What Is Global Supply Chain Management?

In an increasingly globalized market, the need for efficiency and transparency while moving parts and products around has never been greater. Luckily, technology is keeping pace, enabling businesses to conduct tasks while trimming unnecessary costs, identifying issues within the movement of goods and services, and communicating quickly both externally and internally. A global supply chain is a network of different suppliers, manufacturers, warehouses, shipping companies, wholesalers and retailers that work across two or more countries for a single product. A company may have many global supply chains, some that overlap, and others that don’t, and may also own all the links in their supply chain, or partner with other companies. If that sounds complicated, then you’ll understand why global supply chain management is such a critical and growing discipline. Learn more about Supply Chain Management including principles, examples, and templates.

Global supply chain management has many moving parts, all worth studying for SCM students.

The History of Supply Chains

Supply chains have been in effect since the beginning of trade. Think of the Silk Road: traveling merchants and hunters that relied on trade routes to service old empires throughout history. Examples of global supply chains that resemble today’s date back to the European Colonial era, where first Portuguese, then Dutch, and then English, Spanish, and French ships would take various ocean routes to secure new types of raw materials for local companies and new finished goods for their domestic consumers.

Modified image of colonial trade ship - Creative Commons

The next innovation in supply chains came in the 1800s with the Industrial Revolution, where machines enabled workers to produce more food, clothing, and other goods than could be immediately sold. This led to the need of warehousing and logistics for moving products around. Not long after that was the assembly line of Henry Ford in 1913, which sped up production and reduced cost for more complicated products: cars. In the 1950s, container shipping enabled supply chains to more quickly transfer international shipments from boat to train to truck to their final destination.

From there, supply chains only got more efficient and complex. Computer systems allowed faster communication and the sharing of data between companies, making global coordination possible. While at first the giant companies of the world tried their hands at vertical integration (owning the whole supply chain), this became inefficient and unsustainable, and they transitioned to specialization and horizontal integration (owning more market share of one part of many supply chains) - this allowed them to become leaders in a particular field. Find out more about Vertical Integration.

Now, global supply chain management relies on the Internet with more data and faster communication to reduce waste and increase profits for all sorts of products. This is where the next crop of GSCM students can jump in to create tomorrow’s big innovations.

The complex state of global supply chains today

The Types of GSCM Skills You Need

With so many information-dense sub-disciplines and niches, global supply chain management can be an overwhelming field to study. The essentials skills come down to:

- Textual: On paper, you need to understand everything from raw materials procurement to parts manufacturing to supplying product development firms, selling to distributors to storing in warehouses, transporting by train, plane, ship, and truck, to selling at retail to end consumers. This knowledge allows you to design effective supply chains.

- Analytical: Everyone in supply chain management must be able to analyze data for decision making, read sales and demand data, understand the ramifications of particular aspects like shipping lanes or the fuel and weight factors of a delivery, and measure performance of every step in the chain. How do you determine if you should outsource production of a product, or insource it (handle production with in-house resources)? The answer is always data analysis.

- Interpersonal: The ability to collaborate with others and find mutually beneficial solutions to problems. Though there may be a growing number of robots and AI handling actual product assembly, you will deal with real people at all stages of a supply chain. Even with the logic of perfect analysis and numbers to back up claims, you still have to sell to people’s emotions and make sure they feel they’re getting a good deal. Whether in your organization or elsewhere in the supply chain, you must know how to handle people.

Topics for GSCM Certification

The following topics are important for passing most global supply chain management certification programs, and they all fall under the above skill categories. Read the descriptions for a brief overview and prepare for what you’ll find in different courses:

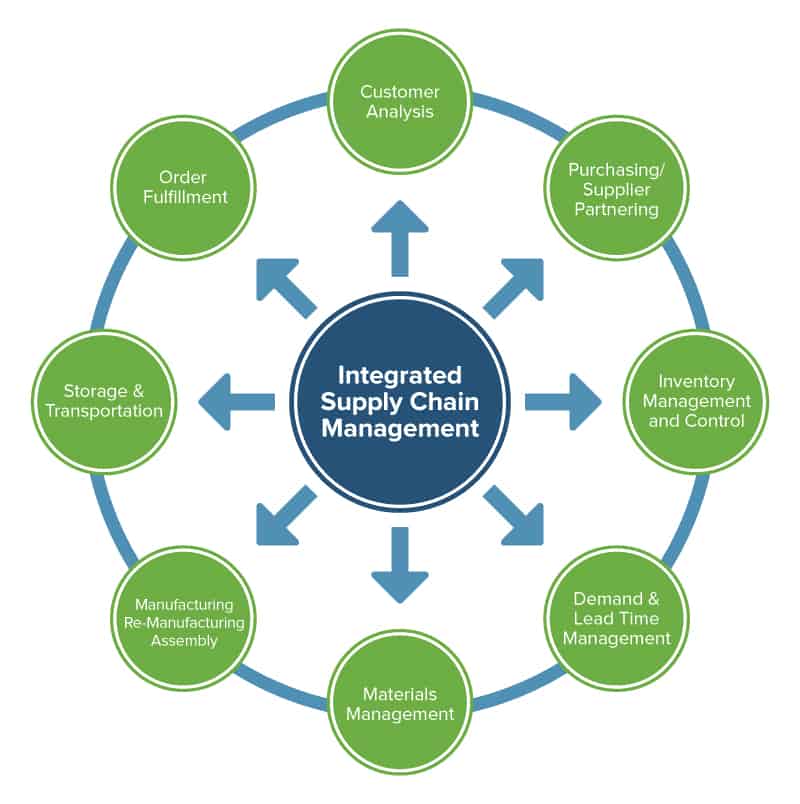

Customer Relationship Management (CRM): Both the literal activities in guiding customers towards purchases and providing customer service. CRM can also refer to software that helps organize and automate communications with a firm’s customers.

Demand Management: Using past data and predictive modeling to plan for future consumer demand in order to manufacture or order the correct amount of product.

Integrated SCM: A type of supply chain management where all links work together as a single company, sharing data, risk, and reward. Learn more about Integrated SCM.

Inventory Management: Keeping components and products stored and moved where they need to be on time in order to continue operations. Learn more about Inventory Management.

Leadership & People Management: Since SCM involves many different organizations and people of many different backgrounds and occupation, true leadership requires inspiration and empathy.

Lean Six Sigma: The methodology of continuous improvement and proactive waste/mistake reduction through product standardization. Learn more about Lean Six Sigma.

Network Design: The conscious choosing and arranging of suppliers in the chain that enable the most efficient, least costly, and highest quality products to be made in the least amount of time.

New Product Development: A joint process involving developers, designers, marketers, salespeople, and business intelligence to determine which products should be made and how, before a supply chain is formed. Learn more about New Product Development.

Operational Accounting: Accounting that is aimed towards monitoring daily activities for a company or an entire supply chain in order to control costs and reduce waste.

Pricing: Using predicted demand, market trends, marketing, positioning, materials, and labor costs to determine end consumer price strategies.

Procurement: The discipline of locating needed materials, products and labor, and negotiating deals that allow your company and the rest of the supply chain to profit.

Project Management: The discipline of tracking and managing many moving parts in a single product’s development and delivery moving for timely completion.

Quality Assurance: The discipline of sourcing from reputable suppliers and balancing the quality and the price of end products.

Risk Management: Using analysis and data to determine risks in various partnerships and deals. Effective risk management will enable you to advise others in the supply chain to build in appropriate margins for lost revenue and time.

Strategic Sourcing: The practice of finding and taking advantage of the best values in the marketplace of possible suppliers and finding synergies that can reduce wasted time or resources.

S&OP: Sales and Operations Planning is the discipline of focusing all the organization’s operations on those activities that contribute to sales. Learn more about Sales and Operations Planning (S&OP).

Technology: As used in GSCM, knowledge of all available technologies, both hardware and software, helps reduce costs, improve efficiency, and keep the market competitive.

Theory of Constraints: Determining the main constraint in the production of a product and the means to eliminate it to increase efficiency.

Transportation: Knowledge of all factors in logistics for physically moving materials, from fuel-limits to time constraints to cross-country tariffs that impact the supply chain.

Warehouse Management: The discipline of keeping inventory, deliveries, and quality in check within your supply chain’s network of warehouses.

Experts Share Why Students Should Study Global Supply Chain Management

Here’s what experts in the field have to say on why students should study global supply chain management (GSCM):

Where Can You Learn Global Supply Chain Management?

Supply chain management is complex in both theory and practice. There is a large field of specialists that continues to expand as market demands grow. Fortunately, many accredited universities offer majors in supply chain management, and many certifications are also available. Formal education of some sort is typically required, and if you’re shooting for middle management or eventual executive roles, an SCM-focused MBA is usually required, too. Discover some of the best options for education here:

Business Colleges and Universities with Degrees in Supply Chain Management

A SCM class taught at a lecture hall at Cambridge University - Creative Commons

Arkansas State University (A State)

- Location: Arkansas, USA

- Summary: A notable state university in Arkansas with international accreditation. The program covers all aspects of supply chain strategies, logistics, purchasing, manufacturing, and e-commerce.

- Type: Four year B.S. in Global Supply Chain Management

- Tuition: $4,239/semester in-state, $7,389/semester out-of-state

- Requirements: Available to all students of Arkansas State accepted to the business school.

- Noteworthy: Seal of approval from the Association to Advance Collegiate Schools of Business.

Brigham Young University

- Location: Utah, USA

- Summary: A private school that caters to the Church of Latter Day Saints. Their program focuses on managing across boundaries in a firm and throughout a channel.

- Type: Emphasis within four year B.S. in Management

- Tuition: $2,650/semester for LDS students, $5,300/semester for non-LDS students

- Requirements: Available to applicants accepted into BYU’s Marriott BS Management Program with seven pre-req classes.

- Noteworthy: Their students have gone on to supply chain giants like Amazon, Boeing, and Goldman Sachs.

Bryant University

- Location: Rhode Island, USA

- Summary: A private school program taught by active supply chain professionals who have taught around the globe, bringing more hands-on experience to their global supply chain theory.

- Type: Offered as a four year B.S. in Business Administration: Global Supply Chain Management concentration, and also as a minor.

- Tuition: $20,850/semester

- Requirements: Must be active student in their College of Business.

- Noteworthy: Feeds into their prestigious graduate program.

Cambridge University

- Location: Cambridge, UK

- Summary: A certification in sustainable value chains for professionals and teams looking to improve understanding of current affairs and CSR.

- Type: Postgraduate certificate in Global Supply Chain Management

- Tuition: £7,543 total

- Requirements: Active in a business career as an individual or sent as a corporate team. Active members of nonprofits, governments, and CSR specialists are also welcome.

- Noteworthy: Discount rates are available for groups, and it accepts global applicants.

California State University Northridge (CSUN)

- Location: California, USA

- Summary: A program with learning outcomes that promote critical thinking, ethics, social responsibility, and global context of business.

- Type: Four year B.S. in Business Administration with a Global Supply Chain Management focus

- Tuition: $2,871/semester

- Requirements: Available to all students of CSUN accepted to the business school.

- Noteworthy: At least 50% of the coursework needs to be completed in residence at CSUN.

- Location: Copenhagen, Denmark

- Summary: A full course from the College of Economics and Business Administration which teaches students to design supply chains, build networks, and form corporate strategies.

- Type: Two year MSc in Supply Chain Management

- Tuition: €6,250/semester

- Requirements: A business project and a master’s thesis.

- Noteworthy: The program has a rotating accompanying minor in topics like IT-based supply chain modeling and maritime business.

Cranfield School of Management

- Location: Bedford, UK

- Summary: A program designed for recent grads who want a role in the supply chain field, and for professionals who want to get to the next level.

- Type: One year MSc in Logistics and Supply Chain Management

- Tuition: £12,500 total for EU students, £21,000 for non-EU students

- Requirements: Acceptance is based on GCSE scores as well as various UK testing requirements. You must also hold an undergraduate degree.

- Noteworthy: Ranked 12th globally for their management program and accredited by CIPS.

Eindhoven University of Technology (TU/e)

- Location: Eindhoven, Netherlands

- Summary: An OML degree program that teaches students to analyze operational performance and improve it.

- Type: One year MSc in Operations Management and Logistics

- Tuition: €2,006/year for EEA students, €10,000/year for non-EEA students

- Requirements: An undergraduate degree is required, with a preference for Industrial Engineering.

- Noteworthy: The program offers 5 tracks: Healthcare, Capital Goods, Consumer Goods, Service Operations, and Transportation.

- Location: Fontainebleau, France

- Summary: A fast-paced program that delivers value, alignment, and sustainability to your organization’s supply chain strategy.

- Type: Five day program for helping managers create, optimize, or redesign their supply chains.

- Tuition: €9,200 total

- Requirements: Students must be professionals with experience in either operations, logistics, procurement, IT management, marketing, new product development, or manufacturing.

- Noteworthy: This program qualifies for the INSEAD Certificate in Global Management.

London Business School

- Location: London, UK

- Summary: A supply chain leadership program that offers experiential learning with visits to job sites, simulations, and many guest speakers.

- Type: Six day program

- Tuition: £7,900 total

- Requirements: Available to students enrolled in the London Business school.

- Noteworthy: The program is taught in partnership with a world leader in business consulting, McKinsey.

Massachusetts Institute of Technology (MIT)

- Location: Massachusetts, USA

- Summary: MIT’s Center for Transportation and Logistics Supply Chain Management is an intense study that takes students with some professional experience to new heights in the field.

- Type: A five-month blended Masters, a 10-month MEng or MASc, and a PhD program

- Tuition: $42,553 - $71,000 plus fees

- Requirements: Students are generally recommended to have 3 to 8 years of work experience prior to joining most of these programs.

- Noteworthy: The 10-month Supply Chain Management Degree is the top ranked among such programs.

Michigan State University Eli Broad College of Business

- Location: Michigan, USA

- Summary: A top-ranked leader in SCM research, education, CSR, and more.

- Type: A B.S., a 24-month Master’s, and a PhD is either Logistics or Operations & Sourcing Management, along with some certificate programs

- Tuition: Undergrad - in-state $7,258/semester, out-of-state $19,730/semester. Masters - $51,600 total. PhD - varies.

- Requirements: Varies based on level.

- Noteworthy: Ranked #1 in Supply Chain Management by US News for undergraduate and graduate programs.

- Location: Oxford, UK

- Summary: The technology and operations management group teaches the top academic talent in the world how to design, analyze, and improve processes at any organization.

- Type: One year MBA or Executive MBA

- Tuition: £52,000 total

- Requirements: Undergraduate degree in a related field.

- Noteworthy: Among the top MBA programs outside the US.

University of Southern California

- Location: California, USA

- Summary: Joint MBA coursework offered by the USC Marshall School of Business and Viterbi School of Engineering to students accepted into USC’s masters program, meaning true inter-organizational skills are developed. Access to Lean Six Sigma courses and STEM certification.

- Type: 16 month MSc in Global Supply Chain Management

- Tuition: $46,170 total

- Requirements: Relevant undergraduate degree.

- Noteworthy: Provides international students with 29 months of work and internship authorization after the program completes.

- Location: Gent, Belgium

- Summary: Modules and mini courses in supply chain management as a supplement for the school’s business program.

- Type: 21-day intensive executive master class in supply chain management.

- Tuition: €12,995

- Requirements: Recommended for professionals, consultants, or managers wanting to improve their global and holistic management supply chain and logistics knowledge.

- Noteworthy: Guest lecturers from major companies like Caterpillar and Johnson & Johnson.

- Location: West Virginia, USA

- Summary: A foundational program in supply chain management that provides students right out of high school with networking opportunities and professional experiences.

- Type: Four year undergraduate degree in GSCM.

- Tuition: $3,540/semester for in-state, $11,160/semester for out-of-state

- Requirements: Available to eligible students enrolled in WVU and accepted into the College of Business and Economics.

- Noteworthy: Strong ties to the Supply Chain Management Association, providing endless networking opportunities for students.

SCM Professional Organizations and Clubs with Certifications

Global supply chain management benefits from a large number of professional associations, which not only provide opportunities for networking and career advancement, but also provide training for students and professionals alike. These certifications can often be instrumental in standing out from other applicants. Best of all, many of these certifications are available online and provide coursework to members, so you can study and stay up to date from anywhere. Noteworthy professional groups to consider in the supply chain management field are:

Supply chain industry networking events are great places to meet members of Fortune 500s- Wikimedia

The Association for Operations Management (APICS)

- Certified Supply Chain Professional (CSCP)

- Certified Production and Inventory Management (CPIM)

- Certified Logistics, Transportation, and Distribution

Chartered Institute of Supply Chain Management (CISCM)

- Chartered Supply Chain Management Professional (CSCMP)

Chartered Institute of Procurement & Supply (CIPS)

- CIPS Certification

Institute for Supply Management (ISM)

- Certified Professional in Supply Management (CPSM)

- Certified Professional in Supplier Diversity (CPSD)

Institute of Supply Chain Management (IOSCM)

- International Supply Chain Certification

International Institute for Procurement and Market Research (IIPMR)

- Certified Supply Chain Specialist (CSCS)

- Certified Procurement Professional (CPP)

- Certified Supply Chain Analyst (CSCA)

International Supply Chain Education Alliance (ISCEA)

- Certified Demand Driven Planner (CDDP)

- Certified Supply Chain Manager (CSCM)

- Certified Supply Chain Analyst (CSCA)

- Certified Demand Driven Leader (CDDL)

- Certified Supply Chain Technology Professional (CSCTP)

- Certified Supply Chain Energy Expert (CSCEE)

- Certified Lean Masters (CLM)

Supply Chain Management Association (SCMA)

- Supply Chain Management Professional (SCMP)

Books on Global Supply Chain Management

Another way to stand out in your class is by looking for self-directed study beyond online courses. Check out some of the most influential books on supply chain management here:

- Designing and Managing the Supply Chain: Concepts, Strategies and Case Studies by David Simchi-Levi

- Essentials of Supply Chain Management by Michael H. Hugos

- Integral Logistics Management: Operations and Supply Chain Management Within and Across Companies by Paul Schönsleben

- Logistics and Supply Chain Management by Martin Christopher

- Logistics Management and Strategy: Competing through the Supply Chain by Alan Harrison and Remko Van Hoek

- Manufacturing Planning and Control for Supply Chain Management by F. Robert Jacobs and William Berry

- Multinational enterprises and the Law by Peter Muchlinski

- Strategic Supply Chain Management: The Five Core Disciplines for Top Performance by Shoshanah Cohen and Joseph Roussel

- Supply Chain Logistics Management by Donald Bowersox

- Supply Chain Management: Strategy, Planning, and Operation by Sunil Chopra and Peter Meindl

- Supply Chain Risk: Understanding Emerging Threats to Global Supply Chains by John Manners-Bell

- The Handbook of Logistics and Distribution Management: Understanding the Supply Chain by Alan Rushton and Phil Croucher

- The Lean Supply Chain: Managing the Challenge at Tesco by Robert Mason and Barry Evans

More Expert Advice from Supply Chain Professionals

"At Oxford University, we provide an MBA elective course on Supply Chain Management - and we find that students readily understand that today's economy needs to be understood from the perspective of the inter-company network rather than the individual firm,” he says. “The key issue is that today's managers have to learn how to manage resources they don't own or control directly, and this requires a repertoire of skills and knowledge often missing from the business school agenda."

New explains his current research at Oxford. "We're exploring how supply chain thinking needs to be applied to some of the 'hidden' chains that are often neglected: one of these is the invisible network of firms and services that sit behind Cloud Computing.” Read a recent paper on this thinking here.

“SCM as a discipline is relatively young compared to its more established business disciplines like Accounting, Finance, Operations, Sales, or even Marketing. Know that this youth, however, drives a fairly wide variety in what concepts are taught in universities around the country. It’s no secret that university business schools focus intently on getting their graduates hired in stable, well-paying jobs upon graduation. To that end, university curricula are often geared toward the clientele they serve. For example, at University of Michigan and Michigan State University, who hold close relationships with the automotive industry in that state, SCM graduates are often well versed in purchasing, supplier management, and other industrial foci. By contrast, my alma mater Miami University is in southwest Ohio near Cincinnati, which is the corporate home for both Procter & Gamble and Jergens. These consumer products giants are in many ways more focused on the physical distribution of finished goods and serving their big box customers like Wal-Mart and Target. That environment prepared Miami grads far better in warehousing and transportation than purchasing and lean six sigma. I’m in no position to say which is better, just that the environments are different, and it shouldn’t be a surprise that the graduates are prepared differently. So choose your program wisely!”

“I earned a dual MBA from The University of Tennessee in SCM and entrepreneurship, which has been an ideal fit for my current role working with Red Stag Fulfillment, a young (in our 3rd year) supply-chain focused company,” he says.

“The attractiveness of a SCM degree, at least in the way that UT teaches the subject, (and I believe more and more universities are adopting) is a broader focus on defining SCM along the lines of the "total value chain." In summary, this "total value chain" definition tends to suggest that SCM is far more than just moving products and goods from point A to point B, but rather explores the ideal integrations and relationships of business functions within a company as well as how and when to leverage partnerships. For example, how well integrated is the procurement department with the sales and marketing department within the same company? Depending on the type of business, an infusion of cash or effort on the marketing side may do wonders to drive up sales and demand for one's goods, but if the procurement/manufacturing and/or supply chain team is unaware of these efforts and hasn't planned for this increase in sales, the total impact on the business (both financially and in terms of brand value) can seriously harm the business. This seems like a simple concept, but when businesses rely on other internal departments and other businesses in order for the efforts of their department to be realized, it's not long before a tangled spider web of relationships form. The same "value chain" approach is used optimize external relationships, such as with suppliers. My MBA course in SCM spent a lot of time exploring the Kraljic Model, as a framework to determine when to outsource what functions, and how to manage these relationships, (single supplier vs. multiple suppliers, outsource vs. insource, etc.). Because of the way UT's MBA program approaches the SCM major, I feel my experience and area of impact for a business is far more than just the logistical operations, but rather takes on a more strategic, total value scope.”

I have an engineering background and an MBA in finance and strategy. I started my career with Procter & Gamble in Asia-Pacific in supply chain and sourcing function. After working for several years, I decided to pursue MBA in the US, followed by consulting work. I had the opportunity to work with leading corporations globally. It has been the most rewarding experience of my life. It opened my eyes to the possibilities. I continue to enjoy my career in consulting and driving business excellence through the supply chain and sourcing for my clients.”

I have a background in finance and started out on Wall Street. After noticing that Internet stocks seemed almost recession-proof, I decided to take my parents' vacuum business online. It started out as Crucial Vacuum, and my brand has evolved into "Think Crucial" and covers a variety of essential items (we still carry vacuum parts, of course). This full-fledged e-commerce business is possible with great supply chain management in a direct-to-consumer model, and does eight figures annually.”

The Student’s Study Guide to Global Supply Chain Basics

Before signing up for a program, use the study guide below to discover what global supply chain management is all about, and if it’s right for you. Review the basics, benefits and challenges, best practices, and current trends in global supply chain management so you can head into your academic program with confidence knowing the surface level of all top concerns in the field today.

Factors and Components of GSCM

Costs: What are the rates for labor? What are the exchange rates of currencies? What about the tariffs on freighters? All of these are key factors in GSCM.

Culture and attitude: What is the local work culture like? Are managers from your base of operations meshing well with workforces in different parts of the world?

Customs Duty: What level of assembly are your products in by the time they move across borders? What are the rates for different levels of assembly? Do they classify as commodities? All of this can affect what you pay at the border in your global supply chain.

Export regulations: Are there any requirements for local governments when contents leave their docks? Do you have all the export licenses required?

Planning and control: How much of the power is centralized, and how much is left in the hands of subsidiaries and partnered suppliers? Are plans shared with everyone in the supply chain, or doled out last minute from headquarters? How much autonomy is afforded down the supply chain?

Risk and reward structure: What incentives and disincentives are in place for the activities you want to occur? These must be constructed thoughtfully to drive behavior, as this behavior is what will naturally occur without supervision from headquarters.

Taxes on corporate income: This is where high-quality global accounting is useful. What is your tax burden if you pay a bunch of suppliers for the parts and then your own laborers to make your product? What about if you just buy the product from one supplier? What areas of operation are considered tax havens, and will you be expected to repatriate those funds when the product leaves such an area?

Time: Time is of the essence. How much lead time do you need from order to delivery? What is the transit time for your goods? How long is a shipment held up in customs for?

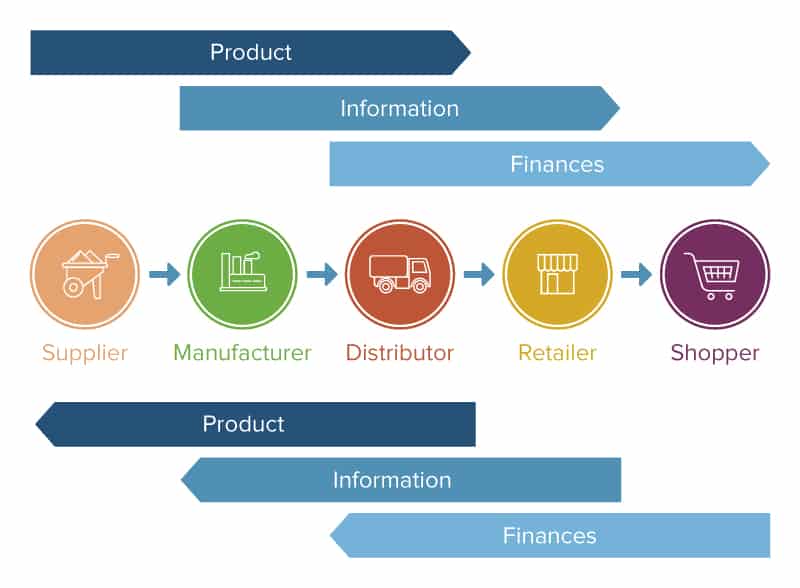

Supply Chain Processes

The following processes are common to all supply chains.

Customer relationship management: Manage potential and existing customers, and their expectations and needs.

Customer service: Determine future needs based on positive and negative feedback.

Demand management: Use CRM and customer service data along with previous order numbers to predict how much product needs to be produced.

Order fulfilment: Getting the product into the hands of the consumer by various means.

Supplier relationship management: Just like consumers, make sure that inter-organizational supply chain partners are satisfied and able to continue working with you under various arrangements.

Product development: Designing, engineering, prototyping, testing, and assembling products for delivery to end consumers.

Returns management: Handling “reverse supply chain” situations where orders are returned and product cycles back into warehousing for reselling, discounting, and/or refurbishing.

Benefits of GSCM

Reliability: Global supply chain management means increasing reliability and predictability for suppliers, buyers, and the end consumers. Consumers can count on the products they want being available when a global operation is behind it. Suppliers have more reason to rush and meet your needs when you’re placing orders large enough to satisfy global demand.

More competitive, better prices, quality: When you can buy from anywhere, competition for suppliers increases. More competition means lower prices and higher quality, which benefits everyone who’s buying.

Reduce costs of operations: Outsourcing the operations that your organization isn’t good at means you take on less risk while assuming major benefits. There’s less direct investment in major facilities or R&D while still procuring all the materials, parts, and products you need to keep things running.

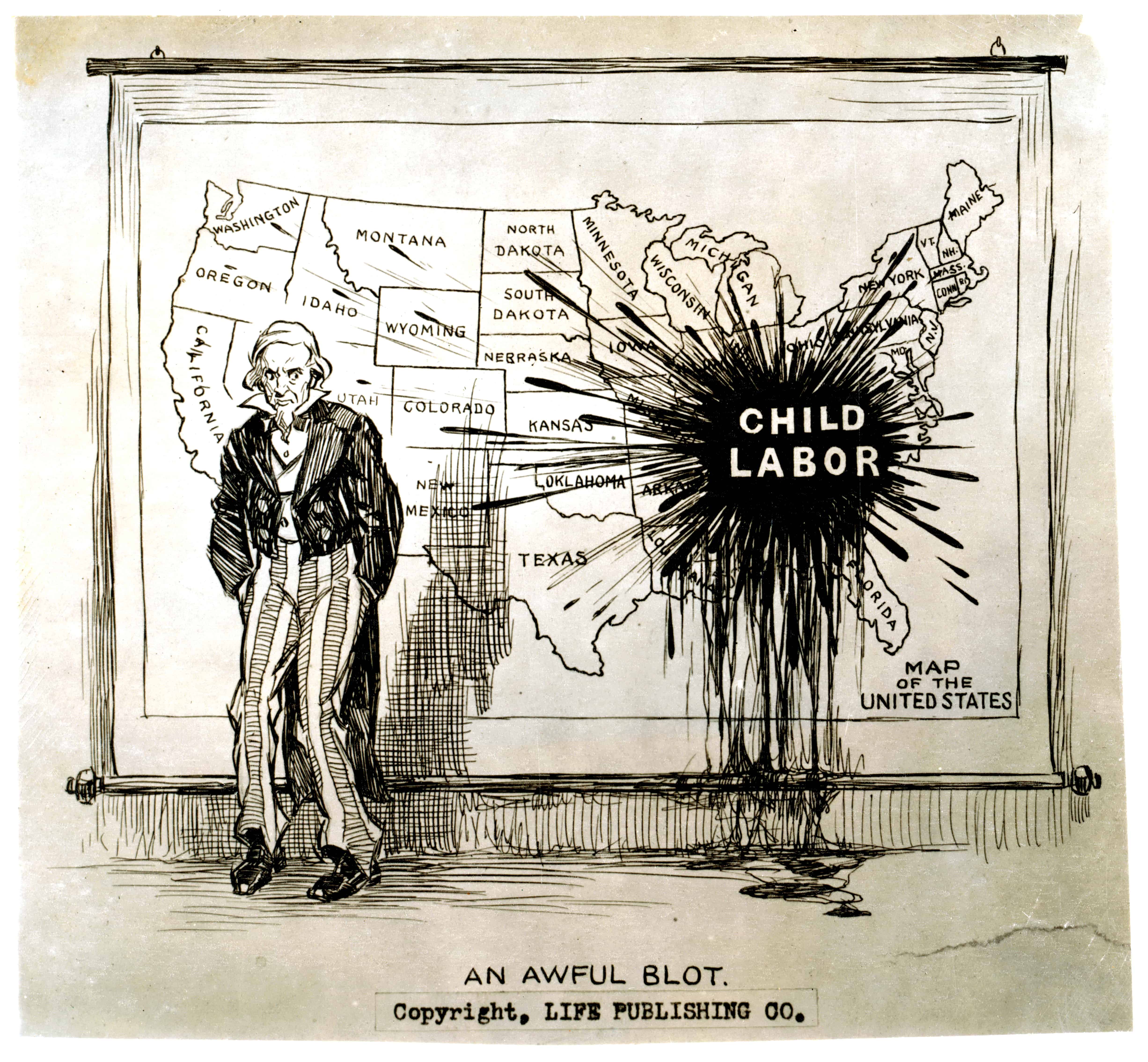

Raising country standards: In many developing areas, the influx of foreign investment combined with those countries’ social and environmental regulations has served to quickly raise standards in order to meet overseas demand. Factory safety, child labor laws, and sustainability causes all progress faster than they otherwise would have been.

Reduce need to warehouse stock: With a tightly integrated global supply chain, goods can be procured just-in-time, meaning inventory doesn’t have to sit around on warehouse shelves for long periods of time, serving no purpose and not bringing in revenue.

Finding/securing items is easy now: For consumers and supply chain operators alike, globalization has made it easy to find exactly what they want, and (most of the time) when they want it.

It’s 24/7: It’s always nine AM somewhere in the world. Global supply chains can be designed so that your operation runs around the clock.

Opens up new opportunities/markets: With the ease of reaching an overseas market, investors and buyers look everywhere for undiscovered opportunities, opening those locations up to capital and the chance to benefit from global trade.

Maximizes supply chain flexibility by necessity: Global supply chains can be long and complicated, but each moving part can also retain some autonomy. They’ll work hard to be flexible to changes in demand, to keep their partners happy and their ROI positive.

Increases chances of survival in global economy: All of the above benefits are being experienced by your competitor, if not by you. Partaking in available global supply chains ultimately helps you thrive in the global economy.

Challenges of GSCM

Ethics in supply chains have been a long standing problem, as this early 1900s poster shows - Wikimedia

Increased cost, complexity, risk: Extending a supply chain beyond your direct control invites increased risks, as more moving parts are complicated to control. Costs can rack up as more suppliers get added up the chain.

Disruption risks and supply shortages: Risks include unexpected shortages, due to disruptions like a strike, an earthquake, or something else that is external that affects your product.

Environmental concerns: Freighting crops around the world isn’t exactly environmentally “sustainable”. Solving energy-related concerns is one of the great challenges of GSCM.

Government regulations in different countries: It’s not enough to contend with local laws - now you have to make sure your product and materials comply with international regulations.

Coordinating partners’ supply and demand: Demand management is not easy. Suppliers participate in the supply chain because they expect to profit. Careful coordination is needed to make sure no one is left holding the bag.

Increasing consumer expectations to quality/service: Globalization and mass production have increased the availability of best-in-class product options to consumers, meaning they expect the best, all the time. It isn’t always easy to keep up.

Lack of transparency/accountability: This raises social and financial issues. Is some of your money being scraped off the top? Is child labor being used by a supplier to save money? You must find a way to remain transparent with your processes.

Consumer backlash: If severe ethical violations occur somewhere in the supply chain, even if the end company wasn’t aware of them, consumers can and will retaliate, damaging the brand and potentially bankrupting them.

Inefficient transportation/distribution: It’s not easy to plan shipments perfectly without any disruptions or wasted space.

Gains may be long term, not immediate: Because of the large up-front investments required, a strong company may not see profits from its global supply chain for a few years.

Modify products for new markets: Not all consumers want the same things, so there can be additional costs and learning curves in adapting your products for the new market, rather than just making more and selling more.

Travel/logistic costs add up: Attributing costs to each product is complicated, and important if you want to determine a profitable pricing strategy. Each time a shipment changes hands, more money is spent.

Increased dependency on technology: The world marches on, and your organization has to keep up. Frequent investment costs can add up, and if it for some reason fails the supply chain could grind to a halt.

Ethics: How far would your organization go to save money? When you start thinking about how much money you can save per unit, you make decisions worth millions of dollars. Ethics can get blurry, which is a frequent challenge in global supply chain design and diligence.

Human capital/talent: The more regions you expand to, the more people you have to rely on. People with incredibly specific skills (for instance, language skills plus management expertise) are hard to find. Now imagine you’re in ten countries with this need, and competing with other top firms with similar needs. The talent pool of these special liaisons isn’t that large, so you can have a difficult time finding the right workers.

SEC regulations: The Securities and Exchange Commission can hit your company with fines for any potential violation, which will either cost money in fines or time and money spent in court.

NGO actions: Activists for a range of causes could end up targeting your large organization if they think something fishy is going on. These groups can be PR nightmares, and even legal ones, with enough backing.

Dodd-Frank: The 2010 Dodd-Frank Decision is a law that requires frequent supply chain audits for US-based companies, adding complexity if your chain runs through one of the named countries where problems occur.

Global Supply Chain Management Best Practices

Global supply chain management has five major best practices that enable success:

- Having a Good Global S&OP System: As your global supply chain expands, it becomes easy to lose sight of sales-driving activities and focus on other operations. Instilling this focus in all partners and liaisons can prevent waste in the global supply chain. This also helps determine what regions to send and sell product to, how to manage shortages, and generally how to make decisions that benefit the global organization (not just regional leaders with self-serving interests).

- Have a Process to Mitigate Complexity: Just because operations are spread out doesn’t mean standards should be. Standardize your equipment, products, and systems throughout the globe, pare down suppliers to the best ones with stronger deals in place, use your company’s scale to leverage better partnerships, and put a single IT platform into place for all parts of your operation.

- Build Strong Supplier Relationships: Build relationships beyond transactional, with larger sets of strategic suppliers who offer more than a core product or service, but instead marry entire industries together, enabling sustainability and integrated profitability.

- Place Talented Local Representatives: Just because your headquarters is geographically far from all your suppliers and regions doesn’t mean you shouldn’t have a strong team on the ground. Find local talent who can bridge culture and language barriers and also send talented, loyal team members to your various regions and suppliers to ensure you have an honest account of local situations. Additionally, consider using incentive systems to keep distant parts of your machine running.

- Install a Rapid Response System: Create visibility throughout your supply chain so that you can quickly recognize and mitigate disasters of all sorts as soon as they occur. This requires all other parts of the best practices to be in place - reliable IT systems, loyal local representatives, simplified suppliers, and strong relationships.

EPIC Framework

The EPIC Framework is a modern way of thinking about supply chains and their design, which will certainly be worth knowing when getting into a GSCM academic program. It is used to determine whether a particular nation should be used in your global supply chain. It includes the following aspects:

- Economy: What is the output of the country and it’s likely future growth? This metric assesses GDP, FDI, inflation, and their balance of trade.

- Politics: Do the politics of this country support supply chain activities? What regulations are there on business, and how much bureaucracy and corruption are there? Are your products going to be held up in customs?

- Infrastructure: There are three measures - their energy infrastructure, physical infrastructure, and telecommunication infrastructure. This also takes the geography of the country into consideration. Is this a “developed” nation for the type of product you’re making? Are roads in good condition; will you be able to get things shipped out on time? Organizations of significant size may even consider investing in infrastructure to take advantage of other factors in the area, like steady workforce or low real estate costs.

- Competence: This measures how productive and skilled the labor force and the logistics industry is within and around the country. Also worth considering are culture, history, and other soft issues. For example, not every country considers 9-to-5 with an hour for lunch a “normal” work day, nor are holidays the same.

Supply Chain Network Design (SCND) Basics

SCND is a major skill common to practitioners of supply chain management. Here are some of the base parts of this decision-making process:

- Strategy Driven: All design decisions need to support your overarching business strategy. Identify risk, allow for innovation, and build with responsiveness to threats in mind.

- Scalable: Make design choices that increase the scale of your business to keep up with demand and further growth. If a partner or supplier cannot keep up with the rest of the chain, it isn’t wise to use them.

- Quantitative Analysis: Using the EPIC framework above, design supply chains around data. You must be able to justify every decision.

- TCO & NPV: Two key data-points are the total cost of ownership (TCO) which takes into account all add-ons and opportunity costs of a particular supply chain investment, and net present value (NPV), which is a standard in determining whether an investment will actually result in a return on investment.

- Holistic Product Design: The products you sell have to be developed and designed while considering everything, from labor laws in the country they’re built to available shipping lanes to get to distribution centers, and beyond. Short-term, quick decisions lead to products that don’t sell.

GSCM Trends Students Should Know

The United Nations Climate Change Conference and the Paris Agreement will affect supply chains across the world - Wikimedia

What’s one way to get a leg up on other students applying for the same program? Being aware of what’s happening now in supply chain management, and having an opinion. Keep up with the following current events and others - there’s always something going on in this field.

Globalization: More companies are expanding outward. Even small entrepreneurs can participate in globalization, for example buying Chinese products at wholesale from Alibaba and repackaging and selling them to American buyers via Fulfilled By Amazon.

Blockchain technology: Blockchain is the technology behind Bitcoin, and is now being used to power the transfer of records, titles, and activity logs so that product flow can be tracked under one global standard. The goal is to increase transparency and also better predict demand and pricing.

Increased transparency: Due to the changing nature of consumer-business relationships and the voice that social media gives to buyers, many companies are becoming more transparent with supply chains. Sustainable supply chains (both socially and environmentally) are even a selling point for many businesses, large and small.

Isolationist forces in US and Europe: The current state of global trade depends on largely free trade. However, in the US and EU, two of the largest consumer markets, there are populist movements gaining momentum that blame globalism for some domestic economic shortcomings. The potential for new tariffs and other protectionist policies could affect the centers of global trade power.

Industry 4.0 movement: This is the trend of automation and open data exchange between robotic machinery, RFID-chip tracking, and cloud computing via the Internet of Things (IoT). It’s already underway and is hard to give an exact “start” date, but it is the silent revolution of internet-enabled systems and machines in manufacturing and supply chains.

Mexico vs. US trade power: As a consequence of new changes in power structure, US companies may have a harder time designing their supply chains, as many rely on NAFTA (North American Free Trade Agreement) to source inexpensive products or materials from Mexico. This is important because Mexico has strong trade agreements with over 100 other nations, while the US has just 20. Mexican suppliers can help US distributors gain access to less-expensive goods from around the world, whereas going direct is often far more expensive because of duties and tariffs. If trade relations between the US and Mexico worsen, it could damage small and even mid-sized businesses’ supply chains.

US Withdrawal From the Paris Agreement: Both the global signing of the Paris Agreement (which sets global goals for carbon-emission reduction) and the US’s withdrawal from it are major events in the supply chain industry. This could affect some US-based companies’ competitiveness with the rest of the world as they would operate on different standards and violate regulations that almost all other nations uphold. However, many US companies’ CSR (corporate social responsibility) programs mean they already target similar or even more aggressive sustainability goals. This could be an area where the free market has more power over businesses’ behavior than the federal government. The companies most likely to be affected are midsized ones that only serve domestic audiences. They have shorter-term goals and are structured to avoid risk (increased costs of environmental sustainability) rather than drive innovation.

Global Supply Chain Finance Study Guide

Global supply chain finance (GSCF) is everything to do with the movement or flow of money within a global supply chain. Consider the fact that between investment, production, transportation, sales, and returns, when money is spent and when profit is made can be very far apart. Attributing return on investment (ROI) to the correct activities, and indeed even staying solvent long enough to make your money back are constant concerns for operators of global supply chains. It’s easy to see why GSCF is considered a field in its own right. It often requires a different sort of person to work on this, as the politics and economics in cash flow throughout the world are far different than products and logistics.

Supply Chain Finance Structures

The state of global supply chain finance can be summed up by the various structures that make up this market. These financing programs are funded and serviced by a few gigantic banks and corporations, controlling 40% of the GSCF system. The rest are controlled by small local banks and service providers. Here are the three major structures that have formed in this environment:

- Buyer managed platforms: The buyer owns the supply chain finance platform, onboarding suppliers as they are contracted and determining the terms of liquidity.

- Bank proprietary platforms: The bank controls the supply chain finance platform, providing funding and managing cash flows from major global buyers.

- Multi-bank platforms: The platform maker controls the supply chain finance platform, with multiple banks buying in and assuming risk to sell funds to buyers.

Benefits of GSCF

Because investment and profit are often so disparate in global supply chains, GSCF providers have taken on the role of enabling such supply chains to exist through lending. They make capital available, particularly to smaller players, and lower their risk for participating. Because these funds are large and controlled by relatively fewer players, they allow capital to be raised at lower rates (much like insurance systems). GSCF also benefits suppliers to the large US and EU markets; without them they would lack access to good capital markets. Ultimately, these major funds provide stability while supply chains get longer and longer.

Supply Chain Finance Challenges

Some of the challenges that providers of GSCF face include:

- Onboarding suppliers to a new single platform from the disparate assortment they were using.

- The Know-Your-Customer (KYC) check required by many funders increases costs and puts deals at risk.

- 90% of GSCF money is supplied by large commercial banks, and many trade assets can’t be covered by their policies.

- Basel III regulation impacts the amount of risk that banks are willing to take on for a smaller borrower.

- Large buyers are being prioritized in general, which is driving down competition throughout the globe.

- Most GSCF deals use proprietary legal documentation that cannot be used across different financial institutions. This increases costs and time.

- There is a massive variance in product definitions, and the lack of standards makes it hard to compare different finance providers’ offers.

GSCF Market Trends

There is a lot of room for growth and innovation in the global supply chain finance market, as most borrowers are unsatisfied with their current solutions. The globalization of supply chains has greatly increased the financial risk that corporations have to take on, which is causing GSCF to grow. CFOs at major corporations have “working capital management” as their top concern, and many suppliers are growing interested in better liquidity and lower financing costs. All of this contributes to making the GSCF market valued at $275 billion and growing.

GSCF Translators Roles

A unique operator in the supply chain field is the GSCF translator. They are a liaison between logistics and transportation providers, and financial services providers. With expertise in each field, they can bring all parties to the table to work out a deal that takes the needs of each party into account. They help supply chain operators choose and structure credit solutions that will keep them running, while insuring GSCF providers get a return on their investment. Students interested in this intersection of finance and logistics, along with the opportunity to work globally, should consider pursuing this path.

Glossary of GSCM Terms Students Should Know

Business logistics management: The production and distribution processes of an organization.

Economic Order Quantity (EOQ): A tool that helps you decide how to order necessary inventory at minimal cost, taking time and cost of placing an order into consideration.

Global Asset Based Lending (GABL): A practice that enables middle market organizations to monetize in-transit and other inventory to improve their liquidity.

Inventory finance: A financing method that allows small suppliers of large buyers to get financing that they hold for said large buyers, which helps maintain liquidity.

Lean Supply Chain: A supply chain that is free from redundancy and waste.

Payables Discounting: A process that uses a buyer’s credit to get better financing rates for suppliers, which provides incentives for integrated supply chains and reduced risk.

Receivables management services: Outsourcing receivables management and collections that provides financing and guaranteed payment on said receivables.

Supply chain diligence: Using true vigilance and supply chain audits to ensure no entanglement in your supply chain with war, slavery, child labor, excess pollution, and other unsavory global problems.

Supply chain event management: The practice of considering all possible scenarios that may disrupt a supply chain. This enables you to proactively put solutions in place to mitigate risk.

Supply chain management system/software/app/tool: By any name, these are software solutions you use within your organization (or potentially with all suppliers in your supply chain) to collect data, track progress, and optimize the chain.

Effectively Manage Your Global Supply Chain With Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.