What Is Lean Six Sigma?

Lean Six Sigma is a methodology concerned with reducing variation and detecting defects, and also with preventing defects. It marries the Lean management principles of improving efficiency and eliminating waste with the data-driven, statistical approach of Six Sigma to find defects and improv processes. Formalized in the 1980s for use in manufacturing, Six Sigma leverages quality improvement methods from the previous 60 years, including Total Quality Management. In the early 2000s, Lean was added to Six Sigma to form Lean Six Sigma. This new approach is now used worldwide in industries such as manufacturing, finance, healthcare, IT, and the military.

Six Sigma greatly refines processes, producing only 3.4 defects per million (DPMO). There are seven sigma levels that denote levels of quality. Note that not every product or business requires a Six Sigma level of quality, while some products (such as semiconductors) require a much higher sigma level.

The power of Six Sigma lies in its ability to create a repeatable method, and facilitate statistics and analysis to define and determine the source of problems. (In Six Sigma, problems are called defects.) The statistical foundation eliminates guesswork and enables real insights into whether or not a solution is effective.

Lean management strives for continuous improvement through understanding customer needs and streamlining processes, reducing costs, and improving quality. Lean is based on the methods developed by Taiichi Ohno at Toyota, who articulated the 7 Wastes, or uses of time and materials which do not add value to a process.

Jennifer Williams, a Lean Master Black Belt and President and CEO of Integrity Business Consulting, describes the methods. “When we talk about Six Sigma, it’s all about reducing variation,” she says. “So the Lean part is doing things faster, but Six Sigma is doing things right.”

The Central Tenets of Lean Six Sigma

You can sum up the history and theory of Lean Six Sigma with a handful of principles:

- Pay attention to customer requirements.

- Understand the value stream (the steps that create the deliverable).

- Continue to improve that value stream.

- Eliminate waste and activities that don’t add value. The simple process is the best.

- Reduce variation.

- Decide based on data, not on guesses.

- Include employees in improvement efforts and give them the tools to find solutions.

Project Management Guide

Your one-stop shop for everything project management

Ready to get more out of your project management efforts? Visit our comprehensive project management guide for tips, best practices, and free resources to manage your work more effectively.

History of Lean Six Sigma

Six Sigma has its roots in statistical process control in the early 20th century. It takes its name from the term for a standard deviation, a sigma. The level six sigma was chosen as a quality goal at Motorola in the 1980s. Soon after, Motorola formalized methodologies around manufacturing quality goals, and also realized that advantages derived from the methods could be applied throughout the company. Six Sigma practices soon spread to other companies, acquiring a reputation as a significant cost saver.

Lean management traces its roots back to the Toyota Production System (TPS) and Just in Time (JIT) production. The methodology was developed in Japan after World War II, in large part under the guidance of American statistician and management consultant William Deming. TPS and JIT focus on the role inventory plays in waste or efficiency in manufacturing.

The 2001 book Leaning into Six Sigma: The Path to Integration of Lean Enterprise and Six Sigma by Barbara Wheat, Chuck Mills, Mike Carnell, is credited with first broaching the idea of combining the two methodologies. Due to its power, Lean Six Sigma is currently used more often than Six Sigma itself.

What Are the Benefits of Lean Six Sigma?

Six Sigma began in manufacturing, but it soon became obvious that the method could provide value beyond the production floor. With the addition of Lean principles, Lean Six Sigma became a universal methodology for not only manufacturing, but for service and transactional industries as well.

“If companies are successful, chances are they are implementing Lean, more than their competitors,” asserts Sermin Vanderbilt, Founder of Lean and Six Sigma World Conference and President of the American Quality Institute. Vanderbilt provides the example of the work Steve Jobs performed when he was rehired by Apple. “He went through the inventory and found they were keeping a huge inventory for at least a month. He calculated the costs and figured, we need to cut this down to two days of storage. By doing so, they had an implementation of Lean.”

Benefits of Lean Six Sigma for Companies

- Data-driven decision making that allows you to see how the numbers change to show improvement or lack thereof.

- Improved processes.

- Increased capacity throughout company.

- Increased revenues.

- Reduced costs due to fewer defects.

- Saved materials, time, and money.

- Continuous improvement throughout the company.

The following are examples of what results might look like in different industries:

- More drinking mugs produced without chips or cracks

- More car loans processed in a bank

- More patients seen by a health nurse per day

- More plates of food cooked and served in a restaurant (the result of an efficient workflow and layout in an industrial kitchen)

Benefits of Lean Six Sigma for Individuals

- A new, clear way of approaching problems.

- Career advancement for certified Lean Six Sigma Belt holders. As Williams explains, “Six Sigma helps in a career, especially if you’re going into a managerial position, or even for an individual contributor who’s empowered to make suggestions or present ideas on improvement. It helps put the data behind it.”

- Higher pay for Lean Six Sigma Belt holders.

- A sense of ownership and responsibility for project success and quality in deliverables.

- Improved quality of work and the work environment, regardless of employee role.

Below is a partial list of the types of jobs that can benefit from Lean Six Sigma practices:

- Accountants

- Payroll clerks

- IT technicians

- HR professionals

- Customer service reps

- Solutions engineers

- Workflow engineers

Here’s What Industry Experts Have to Say About the Benefits of Lean Six Sigma

Sermin Vanderbilt, Founder of Lean and Six Sigma World Conference and President of the American Quality Institute, offers his insight: “One of the misconceptions, especially in Silicon Valley, is that you need a program labelled as Lean Six Sigma. In my opinion, you can have a Lean and Six Sigma program conceptually, [but] you don’t have to name it Lean and Six Sigma. Any time a company needs to cut down on costs or extra steps, in any process, they are implementing the principles of Lean and Six Sigma.”

What Makes Lean Six Sigma Unique?

Lean Six Sigma draws its power from using tools in a framework that identifies customer needs and problems in production. Lean management approaches quality and profit from the perspective of reducing waste; Six Sigma seeks to improve quality and the bottom line by eliminating variation. If you can reduce a process to its most meaningful and successful components, the process should be repeatable, regardless of the people involved.

The focus on defined methods and numbers make Six Sigma different from Total Quality Management (TQM), which provides tools to find the cause of problems and create solutions. However, TQM does not provide a systematic way to measure whether the causes identified are the correct ones, and whether the solution is effective. It essentially leaves it to the customers to indicate whether changes were successful.

Kaizen is an approach that also focuses on continuous improvement. You’ll find Kaizen’s influence in Lean, Six Sigma, and TQM.

It’s important not to focus on the name and the tool, but rather on how to solve problems. As Vanderbilt advises, “It’s not even necessary to label your improvement program as Lean Six Sigma. The important thing is to reduce variation and waste.”

How Do You Execute Lean Six Sigma?

Common wisdom holds that you start with Lean to streamline and reduce waste, and then fine-tune the process by adding in Six Sigma.

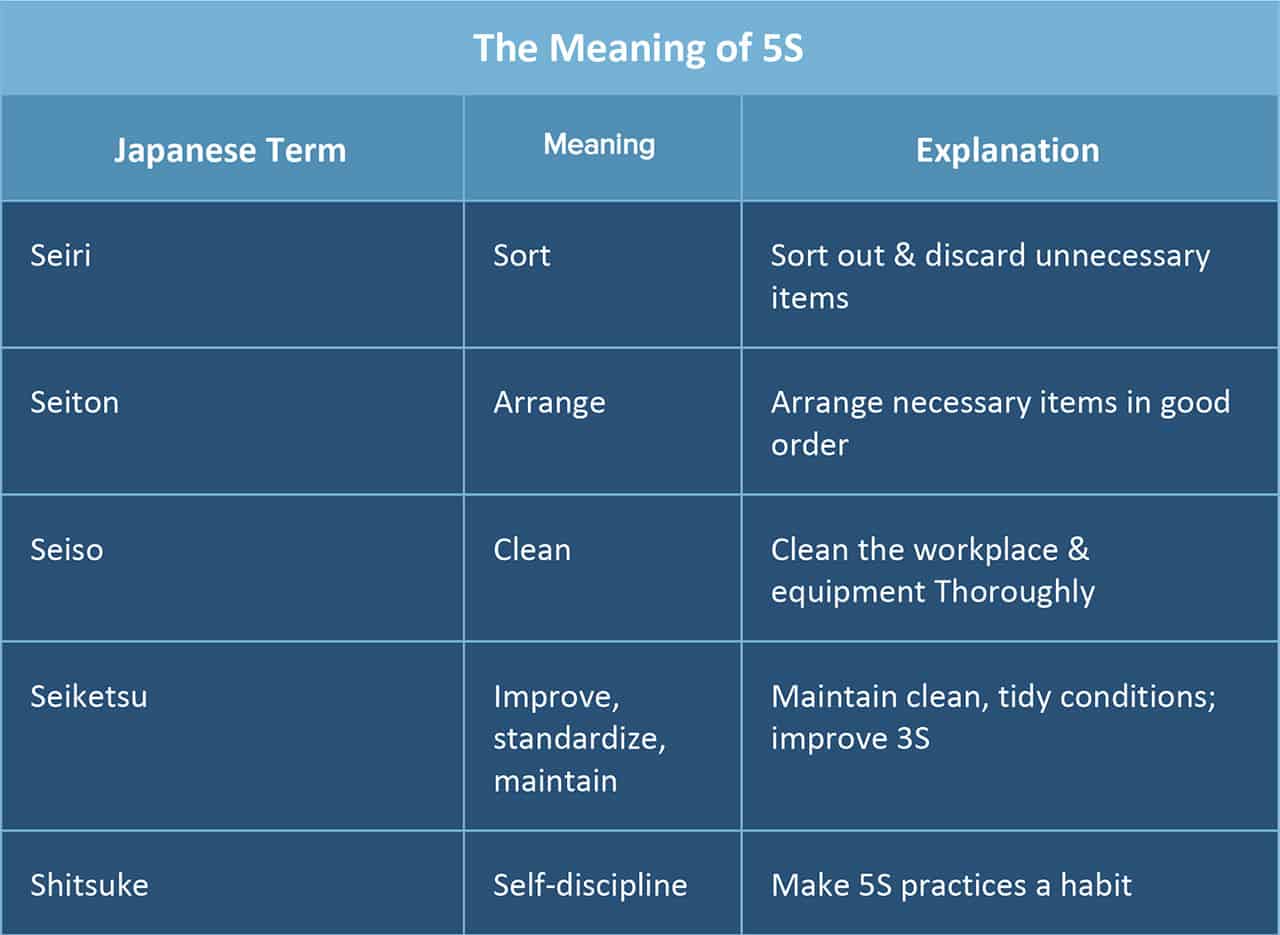

The 5 S’s

Source: Teian Consulting International, Singapore.

You can start promoting Lean culture through a practice such as the 5S’s. In Japanese, the S’s stand for Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. In English, the S’s roughly translate to:

- Sort: Clear the workplace of unnecessary items (things that take up space, present hazards, or clutter).

- Set in Order: Organize the work area so you can easily find, use, and replace things. This concept applies to your desk as well as to the production floor.

- Shine: Like your mother always told you, keep things neat, tidy, and clean.

- Standardize: Make tasks and procedures repeatable. Find the most efficient way to do things and always do it that way.

- Sustain or Self Discipline: Turn the good practices into habits.

Beware the 7 Wastes

The 7 muda (or 7 wastes) were articulated by Taiichi Ohno at Toyota. Waste is defined as anything that doesn’t add value, including actual waste and inefficiencies. The 7 Wastes are what the Lean practice of Lean Six Sigma seeks to avoid. Various mnemonics exist to help you remember the seven wastes. Here we use TIMWOOD:

- Transportation: Moving material or product doesn’t actually add value, but the customer pays for it.

- Inventory: Until the product is sold, it is inventory, and therefore of no direct value. Raw material or an unfinished piece is also inventory. These products may need to be transported, or stored in a warehouse that must be heated or refrigerated, and secured. It is a loss if the inventory is stolen, so it’s imperative to reduce sitting inventory whenever possible.

- Motion: When tools at a workbench or in a kitchen are not organized well, motion is wasted through inefficient movements. Excessive or indirect movement of supplies to work benches and of finished items to a storeroom also wastes motion.

- Waiting: Waiting (for materials from a supplier, for answers to questions from management, etc.) wastes time, and therefore, money.

- Over Processing: This occurs when using the wrong processes or machines for a deliverable. Generally, over processing refers to using equipment much more elaborate than the job warrants. Examples of over processing include launching a CMS to fix an HTML error that would take five seconds to fix in text format, or warming an electric oven for a single-portion casserole.

- Overproduction: Considered the worst waste of all, overproduction is making too much or producing while there is still inventory on hand. Overproduction calls for implementing Just in Time (JIT). You can prevent some timing issues through Takt time, a Lean formula which calculates the rate at which a product must be finished to satisfy customer demand.

- Defects: If caught early, defects result in rework. However, if a defect is caught late in the production cycle - at worst, by a customer - it can result in returns and refunds. One of the Lean tools used to avoid defects is poka yoke.

Lean Six Sigma Analysis Tools

Lean Six Sigma borrows many tools from Lean management. The following are some of the key devices for creating happy and efficient business.

- Kaizen: Most well-known, Kaizen is broadly interpreted as the philosophy of continuous improvement. The ultimate goal may be higher quality products and more money, but achieving that goal is accomplished through empowering everyone throughout an organization, from CEO to janitor. Every employee is taught to recognize waste and how to use analytical methods to find solutions. Kaizen events are improvement efforts that involve a small team who spends a short time (usually about a week) brainstorming solutions and improvements, which they then present to the rest of the company. The solutions are periodically reviewed to ensure that they continue to benefit the team. As part of continual improvement, Kaizen events should be regular events.

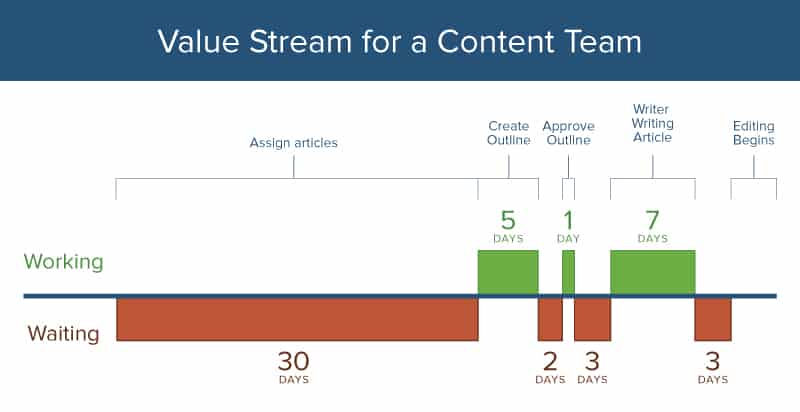

- Value Stream Mapping: Like a process flow, creating a value stream map helps to record and analyze the flow of materials or information used to create a product. Sometimes a value stream map is used with 5 Whys questioning to help filter the flow to its essential steps.

- 5 Whys: An iterative information gathering process that groups use to discover root causes. First, ask why a problem is occurring, then verify that the answer is fact and not belief, and then continue to ask why to each successive answer.

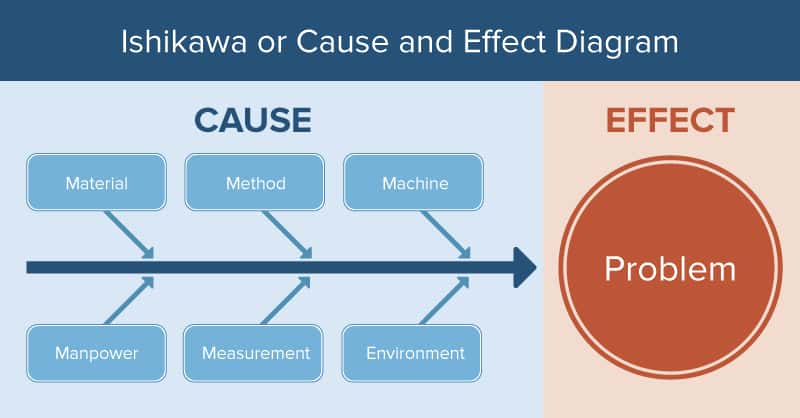

- Ishikawa Diagram: Developed by Professor Kaoru Ishikawa, it is also called a Fishbone diagram or a CE diagram for cause and effect. An Ishikawa diagram is used in group discussions to visualize all the different contributing factors in a problem. Part of the diagram’s benefit is to depersonalize the issue.

- Poka Yoke:The concept of mistake proofing involves designing a process that eliminates room for mistakes. This word comes from the Japanese pokeru (mistakes), and yoke (to avoid). Anyone throughout a company can implement poka yoke. In manufacturing, it might mean presenting all pieces at once so that the assembler can check that everything is present. In a transactional environment, it might mean presenting a checklist for verifying all necessary paperwork.

- Visual Workplace: Closely associated with the 5S’s, a visual workplace was developed from visual thinking, which leverages the power of graphics and pictures to increase safety and efficiency. One essential tenet is that important information should be located as close to the object of the information as possible. Using a visual workspace is a useful tool for factories, healthcare facilities, airports, and any place where safety is paramount.

Gwendolyn Galsworth formalized the notion of the visual workplace in the book Visual Workplace, Visual Thinking. She wrote:

"The visual workplace is a self-ordering, self-explaining, self-regulating, and self-improving work environment—where what is supposed to happen does happen, on time, every time, day or night—because of visual devices.”

- Heijunka: A load balancing japanese word for leveling. Employ this tool after using Kaizen and value stream mapping to fine-tune inventory and scheduling by balancing the load of production based on orders. For example, a jewelry manufacturer may receive 100 orders for an engagement ring every month, but the number of orders may vary by week. The jeweler may then decide to create 25 rings every week. That way, craftspeople are neither rushed nor left without work. A heijunka box is a tool used to organize and display the work load. It is often a wallboard with pockets that contains colored cards, known as Kanban cards.

When It’s Time for Six Sigma

If defects and problems persist, it’s time for Six Sigma. Six Sigma can involve sophisticated statistical tools, but the method, or roadmaps, provide a consistent path for determining problems, causes, and solutions. For existing processes and products, use the DMAIC method:

- Define the problem. Examples of problems include customer complaints, invoicing problems, responsiveness problems, too much inventory, returns and defective products.

- Measure the quantifiables around the process and problem.

- Analyze the cause through findings.

- Improve or implement a solution.

- Control the process to maintain continued success.

For new processes and products, certain methods attempt to preempt defects. The old name for this process is DMADV, or Design, Measure, Analyze, Design (incorporating comments), and Verify. Today the process if often referred to as DFSS, which stands for Design for Six Sigma. DFSS includes four phases, IDOV:

Identify the customer and requirements.

- Design the product, with an emphasis on what’s critical to quality (CTQ).

- Optimize the design by using statistical methods to predict its effectiveness.

- Verify that the implemented design works and meets requirements.

Lean Six Sigma Certifications

Specially trained teams often implement the Lean Six Sigma principles and method. Individual roles in Six Sigma projects are assigned through certifications called belts, a term borrowed from Japanese martial arts. Responsibilities are divided in the following manner:

- Executives, such as the CEO and other C-level staff, establish the vision for the Six Sigma implementation.

- Champions marshall employees and sponsor the Six Sigma initiative.They may have only basic knowledge of Six Sigma methodologies and tools, such as those with a White or Orange Belt.

- Master Black Belts bring advanced project leadership skills and act as Six Sigma coaches, guiding solution definition and execution. A Lean Six Sigma Master Black Belt is known as sensei, and focuses more on shepherding Lean practices than on Six Sigma practices.

- Black Belts lead improvement projects full-time, and focus on the methodologies and perform statistical analyses.

- Green Belts implement Six Sigma solutions as part of their regular duties, and may lead projects part of the time.

- Yellow Belts have limited Six Sigma training, and contribute to projects by creating process maps. They may also manage smaller efforts within larger projects.

- Orange Belts are not common, and often use a basic knowledge of Six Sigma for a specialty area.

- White Belts receive introductory training. Anyone from executives to employees who require a basic knowledge of Six Sigma can become a White Belt. Note that the IASSC, the professional group focused on Lean Six Sigma, does not certify White Belts.

Lean Green Belt and Lean Black Belt training may be offered separately from regular Green and Black Belt training. However, Green and Black Belts may be trained together to increase mutual understanding of their roles within a project. Learn more about the Six Sigma belts in our article, What You Need to Know About Six Sigma Certifications and Belts.

Although no one institution defines a single, agreed upon body of knowledge for Six Sigma, volunteer organizations do exist that issue generally agreed upon bodies of knowledge for Six Sigma. The International Association for Six Sigma Certification (IASSC) is committed to developing and sustaining a Lean Six Sigma body of knowledge and best practices. IASSC provides accreditation for training organizations and certification for individuals. Similar organizations, such as ASQ and the Council for Six Sigma, provide bodies of knowledge, certifications, and accreditations.

What Is Involved In Lean Six Sigma Training?

Training for certifications takes many forms and is offered in class, on-demand, or a blend of the two. Some training establishments boast that training is 100 percent online. Companies who want to establish Six Sigma programs may also sponsor customized, in-house training, where the entire team learns together, addressing problems and situations unique to their company. Williams, who offers online, in-class, and customized training, says that no format is most effective and suggests making your choice based on on your learning style.

Lean Six Sigma is practiced worldwide. Training and consulting are available in the following languages:

- English

- Spanish

- Russian

- German

- Chinese

- Portuguese

Certification exams are multiple choice, and can be taken on-site or online. Depending on the certification and belt, the exam costs between $50 and $400 dollars.

What Kinds of Industries Use Lean Six Sigma?

Experts seem to agree that Lean Six Sigma principles can benefit any industry. The following industries use Lean Six Sigma and employ people with belts.

- Agriculture

- Airports

- Construction

- Consulting

- Design

- Energy

- Government

- Healthcare

- Hospitality

- Hotels

- Law Firms

- Logistics

- Manufacturing

- Mining

- Non Profit Organizations

- Pharmaceutical

- Public Services

- Services

- Transportation

- Universities

Discover Why Six Sigma Practitioners Use Smartsheet to Achieve Optimal Results

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.