What Is a Supply Chain?

A supply chain is a network of suppliers, manufacturers, warehouses, and retailers that work together to create and distribute a product. Think of each step as an essential link in the chain. Every product you buy — whether a smartphone, car, or cup of coffee — relies on these interconnected supply chain links.

Today’s supply chains are often global and complex. Take a smartphone, for example. Its supply chain might begin with raw materials like lithium and cobalt mined in Africa, which are then shipped to manufacturers in China to produce batteries and screens. The parts are assembled in Vietnam, packaged in warehouses in the U.S., and finally stocked on store shelves worldwide.

Each link in the supply chain adds time, cost, and resources — whether it’s labor, materials, or transportation. Companies may have unique supply chains for each product, though many rely on the same suppliers for multiple items. Given the complexities, managing supply chains is no small feat.

What Is Supply Chain Management?

Supply chain management (SCM) is the process of optimizing each link in the supply chain while maintaining a holistic view. It involves checking and adjusting the flow between suppliers, factories, warehouses, and retailers. Strong SCM reduces costs and prevents delays in today’s global market.

Each link in the supply chain is important. A breakdown at any stage — such as supplier delays, transportation issues, or inventory shortages — can cause a business to lose money and customers. To find appropriate SCM tools, see this guide to supply chain management software.

SCM requires different approaches for different industries and business goals. Below are the six main types of supply chain management:

- Global SCM: Global SCM involves coordinating manufacturing, logistics, and distribution across nations. It must account for tariffs, trade regulations, taxes, currency imbalances, and political disputes. Managing a global supply chain becomes particularly difficult when trade wars flare up. Find relevant degrees, certifications, and books in this collection of global supply chain management educational resources.

- Lean SCM: Lean SCM focuses on cutting waste and costs and increasing efficiency. Companies using this strategy operate with low inventory, just-in-time (JIT) production, and streamlined logistics. Given the low inventory principle, supply chain delays present a key challenge for Lean SCM.

- Agile SCM: Agile SCM prioritizes flexibility and rapid response to market changes. It is especially useful for businesses with fluctuating or seasonal demand. Key approaches include smaller production runs, real-time data for quick adjustments, and multi-supplier sourcing to reduce risk.

- Digital SCM: Digital SCM leverages AI, automation, blockchain, and internet of things (IoT) to enhance supply chain visibility, forecasting, and efficiency. Key features include AI-driven demand forecasting, real-time tracking using IoT sensors, and blockchain to keep the supply chain transparent and prevent fraud.

- Vertical SCM: Vertical supply chain management focuses on owning and controlling multiple stages of the supply chain directly. Instead of relying on external suppliers, companies handle key processes themselves, such as raw materials sourcing, manufacturing components, assembly, and even retail distribution. Learn more in this guide to horizontal and vertical integration in supply chain management.

- Hybrid SCM: Businesses can use a combination of SCM types. For example, a company may use Lean SCM for predictable, high-volume products, but apply Agile SCM for trend-driven items. It also may leverage digital SCM for real-time inventory tracking and use global SCM and regional suppliers to mitigate risks.

To see these types in action, see our article on supply chain management examples.

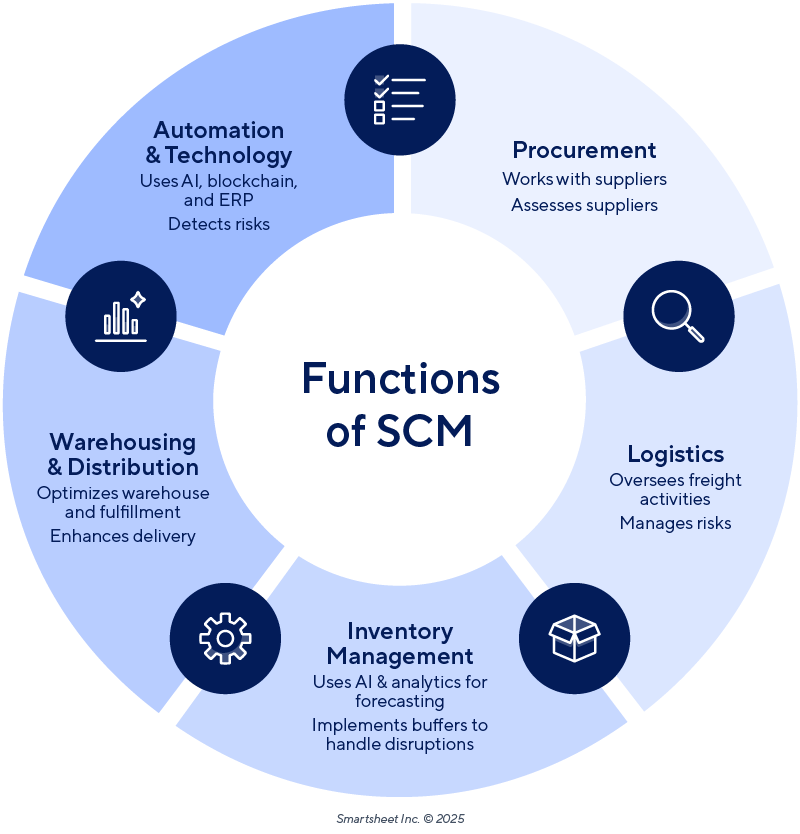

Functions of Supply Chain Management

The five main functions of supply chain management are procurement, logistics, inventory, distribution, and automation. Each plays a key role in increasing efficiency, lowering costs, and handling risks. The functions work together to optimize each link in the supply chain.

Here’s how these five SCM functions work:

- Procurement: SCM professionals work with suppliers to ensure availability, negotiate contracts, and minimize costs while maintaining quality. They also assess suppliers for reliability, including their financial health and delivery performance.

- Logistics: Managers oversee freight movement, route optimization, and regulatory compliance. When selecting carriers, they consider risks like weather, political instability, and seasonal bottlenecks.

- Inventory: Businesses use analytics and AI to anticipate demand and balance their inventory. They don’t want to be understocked or overstocked. Inventory buffers or alternate sourcing can help companies deal with unexpected disruptions.

- Warehousing and Distribution: Supply chain managers coordinate warehouse layouts, automation, and order fulfillment.

- Automation: AI, blockchain, and enterprise resource planning (ERP) systems enhance supply chain visibility and efficiency. These tools also help detect risks early, like shipment delays or inventory inconsistencies.

To carry out these functions, companies employ a range of supply chain managers and specialists, such as the following:

- Procurement Managers: Research, evaluate, and purchase large quantities of products for companies to resell or use in operations. Determine what is in the company’s store, e-commerce shops, and more.

- Business Analysts: Examine the company’s workflow and come up with ways to streamline its business processes.

- Inventory Control Administrators: Ensure that inventory systems’ data is accurate with physical inventory, troubleshoot discrepancies, discover root causes, and communicate with all relevant teams.

- Purchasing Specialists: Work out deals with suppliers and compare bids to optimize costs across the supply chain.

- Operations Analysts: Evaluate, report on, and improve the management of the organization’s core revenue-generating activities.

- Material Planning Managers: Plan, monitor, and manage products and the materials required to make them in the organization’s manufacturing operations. Ensure the constant flow of materials so the factory never runs out.

- Logistics Analysts: Evaluate and report on the transportation of goods and services up and down the organization’s supply chain, ensuring timely and accurate delivery.

How Supply Chain Managers Evaluate Supplier Relationships

Supply chain managers evaluate suppliers by looking at multiple factors. These include value for cost, capacity, leadership, company culture, financial stability, geopolitical risks, and more. A strong supplier must be reliable and scalable to fit your business needs as they change.

Here’s a closer look at how SCM professionals evaluate suppliers:

- Cost vs. Value: Price matters, but the lowest cost isn’t always the best deal. Managers assess whether a supplier provides reasonable prices while delivering high value.

- Reliability and Performance: A supplier must consistently meet delivery schedules, quality standards, and order accuracy.

- Scalability: Is the supplier able to fulfill big or fluctuating orders? A growing business needs partners that can scale.

- Financial Stability: A financially unstable supplier may not be able to fulfill long-term contracts. SCM teams review credit ratings, finances, and reputation to gauge stability.

- Compliance and Risk Management: Suppliers must follow industry regulations, sourcing policies, and sustainability requirements. This includes environmental rules, labor practices, and security risks.

- Communication and Responsiveness: Open communication is critical. Suppliers who provide regular updates, resolve problems, and collaborate on improvements add value to a relationship.

- Technology and Innovation: Forward-thinking suppliers invest in automation and data to improve efficiency. Businesses benefit from partners who embrace innovation and process improvements.

- Geopolitical and Supply Chain Risks: Suppliers in certain parts of the world may be vulnerable to trade restrictions, natural disasters, or unstable governments. Diversifying the geographic location of your suppliers helps lessen these risks.

- Cultural and Strategic Fit: Shared values and strategic aims impact long-term success. Companies want partners who align with their goals and working style.

“Finding a good supplier is becoming more complex,” says Gary Celli, a defense supply chain and SAP expert with over 20 years of experience. SAP stands for Systems, Applications, and Products in Data Processing and is a leading enterprise resource planning (ERP) platform.

“Normally, one would look at the financial security of whom you are buying from and the quality of their products, but today companies need to take into consideration other factors like labor conditions, facility security, location, and corporate ownership,” Celli says. “Companies need first determine the corporate ethical standards but also the standards of their industry. Today, companies can be impacted by a negative social media campaign if their market rejects their sourcing from a particular nation or from a company who is funded by an undesirable source.”

Supply Chain Management Starter Kit for Small and Medium Businesses

Download the Supply Chain Management Starter Kit

Use this starter kit to help implement various parts of your company’s supply chain management. This free kit includes a supply chain dashboard template, a stock inventory control template, and more.

In this starter kit, you’ll find the following:

- A glossary of SCM terminology for Adobe PDF and Word to help you learn key SCM lingo.

- A risk management matrix for Excel , Word , Adobe PDF , and Smartsheet to assess supply chain risks and remedies.

- A stock inventory control template for Excel and Smartsheet to list and track stock in your inventory.

- A supply chain dashboard template for Excel to track monthly stock levels, breakdown by items, and win/loss rates.

- A material resource planning (MRP) scorecard for Excel to compare and score competing software vendors.

- A request for proposal (RFP) vendor template for Excel to generate formatted RFPs for potential vendors.

Supply Chain Management Examples

There is no one-size-fits-all solution for supply chain management — it's about finding the right mix of technology, data, and strategy. Amazon, for example, relies on integration and automation. Walmart emphasizes JIT inventory managed by vendors. Zara uses Agile SCM, while Apple combines in-house production with diverse sourcing.

SCM Example 1: Amazon

Amazon’s supply chain is a model of speed, scale, and technological precision. Its ability to move millions of products globally while delivering orders in hours depends on a highly integrated supply chain. It blends automation, real-time data, and logistics optimization.

SCM Type: Digital and Hybrid SCM

Amazon is a digital supply chain leader, using AI, automation, and real-time data to predict demand, track shipments, and optimize inventory. While Amazon operates globally, its fundamental SCM identity is digital-first.

Amazon also uses a hybrid approach, combining Lean processes for predictable goods (essentials like paper towels) and Agile processes for fast-changing categories (fashion or seasonal products).

Details of Amazon’s Supply Chain Strategy:

- Robotic Fulfillment Centers: Amazon operates over 750,000 robots across its warehouses who assist with sorting, picking, and packing.

- AI-Driven Demand Forecasting: Amazon’s AI predicts local demand spikes and places inventory near customers ahead of time to speed up delivery.

- Drone Deliveries: Through Prime Air, Amazon is testing drone delivery for lightweight packages to reduce reliance on trucks.

- Data Integration: Amazon’s supply chain feeds real-time data into its AI systems, allowing for constant optimization of inventory and shipping routes.

SCM Example 2: Walmart

Walmart's supply chain thrives on cost efficiency and real-time supplier collaboration. By sharing data directly, Walmart keeps inventory low while ensuring shelves stay stocked.

SCM Type: Lean

Walmart focuses on keeping costs low through JIT inventory and real-time data sharing with suppliers. Its vendor-managed inventory (VMI) model, where suppliers track and replenish stock themselves, also reinforces efficiency and reduces excess inventory — key goals of Lean SCM.

Details of Walmart’s Supply Chain Strategy:

- Real-Time Supplier Portal: Walmart’s Retail Link system lets suppliers track sales and inventory directly, aligning production to real-time demand.

- Vendor-Managed Inventory: In many categories, suppliers manage their own replenishment, which keeps costs low for Walmart.

- Logistics Automation: Walmart uses autonomous forklifts and AI-powered routing software to move goods efficiently from warehouse to store.

- AI for Weather Planning: Walmart’s systems even factor in weather data to predict demand for seasonal products.

SCM Example 3: Zara

Zara built its success on an ultra-fast, responsive supply chain that can take a product from design to store in just two to three weeks. By combining regional manufacturing, real-time sales data, and AI, Zara stays ahead in the fast fashion race.

SCM Type: Agile

Zara’s fast fashion strategy makes it a textbook example of Agile SCM. It performs quick shifts in production based on real-time trends, smaller batch sizes, and rapid delivery. Its ability to design, manufacture, and deliver new styles in weeks — not months — relies heavily on supply chain agility.

Details of Zara’s Supply Chain Strategy:

- Nearshoring Production: Manufacturing close to headquarters allows for rapid design updates and faster delivery to European stores.

- AI-Powered Trend Analysis: Zara’s systems monitor social media, sales, and web searches to detect fashion trends in real time.

- Data-Driven Inventory Management: Zara tracks sales across all stores daily and uses AI to automatically adjust production and shipments.

- Real-Time Supply Chain Monitoring: AI detects anomalies and potential bottlenecks before they disrupt inventory flow.

SCM Example 4: Apple

Apple’s supply chain is a carefully balanced mix of global supplier relationships and in-house control over critical technologies. Apple can quickly innovate while maintaining quality and mitigating risks.

SCM Type: Hybrid and Vertical

Apple mixes global sourcing for low-cost, easily sourced parts (i.e., basic electronic components) with vertical integration for high-value, high-risk components (i.e., chips and displays). This combination of global reach, tight internal control, and ethical-based sourcing makes Apple a hybrid SCM player with vertical integration at key points.

Details of Apple’s Supply Chain Strategy:

- In-House Component Design: Apple designs its own chips, which gives it control over product performance and supply chain flexibility.

- Supplier Diversification: Apple works with hundreds of suppliers across regions to avoid depending too much on any one country.

- Ethics and Transparency: Apple employs blockchain to be aware of materials (i.e., conflict minerals) and publishes annual supplier responsibility reports.

- AI-Enhanced Forecasting: Apple uses AI to forecast demand throughout its chain.

SCM Example 5: Tesla

Tesla takes vertical integration to the extreme, controlling much of its own supply chain. This accelerates innovation and gives the company more control over costs, but requires major capital investment.

SCM Type: Vertical and Digital

Tesla leans heavily on vertical integration and controls stages like battery production and software development in-house. It also uses digital tools like AI-driven production monitoring and digital twins to improve manufacturing efficiency. Tesla’s model is rare today because few companies are willing to invest this much in owning their supply chain outright.

Details of Tesla’s Supply Chain Strategy:

- In-House Battery Production: Tesla produces batteries at gigafactories, securing its critical powertrain component.

- Direct Sourcing of Raw Materials: Tesla negotiates directly with lithium and nickel mines, which reduces their dependence on third-party suppliers.

- AI-Powered Production: Tesla’s factories rely on AI to adjust production in real time, identifying defects before they spread.

- Digital Twins: Tesla uses simulations to test and refine adjustments before implementing them.

SCM Example 6: Starbucks

Starbucks built its supply chain not just to deliver high-quality coffee, but also to strengthen farm communities and sustainability.

SCM Type: Global and Hybrid

Starbucks’ global sourcing and worldwide distribution clearly fit the global SCM model. It also uses hybrid SCM by combining direct farmer partnerships — a more vertically integrated practice — with global logistics and blockchain.

Details of Starbucks’ Supply Chain Strategy:

- Direct Farmer Partnerships: Starbucks works directly with more than 400,000 farmers, aiming for fair prices and responsible practices.

- C.A.F.E. Practices: Its Coffee and Farmer Equity (C.A.F.E.) program sets ethical and environmental sourcing standards.

- Transparency: Starbucks uses blockchain to trace coffee beans from farm to stores, giving customers full transparency.

- Climate Adaptation Training: Starbucks invests in farmer education on climate-resilient techniques, like drought-resistant crops and soil conservation.

What These SCM Examples Teach Us

These companies prove that supply chain management can be a competitive advantage. From Amazon’s predictive automation to Starbucks’ sourcing, today’s leaders show that strong supply chains are agile, data-driven, and built to withstand global disruptions.

Businesses that want to future-proof their supply chains emulate these examples by doing the following:

- Moving into AI, automation, and real-time data visibility

- Diversifying suppliers to reduce geopolitical risk

- Building ethical and climate-resilient sourcing programs

Treating supply chain strategy as a core part of business strategy

Supply Chain Management Example Comparison Company

SCM Types Used

Key Technologies

Sourcing Approach

Risk Management Focus

Amazon Digital + Hybrid AI, automation, robotics, drones, real-time data Global sourcing, regional inventory positioning Predictive analytics to prevent stockouts and optimize routes Walmart Lean Real-time supplier portal, autonomous forklifts, weather-linked demand AI Supplier-managed inventory Strong supplier relationships, minimal inventory risk through VMI Zara Agile AI-powered trend detection, real-time inventory adjustments Regional sourcing, fast design-to-production cycles Constant sales monitoring, rapid response to supply disruptions Apple Hybrid + Vertical AI forecasting, blockchain for traceability, proprietary ERP systems Direct control over critical components (chips), global suppliers for others Ethical sourcing standards, supplier diversification to avoid concentration risk Tesla Vertical + Digital AI-driven production, digital twins, direct supplier deals Owns key production, direct raw material sourcing Internal oversight, reduced reliance on third parties Starbucks Global + Hybrid Blockchain for traceability, climate adaptation training Direct farmer relationships, global logistics Climate risk management, ethical sourcing verification

Steps in Supply Chain Management

Supply chain management follows a series of steps to produce and deliver products efficiently. The first SCM steps involve sourcing and procuring the materials you need, followed by inventory management and logistics to coordinate the flow of goods. The final steps are distribution and reverse logistics for returns.

Here’s a closer look at the steps in supply chain management:

- Sourcing Raw Materials: Companies identify and obtain the materials they need for production. This could mean mining metals, harvesting crops, or acquiring pre-manufactured components.

- Procurement: Businesses buy materials, negotiate contracts, and score suppliers on cost, quality, and risk factors.

- Inventory Management: Businesses store materials and finished products in warehouses or distribution centers to ensure they are available when needed.

- Logistics: Companies transport goods between suppliers, manufacturers, warehouses, and customers through freight, trucking, rail, or air shipping.

- Distribution: Products are delivered to retailers or directly to consumers through supply networks, including e-commerce fulfillment and physical stores.

- Reverse Logistics: Companies handle product returns, repairs, recycling, or disposal of defective goods.

Principles of Good Supply Chain Strategy

Modern supply chain principles emphasize flexibility, data-driven decisions, ethical sourcing, and resilience. Companies must balance cost with sustainability, use real-time data to manage risks, and design supply chains that can adapt quickly to disruptions, new technologies, and shifting customer needs.

These SCM principles build on the landmark 1997 Supply Chain Management Review article “The 7 Principles of Supply Chain Management,” which focused heavily on cost efficiency and segmentation. Today’s best practices have evolved to reflect the realities of global disruption, technological advancements, and growing demand for sustainability.

Here are the updated principles of supply chain management:

- Flexibility Comes First: Static supply chains are vulnerable. Adaptable supply chains can shift sourcing, logistics, and inventory strategies when disruptions strike.

- Data Powers Every Decision: Companies use real-time data, not just historical reports, to anticipate demand and track every link in the chain.

- Sustainability Is Part of the Bottom Line: Ethical sourcing, carbon reduction, and circular supply chains are no longer optional; they’re part of brand value and regulatory compliance.

- Resilience Requires Diversity: Multi-supplier strategies — that are, in some cases, globally distributed — reduce dependence on any one country or vendor, protecting against geopolitical or climate risk.

- Technology Is Vital: AI, IoT, and blockchain improve visibility, reduce waste, and help companies act faster when conditions change.

- End-to-End Transparency Is Essential: From raw materials to final delivery, companies must know where everything is, who touched it, and how it was handled.

Performance Means More Than Cost: Supply chain KPIs now measure carbon footprint, ethical labor practices, and supplier compliance, alongside traditional cost and delivery metrics.

7 Principles of Supply Chain Management — Updated for Today Original 7 Principles Updated Adapt to customer segments. Build adaptable, customer-driven supply chains that can shift rapidly when demand changes. Agility matters more than static segmentation. Customize logistics for each segment. Design flexible logistics networks that can handle regional disruptions and sustainability requirements. Align demand planning. Leverage real-time data and predictive analytics to synchronize demand and supply. Differentiate products closer to the customer. Localize manufacturing or customization when possible to cut lead times and reduce carbon footprints. Outsource strategically. Diversify supplier networks to balance cost, resilience, and ethical sourcing. Develop IT for decision-making. Invest in AI, IoT, and blockchain to enable real-time, data-driven decisions across the whole supply chain. Adopt service and financial metrics. Expand metrics to include environmental, social, and governance factors (ESG), alongside cost and service performance.

Current Issues in SCM

Current issues in supply chain management include geopolitical tensions, labor shortages, resource scarcity, and increasing cybersecurity threats. Companies also face challenges related to sustainability, regulatory complexity, and logistics delays. Adopting new technologies like AI and blockchain adds pressure to modernize and secure global supply networks.

Here’s a closer look at today’s challenges in supply chain management:

- Diversified Sourcing: A diversification strategy, however, comes with increased costs, regulatory hurdles, and the challenge of establishing reliable new supplier networks.

“Covid exposed our supply chains to unseen vulnerabilities and brought to light our international exposure to key items,” says Celli. “This caused many companies to reexamine their supply chains to reduce dependency on a single source of supply.” - AI and Technology: The fast adoption of artificial intelligence (AI), automation, and blockchain is transforming supply chains, but these technologies can also introduce complexities, requiring significant investment in talent and data management to integrate into existing systems.

- Supply Chain Security: Cyber threats and data breaches have become major concerns as supply chains become more digitized. Hackers increasingly target logistics systems, inventory management platforms, and supplier databases to disrupt operations or steal sensitive information. Companies must invest in cybersecurity measures such as multi-factor authentication, encrypted communications, and AI-driven threat detection to safeguard their supply chain networks.

“Supply chain security has become a growing challenge to many companies,” says Celli, who works a lot with government and defense organizations. “Knockoff brands have been around for decades, but the level of counterfeit items has grown to include product components. For example, the high cost and high demand for microchips has led to the introduction of counterfeit chips. These chips have often been taken off retired products or are from an older generation, leading to a high degree of failures. For the defense industry, these counterfeit chips may also contain malicious code, resulting in a national threat.”

Celli adds that in-transit security is also becoming a challenge. “Many ports lack the security to ensure that products are not stolen or altered,” he says. “Often, counterfeit products are altered while in transit. This is why we are reading more and more about port management and piracy. While we think of piracy as an 18th-century issue, it is alive and well today in many parts of the world. This has resulted not only in stolen products, but also in higher insurance and shipping costs.” - Defense Supply Chains: The defense industry faces heightened risks due to its reliance on highly specialized suppliers and classified components. Disruptions in the supply chain can delay critical defense projects. Additionally, strict regulatory requirements, such as the U.S. Department of Defense’s Cybersecurity Maturity Model Certification (CMMC) framework — demand rigorous security measures to prevent espionage and unauthorized access to sensitive military technology.

“Defense supply chains face an even higher level of scrutiny due to the nature of their products, but also the impact of supply disruption due to a conflict,” Celli notes. “As military equipment has become more technical in nature, the sourcing of the components becomes more critical. Just as in commercial supply chains, defense products are subject to the introduction of counterfeit or malicious products. In-transit visibility becomes a classified issue.”

Celli also notes the high stakes involved. “There have been attempts by adversaries to try to alter the shipping destination, or at least gain insight into the final destination as a source of intelligence of future plans,” he says. “For these reasons, the systems that are used to manage a defense supply chain are highly classified systems.” - Regulatory Complexity: New standards and certifications keep coming out to help regulate data security, quality management, and other supply chain concerns. Supply chain managers are dealing with new standards such as the CMMC for defense contractors and the Trusted Information Security Assessment Exchange (TISAX) for the automotive supply chain.

- Location of New Facilities: Companies looking to expand must carefully consider where to build new warehouses, distribution centers, and manufacturing plants. Factors like proximity to customers, labor availability, tax incentives, and infrastructure all play a role. Companies navigate a mix of regulatory approvals, community negotiations, and alternative site strategies.

Many businesses regularly encounter the NIMBY (“not in my back yard”) movement, says John H. Boyd (Jack), Founder and Principal of the Boyd Company, which helps clients with warehouse site selection.

“The continued boom in e-commerce since the pandemic has helped to fuel these conflicts, pitting the benefits of new tax revenues for local schools and new jobs that warehouse facilities provide against local concerns over lifestyle changes, truck traffic, stormwater runoff, and other issues,” Boyd says. “We have seen the impact of these conflicts on site selection decisions range from our clients walking away from a community to some kind of middle-ground compromise.” - Accurate Inventory Tracking: Keeping track of inventory is more than just counting stock — it’s about ensuring real-time accuracy across complex supply networks.

“Discrepancies between system records and actual stock levels cause major disruptions, especially when incorrect inventory data leads to missed shipments or unfulfilled customer commitments,” says Wenting Zhang, Sales Operations Specialist for Hankook Tire China Co., a global tire manufacturer. Zhang’s role involves inventory management, purchase orders, supply chain reports, and maritime shipping.

“Even with internal process optimizations,” Zhang adds, “challenges persist when suppliers or factories have inconsistent inventory management practices, leading to stock mismatches and last-minute changes.” - Logistics Delays: Despite advances in shipping and fulfillment technology, logistics delays remain a persistent challenge. Port congestion, trucking shortages, customs slowdowns, and geopolitical disruptions can all lead to longer delivery times and higher costs.

“Limited shipping slots, lengthy documentation processes, and unexpected delays create inefficiencies,” Zhang says. “Customers expect faster deliveries, but external factors, such as freight availability and customs procedures, often limit flexibility.”

Also, logistics plays a more strategic role than simply moving goods from point A to point B, according to a 2023 study for Open Journal of Business and Management titled “Supply Chain Management and Logistics: How Important Interconnection Is for Business Success.” Logistics also acts as the connective tissue that keeps supply chains running efficiently, from sourcing raw materials to final delivery.

As the authors of this study put it: “Supply chain management emphasizes the connection between parts of a business coordinating activities across the supply chain and the importance of efficient logistics. Therefore by tackling the intricacies of integration and fostering collaboration among supply chain partners, companies can enhance their performance in supply chain management.” - Resource Scarcity: Global supply chains are under pressure due to limited access to key raw materials such as semiconductors, lithium, rare earth metals, and agricultural products. Climate change and increased demand for critical minerals can exacerbate shortages. Companies are responding by diversifying their sourcing and exploring alternative strategies.

- Sustainability: Consumers, investors, and regulators are starting to demand greener supply chains with smaller carbon footprints and more responsible sourcing. Companies must comply with sustainability regulations such as the EU’s Corporate Sustainability Reporting Directive (CSRD). Retail giants like Walmart and IKEA are also investing more in renewable energy-powered supply chains.

- Ethical Issues: Governments, consumer advocacy groups, and watchdog organizations are scrutinizing supply chains for human rights violations, labor exploitation, and environmental harm. Common concerns include child labor, unsafe working conditions, and misleading sustainability claims. Forced labor remains a significant issue in industries like textiles, mining, and agriculture. Companies are responding by improving transparency, conducting third-party audits, and using blockchain for supply chain traceability.

- Labor Shortages: The United States is experiencing significant labor shortages in manufacturing and warehousing. A 2024 Deloitte study estimates that nearly 1.9 million manufacturing jobs could remain unfilled by 2033, prompting companies like Boeing to launch aggressive programs to attract skilled workers. A 2024 Descartes survey of 1,000 supply chain and logistics leaders in North America and Europe found that 37 percent were experiencing high workforce shortages, leading some to invest more in robotics and automation.

Find more solutions to today’s issues in this collection of supply chain risk assessment and risk management plan templates.

The Future of Supply Chain Management

The future of supply chain management is rapidly becoming more autonomous, driven by advances in AI, robotics, and real-time data. Self-driving trucks, automated warehouses, and AI-powered forecasting are becoming more common. At the same time, companies are shifting toward more regional supply hubs.

Autonomous Supply Chains

In the next decade, supply chains are expected to become mostly autonomous, as companies leverage technologies like generative AI, autonomous vehicles, advanced robotics, and collaborative tools. These innovations will enhance coordination, decision-making, and responsiveness across the supply chain. For instance, self-driving trucks and warehouse robotics will revolutionize logistics and inventory management.

Boyd is already seeing the acceleration of robotics with his clients in the warehousing industry. “AMRs and robotic picking systems, powered by AI, are increasingly being deployed by our warehousing clients to handle tasks like sorting, picking, packing, and transporting,” he says. “AMRs are drastically improving warehouse efficiencies along with enhancing worker safety. Amazon Robotics, formerly Kiva Systems, is a leading force in the AMR sector and has set the bar high for other retailers like Walmart, Costco, and Target to adopt similar technologies.”

According to a 2021 study titled “Artificial intelligence in operations management and supply chain management: an exploratory case study” in Production Planning & Control, the role of artificial intelligence (AI) is expected to expand significantly in the coming years. AI technologies have already demonstrated their ability to enhance visibility, automate decision-making, and optimize processes across the supply chain.

The authors of this study write, “By means of integration with AI, supply chain management is becoming autonomous [supply chain] with the characteristics of being self-aware, self-governing and self-determining, and self-optimizing.”

Intelligent Systems

The integration of AI, machine learning, IoT, and blockchain is leading to the development of intelligent supply chain systems. These technologies enable real-time data analysis, predictive analytics, and enhanced transparency, which allow companies to anticipate disruptions, optimize operations, and respond swiftly to market changes.

“I believe that the future of supply chain will be one of continuous modernization with the introduction or expansion of new technologies,” Celli says. “Blockchain has the ability to become a significant disrupter to the management of supply chains. The ability to place a token on a supply chain transaction will allow supply chain managers to have greater visibility into their supply chain from sourcing to final distribution. This visibility will ensure a higher degree of security and auditability.”

Zhang of Hankook Tires adds: “I believe AI and automation will be key. AI-powered forecasting, real-time tracking, and automated decision-making will improve accuracy and responsiveness, enabling companies to manage complexities more effectively.”

Regionalization

The future of supply chains will see increased regionalization. Rather than fully reshoring or abandoning established sourcing regions, companies will increasingly develop flexible, regional supply hubs.

According to the 2023 study "Restructuring Global Supply Chains: Navigating Challenges of the COVID-19 Pandemic and Beyond,” supply chains will continue to shift sourcing from heavily concentrated locations to multiple, lower-risk regions. In the future, expect a steady rise in sourcing from alternative locations such as Vietnam, India, and nearshore markets like Mexico and Canada.

The authors of this study write, “Companies should consider moving beyond mitigating firm-level supplier risks to actively addressing and mitigating country-level location risks. While traditional risk management strategies typically concentrate on the potential failure of individual suppliers, such as bankruptcy, the risks stemming from the COVID-19 pandemic are linked to government interventions at the country level and viability of cross-border trade connections.”

Talent and Workforce Transformation

As automation and AI grow, supply chain management jobs are evolving. Companies must invest in upskilling their workforce, focusing on AI, technology, data analysis, and automation management to stay competitive.

In his 2023 book, The Magic Conveyor Belt: Supply Chains, AI, and the Future of Work, author Yossi Sheffi explores how AI and automation are changing jobs in supply chain management. Sheffi, Director of the MIT Center for Transportation and Logistics, argues that while some jobs will disappear, technology will mostly enhance human roles and create new opportunities. He highlights the importance of human skills like problem-solving and collaboration, which machines can’t replace.

In an interview for Alcott Global, Sheffi reflects on the broader historical context of technological change: “In the book, I tried to look at all the industrial revolutions and what happened,” he says. “And in every one of them, a few jobs were lost and many jobs changed. But mostly a lot more jobs were created than lost.”

History of Supply Chain Management

The concept of supply chain management has existed far longer than the term itself. For centuries, merchants have moved goods from suppliers to makers to customers. Examples include ancient trade routes, colonial shipping lines, and early factories.

The actual phrase supply chain management started to gain traction in the early 1980s and is often credited to Keith Oliver, a consultant at Booz Allen Hamilton. In a 1982 interview with Financial Times, Oliver used the term to describe a new, integrated approach to managing suppliers, manufacturers, warehouses, and retailers as a single system. While some experts debate whether Oliver truly coined the term, the concept itself was already evolving as companies sought ways to reduce costs, speed up production, and gain competitive advantage in increasingly global markets.

Here are major milestones in the history of supply chain management:

- Pre-1900: Trade Empires and Early Logistics: Long before anyone used the term supply chains, people were already building them. Ancient traders moved goods across the Silk Road and the shipping routes of the East India Company. These early supply chains were global, even given the early technology of those long-ago times. Later, the steam engine, railroads, and the telegraph made it easier and faster to move products across long distances.

- 1900-1940s: Factories and Mass Production: The Industrial Revolution changed how supply chains worked. Factories produced large amounts of goods, so companies had to manage materials, production, and deliveries on a bigger scale. In 1913, Henry Ford’s assembly line showed how coordinating every step — from raw materials to final product — could save time and money.

- 1950s-1970s: Logistics Becomes Its Own Job: After World War II, companies started treating logistics — moving and storing goods — as a separate, important business function. In the 1970s, Toyota’s Just-in-Time (JIT) system became famous. It showed that if you could perfectly time deliveries from suppliers, you didn’t need to keep as much inventory. But if any supplier failed, production could stop completely.

- 1980s-1990s: Global Supply Chains and Digital Tech: During the 1980s and 1990s, global trade deals made it easier for companies to work with suppliers in other countries. Instead of making everything themselves, companies outsourced production to cheaper suppliers overseas. At the same time, companies started using barcodes, electronic data interchange (EDI), and ERP software to track inventory and shipments across their growing supply chains.

- 2000s-2010s: Digital Supply Chains and Risk Management: The Internet changed supply chains again, letting companies work with suppliers in real time. Technologies like radio frequency identification RFID made it easy to track shipments from factory to store. After major shocks like 9/11, companies realized they needed better risk management plans in case their supply chains were disrupted.

- 2020s and Beyond: Modern Supply Chains Under Pressure: The COVID-19 pandemic showed how fragile global supply chains could be. Suddenly, companies couldn’t get critical materials, and products were delayed everywhere. In response, companies started rethinking their supply chains. Many began using more suppliers, storing extra inventory, and moving production closer to home. Companies now face new rules for sustainability reporting, ethical sourcing, and cybersecurity standards like CMMC and TISAX. Today’s supply chain managers rely on AI, blockchain, and predictive analytics to see problems before they happen and react faster when they do.

Optimize Your Supply Chain Management With Smartsheet for Work Management

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.