The designer will indicate both door and window sizes and give dimensions, including lengths, widths, and internal square footages. Homeowners tend to be most interested in the floor plan, as it’s perhaps the most straightforward and modifiable of all construction documents. The floor plan also makes it easy to picture how foot traffic will flow and how people will use the space.

One uncommon variation of the floor plan is the ceiling plan, which is a view of the ceiling as seen from below. Ceiling plans are only used for structures that have significant ceiling fixtures (so typically not residential projects).

Elevations are side views of a building that may show either the exterior or the interior and omit external walls. Exterior elevations show the placement of doors and windows, the external finish of the building, including any masonry or other decorative elements, and a side view of the roofing. They may also indicate the natural slope of the ground around the base of the building. Interior elevations show the height and placement of cabinets, countertops, and detailing, such as tiles on bathroom walls.

Elevations communicate height, a dimension that bird’s-eye views can’t display effectively. Elevations also indicate the direction that an elevation faces, as the direction of sunshine and wind patterns is important when deciding how to place buildings, especially houses.

You should cross-reference elevations with floor plans. Many people assume the architect will include an elevation for every exterior wall, but this is not always true. Compare the floor plans to the elevations to make sure you haven’t missed anything.

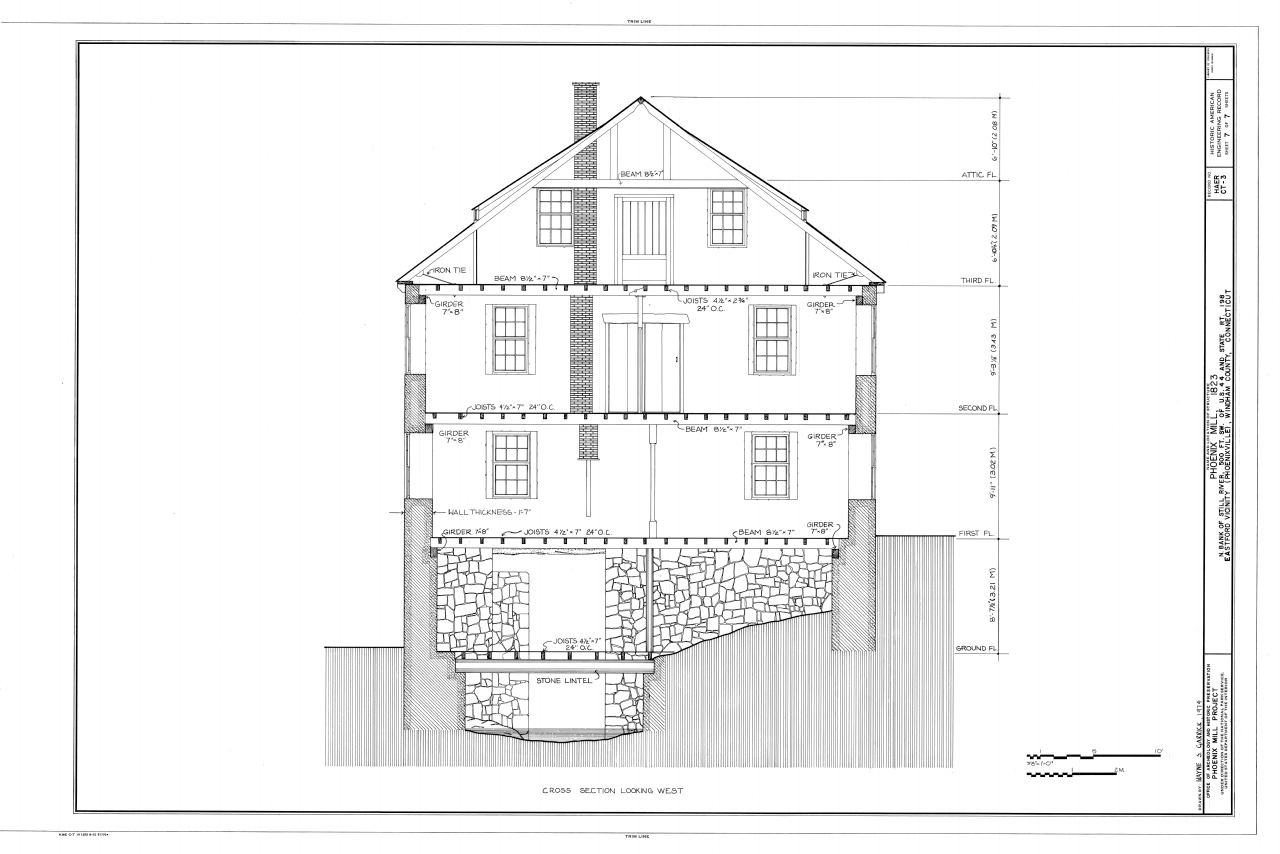

Cross sections are also a kind of side view, but these represent a vertical slice through the building to show all internal components. A cross section details both visible components, such as stairs, sidings, and roofing, and concealed components, such as framing members, headers, and insulation. A cross section can pass through any level of the house, from the roof to the footings. It captures things like cabinets and countertops, and also internal framing components (this is important because bird’s-eye views can’t depict them effectively). One common type of cross section is a wall cross section that shows both the inside and outside faces of walls as well as internal components, such as studs and insulation.

Where a simple residential project might only require a few cross sections, a more complicated commercial structure might need many more, since there are many variations in the components that go behind walls. You will cross-reference cross sections on plan views and elevations.

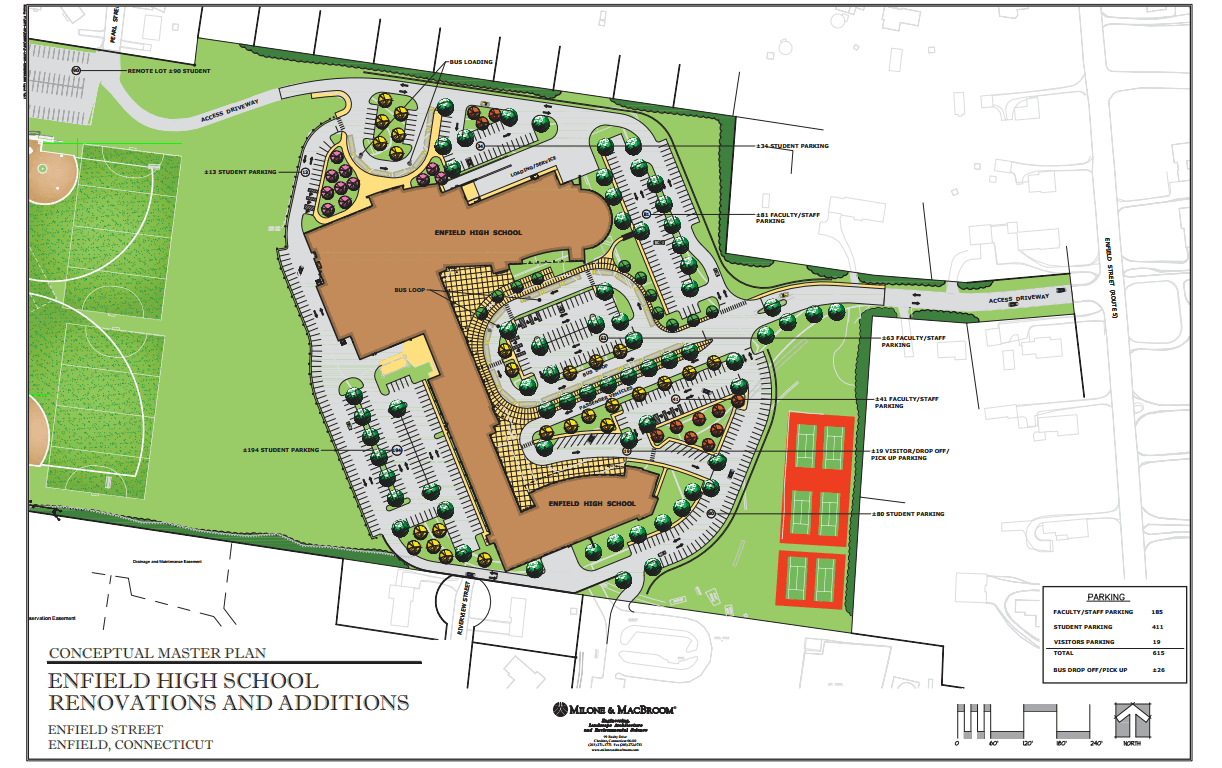

Site plans locate a building in the wider context of the land or parcel. They detail the general dimensions and location of the site with reference to neighboring lots and their boundaries, and also mark the building’s footprint on the site, and identify site landscaping features,roads, and pavements. Ultimately, the site plan summarizes work you will complete on site.

The site plan locates existing infrastructure that you need to protect during construction, such as sewer lines and utilities connections. It contains information on the grade and elevation of the construction site. These plans show the location of structures that are not part of the building proper, such as drainage systems and roads. Building inspectors considering whether to award a construction permit will check whether parking will accommodate the new structure’s occupants.

Mechanical plans, like floor plans, are overhead views. They feature the mechanical components of a structure, such as HVAC, gas lines, and plumbing. Putting these details on a separate sheet prevents conventional plans from becoming too crowded and hard to read. Not all construction projects will have separate mechanical plans - you usually only create them for projects with complex mechanical systems.

Mechanical plans will depict both the visible and concealed components of mechanical systems — both ventilators and ducts for a HVAC system, for example. These plans may also show any appliances connected to a mechanical system, such as gas ovens. When examining mechanical plans with multiple extensive systems, remember that space restrictions may mean that subcontractors have to work in series, not simultaneously.

Environmental plans address how the project will manage erosion and sedimentation of waters near the construction site. Given the amount of earth displaced and moved during construction, they’re designed to ensure that all that soil doesn’t end up polluting and blocking nearby waterways. Environmental plans also include procedures for minimizing plant removal and dealing with chemical spills.

The environmental plan typically lists a series of best management practices (BMPs) designed to minimize the harmful impact on the environment. In many jurisdictions, an environmental plan is a requirement to proceed with construction.

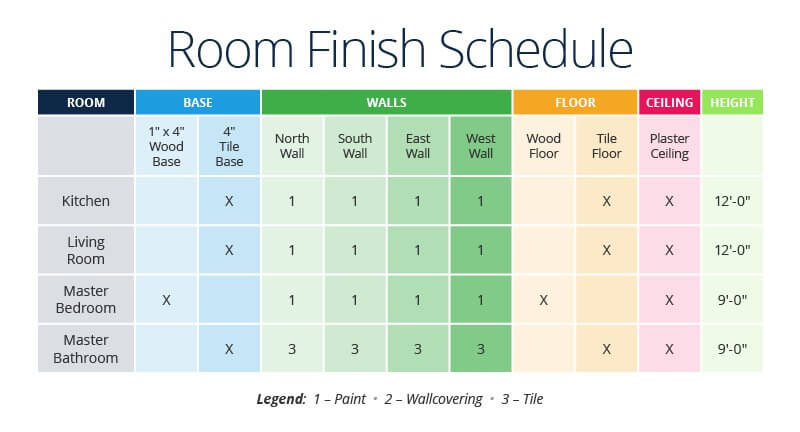

Schedules feature all the details an architect doesn’t want to squeeze into a floor plan. A schedule is a simple matrix of building component information, where each entry corresponds to a number that also appears on the floor plan. Schedule information is highly detailed: A door schedule, for example, will feature information on doors, door frames, and locks. A finish schedule is a comprehensive table of finishes (paint, flooring, etc.) in each room. Windows and light fixtures will also appear on schedules.

Schedules will also include items labeled OFCI (owner-furnished, contractor-installed), GFCI (government-furnished, contractor-installed), NIC (not in contract), and by others (those items provided outside the scope of a particular trade or contractor). In general, the schedule will also show delivery dates for items that you have ordered.

To learn more about blueprints and how to read them, check out this course by Construction Experts Inc. The book Blueprint Reading: Construction Drawings for the Building Trades also covers the topic, and Francis D.K. Ching’s Building Construction Illustrated is a helpful reference. Print Reading for Construction, by Walter Brown and Daniel Dorfmueller, is another resource.

Construction Safety Plans Can Save Lives

So far, we’ve talked about construction plans specifically as documents that provide technical information about a structure and how to build it. These plans include blueprints, specifications, and schedules. But construction plans also refers to the results of the broader planning process that encompasses environmental, safety, and quality plans.

Safety plans are important because construction is hazardous, and the best way to prevent an accident is to anticipate what could go wrong. In 2015, according to the Occupational Safety and Health Administration (OSHA), one in five private-industry worker fatalities — a total of 937 deaths — occurred in the construction industry. About one in 10 U.S. construction workers will sustain injuries in any given year. Falls cause the most injuries.

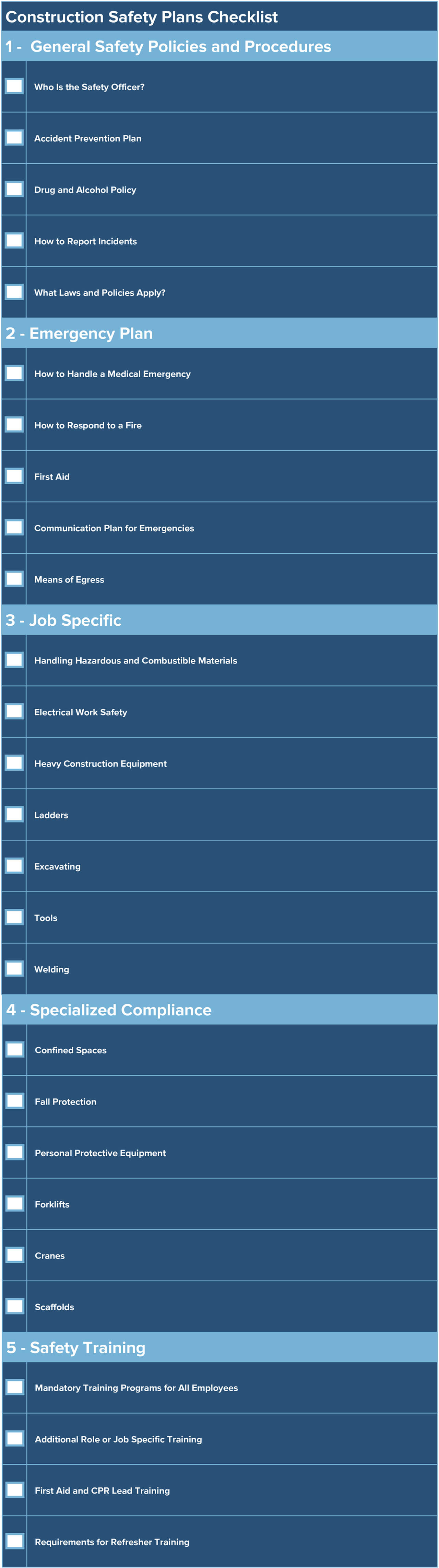

Safety planning isn’t as rigorous in small residential projects, but it is a regulatory requirement for large projects. OSHA standard 29 CFR 1926, “Safety and Health Regulations for Construction,” defines construction project safety standards, and OSHA has 10 construction safety plan requirements for the construction industry.

Safety planning revolves around risk reduction and hazard elimination to avoid on-site accidents. It’s most effective when integrated proactively with project planning so that it evolves with site and environmental conditions.

Safety planning is an integral part of construction design and scheduling. Builders who identify potential hazards for construction crews — a practice called job hazard analysis — can proactively mitigate them by implementing safety measures and emergency response equipment. This extends from observing occupancy limits for confined spaces to making fire safety equipment available close to where it might be needed. These risk-control steps, along with plans for what to do if an accident occurs, are the project’s safety management strategies.

If you need to compile or evaluate a construction plan, it helps to know the traditional elements. Review OSHA's safety checklist for construction. A construction safety plan must include certain sections and answer key questions, such as who is in charge of safety on site, what arrangements exist for medical treatment, what safety training you will conduct, and the lockout/tagout procedures.

Use the checklist below as a starting point for your site safety plan. However, remember that your final safety plan needs to be specific to the hazards present in your unique circumstances. Follow all applicable regulations, such as OSHA requirements.

Quality Plans Help Builders Thrill Clients and Users

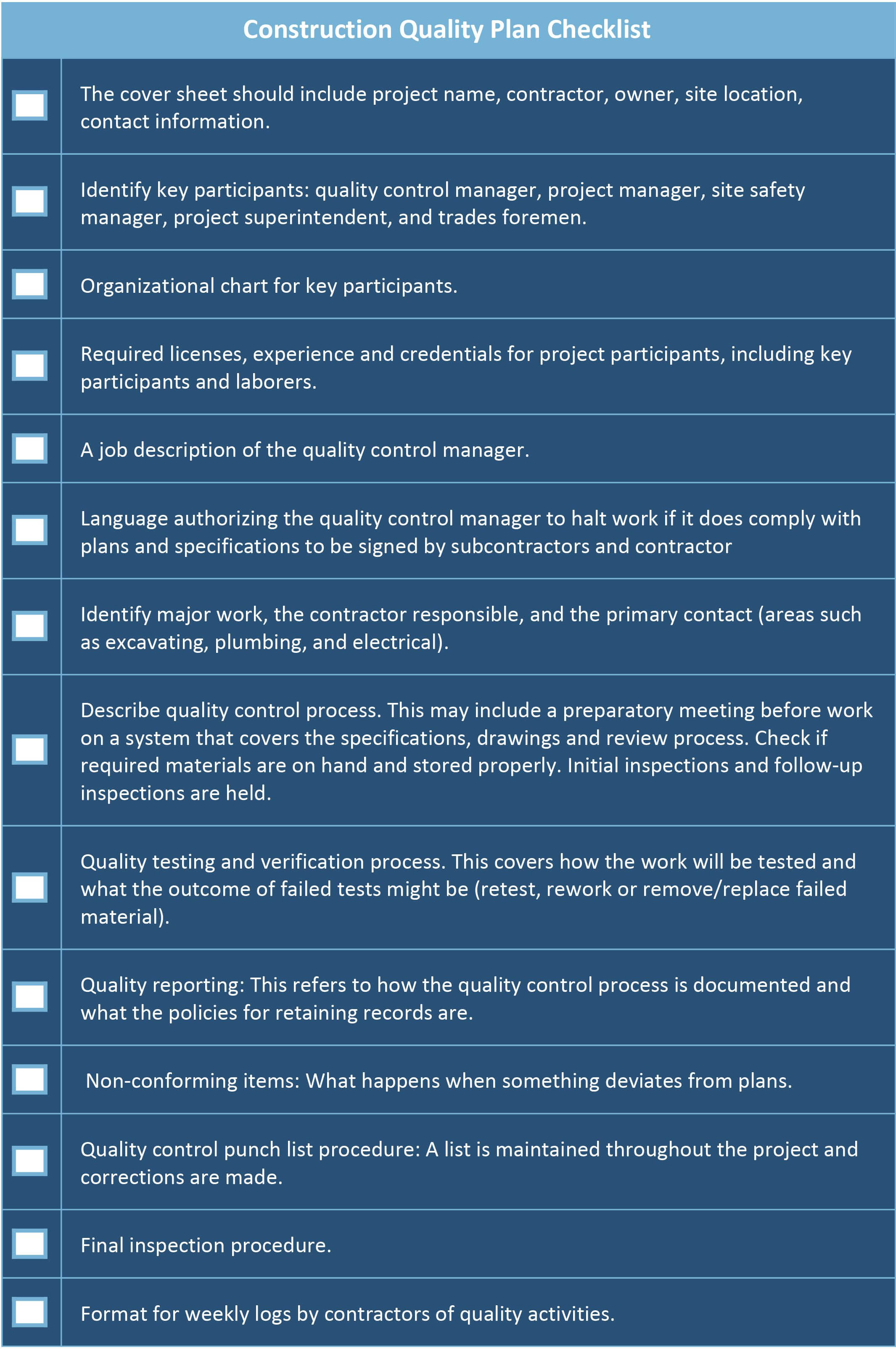

A construction quality plan is a document that explains how a contractor will meet the quality requirements for a specific project. It’s not the same as a company’s general quality policies, since it addresses quality management for an individual project.

Whether formally required in a contract or informally requested, the quality plan is an important part of the client-contractor working relationship. For the client, it improves confidence in the contractor’s ability to get the job done and builds in a mechanism for accountability. For the contractor, it ensures all parties are on the same page and that the project outcome will enhance their reputation.

The quality plan for a project identifies those responsible for quality management and establishes protocols for quality-related communications. It highlights the regulations and industry standards that apply to a project, and explains procedures for assessing quality. Lastly, it explains how subcontractors comply with the plan and the quality requirements for materials procurement.

Ed Caldeira of First Time Quality explains what a good quality management plan will tell a client:

- “Who is in charge of quality management on the project, and what are their qualifications?

- How and when will you communicate quality-related issues to the contractor’s personnel and the client?

- What sort of quality oversight system will you put in place?

- How will you ensure quality from subcontractors and suppliers?

- What constitutes satisfactory quality for a project? What quality standards will you set?

- How will you test quality?

- Should they arise, how will you fix quality issues?

- How will you assess the project’s deliverables quality?”

When developing a quality control plan for construction, consider covering the following topics:

Technology Eases Construction Planning

Earlier we talked about the difficulty of working with blueprints. Construction has lagged behind other major industries in digital adoption, and planning technology solves many of the problems and constraints of conventional paper construction plans.

Construction planning technology covers a number of software solutions, from scheduling apps to SaaS suites. The design modules reduce the time and money costs of manually updating construction plans and reworking design elements.

The most helpful features include the following abilities:

- View, edit, and share drawings

- Access plans and documents in the field from mobile devices

- Zoom in with high-resolution plans to capture detail

- Ensure sheet version control

- Store in the cloud

- Call up plans quickly with fast-loading optimization

- Annotate with markups and as-built notes

- Take photos and share and archive them

- Automate quantity takeoff

These capabilities unlock some strong advantages for builders and project managers. With these tools, collaboration flows more easily, everyone always has the current set of plans, accuracy rises, and all participants (whether they are in the office or the field) share the same information. Scheduling engines give contractors a competitive advantage by increasing productivity. Quality also rises since project teams can update and share blueprints, punch lists, specifications, and RFIs instantaneously.

These capabilities increase efficiency. One construction software company surveyed its customers, who said that on average they saved $15,000 in labor per year per employee by using a construction solution.

That financial benefit accrues from greater efficiency. But not using paper plans also saves on printing costs. Aside from architect fees, plans typically cost $2 to $4 a page to print. The documents sets for large commercial projects will have hundreds of pages, and many project managers, supervisors, and foremen need their own set. You’ll also have to reprint sheets when there are changes, and since changes are common, the costs quickly add up. Of course, using digital plans means team members must have tablets or laptops and a subscription to an application that generally has a fee.

These tools would not exist without other technological innovations in the construction plan world, such as CAD and building information modeling (BIM). CAD was the precursor to BIM: It began as the groundbreaking use of software to design physical components, especially in manufacturing, though civil engineering projects used it as well. Designers then embraced it for drawing plans.

BIM is the next stage in construction design. It goes beyond two-dimensional CAD to 3D building information models that offer comprehensive data for entire construction projects. BIM provides highly complex digital representations of building design, and it’s stretching beyond 3D visualization to so-called 4D and 5D integration of time and cost information.

CAD made it easy to view, edit, and share construction drawings, with no perceptible loss of quality. CAD plans also make dimensions easier to measure. These drawings mimic some of the strengths of traditional paper plans but are easier to share and mark up.

Glossary of Key Terms in Construction Plans

Below, you’ll find a useful list of terms concerning construction plans.

- Building Envelope: The complete set of physical structures that separate a building’s interior from its exterior, such as walls, roofs, and floors.

- Civil Drawing: A type of site plan designed for use by civil engineers that shows topographical features, landscaping, and utility connections.

- Eastings: A set of eastward-extending coordinates on a geographic plane. Together with northings, they constitute a system of Cartesian coordinates that you use to plot building locations with reference to already existing landmarks. See also northings.

- Footing: A component of a building’s foundation that transfers the weight you place on walls to the ground. Compared to other types of foundations, footings are typically quite shallow, though there are restrictions on minimum footing depth.

- GFCI (Government-Furnished, Contractor-Installed): This acronym, used on construction plans and specifications, indicates materials or components that the project owner will procure — in this case, the project owner is the government, and they provide the GFCI to the contractor for installation. The GFCI mark on construction plans tells cost estimators which work items they do not need to procure. It’s also a reminder for the contractor to coordinate a delivery schedule with the government.

- Level of Detail and Level of Development: We often refer to both of these terms as LOD. Level of detail describes the increasing amount of detail in graphical representation as construction plans become more refined. A conceptual drawing is much less detailed than a detailed drawing. Level of development describes how much development and engineering have gone into the feature.

- NIC (Not in Contract): This acronym, used on construction plans and specifications, indicates work items that are not the main contractor’s responsibility to deliver. The project owner either delivers these work items or contracts with another party to have them deliver the items. The NIC mark on construction plans tells cost estimators which work items they should not bid for.

- Northings: A set of northward-extending coordinates on a geographic plane. Together with eastings, they constitute a system of Cartesian coordinates that you use to plot building locations with reference to already existing landmarks. See also eastings.

- OFCI (Owner-Furnished, Contractor-Installed): This acronym, which you use on construction plans and specifications, indicates materials or components that the project owner will procure and provide to the contractor for installation. The OFCI mark on construction plans tells cost estimators which work items they do not need to procure. It’s also a reminder for the contractor to coordinate a delivery schedule with the owner.

- Outside Building Line: A commonly used reference point in construction drawings that helps planners determine distances to other structural components.

- Quantity Takeoff: A technique for estimating the types and quantities of materials and labor required to complete a construction project. The quantity takeoff is part of the project cost estimating process. It gets its name from the way cost estimators would originally perform the function, when they would “take off” quantities of all materials from blueprints and specifications to prepare an itemized list.

Improve Construction Plans with Smartsheet for Construction

From pre-construction to project closeout, keep all stakeholders in the loop with real-time collaboration and automated updates so you can make better, more informed decisions, all while landing your projects on time and within budget.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.