What Is Project Delivery?

Project Delivery is the method used to execute and complete a building, facility, or structure including planning, design, and construction. Owners or agencies use project delivery to organize and finance the design, construction, operations, and maintenance of structures or facilities through legal agreements with one or more parties or entities.

Building projects have a delivery method that is most advantageous for the business conditions and their unique environments. To support success, owners and project managers analyze conditions and match the method to the project.

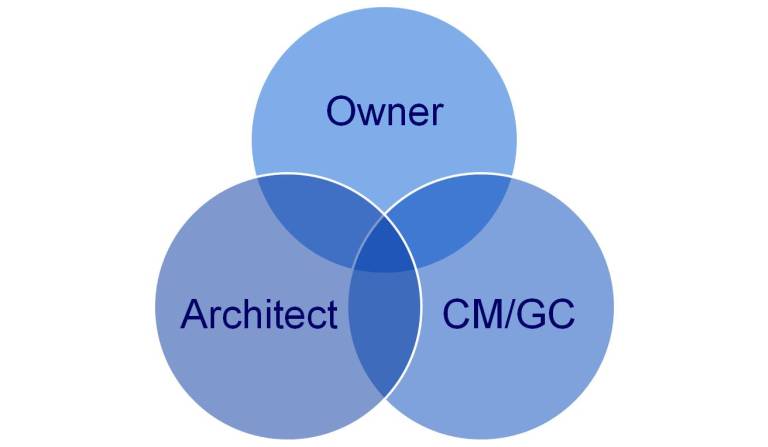

Every delivery system has a minimum of three parties: owner, designer (often an architect), and contractor. Here’s an overview of the delivery system methods:

- Design-Bid-Build (DBB): This is the dominant project delivery method in the U.S. With DBB, the owner engages an architect to supply complete design services. Then, the owner advertises and awards a separate construction contract based on the architect’s documents. The owner is then accountable for design details and liable to the contractor for the quality of the construction contract documents. DBB projects can also be awarded on a best value or negotiated basis to lower the probability that the project will go to a contractor who has provided a mistakenly low bid. DBB has no contractor involvement during the design phase, and the owner relies on the architect's team for construction feasibility reviews

- Multi-Prime (MP): Similar to DBB, MP has three project phases with one important difference: The owner contracts directly with separate specialty contractors for specific work elements, rather than with a single prime or general contractor.

- Construction Management Agency (CMA): The owner hires the contractor at the same time as the architect and receives continuous technical consultation and service throughout the project. The CMA has no liability for the actual construction.

- Construction Manager-at-Risk (CMR): The owner contacts a construction manager to oversee all details during the project’s lifecycle. CMR contracts typically have a provision for a guaranteed maximum price (GMP) from the construction manager. If the construction manager exceeds the GMP, the owner does not cover the additional costs. Often, the contract includes incentive clauses that state that the construction manager and owner divide cost savings below the GMP. Most often, the owner has a separate design contract and provides the construction manager with a full set of plans and specifications.

- Design-Build (DB): DB is often used for fast-track projects because of its greater perceived simplicity. The owner hires both the designer and contractor in the same contract as a single, legal entity called the design/builder to provide architectural and engineering services and construction.The DB entity is responsible for all design and construction costs and in most cases, provides a fixed price and delivery schedule in its proposal.

These are the traditional ways of managing projects, but there is a new approach that’s gaining momentum: Integrated Project Delivery.

What Is Integrated Project Delivery (IPD)?

Integrated Project Delivery (IPD) is a project delivery method created to align the interests of stakeholders and team members that integrates their work for optimal project performance using a collaborative, value-based process for high-outcome results for every team member. The main thrust is that you work through any potential issues in the early phases, before construction begins, to eliminate possible waste and risk.

To help us understand the many facets of IPD, seven experts share the facts about this up-and-coming — and sometimes controversial — project delivery method:

IPD is less than two decades old and differs from traditional delivery methods. “This is an emergent model,” says Allison. “There are no firm numbers, but I would say that in the U.S. and Canada, there are between 300 and 350 completed to date.”

“All parties are bound by a single agreement to deliver a project,” adds Allison. “It’s a bullet list of characteristics: Shared risk and reward, a jointly developed project targets criteria, early involvement of key stakeholders, open sharing of information, but most of all, a common purpose.”

“This is a disruptive methodology that is changing — or will change — how buildings and infrastructure are designed and built,” explains Cherf. “In traditional methods, there is generally a downward flow from the owner to other stakeholders, but in IPD, the owner, architect, and constructor work together. I would say that at this point, there is some confusion about what IPD is. But as more professionals get into it and more buildings are completed, they can see the value of breaking down silos and working together. Some projects are now IPD-ish using some, but not all, of the principles and Lean.”

Key Stakeholder Collaboration in Integrated Project Delivery

Source: LeanIPD.com/James Pease

In IPD, the owner, architect, and construction manager/general contractor work together and share the risk and rewards.

The Integrated Project Delivery Method Disrupts the Construction Industry

Why is yet another project delivery methodology needed? Research by Stanford University’s Center for Integrated Facility Engineering and Paul Teichotz compared construction productivity to (Non-Farm) productivity in the United States since 1964. While most industries doubled productivity in the last five decades, construction figures have tumbled. IPD came about as a solution to the multiple issues that have contributed to its decline due to blown schedules and budgets.

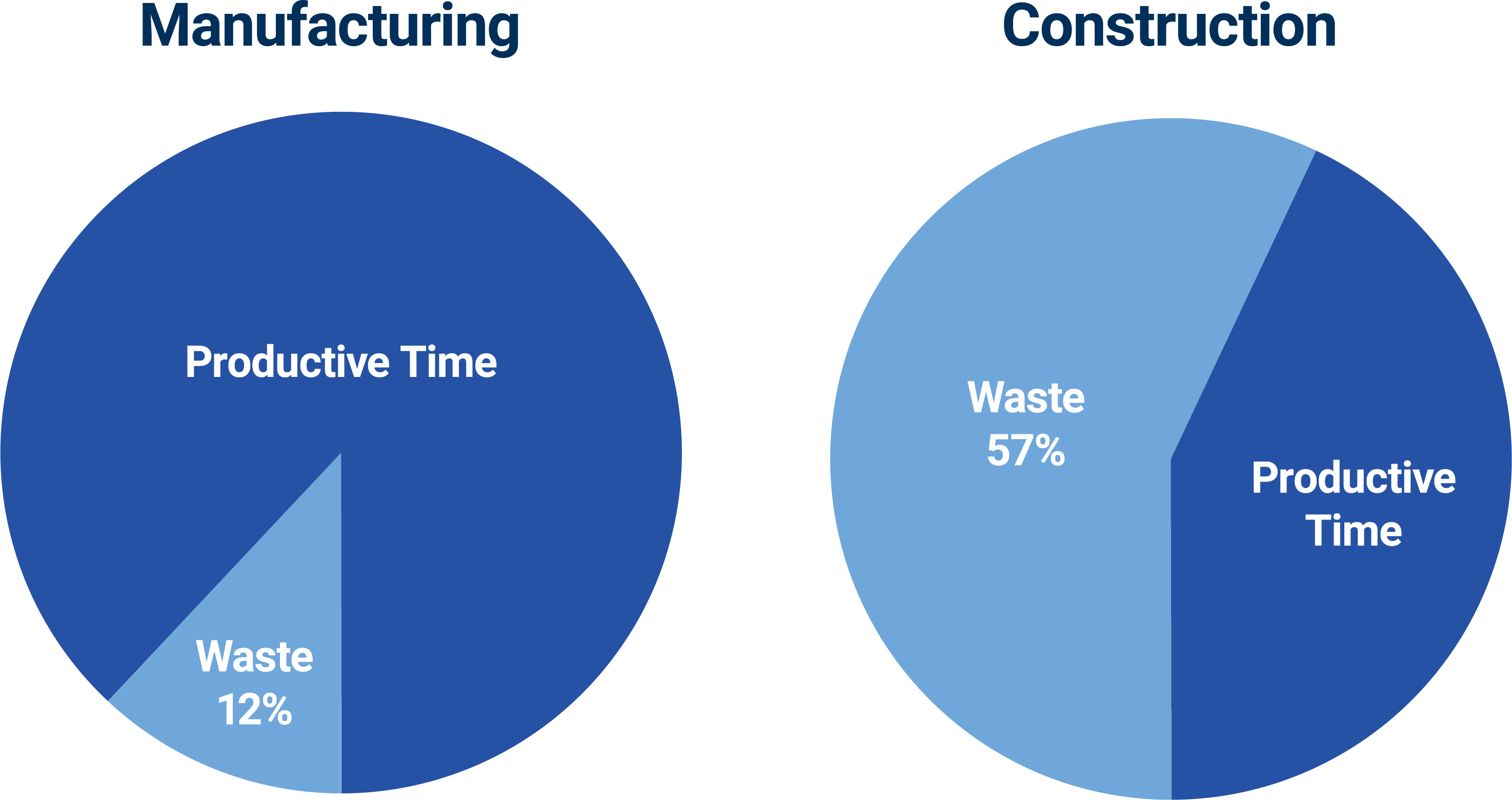

The Construction Industry Institute published a report in 2004 that compared wasted time against productive time in the manufacturing and construction industries. The results are illuminating:

88 percent of time in manufacturing is productive while only 43 percent of time in the construction sector is productive. More than 50 percent of time spent on construction sites was found to be wasted (nonvalue-added) by Stanford University research.

Construction Productivity Has Been Lagging Since 1964

Source: LeanIPD.com/James Pease

Zandy adds that there are two aspects of IPD. “When discussing Integrated Project Delivery, it is important to distinguish the difference between IPD as a delivery method vs. IPD as a philosophy. Per the Association of General Contractors, the two are differentiated.”

- IPD as a Delivery Method fully integrates project teams in order to take advantage of the knowledge of all team members to maximize the project outcome. Integrated Project Delivery is the highest form of collaboration because all three parties (owner, architect, constructor) are aligned by a single contract.

- IPD as a Philosophy occurs when integrated practices or philosophies are applied to more traditional delivery approaches such as CM-at-Risk, Design-Build or Design-Bid-Build (where the owner is not a party to a multi-party contract).

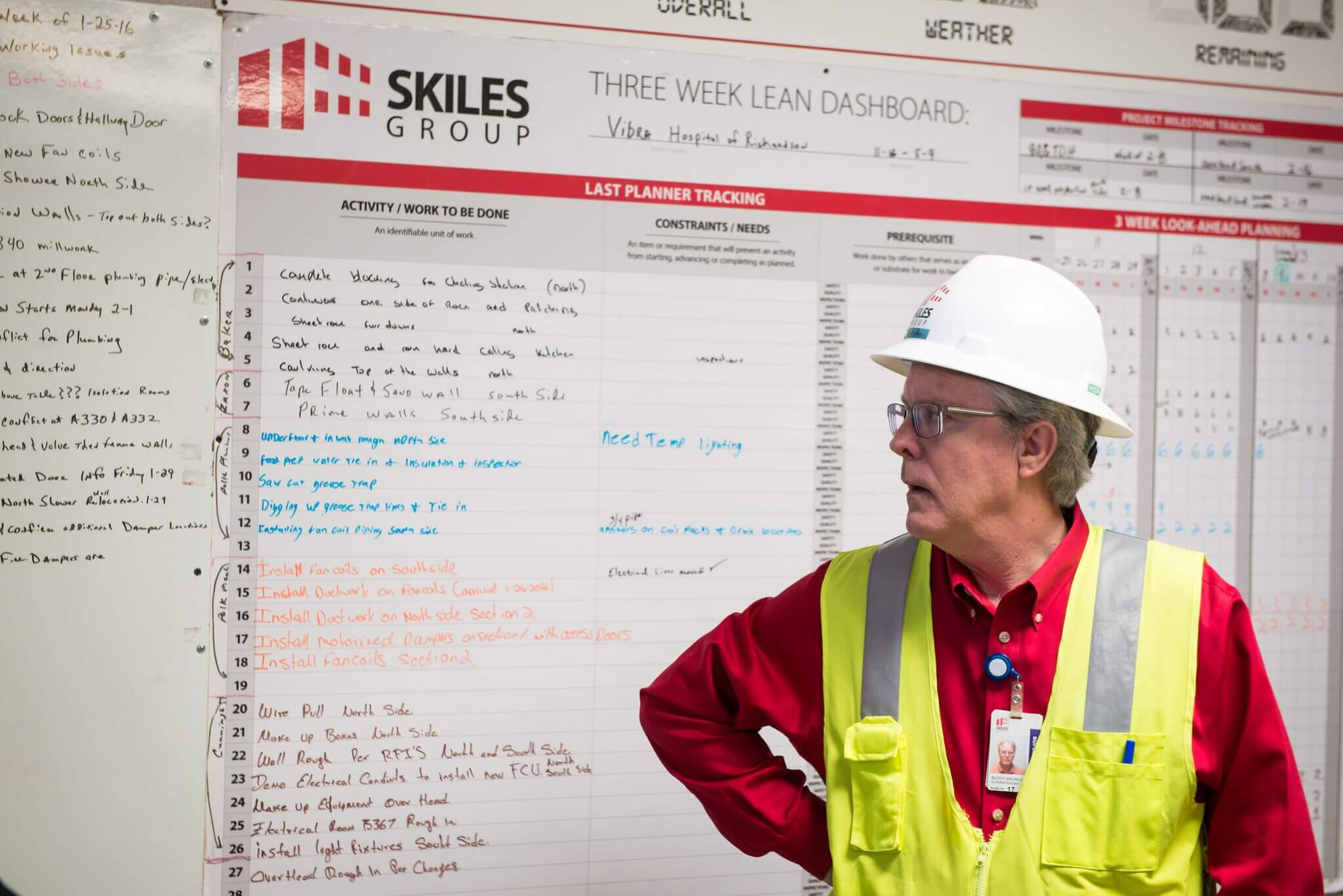

Construction Planning Using a Lean Dashboard

Source: Courtesy of Skiles Group

IPD shares information to keep the team on track. To create transparency, wall-mount or digitally share Lean dashboards. Look into and download tools at the Sample Dashboard Roundup.

Team Members Using Kanban

Source: Courtesy of Skiles Group

Kanban is another useful method for tracking work in progress. Use physical, wall-mounted Kanban boards or an online program to virtually see a project’s status. Learn more about digital Kanban at Everything You Need to Know About Kanban Cards.

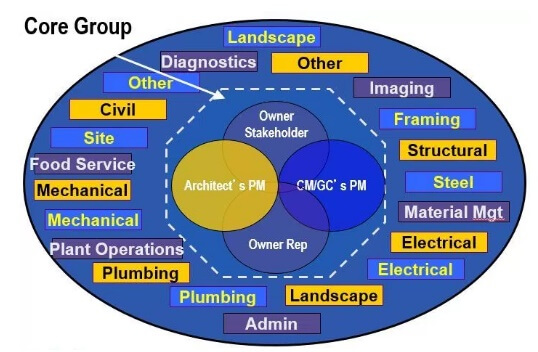

Breaking Down Silos

Breaking down traditional silos combine the how, what, and why of project delivery into a unified system that continuously flows from start to finish. This option also supports communication flow by contracting the entire team under one contract with the owner (stakeholder) and/or the owner’s representatives, architect (project manager), and construction manager’s representatives. This centers decision making authority within a design, construction, and owner representative core group.

Source: Courtesy of LeanIPD/James Pease

IPD & Lean

IPD and Lean work hand-in-hand, and many use the terms interchangeably. Strictly speaking, IPD applies to the contractual, multi-party agreements, and Lean is the pathway to achieving it, although it’s rare to effectively implement of IPD without Lean.

As Cheng explains in a recent article in the Lean Construction Blog, IPD + Lean, A Marriage Made in Heaven, “IPD sets the stage for teams to be highly motivated to collaborate and also produces the foundation of positive team culture. In these conditions, Lean practices provide the means for the teams to effectively collaborate.”

“The purpose of Lean is to eliminate waste and wasteful activities in the entire design and construction process,” says Zandy. “The elimination of waste gained via the focus on workflow reliability creates momentum throughout the project. The best approach to ensuring the reliability of workflow is to clearly schedule the work, gain commitments to the schedule from the participants, and measure compliance to those commitments.”

Zandy applies the five Lean Principles to approach his IPD projects for waste elimination:

- Specify Value: Establish the value (goal) that the project must achieve.

- Chart the Value Stream: Lay out the path to realize value via a logic trail called the value stream.

- Maintain Flow: Utilize your value stream to maintain the logic flow of the project.

- Create Pull: Focus short-term schedule activities on those that "can" be done rather than those that "should" be done.

- Achieve Perfection: Measure the plan and the commitment via the Percent Plan Complete (PPC) method.

Heinemeier notes that a continuous improvement will positively affect present and future projects. “Lean is continuous; there is no apex where you are done learning,” he explains. “Lean is a journey where there is always more to learn and different perspectives to take into account.”

In other words, everything learned from one project can be brought to the next engagement.

Continuous Improvement Cycle in IPD

Source: Courtesy Lean Construction Institute

The Lean Construction continuous improvement process Plan, Do, Check, Adjust (PDCA) consists of four stages, described in the Deming Cycle:

- Plan: Find the cause of a problematic state and create a proposed action to modify or resolve it.

- Do: Carry out a test plan implementation.

- Check: Assess effectiveness of test results.

- Adjust: If the results are good, adjust the original state or define a new standard process. If the results are unacceptable, refine the plan and repeat the cycle until you attain satisfactory results.

To learn more about Lean, read The Complete Guide to Lean Project Management.

How Integrated Project Delivery Differs from Other Types of Project Management

In the Integrated Project Delivery method, all the stakeholders equally share the design and management of work, as well as the risks and rewards. In an integrated project, the key participants are involved as early as practicable. The inrush of knowledge and expertise of all key team members improves decision making. Their combined expertise and knowledge is most potent in the earliest stages of the project when informed decisions have the most significant impact.

Work is about deliberately and systematically organizing materials and design to maximize the project as a whole, and not the discrete pieces of the project (as they are in more siloed methodologies). Solving problems and learning is the job, and not just part of the job. Whenever possible, deliver any materials brought on-site and consider them before the project starts eliminating waste. In other words, the goal is to not have a punch list at a late stage — instead, you should zero-out an ongoing punch list while work occurs.

“In general, projects that are very complex are a perfect fit for IPD. Public works are a good fit because many public agencies have a goal of maximizing value, not necessarily just saving money. Any project that has an unusual or aggressive constraint [is a good fit], like time at a difficult site, as are projects that have to satisfy a lot of stakeholder groups. Green, high-performance buildings are a great fit because interrelated problems need to be solved.”

Most importantly, IPD calls for an experienced owner who wants to be deeply involved in the project.

IPD vs. Design-Build

Traditional Design-Build (DB) can be a catalyst for an anti-collaborative, “every man for himself” mindset — this is unfortunate because the owner may never realize the strength of fully integrated teams. Architects and engineers don’t fully engage with contractors under the traditional DB process. Also, subcontractors often follow engineering assumptions without being coordinated or validated by the design professionals. Once value engineering or other scope/price reductions occur, the designer often asks for additional fees to rework drawings to reflect the contractor’s input. These time and cost overruns lead to potentially more adversarial roles between designers and contractors. In contrast, IPD is all about highly collaborative interactions, shared risk, and team building.

The Principles of the Integrated Project Delivery Method

Allison is one of the developers of the American Institute of Architects’ Integrated Project Delivery: A Guide, known as the “bible” of IPD. The guide sets out the following standards to be followed for successful IPD implementation:

- Mutual Respect and Trust: All involved parties — owner, designer, contractor, consultants, subcontractors, and suppliers — realize the value of collaboration and commit to teamwork in the project’s best interest.

- Mutual Benefit and Reward: IPD compensation recognizes and rewards early involvement. Compensation is based on added value, and it rewards positive behavior, often by providing incentives tied to project goal achievement.

- Collaborative Innovation and Decision Making Innovation: The free exchange of ideas is supported, and ideas are evaluated by merit, not by status or role. Major decisions are weighed by the team and when possible, are made by unanimous judgment.

- Early Involvement of Key Participants: Key participants are involved as early as is practical. Decision making is improved by the inrush of key participants’ expertise, and this shared knowledge is most profound during the project’s early stages when informed judgments have the highest impact.

- Early Goal Definition: Project aims are developed and agreed upon early in the process and upheld by all participants. Insights from every participant are valued to support innovation and superior performance.

- Intensified Planning: The point of IPD isn’t to make less of a design effort, but rather to advance design results in order to streamline and shorten the much more costly construction effort.

- Open Communication: Direct and honest communication among team members is fundamental. In a no-blame culture, the goal is to identify and resolve problems rather than assign liability or blame. When disputes arise, they are acknowledged as they happen and quickly resolved.

- Appropriate Technology: IPD often relies on cutting edge technologies. Specifying which technologies you will use at the start of the project maximizes interoperability, and technologies that support interoperable data exchanges are essential to project support.

- Organization and Leadership: All team members must be committed to the goals and values of the project team. Leadership is given to the most capable team member based on specific situations. Clearly define roles, but keep in mind that creating artificial barriers can tamp down open communication and risk-taking.

The Phases of Integrated Project Delivery

Once the stage is set, contracts have been written, and the team is in place, it’s time to put an IPD project into practice. Here are the phases involved in delivering an IPD project, and some free templates to use to facilitate IPD processes:

- Building an Integrated Team: Successful IPD relies on assembling a team dedicated to collaboration.

- Conceptualization: Stakeholders gather early in the process and analyze multiple solutions. The goal is to reduce waste and errors, minimize problems, and prevent rework or redesign.

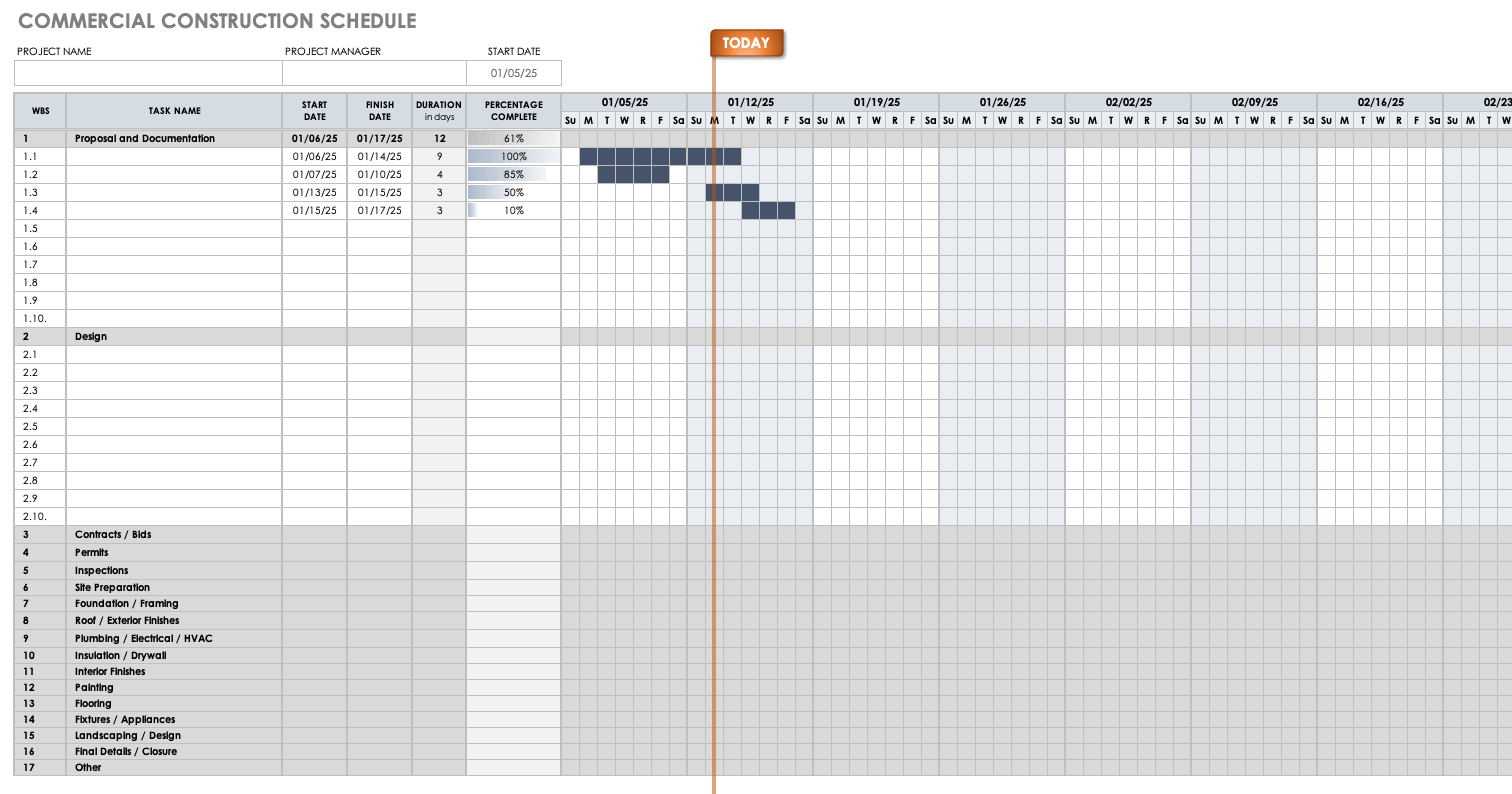

For commercial construction projects, this template can help you stay on track. The template is divided into separate sections for each phase of construction, so you and your IPD team can use it to ensure that essential tasks are correctly scheduled and completed, from conceptualization to project closeout. Keep all stakeholders in the loop with this comprehensive, easy-to-use template. Check out other free tools for new home, renovation, and schools at the Complete Construction Timeline Template Collection.

Download Commercial Construction Timeline Template

- Criteria Design: In this phase, team members review and test different design options. In a project using Building Information Modeling (BIM) software, you can use the model to test potential scenarios and establish what the IPD team will achieve.

- Detailed Design: Finalize key design decisions in this phase, with an eye to reducing waste and producing savings. Construction code regulations and sustainability goals are incorporated into the design process.

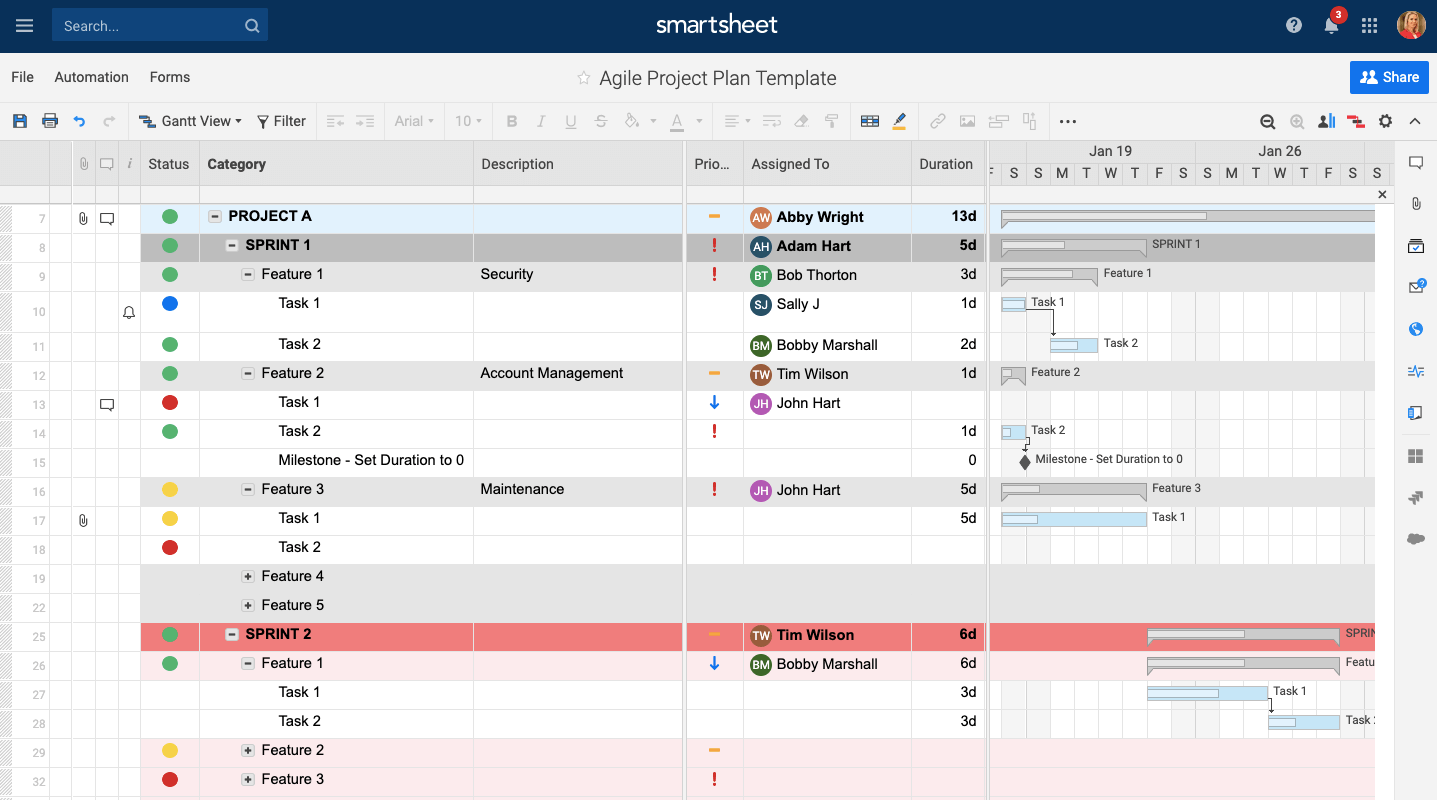

If you’re managing your IPD project with Agile, use this template, designed for Agile projects with risk flags, sprints, tasks, features, and a Gantt chart timeline view. This template improves transparency and limits time and task waste. Your IPD team members can update progress, track deliverables, store files, and set alerts — all in one shared sheet.

Create the Basic Agile Project with Gantt Timeline in Smartsheet

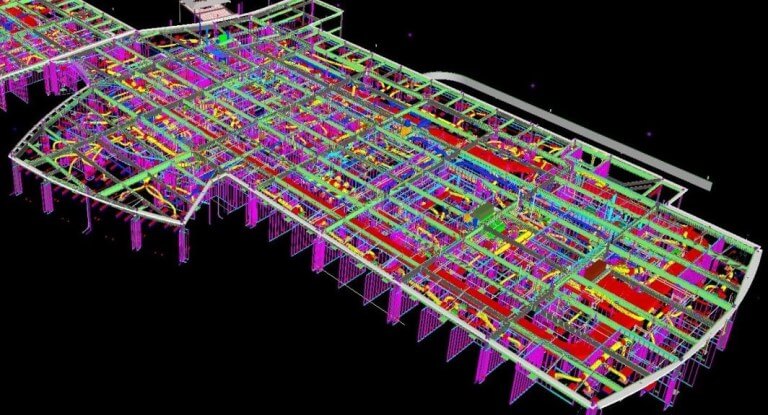

- Implementation Documents: Once the design is set, implementation begins with design data analysis and computer modeling. Often IPD integrates BIM and/or CAD modeling to visualize the project. During this stage, analyze and virtually test proposed systems to ensure design performance. Contractors, subcontractors, and suppliers document how they will create systems and structure. In this phase, documents are generated to use for a permit, finance, and regulatory needs.

- Agency Review: Reviewing and permitting agencies usually requires traditional deliverables. However, BIM can provide information directly or through links to check the design for regulatory or building code criteria. You can use analysis software to model information to generate criteria or performance analyses for design validation.

- Buyout: Buyout means obtaining price commitments for all project work packages. In IPD, those promises are usually developed in an ongoing fashion from subcontractors and suppliers participating in the design, and then refining pricing based on current information. That means that in IPD, the buyout phase is usually limited to obtaining price commitments from any remaining suppliers and subcontractors who weren’t directly involved during the two design phases.

- Construction: Architects typically consider building in the final stage of design, when issues are addressed and solutions are provided to resolve real-life problems. But in IPD, this is completed during the Detailed Design and Implementation Documents phases. This means that construction administration is about quality and cost control monitoring.

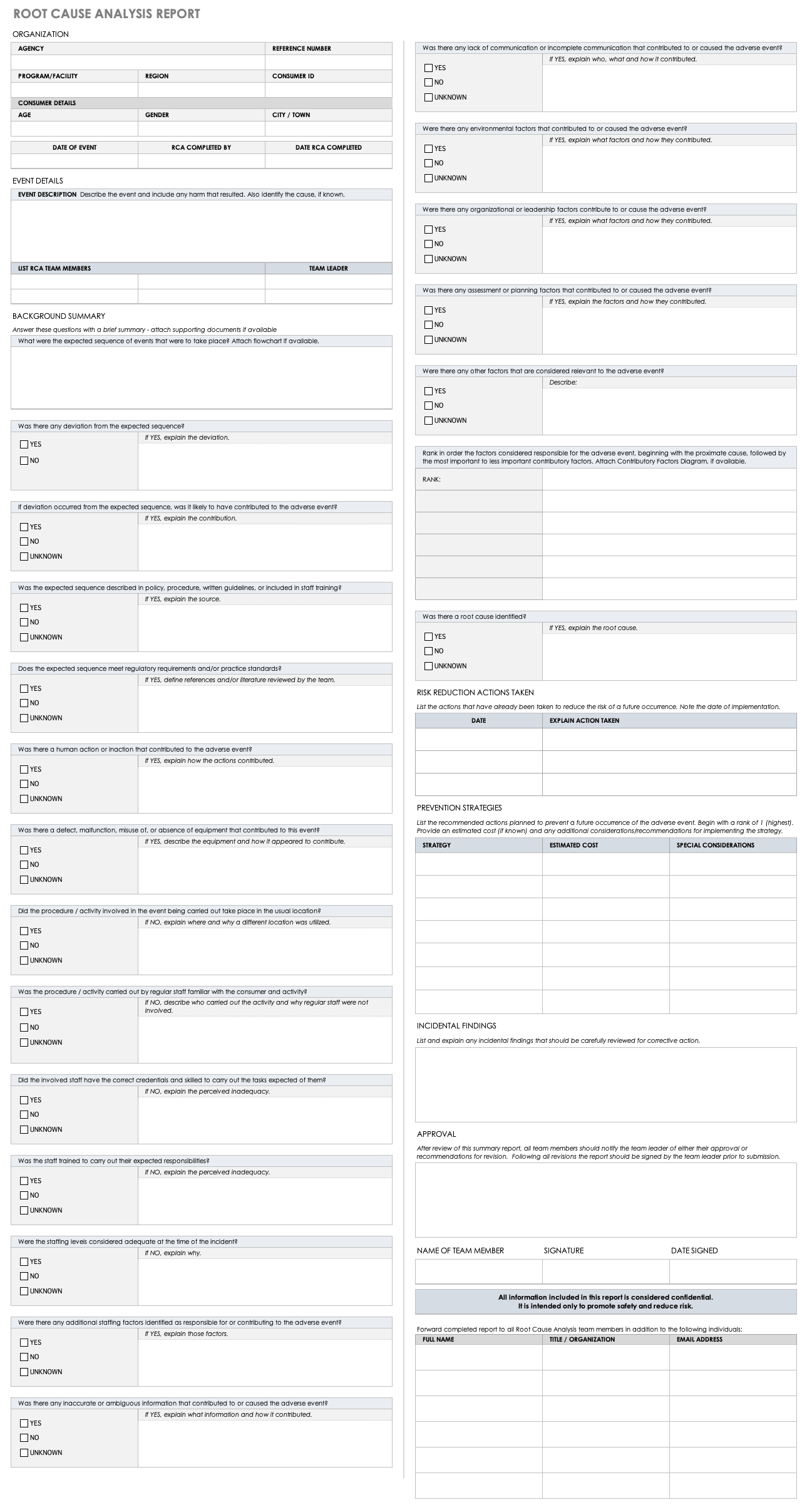

Should problems arise (although there will likely be far fewer using IPD), teams can use the Deming Cycle/PDCA approach to address process-related problems to understand the underlying causes, known as the root cause, which then needs to be improved. The IPD team can use this template to conduct its root cause analysis and then take appropriate action.

Download Root Cause Analysis Report Template

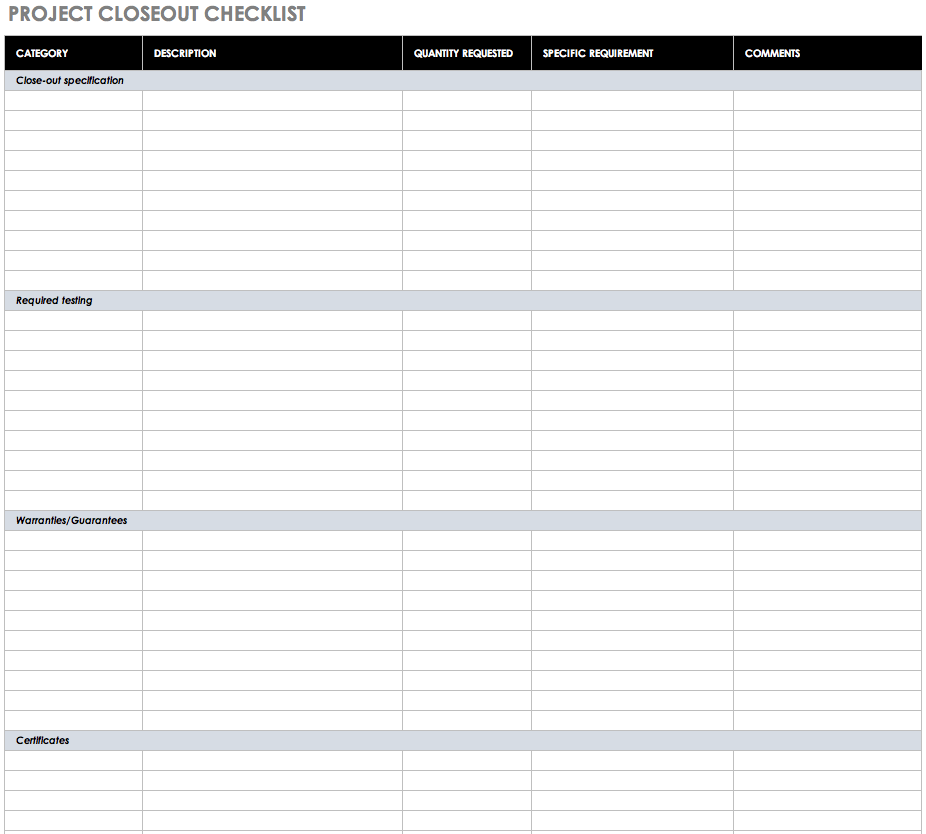

- Closeout: The exact nature of closeout of an integrated project depends upon the contracted business terms. For example, if the contract contains compensation incentives or penalties, the closeout will include calculation of appropriate credits and bonuses.

Eliminate loose ends as your team moves toward project completion. This customizable template ensures that all expectations and agreements have been met. You can list required test, contract closeouts, certificates, warranties and guarantees, and final submittals.

Download Project Closeout Checklist Template

- Facilities Management: Coordinating the physical workspace with the people and the tasks of an organization falls to facilities management. This role integrates architecture, business administration, and engineering and behavioral sciences. In the most basic terms, facility management covers all activities that keep an occupied structure operating. Practical facility management after the building is completed may or may not be included in an IPD engagement unless it is in the contract.

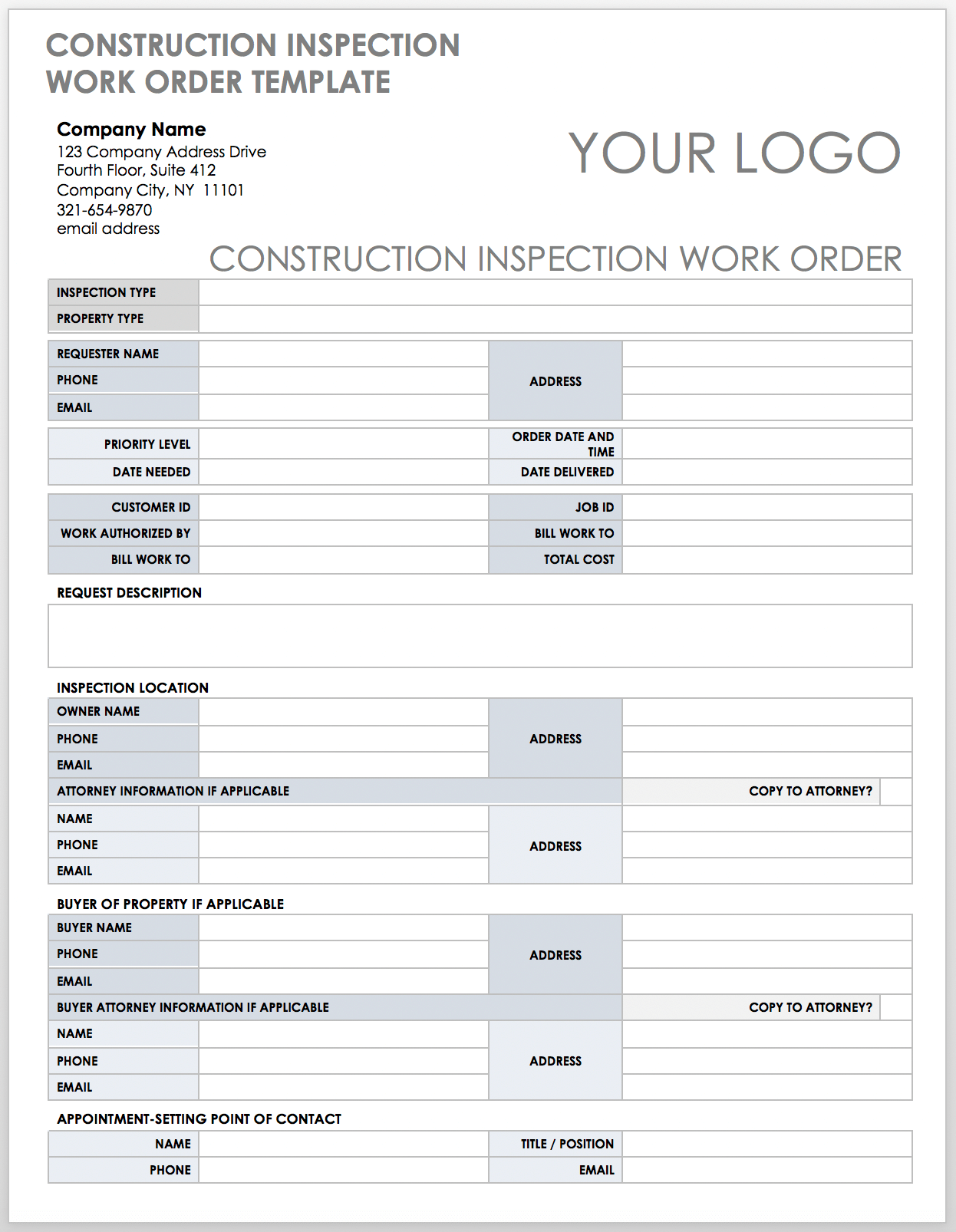

This easy-to-modify template simplifies any inspection your IPD contract requires. In addition to the type of inspection, you can add details about the property and area to be inspected, along with any essential details in the dedicated space.

Download Inspection Work Order Template

For more free templates, read Excel Construction Project Management Templates.

Integrated Product Delivery Pros and Cons

All of our experts linked IPD to Lean practices and noted that there are multiple benefits of pairing them. Heinemeier works to transform the built environment through the use of Lean principles, tools, and research. “The benefits of IPD and Lean construction include safer working environments, more efficiently completed projects, increased productivity, and satisfied stakeholders,” he says.

The right tools are essential in making IPD projects successful. “It’s important to utilize tools and processes that allow superintendents and foreman to communicate quickly,” advises Zandy. “The jobs that have the best communication are the most successful.”

Here are just some of the many benefits of IPD for every team member:

- Improved Planning and Management: Collaborative management that takes advantage of multiple team member’s expertise helps achieve optimal solutions. Decision making timelines are shorter since significant players are typically in the same space and accessible for the duration of the project. When challenges occur, a democratically structured workflow supports optimized solutions, fast turnarounds, and quick implementation.

- Risk Mitigation: When all parties are equally vested in a project based on IPD philosophy, it’s in everyone’s best interest to quickly solve problems. This process eliminates the usual “blame game” and passing of responsibility, and replaces it with a working environment where everyone is looking for project harmony and ultimate prosperity.

- Transparency: When all team members meet regularly to share their ideas and experiences, or use collaborative software, everyone is up to speed and aware of every aspect of the project. There are no hidden agendas, cost surprises, or delays.

- Time and Money Savings: Taking an integrated approach can speed up project delivery, and incentivizing everyone to share in the savings motivates everyone to operate at a profit.

- Teamwork and Collaboration: Because all involved parties act as one entity (due to multi-party contracts or partnership agreements), both project transparency and integrated financial interests increase while fostering mutual support. Contracts also give team members the freedom to share documents without the proprietary or legal risk found in other forms of project delivery.

- Shared Accountability and Shared Risk: IPD spreads responsibility for the project across all team members, whereas traditional models can force contractors and subcontractors to take on a lot of risks. Since IPD involves an overall shared risk, you must have high levels of both owner involvement and trust among all parties.

- Better Business Continuity: There is full alignment with the owner’s goals, which makes successfully completing a project on time and within budget greater than traditional delivery methods.

- Higher Standards: When everyone has skin in the game and potential financial incentives or liability, and a sense of unity with their colleagues, they tend to work to benefit the project, their team members, and themselves.

- Customization: A one-size-fits-all is not part of the equation in IPD. By its nature, IPD creates an environment that provides custom solutions to design and construction challenges. While there is continuous learning that you can apply to subsequent projects, every engagement provides an opportunity to learn and deliver unique solutions.

- Increased Stakeholder Satisfaction: In essence, this is the goal of IPD, in addition to maximizing value and minimizing waste.

A Big Pro for the Environment: IPD & Green Construction Are a Natural Fit

“IPD and the use of Lean all go together well in Green, and high-performance LEED rated structures, and we need to make more effort to build sustainably,” says Barnes. The U.S. Green Building Council (USGBC) tells us that buildings are responsible for much of the world’s energy use — 41 percent on average. The next largest energy consumers don’t even come close: “Buildings are responsible for 73 percent of the electricity consumption in the U.S., and our building construction is responsible for much of the greenhouse gas emissions that affect climate change. Buildings are responsible for 38 percent of all CO2 emissions.”

It makes sense to use collaboration to lower those numbers. Designing and planning to reduce those numbers is logical. “It’s important to thrash out all the potential risk far in advance and stay in tight communication with other stakeholders from start to finish, but especially at the start,” adds Barnes.

Barnes says that any firm can use IPD. “The method can scale to small projects — it isn’t only for mega commercial projects. Everyone wants to save money and waste less. Taking a Lean approach and using an ongoing process of rethinking and improving methodology is important to me as an architect and someone who is interested in sustainability. IPD is a critical process for all green or LEED projects.”

The Cons of IPD

“Right now there is a strong method and increasing industry understanding of Lean in construction, but not in design,” says Cheng. “By lagging, Lean design is at risk to be seen as just another phase to apply robust Lean construction processes and tools. In fact, Lean design needs a different approach and method, and will require its own kind of culture shift. Until we spend some time working through what Lean means for design phases, we are in danger of trying to apply Lean methods developed for construction to the whole design.”

“IPD is sometimes seen as onerous and complex because it demands that owners and project teams negotiate contract terms such as the shared risk/reward pool and terms of fiscal transparency,” writes Cheng in one of her recent post about her IPD research study. “Our research team found that the time and energy spent on negotiations was an investment that paid off in forming the foundation for mutual trust and respect, key elements of successful collaboration.”

- Owner Engagement: “You must have an involved client who will provide strong leadership, with detailed, defined project goals and deep construction process knowledge,” says Zandy. “It’s a different set of owner responsibilities compared to other delivery methods that can lead to resistance.”

- Resistance to Change and Training: As Heinemeier says, “It can be difficult to implement a cultural change.” Industry professionals sell their services based on past projects and can tend to devalue taking on a new practice. The idea that learning and performance improvement is a necessity may appear as a threat instead of an exciting opportunity. “Training requires a significant investment of time/resources. Adopting IPD and Lean tools and principles will require time and energy training clients, designers, builders, and trade partners,’” adds Zandy.

- Rigor Is Required: With a goal of extraordinary results, IPD demands the use of metrics. Design metrics need to be balanced with the others — engineering, costs, budget — to meet stated goals. In fact, the entire team needs to identify metrics at the outset and track them throughout the IPD process, and also monitor associated costs. The project team is responsible for managing how successfully metrics are being met at milestones throughout the various stages of design and construction.

- Difficulty Finding IPD Experts: Despite the surge in interest and positive results of IPD, there currently aren’t many seasoned practitioners. For owners, there aren’t a large pool of experienced practitioners who have completed projects as a firm, individually, or as a multi-disciplinary team member.

- Contract Challenges: “The shared risk and reward (we all sink or swim together), and the idea that one team member can hurt the entire team’s financial outcome is a great incentive or a challenge to those who are new to IPD,” explains Allison. Several new contract models have been developed as legal and insurance entities have learned about IPD. When risk is explicitly assigned, legal bodies and insurers can provide the necessary support. Request for an Integrated Team (RFIT) is an IPD-driven agreement. You can find samples of multi-party, RFIT multi-party agreements, more contracts, and shared risk-healthcare providers and IPD/lean construction here.

- Financing and Insurance Hurdles: “Integrated project delivery as a delivery method can sometimes have insurance issues if professional advisors are not brought in early,” says Zandy. “To clarify the issues and obtain coverage to protect the IPD project, insurers must understand how the parties work together and how that reduces the risk of common claims. It is important to have insurers sculpt builder’s risk as well as professional and general liability policies to meet the intent of the project.”

- The Essential (and Most Difficult) Element of IPD Is Trust: “Nurturing a positive environment of mutual respect and trust is critical to team integration,” explains Zandy. “Participating parties must become strong teams to be successful. In my practice, I often refer to Patrick Lencioni’s The Five Dysfunctions of a Team.” The following are the five dysfunctions:

- The fear of individual vulnerability

- Working toward artificial harmony over constructive authentic debate

- A lack of commitment and feigning buy-in for group decisions

- Sidestepping the duty to call colleagues on disadvantageous actions

- Having attitudes that set low standards and focus on personal prestige and ego before the success of the entire team

“By not falling into these traps, and by understanding trust can be realized through teams fulfilling commitments to each other, projects can experience great success with IPD,” says Zandy.

But you need some patience at the beginning of the process, Zandy explains. “Trust takes time. Implementing IPD won’t automatically make team members trust each other. Training is required.”

Pease believes that co-location (putting everyone in the same room) for projects is essential. He also takes the time to help team members bond. “We use team building exercises, play games, do simulations. We have a big poster on the wall that says, ‘If I can’t say no, my yes means nothing.’ You need to challenge things, and we recognize individuals.”

Integrated Project Delivery Case Studies

The most thorough and recent study of 10 IPD and Lean structures can be found in a 255-page research report Motivation and Means: How and Why IPD and Lean Lead to Success. The study was spearheaded by Cheng, her colleagues at the University of Minnesota, in collaboration with the University of Minnesota, Scan Consulting, Integrated Project Delivery Alliance (IPDA), and the Lean Construction Institute (LCI).

All of the projects were completed early or on time, and below or on budget — highly unusual in building projects of any kind. Below are three case studies in brief from the research.

Sutter Health Fairfield Medical Office Building Fairfield

The project is a three-story medical office building housing primary care medical practices and laboratories, with administrative offices and cardiology, oncology, rheumatology, and pediatric departments. Under budget and within schedule, there were virtually no change orders. Lessons learned are being unearthed in larger and more complex projects that Sutter is currently undertaking, including the Sutter Medical Center in Castro Valley, California and Cathedral Hill Campus in San Francisco, California, which together are budgeted at 2 billion dollars. More upfront, intense effort was needed than in negotiated or design-assist projects, but subcontractors found that the ultimate payback was that the usual rework in other projects was almost entirely eliminated.

Building Size: 120 square feet

Budget: $136,549,608

Schedule: 29 months design | 28 months construction

Final Profit: $1,165,105

T. Rowe Price Owings Mills Campus Building 1

As a global investment and financial-planning company with more than twenty offices worldwide, T. Rowe Price had experience (but not satisfaction) with tenant build-outs and new construction. Inspired by the book The Commercial Real Estate Revolution, the company decided to proceed with IPD. The Owings Mills Campus Building 1 project is a renovation of an existing four-and-a-half story structure. The seventeen-year-old office building is owned, occupied, and located on their corporate campus in Owings Mills, Maryland. The owner’s objective was to relocate two project teams from their downtown headquarters to the campus building, as well as maintain and integrate significant IT requirements. The scope included space renovations and an entirely new mechanical system. The project goal was to achieve LEED Silver, and the team was able to deliver significant value-add items through IPD. A key phrase the project team often used when describing their experience with IPD on the project was “stay at the table,” meaning that you should work through any problems and conflicts.

Building Size: 111,000 square feet

Budget: $20,241,000

Schedule: Four months design | Eight months construction

Final Profit: $1,614,048

Rocky Mountain Institute Innovation Center

The Rocky Mountain Institute (RMI) is a nonprofit committed to advancing efficient uses of energy. They have worked with many building owners but haven’t played the role of owners themselves. Although the use of IPD is not typically used for buildings of this scale, RMI understood that the complex technical requirements and the desire to create a culture of collaboration made it an ideal use case. To advance their mission and propel the industry, RMI used the Innovation Center to show how net-zero carbon buildings should be designed, contracted, constructed, and occupied. Among the unique challenges of the project was applying passive house strategies to a commercial program and establishing goals at all scales of impact. The contract also included incentive compensation, meaning that everyone shared in any profits at completion of the project — an additional motivating factor.

Building Size: 15,610 square feet

Budget: $8,882,090

Schedule: Eight months design | 12.5 months construction

Final Profit: Confidential

Learn more about the IPD/Lean approach used to design and build the RMI Innovation Center by watching this virtual tour video.

Technology in IPD and the Growing Importance of BIM

Building information modelling (BIM) is essentially shared data software that provides 3-D model-based process and non-graphical information that gives architects, engineers, and constructors the ability to more efficiently share information and concept, design, build, and manage structures of all kinds. BIM is increasing in sophistication: In addition to 3-D modeling, 4-D BIM provides scheduling data, 5-D ties cost information and calculation, and 6-D delivers project lifecycle information to extrapolate data.

“BIM helps with computer simulation in our projects,” says Pease. “In general, we use it for clash detection.” Clash detection is finding where elements of separate models occupy the same space,; for example, when a beam and ducting run into each other. Clashes can also occur around sequencing or changes that haven’t made it into schematics.

BIM Provides a Look Into a Project Before It’s Built

Source: Courtesy of LeanIPD/James Pease

The Means and Methods research study found that BIM can greatly improve collaboration and effectiveness of IPD.

“BIM is where we’re heading in IPD and all construction in general,” Cherf explains. “The major contractors who work on big projects all use BIM, and it will eventually shape the way everyone works. We’ve installed a BIM lab because we must train the next generation of engineers and architects now.”

Collaboration Software and Dashboards

“We use dashboards on all of our projects,” Zandy says. “We track the milestones and then have our subcontractors show where they’re working and how many men they have each week to help us try to meet those deadlines. If they get off track, we identify the associated constraints and try to help trades resolve them.”

Pease uses Smartsheet for goal setting, staff development, and scheduling overall. “We use it at the beginning of a project to capture information and hold all the documents,” says Pease. “We use it as a digital footprint and internal CYA — everybody forgets when something goes wrong!”

For more information, read How to Pick the Right Construction Project and Scheduling Software for Your Company and What the Future Holds.

IPD and Lean Construction Resources

IPD courses, seminars, and workshops are available through professional organizations (see list below). Courses for credit are available at technical colleges and universities throughout the United States, including the University of Maryland, Harvard University, Lawrence Technological University, and Northwestern University.

Organizations:

- Associated Contractors of America/Integrated Project Delivery

- The Integrated Project Delivery Alliance

- Lean Construction Institute

- Lean Construction Institute Canada

Online Magazines and Guides:

- Constructurr Podcast

- Lean Construction and Integrated Project Delivery

- Lean Construction Blog

- Integrated Project Delivery: A Guide

- Choosing A Project Delivery Method

- WorkDesign Magazine

Books:

- BIM and Construction Management: Proven Tools, Methods, and Workflows 2nd Edition by Brad Hardin, Dave McCool

- The Commercial Real Estate Revolution: Nine Transforming Keys to Lowering Costs, Cutting Waste, and Driving Change in a Broken Industry by Rex Miller, Dean Strombom, Mark Iammarino, Bill Black

- The Designer’s Field Guide to Collaboration by Caryn Brause

- Integrating Project Delivery 1st Edition by Martin Fischer, Howard W. Ashcraft, Dean Reed, Atul Khanzode

- Managing Quality in Architecture: Integrating BIM, Risk and Design Process by Charles Nelson

- The Owner's' Guide to Starting Integrated Building Projects Paperback by Oscia Wilson

Videos:

Improve Integrated Project Delivery with Smartsheet for Construction

From pre-construction to project closeout, keep all stakeholders in the loop with real-time collaboration and automated updates so you can make better, more informed decisions, all while landing your projects on time and within budget.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.