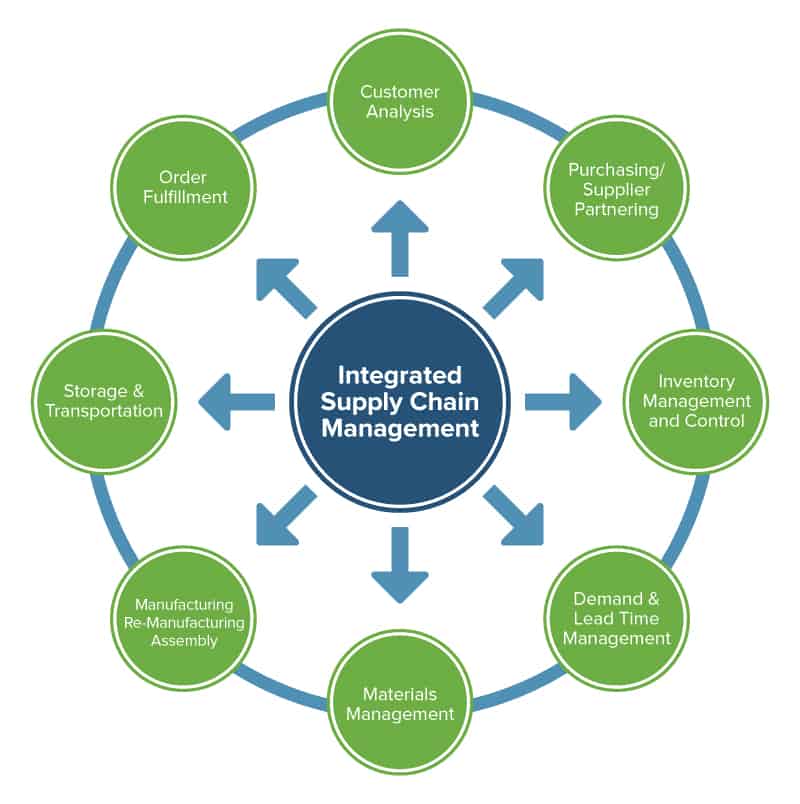

What Is Supply Chain Integration?

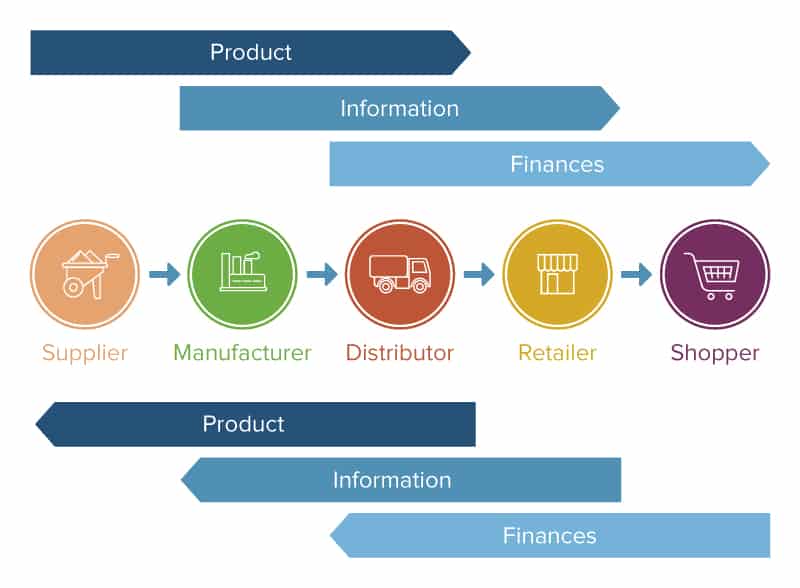

To understand integrated supply chains, it’s first important to grasp just what a supply chain is. A supply chain is a collection of suppliers required to create one specific product for a company. Each supplier is a “link” in the chain that adds time and monetary costs. Supply chain management is the collection of methodologies, theories, and practices that go towards keeping a supply chain running and improving its efficiency for the benefit of most, if not all of the links.

Supply chain integration is a large-scale business strategy that brings as many links of the chain as possible into a closer working relationship with each other. The goal is to improve response time, production time, and reduce costs and waste. Every link in the chain benefits. An integration may be done tightly through a merger with another firm in the supply chain, or

loosely through sharing information and working more exclusively with particular suppliers and customers. In the latter case, the supply chain isn’t truly “owned” by one company, but the various links operate almost as if one company to increase efficiency and benefit everyone through steady, reliable business.

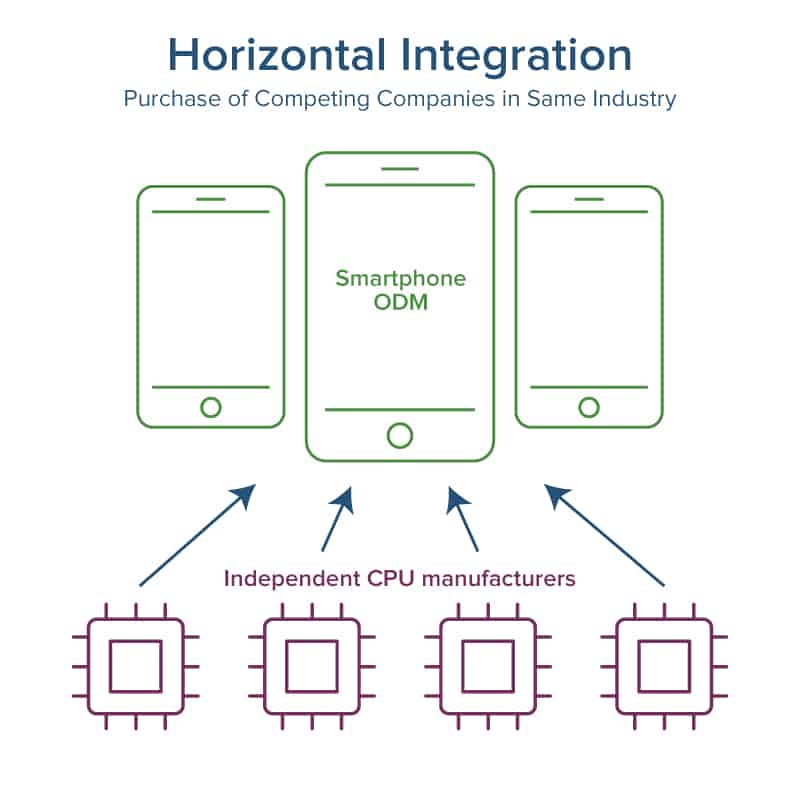

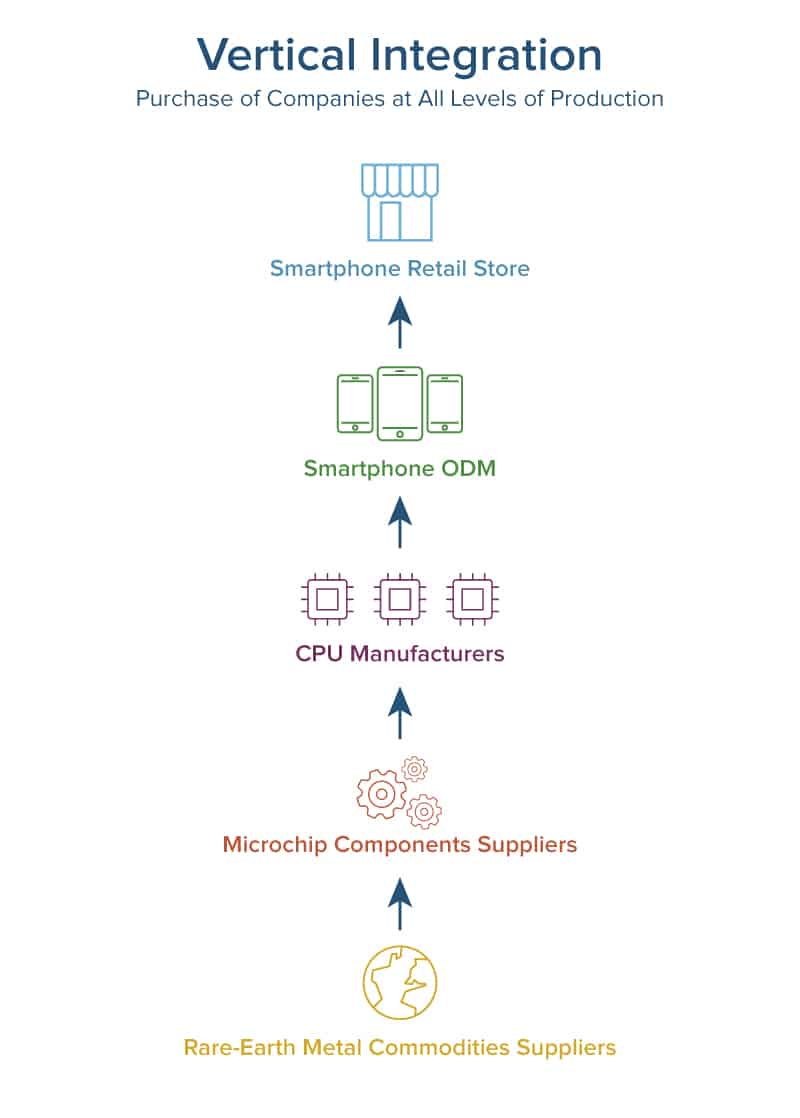

Horizontal Integration vs. Vertical Integration

Horizontal integration involves any moves related to the same “level” of the chain as the organization making them. Integration could include merging with or purchasing firms that supply similar products, such as a central processing unit (CPU) manufacturer buying another in order to serve a larger swath of the CPU market. This type of relationship could help the firm gain many more customers, and give them greater control over the price and supply of CPUs.

Vertical integration refers to any moves that include different levels of the chain. It could involve merging or buying out a link ahead of or before your organization, or possibly developing your own capabilities for handling the entire supply chain, front to back. For example, if the CPU manufacturer mentioned earlier also purchased a smartphone product development firm, they would control more levels of their supply chain - the major parts and the product. This type of acquisition could gain the firm greater control over their costs, net them a larger share of profits, and reduce waste and time spent in production.

Example of Loosely-Integrated Supply Chains: P&G and Walmart

Procter & Gamble (P&G) is one of the most prolific consumer goods producers in the world. As they scaled up their manufacturing capabilities to keep up with the fluctuating demand and prices, they sought a better way to stabilize supply and demand to end promo-driven pricing. P&G formed a famous partnership with super retailer Walmart, becoming an exclusive supplier of some of the product categories they produced for the big-box retailer, and integrating their backend information systems to ensure they matched stock perfectly across stores, rather than over-supplying and then discounting as before.

Though neither firm owned the other, their loose vertical integration of information and product supply chains enabled both companies to increase their sales eightfold.

Example of Tightly-Integrated Supply Chains: Dell Computers

Notable third-party PC manufacturer Dell is a study in vertical supply chain excellence. Their strategy was to eliminate the things they weren’t good at, such as software (which is always supplied by Microsoft and partners), and retail reselling. They instead narrowed down to their core competencies, enabling fast delivery of superior made-to-order PC hardware direct to consumers with an integrated supply chain. The company handled product design and development, and assembly and delivery of final products.

Dell vertically integrated everything in its in-house supply chain save for parts procurement, and reaped the benefits of low excess inventory and just-in-time delivery to customers to beat the PC market’s growth for a very long time.

The Biggest Challenges in Supply Chains

Before bothering with the specifics of integration, it’s important to understand what problems plague supply chains in the first place:

- Order Changes and Cancellations: This happens at the end of the supply chain, and sends reverberations throughout. The retailer is stuck with excess product, the wholesaler deals with fewer orders and backing up inventory, and every other supplier feels the waves. Plus, consumer whim dictates changes and cancellations, meaning there’s little way to predict it, and every case could have different reasoning.

- Workers Unavailable: Companies provide quotes and production orders based on expected capacity, and when workers are ill or otherwise unexpectedly absent, that can dramatically affect a supplier’s capability. This scenario is especially true in the age of automation, where fewer workers are required but each is responsible for overseeing the smooth production of many more units.

- Production Facility Failure: Like with workers, unexpected mechanical or software problems with manufacturing plants can devastate a supply chain, especially if it is operating on just-in-time, Lean manufacturing methodologies.

- Late Delivery of Materials: This logistical problem can stem from a number of transportation issues, from as mundane as a traffic collision to as severe as genuine theft and piracy, depending on which regions the supply chain serves.

- Suppliers’ Conflicting Obligations: Independent suppliers all have one honest goal - make as much money as possible by taking on as many orders as possible. In non-integrated chains, this means they might have some tolerance for overlap between different customers’ orders. Should one customer decide to increase production, another suddenly might be out of a production facility because the supplier overcommitted.

- Adversarial Relationships: Whether for the conflicting obligations cited above, or for simple reasons of maintaining secrecy and negotiation advantages, customers and suppliers may have a relationship that’s more foe than friend. They don’t share risks or benefits and lose out on potential gains from working more closely together.

- Transactional Relationships: Even when not adversarial, supplier and customer relationships in non-integrated chains could be “just business,” emphasizing direct delivery and cost with no added value. Every deal is a new negotiation, focused on the bottom line, and terribly short-sighted.

- Limited Communications: Non-integrated supply chains may only talk to firms just one or two links away from them, whether up or down the chain. If they have a buying relationship with the link before them, focused on minimizing cost, and a selling relationship with the next link, focused on maximizing profit, they can’t learn about bigger impending problems or greater opportunities further up or down the chain.

How to Create a Supply Chain Strategy

When deciding how to position your organization in the market, knowing which of the above challenges you face is a good first step. From there, use this framework to make some honest choices on what supply chain strategy you need to make to be competitive.

- Define the strategy and the vision of the role that supply chain management plays within the organization. Is it a practice for reducing waste and speeding up delivery, for tightening relationships with partners, or for market dominance and increasing barriers to entry for new competitors? You should refer to every part of your strategy and methods for growth in this vision.

- Decide what your firm, and ultimately your supply chain, will compete on: low cost or differentiation. Low cost supply chains require cutting out middlemen, limiting transportation needs, and reducing specialization to save dollars at every stage. Differentiation may require special relationships with manufacturers who can respond to specific customer requests way down the supply chain promptly.

- Divide every supply chain activity into “insource” or “outsource.” Determine what your firm does better than anyone else, and double down on all activities that fall under this facet. If your company creates value in something that others can’t, insource it. Then, determine if you can reasonably invest in new core competencies, or if it will never be profitable or efficient, and partner up with outsourced suppliers accordingly.

- Assess your supply chain architecture. How is the chain “designed,” what are your logistics realities, how are information flows set up, and what is the timeline for cash flows? Without deliberate management, these different supply chain attributes may have formed a tangled web over time as your organization grew, born out of convenience or necessity. Each represents an area for improvement as you create your strategy.

- Consider your organization’s current abilities and future plans in product and service design. If you want to create more customized, made-to-order experiences, for example, investing in vertical integration may be worth it. If you want to be the go-to parts supplier for your industry, horizontal integration would be a strong choice. Make supply chain decisions that cause your organization to be more like the one it claims and aims to be for customers.

- Determine the level of integration you have, the level you want, and the tolerance for each your organization has.

- Baseline: This level of integration has siloed information as each department in one company works on issues separately.

- Functional Integration: Information and operations are shared throughout all departments in one company, working to increase efficiency.

- Internal Integration: All departments are connected in one IT structure, but each link in the chain is still functionally separate and working off their own motivations.

- External Integration: All companies in the supply chain are sharing information and operating nearly as one to fulfill customer needs, and increase efficiency and profits all around.

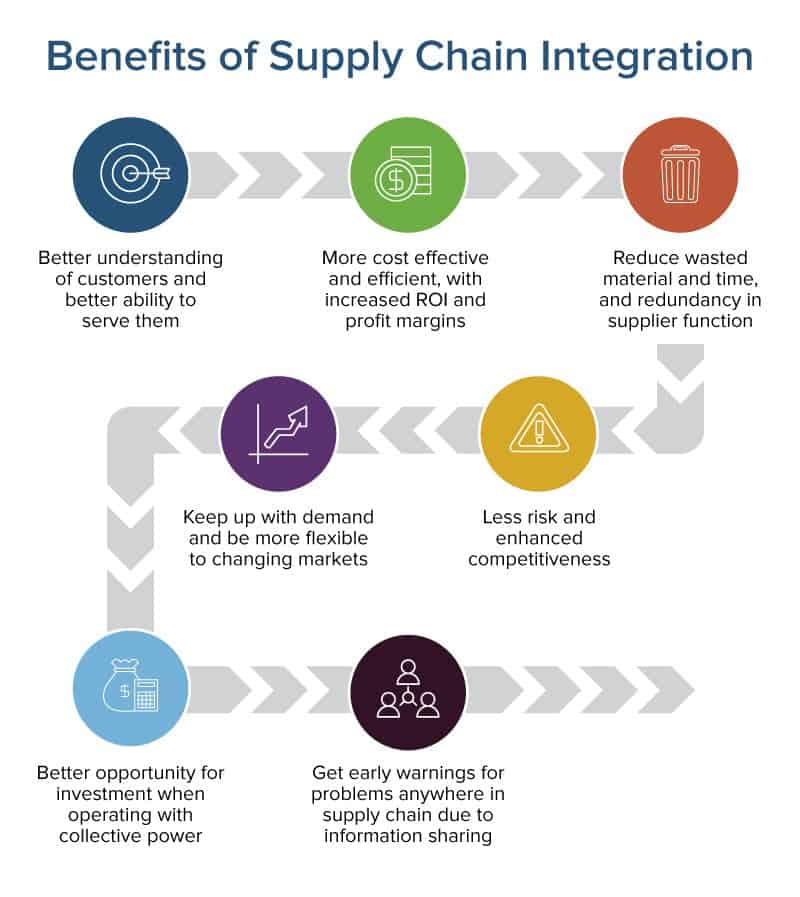

The Benefits of Supply Chain Integration

Just how does integration help companies overcome the challenges in their supply chains and meet the strategies they set forth? Supply chain integration benefits include:

Vertical Integration-Specific Benefits

- Better quality control since all links are working to the same goal and products

- Lower costs for end consumers with elimination of middlemen

- Increased control of market share and raised barriers to entry for competitors

- Eliminated reliance on competitors and suppliers with conflicts of interest

How to Integrate Your Supply Chain

With a strategy in hand and benefits to your company on the books, it’s time to look at how to get everyone else on board. This includes people in your firm and organizations throughout the supply chain.

Start by convincing all relevant parties in your organization that integration will benefit the firm. Use the benefits of integration from this article, and find data specific to your company that can support this.

Reduce redundancy by carefully selecting partner suppliers with whom you want to tightly integrate information and logistics flows. Create an end-to-end plan that makes integration logical, touches as few hands as possible, and covers the variances in your production needs with the possibility of increasing as all companies grow.

With your preferred suppliers selected, demonstrate to them that it’s in their best interests to integrate with you and the others using compelling data on wasted time, warehousing costs, and more. The bottom line is it’s important for suppliers, manufacturers, product developers, wholesalers, shippers, and retailers alike, so be sure to have sales projections as well.

In pitching the integration to partners, find ways to add value to all buyers and suppliers that will be in the final chain. Improve service levels through closer commitment with all parties.

Once you have your partners on board, it’s time to begin integrating functions and data. If you can all use the same logistics and supply chain management software, it will be ideal, but this depends on the chains desired level of integration:

- Extended Enterprise: At this level, information is shared throughout the chain’s organizations, improving relationships, and blurring the boundaries to allow better outcomes for all involved.

- Virtual Integration: At this level, all partner organizations use the exact same information system and software, so you’re not only sharing data, but it is also accessible to all relevant parties in the chain. Everyone can operate on the same data.

- Superefficient Company: At the highest level, not only are you sharing information, but so are all the processes. You behave like different departments at the same company, smoothly receiving orders, manufacturing products, and transporting them where they need to be. You might even appoint inter-organizational managers to oversee and coordinate specific transition points. Implement Lean and Agile practices to make this feasible.

With the supply chain fully integrated, all partner organizations can now have reliable order quantities, increased profits, gather intelligence via the supply chain, and be aware of what competitors are planning months ahead of time. From here on out, it is the job of all members to find ways to increase efficiency that mutually benefits everyone throughout the chain, helping each other grow and be stronger in their industry.

Advice from a Supply Chain Expert

One of the strategies I am using is to have suppliers who make complementary products work together to integrate those items into a high-level assembly. Recently, I hosted a strategy session on a new product with the three key suppliers who contribute the majority of the content. By getting them to know each other and work together directly we expect a reduction in some areas such as responsiveness, lead-time, and ultimately cost.

My goal is to become the “conductor” or facilitator who brings suppliers together to work in a direct engagement with each other as a strategy to reduce our needs for resources. We negotiate all terms and pricing with each supplier. The drawback can be a loss of control and price creep. This is where it is important to not just assess a supplier for their individual capabilities, but to also assess them for their ability to operate successfully in a cross functional/cross supplier way with other companies.

- Start discussions with suppliers and only add new suppliers who are truly strategic and can operate with others.

- Establish a learning exercise by selecting projects where two suppliers can engage. As their experience grows, and processes and your own learning grow add other suppliers to the mix.

- Attempting to have all suppliers trying to engage each other at one time cannot work because the customer needs to focus on working out unexpected issues.

Challenges of Supply Chain Integration

Integration is easy in theory, but difficult in practice. See this list of sticking points you should be aware of in any attempt at integrating supply chains:

| Creating a shared vision of how integration will improve both financial and intangible results |

| Building an organizational culture that incentivizes people to support the supply chain vision |

| Establishing end customer-centric metrics throughout the chain to improve quality control |

| Organizing multiple supply chains to meet the needs of different customer segments |

| Making product and service design decisions based on broader shared supply chain considerations |

| Maintaining consistency in relationships with suppliers and customers, even during downturns |

| Joining sales and operations into one effective process, preventing miscommunications |

| Implementing reliable databases and keeping all partner suppliers on the same IT infrastructure |

| Developing analytics capabilities to make effective decisions in a complex partnership |

| Building trust both inside and between all organizations in the supply chain |

| Sharing risks and rewards among supply chain partners in a way perceived by all as fair |

Challenges Specific to Vertical Integration

|

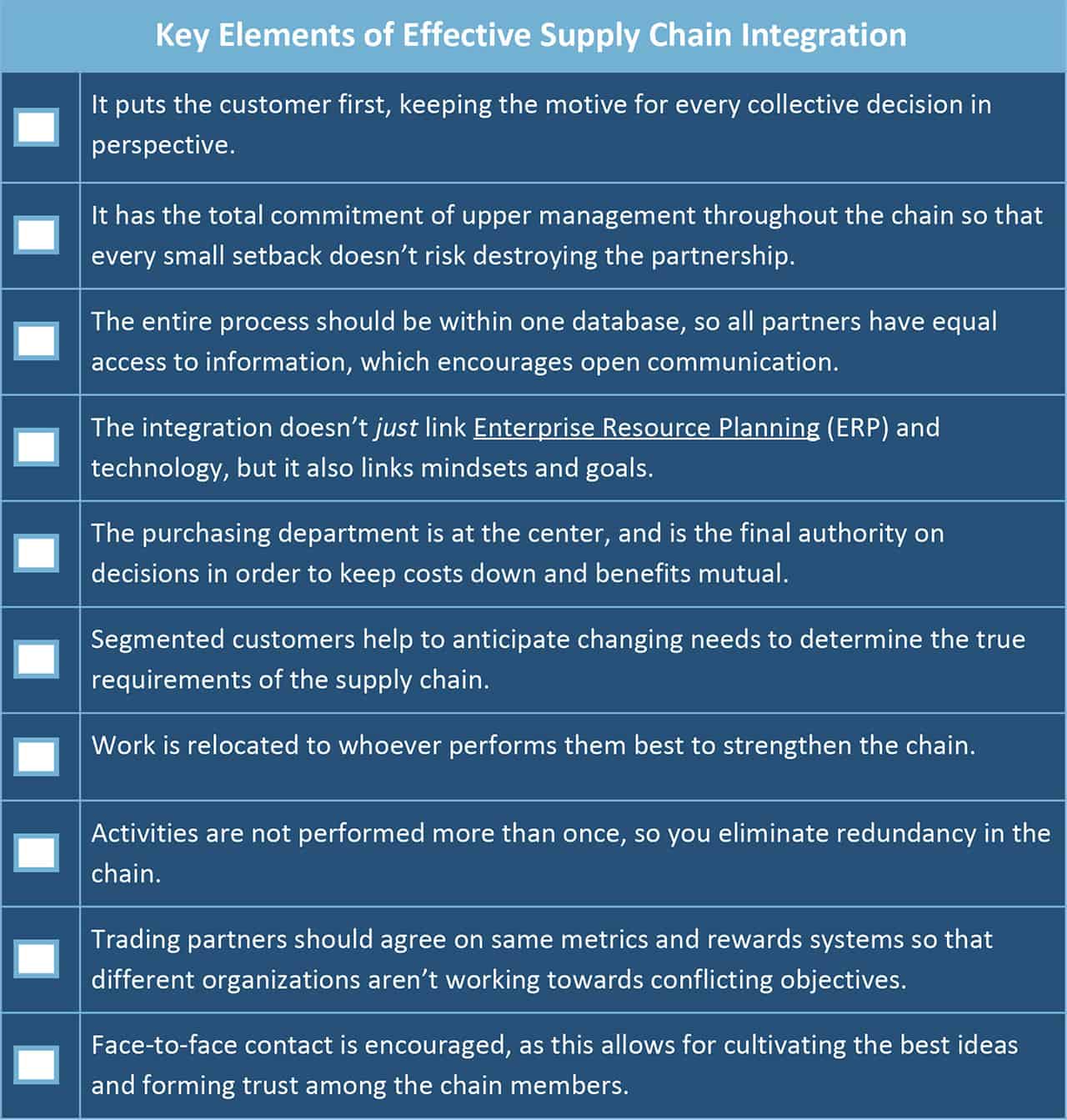

Elements of Effective Supply Chain Integration

When supply chain integration is done correctly, companies can reap a multitude of rewards. Here are some key elements to keep in mind when discussing a move toward supply chain integration within your organization:

Download Key Elements of Effective Supply Chain Integration Checklist

The Present and Future of Integrated Supply Chains

Supply chain management is an ever-changing field with many players. First, here are some predictions on how integration is affecting strategy for the biggest players, and where it’ll go from here:

Amazon, Boeing, and automotive companies are in the news for vertical integration. The main reason for vertical integration is to ensure supply continuity and buying critical technology. For example, Amazon is getting into the transportation business and developing their capabilities for air, road and sea shipments to augment suppliers such as FedEx, UPS, and others during peak season. On the other hand, Boeing shipments are impacted by non-availability of parts, and they are buying financially unstable suppliers to ensure business continuity. The automotive companies are buying autonomous driving tech companies. The supply chain in vertical integration is asked to expand their capabilities in newer areas to support corporate goals. Removal of bottlenecks that created supply issues is a key challenge in the vertical integration.

Horizontal integration is driven by the need to launch products and services for new markets and customers or to reduce costs. Recently, Amazon bought Whole Foods to enter the grocery market. Horizontal integrations have been going on for several years in pharma and consumer good industries to reduce overhead costs. Pfizer and 3G Capital (Kraft) are at the forefront of these type of mergers. The role of supply chain in horizontal integration is complicated. Customer requirements for the new markets are usually different from the base business, and therefore the existing supply chain may not be able to support the new demands. However, in many cases, leaders ask that supply chain support the new products and markets with existing capabilities with the belief that a single supply chain will reduce cost or speed up market entry. Unfortunately, this strategy creates a significant problem for both the new and existing businesses as complexity increases result in poorer response time, bad customer service, and higher costs.

Both horizontal and vertical integrations are likely to continue over the next several years. Business continuity will become a bigger issue as the Fed continues to increase interest rates and developed countries focus on protecting of jobs. The Fed’s move will soak up liquidity from the market that it had released in 2009/2010 as part of quantum easing. The quantum easing led to a supply capacity boom in developing markets and with the interest rate increase, we will probably see the failure of suppliers as they will likely struggle with lack of liquidity or higher cost to service their debt. Also, the nationalistic trends in the developed markets would mean supply base will have to be moved back to take advantage of the changed economic environment. All industries that are involved with the movement of goods or people across borders to support their customers will likely be impacted. The above trends would mean companies have to rethink their global supply chain strategies. Manufacturing and supply base will become fragmented in addition to escalating supply continuity issues.

From supply chain perspective, it may mean helping suppliers with financing or encouraging one supplier buy-out another in addition to vertical and horizontal integrations.

We at Three S Consulting have experience in helping clients with both vertical and horizontal integrations. To be successful in either of the integrations an excellent current state analysis is required and then plans have to be developed to achieve new corporate objectives. It may mean doing things that are different from the past and accepted industry practices. Much of the strategies are discussed in our book – The Supply Chain Revolution. - Suman Sarkar, Partner at Three S Consulting

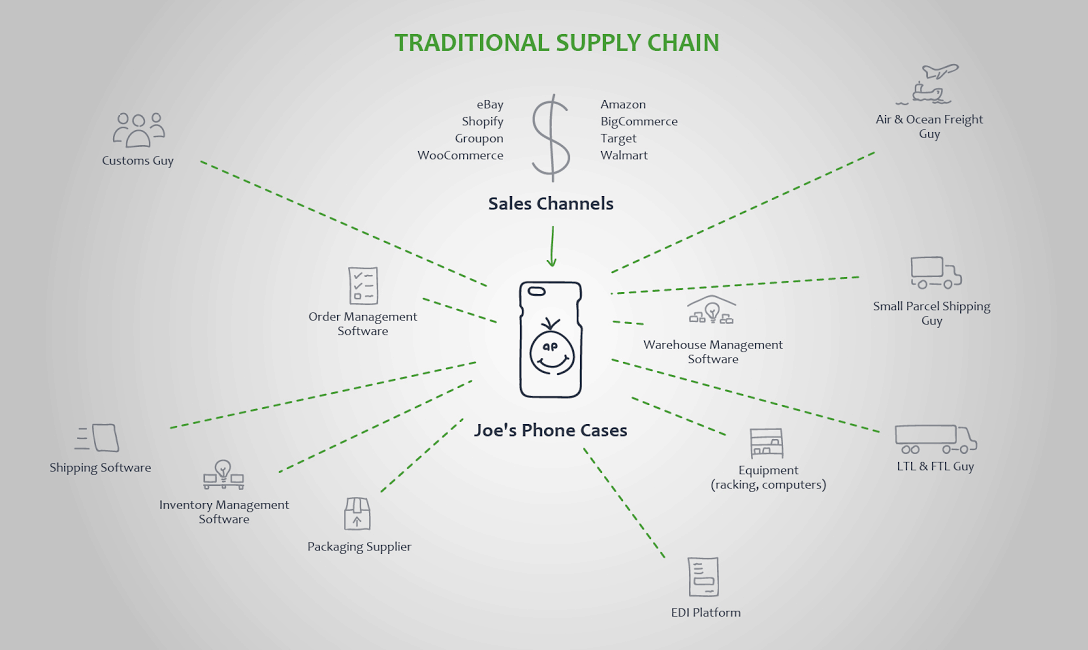

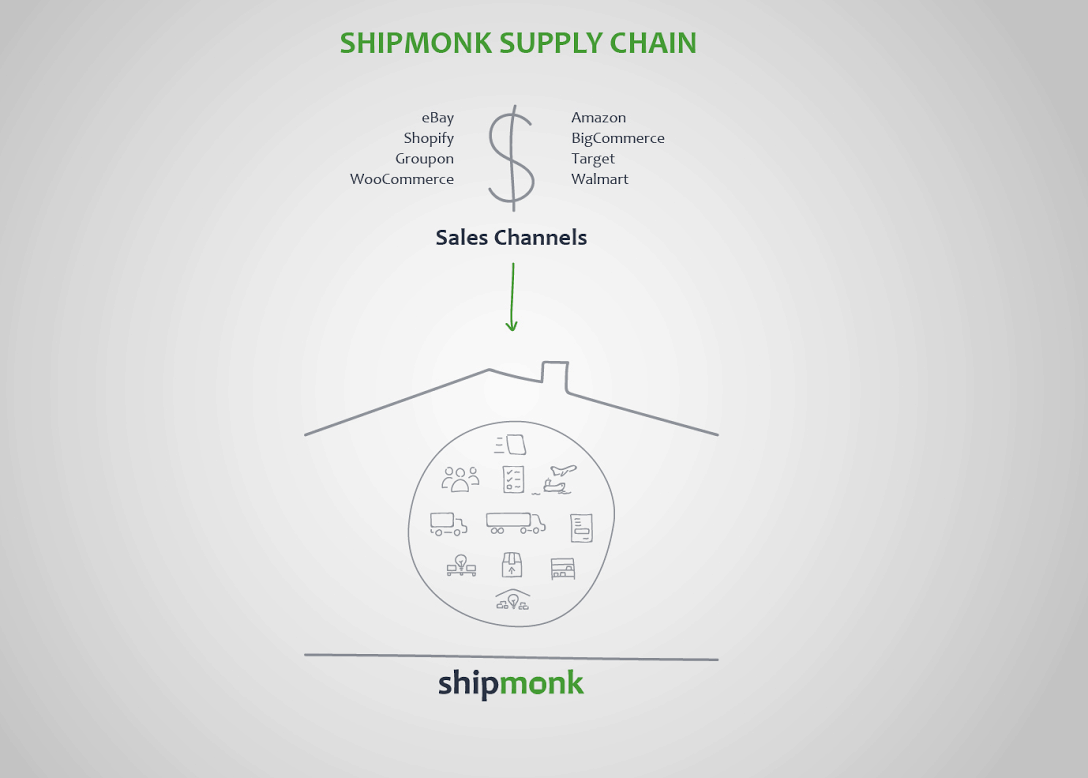

Next, here are some thoughts from Kevin Sides, Chief Marketing Officer, ShipMonk on how software, technology, and the startup economy is democratizing and disrupting supply chain management and integration:

Technology is streamlining the supply chain in three major ways. First and most obvious is that there is access to more tools, which speeds up the process. Second, it makes it easy for smaller business to enter new markets. Finally, some companies in the SCM space (i.e. ShipMonk) are looking to simplify that process even more and bridge the gaps between the various tech to make the process smoother, cheaper, and faster.

It’s going from this:

To this:

Look at a platform like Shopify; they've completely disrupted the eCommerce space. They may look like a simple shopping cart, but their massive growth is a result of integrating numerous features for eCommerce businesses. Through Shopify's App Store you can find any app to assist with your online store - live chat widgets, shipping companies, product reviews, shopping cart abandonment, email marketing, and the list goes on. They made it easier than ever to start a business and leverage all the necessary tools for growth. They even build in terms and privacy templates to overcome that small obstacle for eCommerce businesses. The point is there are so many moving parts with eCommerce that the easier you make it for people, the greater the market.

SCM isn't any different. Instead of having to take an extra step to reach out to a freight forwarder or packaging supplier, business (of all sizes) will be able to rely on a one-stop-shop solution.

Technology is important for two reasons: it makes things scalable and it’s cost-effective. Shopify does everything I spoke about for $29/month. Although SCM is a little bit more hands on than just tech, the future looks the same: the easier you make it for business equals a larger market, which results in more growth for your company.

I do think there is a major advantage for companies to focus on what they do best, which seems to be a contradicting statement from what I touched on earlier. Instead of one platform offering all the services within SCM, I believe the API integrations between strategic partners will win out. The reason being is the tech needs to constantly adapt, so when each business functions separately they are able to focus on their specialities. Also, it creates less risk for the companies and the end-user.

Glossary of Supply Chain Integration Terms

Alignment: Having a common vision, purpose, and goals with partners throughout supply chain.

Backward Vertical Integration: Purchasing or merging with suppliers up the supply chain, who sell to your organization.

Balanced integration: Purchasing or merging with suppliers both up and down the supply chain, i.e. your suppliers and your buyers.

Captive Suppliers: Segments of a large organization that typically supply the parent organization, and you don’t negotiate with them.

Constraints: A limiting factor within one or many organizations in the supply chain that prevents certain activities or growth from occurring.

Disintermediation: A type of vertical integration wherein purchasing departments take over the role of wholesalers, sourcing products directly.

Downstream: The next links in the chain that an organization sells to or supplies.

DTO Approach: Design-to-Order is a type of product that is made to customer requirements, and has far more customization and specialization than a mass-produced, out-of-the-box product.

Forward Vertical Integration: Purchasing or merging with suppliers down the supply chain, who buy from your organization.

Industry Value Chain: A representation of the value each industry that your chain touches adds to the process. For example, a typical chain might have raw materials, intermediate goods, manufacturing, marketing and sales, and after-sales services.

Inventory Management: A function of supply chain management that allows firms to reduce the amount of inventory they purchase and store at a time, moving towards ordering exactly how much is needed by anticipating demand and emphasizing just-in-time delivery.

Known Costs: A set value with a specific supplier for a particular material or product that can be put into a long-term contract, making profitability and consumer pricing much simpler.

Logistical Execution System (LES): A system that allows an admin to manage processes and information at each link in the supply chain, from materials procurement to distribution and delivery of products.

Linkage: The sharing and communication of information required for decision-making among firms in a supply chain.

Product Mix: The different product lines that an entire supply chain supports in-part or in-full. For example, maybe every product line gets materials from the same supplier, but not every end product is assembled by the same manufacturing plant.

Supply Chain Strategy Planning Decisions: Aligning supply chain management decisions with overall business strategy, product and service design, and the architecture of the supply chain itself.

Theory of Constraints: A methodology based on the idea that a chain is no stronger than its weakest link, meaning that organizations should be structured around constraints to mitigate and minimize their impact.

Upstream: The previous links in the chain that an organization buys from.

Vertical Expansion: Growth by way of acquiring companies that produce goods needed by the organization, or help position and deliver its products.

Supply Chain Management Templates

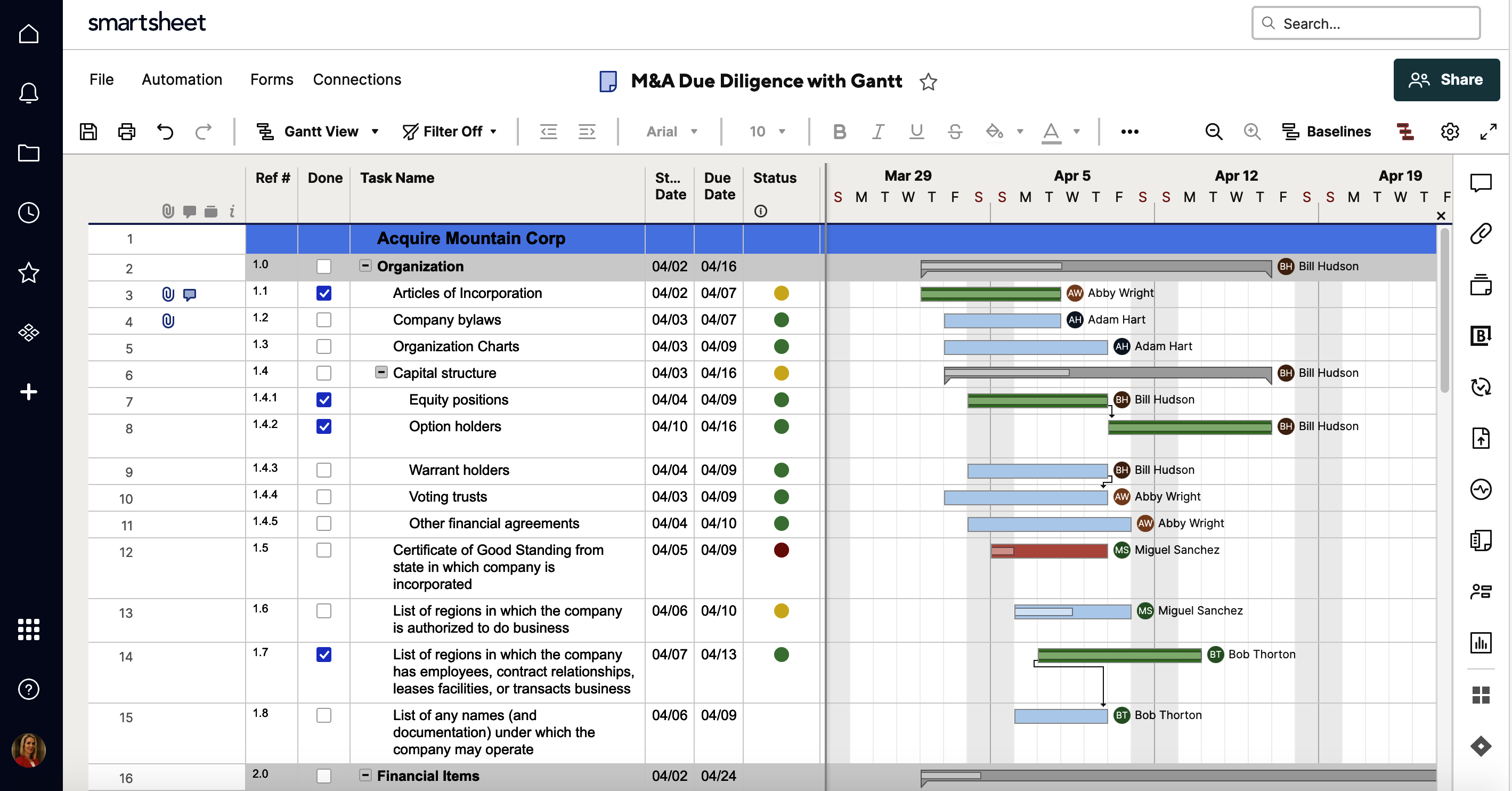

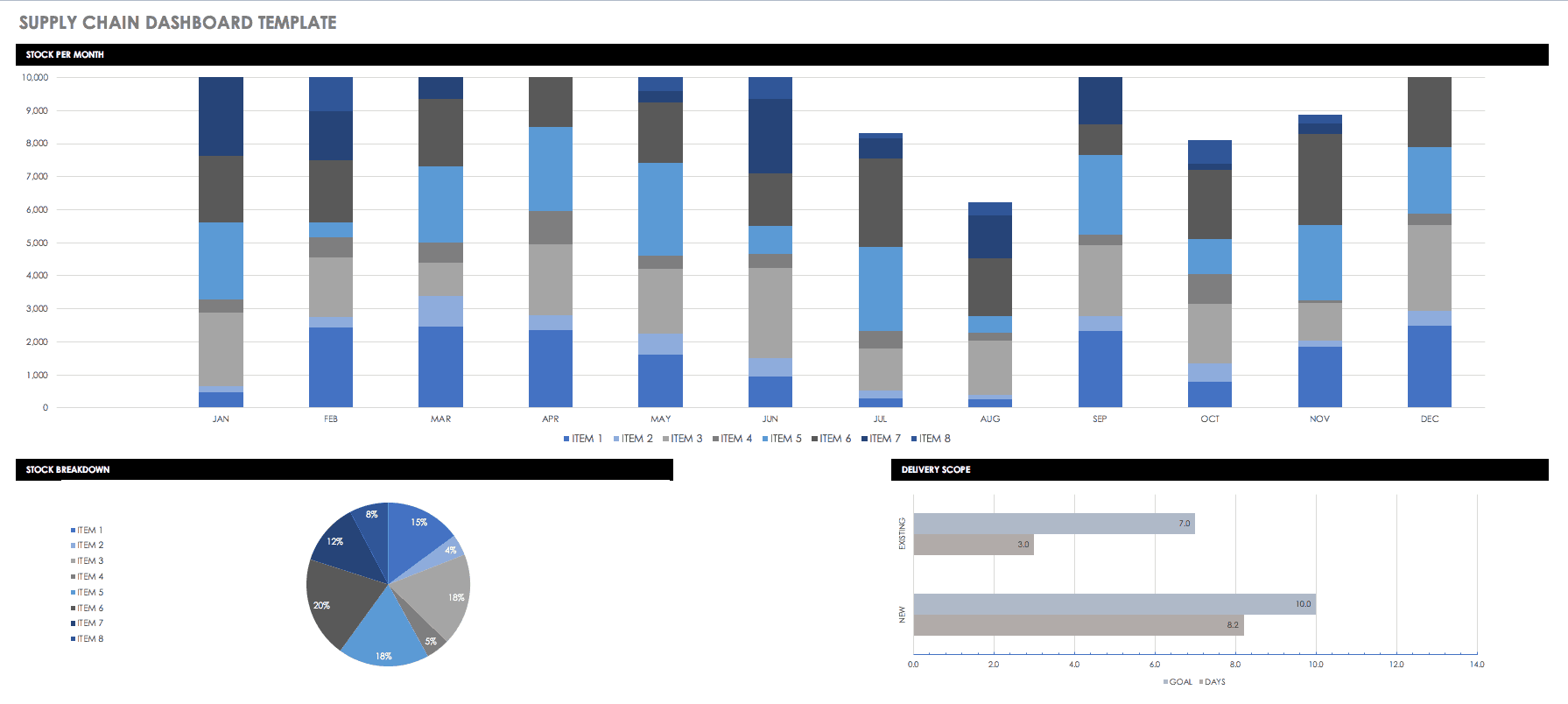

Managing expansion and supply chain integrations can be complex. However, using a template that helps you plan, track, and manage the steps and key metrics will help you get started quickly. Here are a couple templates for you to consider:

Use Merger & Acquisition Due Diligence Template

Seamlessly Manage Supply Chain Operations with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.