What Is the Critical Chain Method?

Critical chain method is a project management technique that aims to improve performance by addressing resource constraints and recognizing that people often overestimate how long a task will take.

Critical chain project management (CCPM) aims to overcome problems common to projects, including unproductive multitasking, late completion, and budget overruns.

To do so, the critical chain method addresses three key areas:

- Project Network: CCPM users determine project plans using necessary condition logic. This means that planners start at the end point and work backward, which helps them to more accurately determine the steps and resources needed to achieve the outcome, without any other unnecessary factors.

- Resource Availability: Critical chain takes into account resource availability and competing demands for resources. (Resources include people, materials, equipment, capacity, and anything else needed to accomplish project tasks.) As opposed to most project methods that do not address resource constraints early in the process, CCPM makes these constraints explicit and updates resource availability throughout the project. Additionally, when more resources are needed, the method inserts resource buffers into the network diagram to ensure the resource will be available. In cases where the needed resource is more humans, the resource buffer signals that they need to be ready to work on the critical tasks.

- Task Duration: In CCPM, project planners set task durations at only their estimated active or touch time, rather than adding safety or buffer time. They only insert buffer time at the project level and at points where dependencies join the main project flow. In a CCPM project, the project buffer is shared among all its activities.

What Is Critical Chain?

In critical chain project management, the critical chain is the longest-possible path in the project network diagram that factors in both task dependencies and resource constraints.

Critical chain evolves from the critical path method (CPM), one of the most widely used project management methodologies. Projects that use CPM and other methods, including Waterfall, Agile, and Lean, often struggle to achieve on-time and on-budget completion. In 2021, a survey of project planners by the Project Management Institute found that 65 percent of projects were late or over budget.

In CPM, the critical path is the longest series of dependent activities in the project that has zero float, meaning that a delay in any of the linked tasks will delay the whole project. Critical path does not specifically address resource availability in the project schedule. Task durations are based on highly achievable estimates, which usually means they include extra time. The method does not enable the project to move ahead of schedule if a task finishes early.

Critical chain method incorporates the critical path, but it adds resource availability to the project network. In CCPM, you ensure there are no resource conflicts and use resource buffers to make sure resources are available when needed. CCPM also has a different way of decomposing the project into tasks.

Critical Chain Method Buffer Types

CCPM has three kinds of buffers: project buffers, feeding buffers, and resource buffers. The first two add time to the project schedule, while resource buffers do not.

- Project Buffer: You include a project buffer at the end of all project activities, before the completion date. Every project has only one project buffer. Typically this buffer is half of the estimated project duration.

- Feeding Buffer: Sometimes called an integration buffer, a feeding buffer refers to time added at the end of a sequence of non-critical tasks, before this sequence joins the critical chain. The feeding buffer is usually half the duration of the relevant task sequence. There can be as many feeding buffers as chains of dependent activities.

- Resource Buffer: Resource buffers alert project participants that you are approaching a need for additional resources. Project planners insert resource buffers in the project diagram before the resource is required.

What Are the Steps in Critical Chain Scheduling?

The critical chain method starts by defining all the work in the project. Then, planners make aggressive time estimates for all the project tasks and assign and allocate resources. Next, they add buffers and complete the project schedule.

Broken out, the steps in critical chain are as follows:

- Identify project activities by working backward from the goal.

- Estimate task durations with 50 percent confidence.

- Assign resources and resolve any resource conflicts.

- Find the critical chain and look for opportunities to shorten project duration.

- Add buffers and finalize the schedule.

In the following sections, you’ll find more detail on each step in the critical chain method.

1. Identify Project Activities by Working Backward from the Goal

Determine all the work that will occur in the project. Critical chain does this in a specific way, applying what practitioners call necessary condition logic.

“We start with the end in mind: the project objective,” notes Dr. Lisa Lang of Velocity Scheduling System. “We ask, ‘In order to achieve that objective, what must we do?’ And step by step, we work backward.”

Lang likens the process to planning a car journey by starting with the destination. You then map the route back to the starting point. “You would never plan a trip without knowing where you want to go,” she explains.

Typically, project managers use software that operates on the principles of critical chain. But in a CCPM example, if the goal is to produce an airplane, the project planners might begin by noting that the outcome requires a fully assembled fuselage, wings, cockpit, engines, tail assembly, and landing gear.

They would then work backward to identify the activities, materials, skilled workers, and other inputs needed to make each of those pieces. Next, they figure out what needs to happen in the step prior to that, and so on. This system helps you systematically identify all the activities, dependencies, and resources required, leaving nothing out and adding nothing unnecessary.

Based on this information, the project manager would design a project network diagram that includes all tasks and dependencies. They would leave buffers aside for now.

This approach contrasts with traditional project management methods that work from start to finish. These methods move from left to right on a time axis, whereas critical chain moves from right to left. Traditional methods also rely on the work breakdown structure. Though the WBS information is similar, it does not use necessary condition logic and does not include resources. Overall, it is very time consuming to create in complete detail.

CCPM practitioners say this can result in missing tasks and dependencies or dangling activities, meaning they lack successors. The lack of resources in the WBS can lead to conflicts.

Project planners who don’t use necessary condition logic often try to combat the shortcomings by getting more detailed and adding more subtasks, Lang says. This results in bigger and busier project network diagrams. But it does not solve the underlying problem because the project logic does not address all the essential issues, such as resource needs.

With the critical chain approach, the project network tends to be tighter and every task has a successor until project completion. The diagram typically has shorter chains of activities and more activities in parallel than with traditional methods, Lang says.

Comparison of Network Diagrams: Sequential vs. Parallel Activities

2. Estimate Task Durations with 50 Percent Confidence

CCPM sets task durations at exactly the amount of time the activity is expected to take, without anticipating any complications or delays. This is referred to as a 50 percent confidence interval without any buffer.

Of course, project managers should communicate to the team that they understand things may sometimes take longer than expected. But this isn’t a problem — it’s how CCPM is supposed to work.

Planners add time equal to 50 percent of each estimated task duration to a buffer at the end of the project. If a task runs over, the time comes from this buffer.

In most project methods, participants set task duration so they are highly confident they can finish in the time provided. It’s human nature to want to meet a commitment, so they build a lot of safety margin in the time estimate. While critical chain calls for 50 percent confidence estimates, planners in other methods often use durations that they are 80 to 90 percent confident will be enough time.

CPM managers believe this results in schedules that are realistic and achievable — if the confidence level is high, the task and project should finish on time. In theory, this should increase the odds of on-time project delivery. In reality, the added safety time is usually unnecessary (but taken anyway), and the project takes longer than needed.

Certain human weaknesses come into play, such as student syndrome. When a student sees they have two weeks to finish an assignment, they often procrastinate until the last minute. In a real-world project, a team member suffering from student syndrome begins at the last moment they can and still meets the deadline. As they procrastinate, they waste safety time built into the duration estimate.

Another phenomenon known as gold-plating may also occur. In this scenario, the worker finishes the assignment ahead of schedule. But rather than advancing the work early to the next step, the worker uses the extra time to add flourishes, double-check the task, or look for potential improvements. This is Parkinson’s Law, which says work expands to fill the time available. Once again, buffer time goes to waste.

Even if neither issue comes into play, the project is still unlikely to benefit from the worker finishing ahead of schedule. People and resources involved in the next step may not be ready early because the project plan has not prepared them for the possibility. The time saved in the prior activity is not passed on and doesn’t benefit the overall project.

Unfortunately, if a task runs over its allotted time — even in the generous CPM duration estimate — that late finish will always impact successor activities. The traditional project method passes on all the negative time consequences and none of the potential windfalls.

In CCPM, the tight duration estimates help keep project staff focused on the task and discourage distraction, procrastination, and multitasking. The aggressive estimates also motivate managers to make sure resources are available where and when they need to be.

CCPM has other practical advantages, too. Project buffers promote ownership of the team’s collective commitment, while individual task buffers promote individual ownership of individual pieces of work.

We can look to insurance as an analogy for the difference in these methods. In traditional project management, each homeowner in a neighborhood assumes that their home will have a problem, and each homeowner self-insures. If a house suffers a major problem (for example, a bad fire), the amount an individual has set aside may not be enough to cover the worst-case scenario. And in cases where no problem occurs, the money set aside is underutilized.

In CCPM, the homeowners in the neighborhood get together and recognize that it’s unlikely all the houses will have a serious problem at the same time. Each owner puts a smaller amount of money than when they self-insured into a pot. Collectively, they have enough to cover the worst-case scenario and the costs of some ordinary problems. Each owner saves money, too.

3. Assign Resources and Resolve Resource Conflicts

Next, determine the resources needed for each task, and confirm resource availability. Identify if there are any resource constraints, which is when demand for the resource exceeds its availability or capacity. The constraint will be a limiting factor in project progress.

A constraint may occur when simultaneous tasks need the same resource. For example, a building project may have planned an excavation of the foundation to happen at the same time as grading for an outbuilding. But the contractor has only one excavator. This machine is a constraint, what CCPM calls a capacity-constrained resource (CCR).

In a simpler example, Ed is the only graphic designer at a small ad agency. The agency has to present a new campaign to its major client in three weeks, but Ed is away on vacation for two of those weeks. Ed is a constrained resource.

To resolve these conflicts, buying another excavator or canceling Ed’s vacation are simple solutions. But usually other considerations, such as labor regulations, cost, and lead time, force project managers to take other steps.

Critical chain embraces resource leveling, the process of adjusting task start and end dates to spread out the demand for the resource. For example, a project manager may push back the start of one task so that a skilled worker is not scheduled to perform two tasks at once.

In the example below, a resource conflict arises because two tasks need Joe at the same time.

To resolve this conflict, CCPM adjusts the start dates of the tasks. There are multiple solutions, including Joe starting a day ahead of Susan. This enables Joe to focus on one task at a time.

4. Find the Critical Chain

Using the work identified in step one and durations from step two, start creating a project schedule and network diagram. Remember, the critical chain is the longest sequence of dependent tasks with resource constraints accounted for.

Schedule each task to begin as late as possible. This serves to limit work in progress (WIP) and multitasking, and it minimizes the risk of rework if a problem turns up in a predecessor step. This also preserves cash by deferring spending until materials are needed.

5. Add Buffers and Finalize Schedule

Next, add your resource, feeding, and project buffers in the appropriate spots. Resource buffers occur before a new resource is needed while project managers insert feeding buffers before non-critical task sequences join the critical chain. Remember, project buffers are placed at the end of the project.

In this network diagram, the feeding and project buffers are ovals, and the resource buffer is a square. The critical chain connects activities 2, 6, and 8. The project buffer is placed at the end of all project activities. Planners place the feeding buffers at the end of the dependent task sequences before they join the critical chain at task 6 and task 8. The planners insert the resource buffer before task 6 to notify participants that the resource need is ahead.

Aside from protecting the project’s completion date, feeding and project buffers act as an early-warning system. When a task starts to consume buffer time, project managers are alerted to pay attention to the activity for potential risk. Because CCPM task durations are shorter than other methods’, managers get this alert earlier and have a greater opportunity to address any issues before they hurt the project.

Once the project begins, the buffer sizes are locked and do not change. If they were adjustable, they would lose their value as an early-warning system. As the project progresses, participants can check on-time status by looking at the buffer. If there is still buffer time left, the project is on schedule.

Critical Chain and the Theory of Constraints Applied to Project Management

CCPM stresses addressing constraints, which are factors that limit progress or bottlenecks. CCPM grew out of Israeli management consultant Eli Goldratt’s Theory of Constraints (TOC).

TOC seeks to improve systems and processes by finding the constraint with the biggest impact and addressing it. Goldratt called this “breaking” the constraint.

A simple example of a constraint would be an auto manufacturer that wants its assembly line to produce 100 cars a day. The resources are in place to do this, except one machine on the assembly line can handle only 20 cars a day. That is a big constraint. Until the manufacturer fixes this equipment constraint, the production goal is impossible.

CCPM focuses on resource constraints. In this example, that is equipment. But there are other kinds of constraints, as listed below:

- Market Constraints: There is not enough demand in the marketplace for the amount you can produce.

- Material Constraints: This occurs if you have a shortage of raw material or other inputs.

- Policy Constraints: The organization adopts a policy that hurts performance, such as banning overtime.

- Dummy Constraints: These are constraints that are no-brainers to fix because the solutions cost very little and are simple to execute. Examples include not having enough phone lines or having a machine sit idle because everyone takes a lunch break at the same time.

Drum, Buffer, and Rope in Critical Chain

The Theory of Constraints uses a scheduling technique called drum, buffer, rope. It is focused on resolving resource constraints and shows up in CCPM. The drum represents the constraint, the resource that limits progress. Goldratt called this the drum because it sets the pace for the entire system or process.

Let’s say our project is manufacturing a new car. The work cannot flow any faster than the machine on the assembly line that can only handle 20 cars a day. Therefore, the machine is the drum that determines the pace of the whole project: 20 cars a day.

As opposed to other buffers in CCPM, this buffer is an amount of work waiting before the constraint. Positioning this small, controlled backlog before the constraint ensures the constraint always has work and can always operate at maximum capacity Suppose in our car manufacturing project we discover that 20 cars on the assembly line have a defect and need to be removed. If we did not have a buffer of partly assembled cars ready for the constraint step on the production line, that machine would sit idle as a result of the 20 cars being pulled out of production.

If the constraint is the paint sprayer, the project planner would add a buffer of cars primed and ready for paint application. Doing so would ensure that production will never stop, even if one day the paint sprayer is able to handle 22 cars. Two cars are pulled from the buffer and the paint sprayer has no downtime.

The rope pulls new work into the system. Be careful not to overwhelm the assembly line and build an unmanageable backlog of work waiting for the paint sprayer. Instead, pull in raw materials for more new cars at the pace the constraint can handle.

Buffer Burn Rate in Critical Chain Project Management

As noted, project managers monitor buffer consumption for alerts that a task is exceeding its estimated duration. The buffer burn rate is a ratio of the percent of buffer consumed to percent of project completion.

If this number is less than one, the project is running on time. As this figure approaches one, project managers can consider the project at risk of being late. If the figure is more than one, the project is behind schedule.

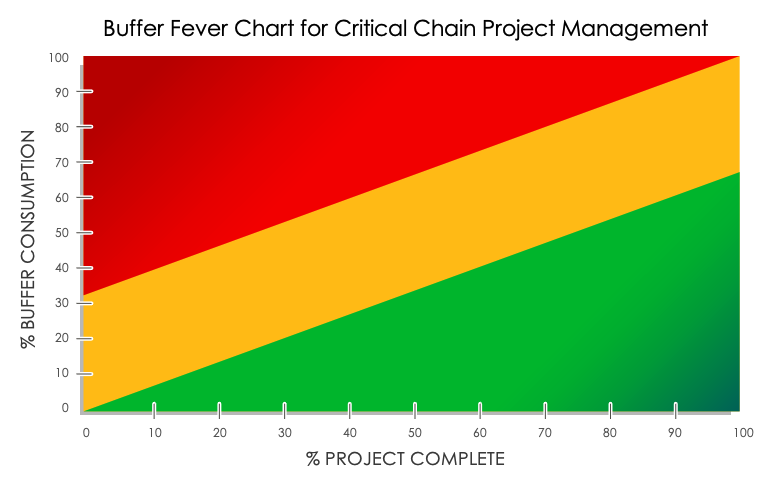

Buffer Fever Chart

In CCPM, project managers use a color-coded graph of the buffer burn rate for a visual representation of project progress.

The graph is shown below. The horizontal axis is percentage project complete and the vertical axis is percentage buffer consumption. The three colors – green, yellow, and red – show whether the project is on schedule, at risk, or late. If the project is in the yellow or red, managers must take urgent steps to correct problems.

Critical Chain Project Management Template

Download a Buffer Fever Chart Template for

Excel

| Google Sheets

Download this buffer burn fever chart template to track your own project’s risk and progress under critical chain project management. By comparing the amount of buffer consumed relative to project time, this graph shows whether you are on track, at risk, or in the danger zone.

How to Create a Critical Chain Network Diagram

To build a network diagram for a critical chain project, represent each project task as a box. Sequence these boxes in chronological order, connect them with arrows, and insert buffers.

A project network diagram is a visual representation of a project in which you organize tasks, represented by boxes or circles, sequentially and connect them with arrows that show both chronological and logical relationships.

In the following sections, you’ll learn how to create a project network diagram.

1. Gather Project Information

Gather all information about tasks, dependencies, and resource needs. You can put this in a table like the one below. You can also draw information from a work breakdown structure, but be sure to apply necessary condition logic.

Download a Project Information Table for

Microsoft Word

|

Adobe PDF

| Google Doc

2. Design Task Sequences

Enter a start point, and then create task chains. To do this, create a box for each task that does not have a predecessor. Next, identify the critical chain, which is the longest sequence of tasks.

Note task durations with the number of days inside the task box. Remember, you will have already performed resource leveling, which determines the tasks that can happen in parallel. Display dependent activities in chains that feed into the critical chain.

Add the completion point.

3. Add Buffers

Insert a project buffer before the end point, and insert feeding buffers when dependent activity sequences join the critical chain. Add resource buffers to signal new resource needs.

Critical Chain Method Scheduling Example

Managers of complex projects based on CCPM would use software that automates the critical chain process. But we have put together an example of how the principles apply to a simple project: baking a cake.

Start by identifying all the tasks and resources, working backward from the finished cake.

Then, record all the information in the table. In this example, tasks include buying ingredients, mixing them, baking the cake, frosting the cake, and more.

Then, estimate task duration, using aggressive estimates. For example, while buying ingredients for the cake could take four hours if you have to go to a specialty store across town for an uncommon spice, you can say with 50 percent confidence that you can do it in a half-hour nearby. Next, add the durations in a new column on the table. In this example, we use minutes as the time measure, but longer-term projects typically use days.

Example: Breaking Down Tasks and Estimating Duration

for Baking a Cake in Critical Chain Project Management

| Task | Duration (minutes, 50 percent confidence) | Predecessor | Resource(s) Needed |

|---|---|---|---|

| 1. Buy ingredients | 30 | Money, a person to do the shopping | |

| 2. Measure ingredients | 5 | 1 | Baker, measuring cups, ingredients |

| 3. Mix ingredients | 5 | 2 | Mixer |

| 4. Grease and fill cake pan | 3 | 4 | Cake pan |

| 5. Bake | 40 | 3 | Oven |

| 6. Make frosting | 10 | 1, 5 | Frosting ingredients, mixer |

| 7. Cool cake | 120 | 6 | |

| 8. Frost cake | 15 | 5,6, 7 | Piping bag, spatula |

Then, consider ways you can shorten the project duration by doing activities in parallel. For example, the dependent activity of making the frosting can happen while the cake cools. Making the frosting at another time would require an additional person, so this is resource leveling. Next, start building the network diagram reflecting this information.

Record the task durations in the activity boxes. Now it is time to add buffers. The critical chain takes 218 minutes to complete, so you add a project buffer of half that time (109 minutes) at the end. Then, add a feeding buffer to the end of the dependent frosting chain of half the time it takes or about eight minutes. Finally, add resource buffers before new resources are needed to remind us those requirements are coming up.

Critical Chain Project Management Case Studies

The real-world impact of CCPM can be significant in terms of shortening project duration, increasing on-time performance, and improving efficiency. Organizations, including NASA, the Air Force, and manufacturers of appliances, pharmaceuticals, and aircraft, have used critical chain.

NASA used CCPM to manage wind tunnels at its Langley research facility. A study on the implementation found that, by using critical chain, the facility was able to maintain the number of tests it completed despite a 50 percent reduction in personnel due to budget cuts.

This network diagram shows how some activities can happen in parallel with feeding buffers as those workflows join the critical chain. A project buffer at the end helps ensure the project completes on time.

The Air Force began using CCPM at the Warner Robins Air Logistics Center in Georgia. It cut lead times for repairing C-5 transport planes, returning five additional aircraft to operational inventory and generating nearly $50 million in additional revenue, a study found.

In this network diagram, you can see how project managers inserted resource buffers at critical points to ensure planes did not move to the next activity until needed parts and workers were available. Before using CCPM, the operation often had too much WIP, which strained the part-machining shop and caused stress for workers.

Philip Marris of Marris Consulting says his firm worked with aircraft manufacturer Embraer in France to apply critical chain to aircraft maintenance. The goal was to reduce downtime for airplanes. The company scheduled mechanics’ tasks using critical chain and monitored buffers. The results included a 50 percent reduction in turnaround time for maintenance and a 20 percent increase in the mechanics’ productivity. Moreover, managers had improved visibility into performance and were better able to set their priorities.

In another Marris Consulting case study, Tax Valet, a company that handles U.S. sales tax calculation, payment, and reporting for ecommerce stores, suffered bottlenecks with its onboarding team. It slowed growth of the business, and onboarding managers were multitasking, stressed, and unable to deliver high levels of service. About one-quarter of onboardings took more than the scheduled 90 days, and some were significantly later.

Using critical chain, the company identified constraints and issues with onboarding. Managers reduced WIP by limiting the number of customers assigned to an onboarding manager at any given time. They used critical chain to schedule new onboardings and began weekly reviews of project buffer status. Onboarding on-time delivery increased to more than 95 percent, and lead time fell. After the changes, most clients moved through onboarding in much less than 90 days.

Critical Chain Project Management Pros and Cons

Project management experts say a big benefit of CCPM is that it helps bring projects to completion sooner. But there are drawbacks. For example, aggressive time estimates may put unrealistic time pressure on workers if buffers are not presented correctly.

Summary of Critical Chain Pros and Cons

| Pros | Cons |

|---|---|

| Faster completion, 10-30 percent quicker than CPM | Many project participants may not be familiar since CCPM is newer; may require education |

| Factors in resource use and constraint | Does not work well with small projects |

| Less multitasking | Task duration estimates may be unrealistic |

| Addresses Parkinson’s Law and student syndrome | Not easy to revise schedule because it could alter the critical chain |

| Prevents wasting of slack/buffer time | Most project planning software does not include critical chain method functionality |

| Alerts project managers to risk sooner than CPM |

Critical Chain Management Tips

CCPM pros recommend a few tips to make sure your project succeeds:

- Use necessary condition logic for identifying the work and resources. Lang says doing so helps ensure that you don’t forget anything and enables you to shorten the project when possible by doing as many tasks in parallel as possible.

- Success with CCPM is higher with organizations that are strict about scope creep. Companies that are able to clearly define scope and control scope changes throughout the project have better results. Refrain from frequent rescheduling and changing priorities.

- Educate project participants about the Theory of Constraints to build buy-in for CCPM. Resistance to the aggressive time estimation techniques in CCPM can hinder success, so make sure participants understand the ideas behind it and the availability of buffers.

- Use CCPM on projects in which resources, notably people, will not face pressure for multitasking. If you cannot eliminate multitasking through resource leveling, reconsider the project.

- Start with projects that can demonstrate a positive financial contribution. This helps build support for CCPM at your organization.

- Implement robust buffer management. Managers should actively monitor buffers and take action to recover lost buffer time if necessary.

Critical Chain vs. Critical Path

Task duration estimates are the biggest difference between critical chain and critical path. In critical path, team members create estimates they think they can meet. Critical chain assumes people overestimate task time and overcorrects by scheduling shorter task durations.

Another big difference is the role of slack, float, and buffer time. In CPM, slack or float is the amount of time an activity can be delayed without delaying the whole project. CCPM uses buffer time to cover contingencies when tasks do not go as scheduled.

CPM calculates project float as the difference between the critical path and the non-critical path and for activities as the earliest possible finish date and the latest possible finish date. Some project methods also add buffer time before milestones or at other points when project managers want to create leeway. CCPM adds buffer time when dependent task sequences join the critical chain and at the end of the project. This time is consumed by any predecessor activity that runs over its estimated duration.

Differences Between Critical Path and Critical Chain

| Critical Path | Critical Chain |

|---|---|

| Task time estimated with 80-90 percent confidence | Task time estimated with 50 percent confidence |

| Slack or float built into activities | No buffer in activities. Buffer occurs at predetermined points and is shared by task sequences |

| Critical path has no float | Critical chain has buffer time |

| Focuses on activities and tasks | Focuses on resources |

| Works best without resource constraints | Designed to address resource constraints |

| Activities have early and late start dates and early and late finish dates | Activities have only one start and end date |

| If a task finishes early, the project does not move ahead of schedule because the next task cannot start before its early start time | If a task finishes early, the next task is ready to begin and the project may finish early |

Get the Most Out of Critical Chain with Smartsheet Project Management

From simple task management and project planning to complex resource and portfolio management, Smartsheet helps you improve collaboration and increase work velocity -- empowering you to get more done.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.