How to Create a Barcode Inventory System

To create a barcode inventory system, first understand its components, including a barcode printer and scanner. Next, organize your stock in a spreadsheet, assign unique stock-keeping units (SKUs), and generate a barcode for each. Then print and attach barcode labels to products, and start scanning.

Here are the step-by-step instructions to create a barcode inventory system:

- Understand the Key Components

Most barcode inventory systems include the same basic components, as listed below:- An organized inventory list, which is a database or spreadsheet of all your products

- Unique identifiers for each item, such as SKUs or product codes

- A method by which you generate barcodes from those identifiers

- Tools for scanning, such as a barcode scanner device or a smartphone app

- Organize Your Stock Items in a Spreadsheet or Database

Choose a platform to manage your inventory data. Many small businesses start with familiar tools such as Excel, Google Sheets, or Smartsheet, all of which can track item details and support barcodes and don’t require specialized software. If you already use a point-of-sale (POS) system or a dedicated inventory software, you might already have built-in barcode support. In this guide, we’ll focus on tools you can set up yourself that don’t require a full software package.

- Assign Unique SKU or ID Numbers

Create a unique identifier for every product or item variant. Many small businesses use SKUs or internal product codes. Each code should correspond to one item or product type. Having unique ID numbers is critical because you will use these codes in your barcodes.

- Choose a Barcode Type

Choose the barcode format that best suits your needs. A 1D barcode format, such as Code 128 or Code 39 (characterized by typical black lines), works well for encoding alphanumeric SKUs for most inventory systems. If you need to store more information or need to be able to easily scan barcodes with a phone camera, consider 2D barcodes, such as QR codes. Whereas 1D barcodes are commonly used for retail products, QR codes can hold more data but may not be necessary for basic inventory tracking.

“Choose a standardized barcode symbology to code them depending on your industry,” says Enrique Pratdesaba, General Manager at Grupo Barcode. Examples of standardized barcode symbology include UPC, EAN, GTIN, Code 39, or Code 128. “Group items by categories, SKUs, or locations to make scanning and tracking efficient.”

- Generate Barcodes for Each Item ID

Using your chosen format, create a barcode for each SKU or ID in your inventory. You can use software or online barcode generators to do this. For example, if you use Google Sheets, you can generate barcodes by using barcode fonts (see more information on this below). The result should be a scannable label with a black-and-white pattern for each item code.

- Print and Attach the Barcode Labels

Once you’ve created the barcode images, print them on label stickers or paper. Affix each barcode label to the corresponding item or its designated shelf or bin. Place the labels in an easy-to-scan location (flat and visible), and use durable printing so that the labels don’t fade or smear with handling. Consider investing in higher-quality printing equipment, if budget allows. Proper labeling ensures that when you or your staff scan an item, you always capture the right product information.

“It all starts with the label,” Pratdesaba says. “Choose a dependable label printer paired with labeling software with comprehensive features and room to grow. Also, choose labels that suit your needs. Consider durability, size, environment, etc. Don’t underestimate this step, as barcode readability depends on it.”

He gives this recent example: “A customer already had a system in place but had barcode reading problems. They even invested in very expensive scanners to read some pallet labels with little success. We redesigned the barcode label, barcode density, and position, which enhanced readability and improved performance to a 100 percent readability rate, faster and from farther distance, even with simpler scanners. Again, designing the right barcode label from the beginning is key.”

- Choose Your Scanning Method

Determine how you’ll scan barcodes during daily operations. For a budget-friendly option, download a mobile app (such as Smartsheet) that uses your phone’s camera. You can also invest in a handheld scanner that connects via USB or Bluetooth. Many Bluetooth scanners can pair with smartphones. Make sure your scanning method works seamlessly with your inventory software or spreadsheet, so scans go to the right place. After labeling and selecting your scanning method, test a few entries by scanning barcodes and confirming that the right item records appear in your software or spreadsheet. Make adjustments if needed before rolling out the system.

“Choose handheld scanners, mobile computers, or forklift-mounted computers with scanners that suit your environment (wireless for mobility, rugged for warehouses) and the way you operate your store or warehouse,” Pratdesaba advises.

Learn more about barcode inventory management and inventory control systems in our comprehensive guide.

How to Use a Barcode Inventory System

A strong barcode inventory system depends on a strong process. Label and scan all items as they come in and go out to track stock levels and trigger reorder requests. When done correctly, this helps you manage sales, shipping, and receiving for your full inventory cycle.

Here’s a closer look at how to operate a barcode inventory system:

- Scan Inventory In and Out

Once you’ve labeled your items and set up your process, use the barcode system in everyday operations to keep accurate stock data. For example, when new stock arrives, scan each item's barcode to add it to your inventory list; this way, you can record the increased quantity on hand in your system. Likewise, scan the barcode to decrease the stock count when a sale is made or an item is shipped out. The act of scanning replaces typing in SKU numbers or item names manually – a quick beep, and the system records the transaction in real time. In a cloud-based or synced system, anyone viewing the inventory will see changes as they occur. Real-time tracking prevents problems such as selling an item someone else has just sold.

- Track Stock Levels and Reorder Points

With consistent barcode use, businesses can easily monitor how many units of each product are available. You can set up your system to alert you when stock hits a reorder point, or the inventory level at which you need to order more product. For instance, if you decide that you should always reorder an item when only five are left in stock, your inventory system can flag that item once the quantity drops to five (this could be as simple as a colored highlight in Excel or Google Sheets, or an automated alert in a tool such as Smartsheet). Scanning items during sales and deliveries keeps these counts accurate without extra manual work.

- Manage Sales, Shipping, and Receiving

The barcode system plays into different operations. At the point of sale (or when packing an order), scan each item’s barcode to automatically pull up its details or subtract it from inventory. When receiving shipments from suppliers, scan items as they are unpacked to add them to inventory records. This unified process means that the same system handles all inventory movements, reducing the chance of errors or oversight.

- Sync Across Devices and Users

A big advantage of modern barcode systems is connectivity. If you’re using a cloud-based program like Google Sheets or Smartsheet, multiple team members can use it at the same time. A staff member in the stockroom with a tablet can scan in new stock, while a salesperson with a phone can check inventory for a customer, and all updates will sync in the cloud. This ensures everyone is working with the same real-time data. You can even store an Excel file on a shared drive, such as OneDrive or Dropbox, to allow access; however, you will not have real-time editing in the desktop app. The goal is to ensure that the data stays consistent and current for all users, whether you update inventory from a warehouse PC or a mobile phone on the store floor.

- Sync Your Barcode System With Other Tools You Use

Even if you’re starting small, consider how your barcode inventory system will work alongside the other software you already use, such as accounting, online sales, shipping, or customer management tools. The more your systems “talk” to each other, the less manual entry you'll need to do — and the fewer mistakes you’ll make.

“The best tip for integrating software into a barcode inventory system is to prioritize seamless data synchronization and data integrity across platforms,” Pratdesaba says. “Taking good care of your data flow is key. If your inventory software doesn’t integrate smoothly with your existing systems (e.g., accounting, sales, or ERP), you’ll face isolated data repositories, manual entry errors, and reporting inconsistencies.”

For example, a business that sells online might want inventory updates to sync automatically with their e-commerce platform. Even using a shared Google Sheet linked to other business tools through automation, such as Zapier or AppSheet, can save time and reduce duplicate work.

Best Practices for Setting Up and Using a Barcode Inventory System

The best practices for a barcode inventory system include standardizing your barcodes and procedures, training your staff, monitoring your progress, and adjusting as necessary. Do regular audits to ensure inventory accuracy and effective reordering. Also, plan for the future, which could include QR codes.

Here’s a more detailed review of best practices for barcode inventory systems:

- Standardize Your Barcode Formats and Procedures: Choose one barcode format for all your items and stick with it. For example, use all 1D Code 128 barcodes for products or all QR codes for specific assets. Consistency makes it easier for staff to scan and for the system to recognize entries. Also, establish a standard way of labeling (e.g., the size and placement of the barcode on products) so that employees know where to find and scan the code. This avoids confusion and speeds up the scanning process.

- Train Your Staff and Enforce Usage: Ensure all employees know how to use the barcode system properly. Provide a short training session on how to scan items, what to do if a barcode won’t scan, and how to handle exceptions (such as a missing label). Encourage team members to always use the scanner instead of typing numbers, so the system stays accurate. Well-trained staff will use the system consistently and confidently, which ensures that your inventory data is up-to-date.

- Conduct Regular Audits and Inventory Checks: Even when you have a barcode system in place, it’s wise to do periodic manual inventory counts or spot checks. This helps verify that the barcode records match the actual stock on shelves. Schedule routine audits, such as a small cycle count of select items each week or a full inventory count quarterly. Regular checks can catch issues, such as lost or unscanned items, and ensure your system’s data remains trustworthy.

- Back Up Your Data and Have a Contingency Plan: Technical issues can happen, so always back up your inventory data. If you’re using spreadsheets, keep backup copies of your files or use cloud services that save a version history. Cloud-based systems such as Smartsheet or Google Sheets save data in the cloud, but consider exporting a backup periodically. Also, make a plan for if your scanner or app malfunctions – for instance, you might have a spare scanner or the ability to manually input data. This way, a hardware glitch won’t paralyze your operations.

- Optimize for Mobile Use: Since one of the key benefits of your system is mobile scanning, ensure your devices are set up for smooth use. This could mean using tablets or phones with durable cases for warehouse work, ensuring batteries are charged at the start of a shift, and the inventory app or spreadsheet is easily accessible on all mobile devices. If you're using a mobile app, configure it to load the correct sheet or form when you open it to save time. Small optimizations, such as enlarging barcode fields or using forms with large scan buttons, can make the scanning process faster and more foolproof for employees on their mobile devices.

- Plan for Future Flexibility, Including QR Codes: While 1D barcodes such as Code 128 work well for most small businesses, it’s smart to think ahead. QR codes can hold more information and are easier to scan with mobile devices, which could be useful if you later want to include links, batch data, or item history. You don’t need to switch now, but choosing a system that could support QR codes later (such as Smartsheet or a flexible scanner app) gives you room to grow without having to overhaul your setup.

“Transitioning to QR codes can be fairly easy as long as you have scanners that are capable of scanning both – otherwise, you will have to purchase new scanning equipment,” says Jillian Bishop, marketing director for Barcode-Labels.com.

“The best part about QR codes is that you can convey more information in a smaller print area, which is great for complex data,” she says. “Another great thing about a QR is the ability to set the code up for error reduction in case of possible damage to the print area. If enough error reduction is built in and the label gets damaged, you are more likely to retain the ability to scan the information.”

Pratdesaba says the move to QR codes is part of a broader shift toward smarter, more interconnected inventory systems.

“Businesses that adopt these technologies early will likely benefit from better efficiency, improved accuracy, and enhanced supply chain transparency,” he says. “QR codes can store significantly more information than traditional 1D barcodes, including product details, batch numbers, expiration dates, and URLs. GS1, the global barcode standardization entity, is encouraging the shift to 2D barcodes (both QR and Data Matrix) through the GS1 Digital link standardization.” (Note: A Data Matrix is an alternative to QR codes that is optimized for very small labels.)

How to Integrate Software Into a Barcode Inventory System

By integrating barcodes with software, you automate data collection and inventory tracking. Simple software solutions can be very cost-effective for small businesses. Accessible options include Excel, Google Sheets, and Smartsheet.

The idea is to use tools you might already have or that are easy to adopt, so you don’t need an expensive proprietary system to get started. For a fuller comparison, see our article on how to choose a barcode inventory system.

How to Create a Barcode Inventory System in Excel

Excel can be a simple and effective tool for setting up a barcode inventory system, especially for small businesses that want to track stock without investing in new software. This system is manual, but it can be effective with minimal expense.

Follow the step-by-step guide below to create a barcode inventory system in Excel:

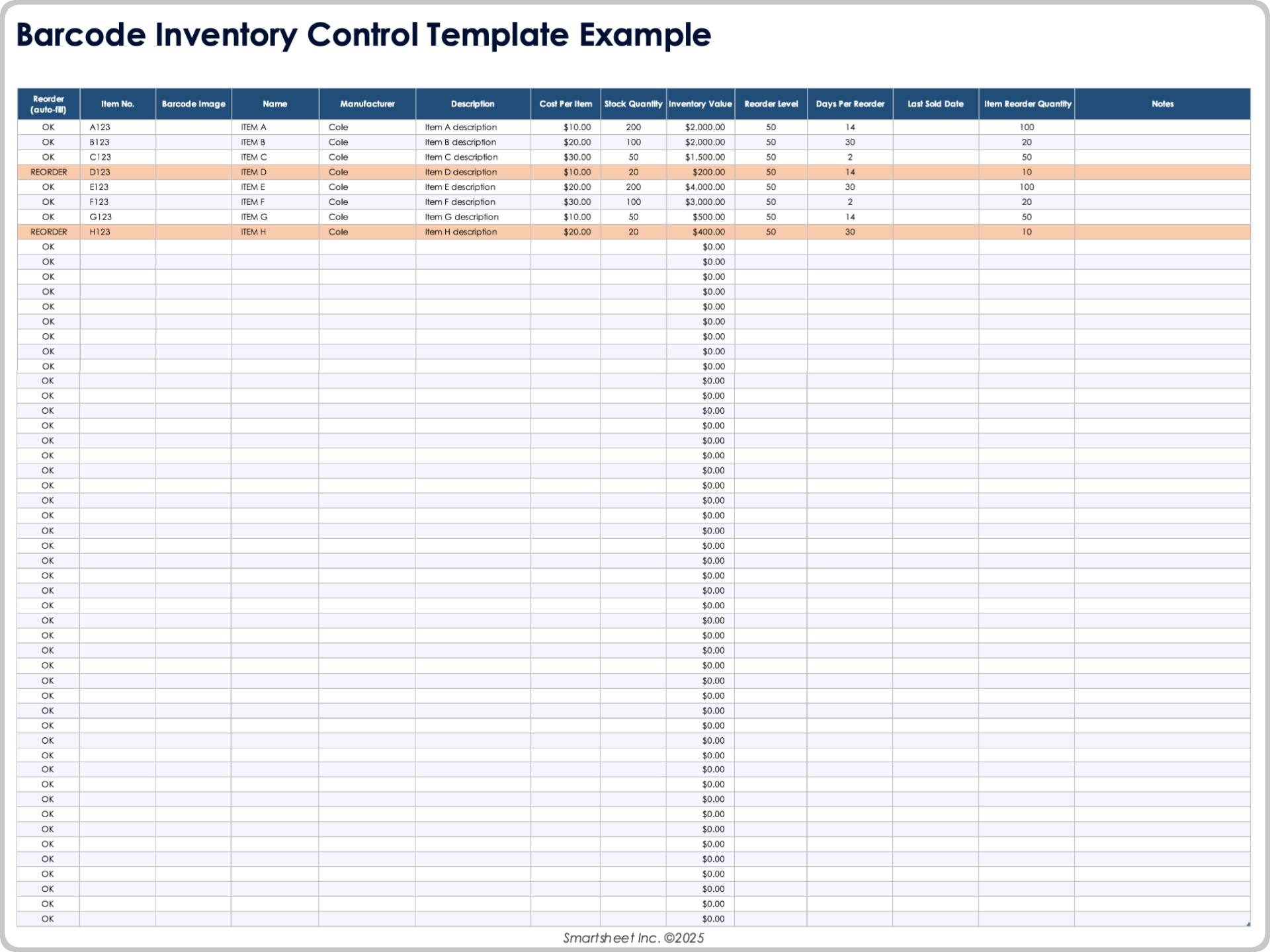

-

Download the barcode inventory control template in Excel

. Open the file. The template is pre-built with column headers for the unique item number or SKU, barcode image, product name, quantity, and other key inventory info to provide full tracking.

- Click on the blank template (the second tab in the sheet) and enter your inventory line by line. Input a unique item number (or SKU) for each item, and add or delete columns to reflect your business’s needs.

- If you already have barcodes, scan, copy, and paste them into the Barcode Image cell.

- If you don’t have existing barcodes, see our guide on how to create a barcode in Excel to generate new barcodes.

- Print barcode labels directly from your sheet as needed. Use a durable black-and-white printer capable of producing easily readable barcodes.

- Share the spreadsheet with your team. Train the team in your new process and keep enforcing it.

- Update the sheet consistently to track available quantity, reorder dates, the value of your current inventory, and more. This is a largely manual process, but it’s inexpensive and provides transparency into your inventory.

For other template options, see our free inventory management templates for Excel.

How to Create a Barcode Inventory System in Google Sheets

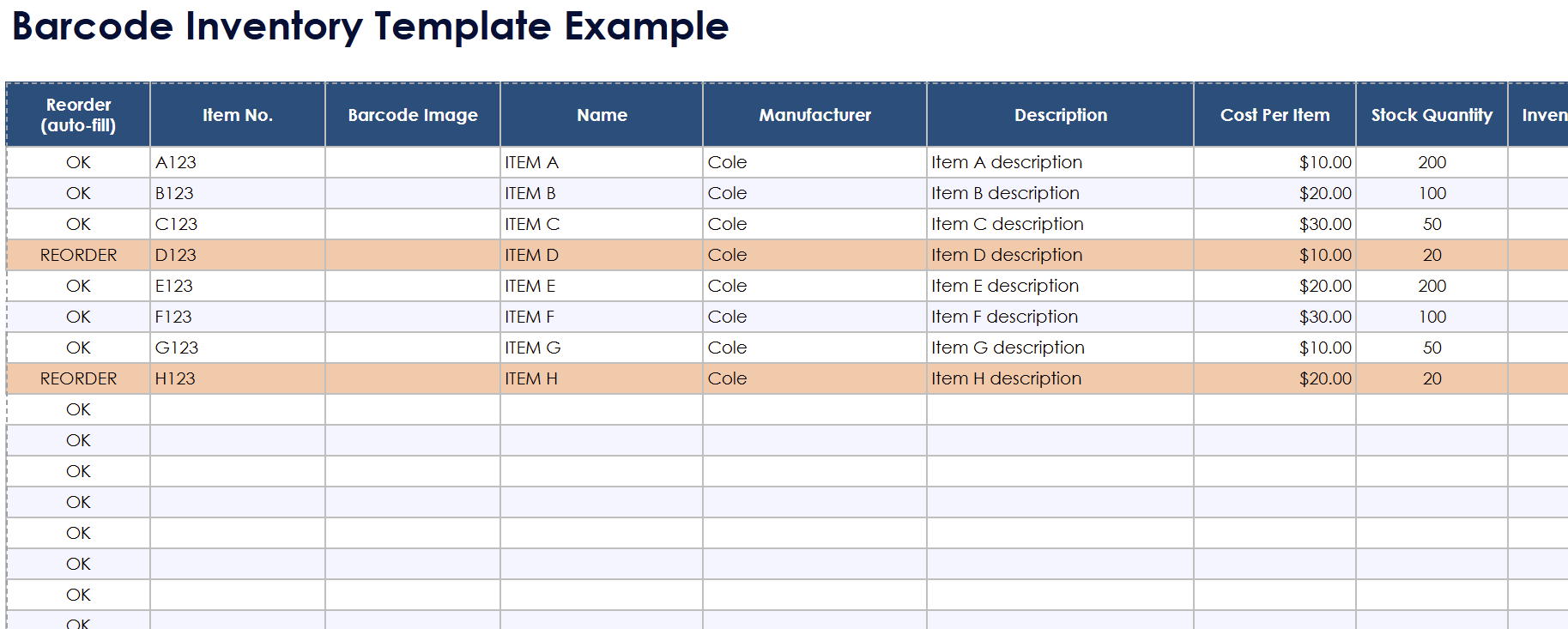

Follow these steps to create a simple barcode inventory system in Google Sheets. This setup will let you track items, scan barcodes, and manage stock — all from a shareable, cloud-based spreadsheet.

Follow these steps:

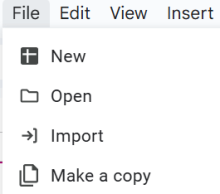

- Open the barcode inventory template in Google Sheets. Click File > Make a Copy.

(Note that this template is based on the Excel sheet in the previous section.)

- The column headers include the unique item number (or SKU), barcode image, product name, manufacturer, product description, quantity, and other key inventory info to provide full tracking. You can customize the template using Google Sheets standard functionality, such as deleting or inserting columns.

- To input your stock, click on the template’s Blank tab and begin adding your stock items. Fill in each row with item details. (The rows follow the same format as the Excel sheet in the previous section.)

- If you already have barcodes, scan, copy, and paste them into the Barcode Image cell. You can also generate barcodes in the sheet.

- Print barcode labels from your sheet as needed. Use a durable black-and-white printer capable of producing easily readable barcodes.

- Share the file with your team and set permissions based on their role (View or Edit). Because Google Sheets is cloud-based, you can access it from multiple devices, including phones and tablets.

- Train your team in your new process and keep enforcing it.

- Consistently update the sheet as inventory comes in and goes out.

How to Generate New Barcodes

If you don’t have existing barcodes, you can generate barcodes from the item numbers (or SKUs) in your sheet. Follow these steps:

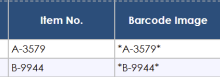

- Repeat the item number in the Barcode Image column and put an asterisk before and after it.

- Highlight the entire Barcode Image column.

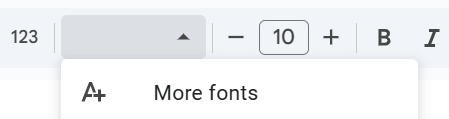

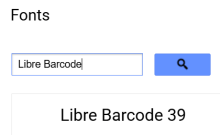

- Click More fonts in the toolbar.

- Search for and select Libre Barcode 39 (or any barcode font of your choice).

- Apply the barcode font. Doing so will translate the item number or SKU into a barcode image.

For more options, see our article on free Google Sheets inventory templates.

How to Create a Barcode Inventory System in Smartsheet

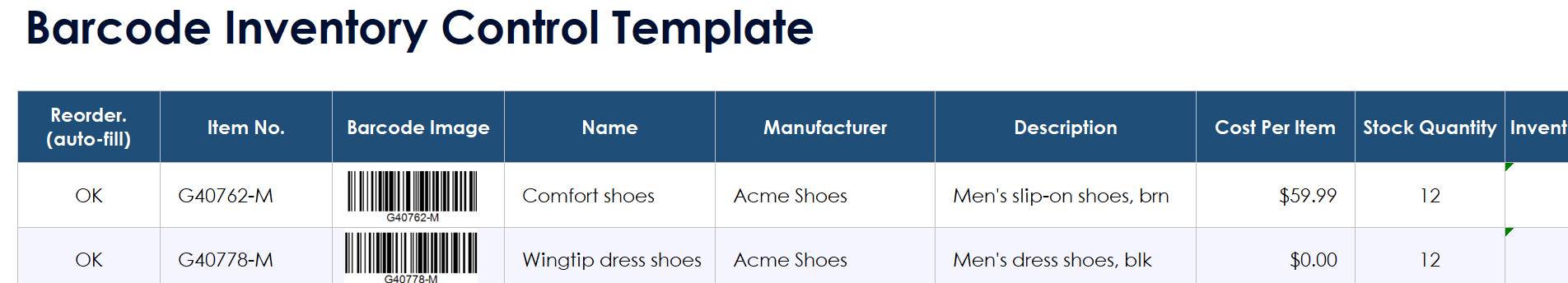

Smartsheet, a cloud-based work management platform, offers a free, user-friendly barcode inventory management template to help you manage your inventory efficiently using barcodes. Follow these steps to get started:

- Create a free Smartsheet account if you don’t already have one.

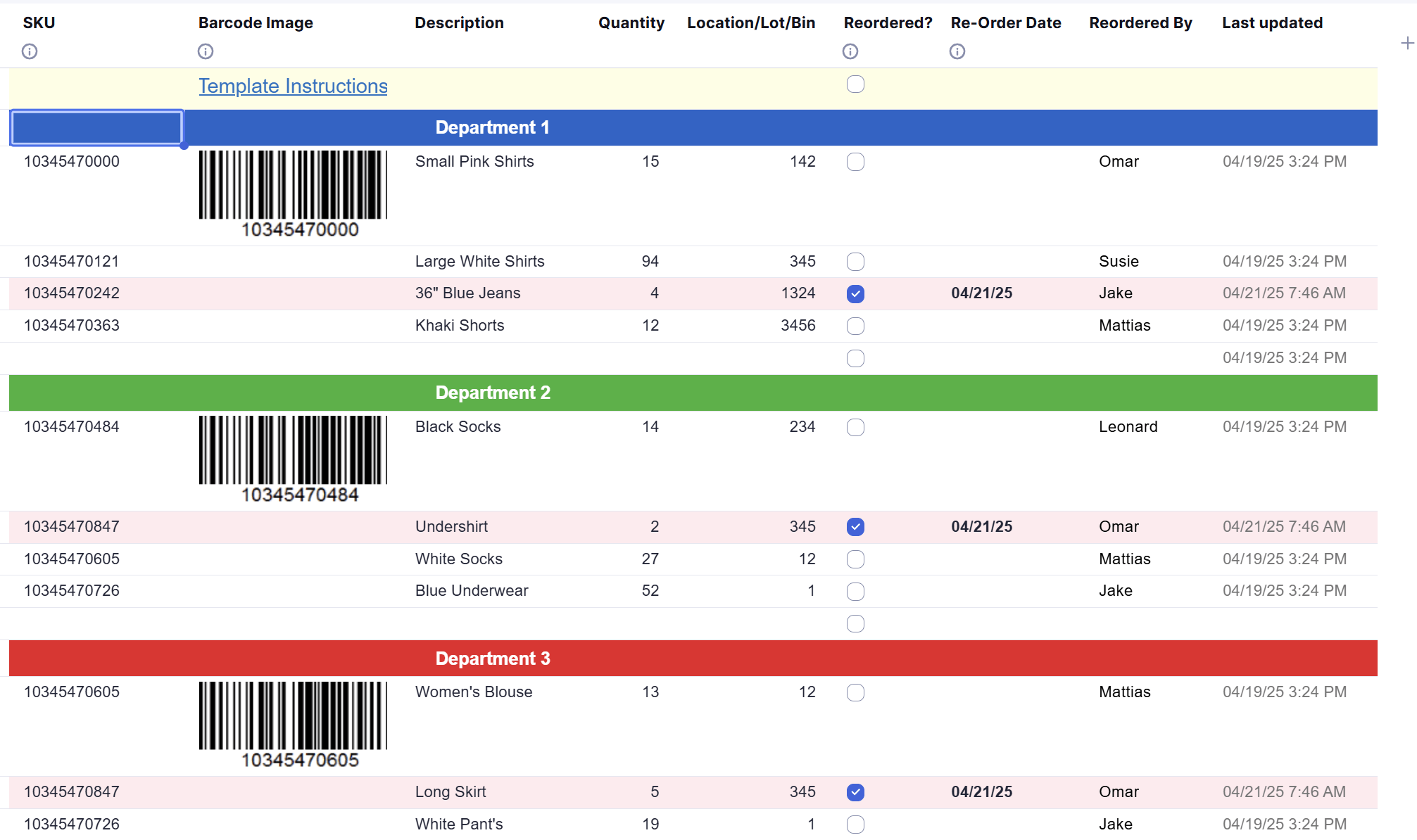

- Open the Smartsheet barcode inventory management template. Click on Use Template to add it to your workspace. Open the newly added sheet to begin a quick lesson in using it.

- The template includes preset column headers and example entries. You can add columns by using the standard Smartsheet functionality.

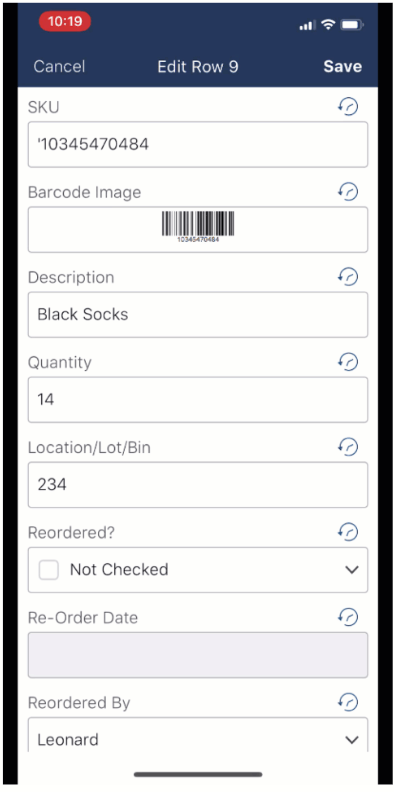

The column headers are as follows:

- SKU/ID: A unique identifier for each item.

- Barcode Image: The barcode associated with the item.

- Description: The name or description of the product. You can also create separate columns for these if you prefer.

- Quantity: The current inventory count.

- Location/Lot/Bin: The place the item is stored, such as a bin number.

- Reordered?: Note whether or not you’ve reordered this item.

- Re-Order Date: The date you reordered the item.

- Reordered By: The team member who made the reorder.

- Last Updated: The date the row was last updated.

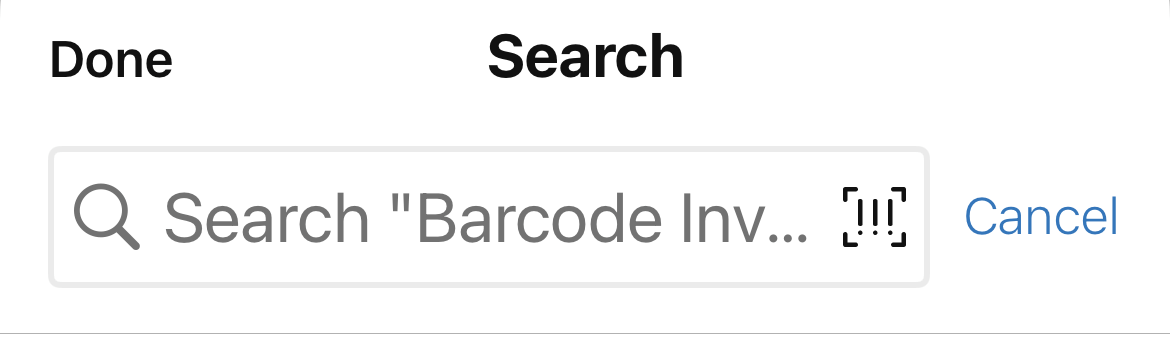

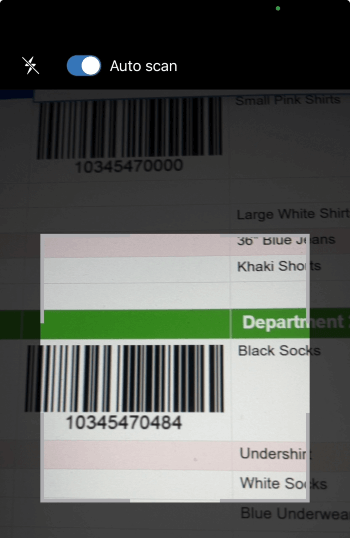

- Download the Smartsheet mobile app from the Apple Store or Google Play. Open your mobile app, and find your sheet in the mobile app and open it. Tap the Search icon. Tap the Barcode icon at the right side of the Search box.

Your Auto Scan automatically opens.

- For practice scanning a barcode, open your template on a computer, and use your phone or tablet to scan a barcode label from one of the prefilled examples in the template. (You can scan any barcode, though it won’t return any results since it’s not in your sheet yet.)

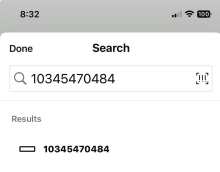

It will quickly find the row in your sheet.

Open the result to view and edit the row as necessary.

- Enter your product data row by row. Each product needs a unique SKU or identifier.

- Repeat step 3 to auto-scan barcodes with the Smartsheet mobile app. This time, point your phone at actual barcodes on your products.

- Print your barcode labels. Use a durable and reliable printer, as well as sticky labels. Open them in your sheet to print, and use the standard printing functionality.

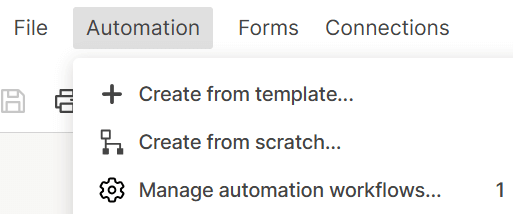

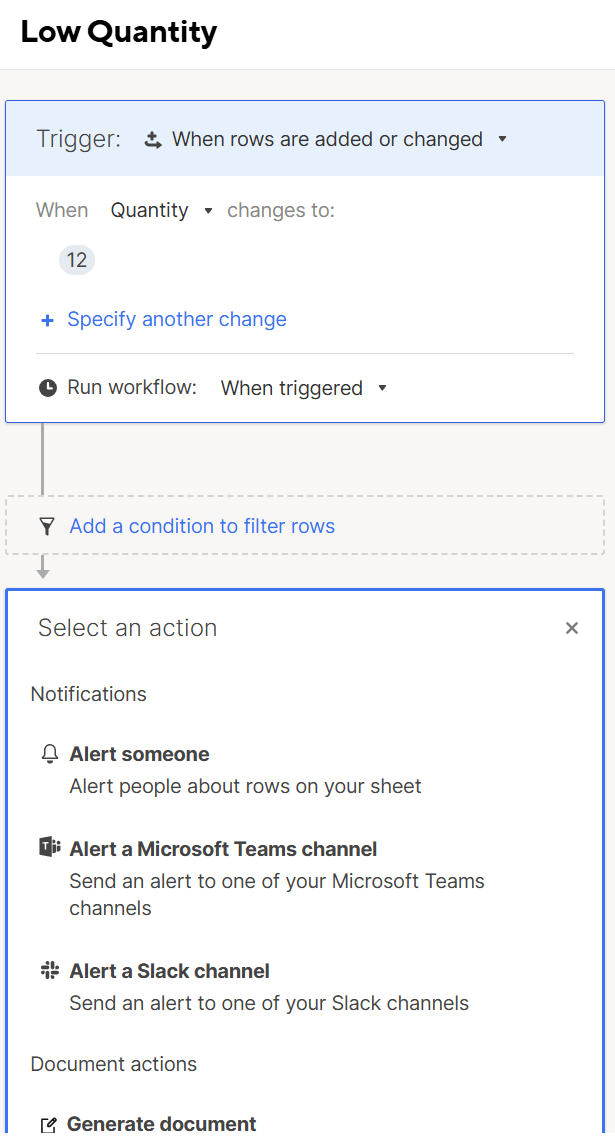

- Set automated alerts for low stock to ensure you never run out of stock by setting up alerts: Click on Automation in the top menu. Select Create from scratch.

- Choose a trigger, such as when Quantity falls below a certain number. Set the action to send an email notification to the relevant personnel.

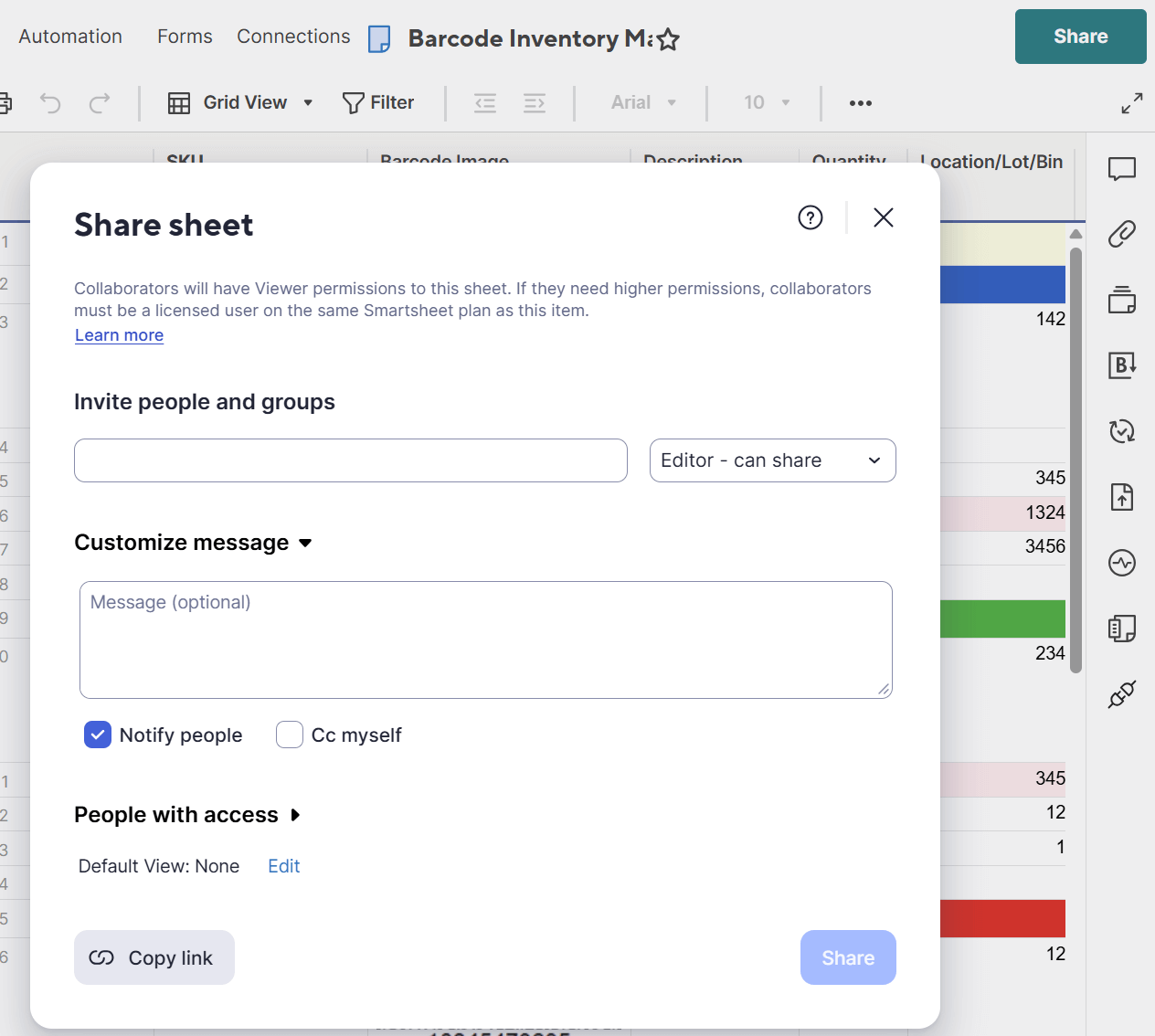

- Share the sheet with your team to collaborate seamlessly. Click on the Share button in the top-right corner, and enter the email addresses of team members. Assign appropriate permissions (Viewer, Editor, Admin) based on roles.

- Monitor and update inventory regularly. You can maintain accurate records by regularly scanning items during stock intake and dispatch, updating quantities in real time using the mobile app, and reviewing the sheet periodically to ensure data accuracy.

Smartsheet’s barcode capabilities help you manage your stock effectively. This system offers real-time tracking, automated alerts, and seamless collaboration, making it an excellent choice for small to medium-sized businesses (SMBs).

How Smartsheet Helps With Barcode Inventory Management

Smartsheet includes certain features that make barcode inventory management easier for small to medium-sized businesses. These features include a mobile app for scanning, automated alerts, real-time collaboration, and scalability as you grow.

Here’s a closer look at Smartsheet’s benefits:

- Easy to Set Up and Use: Smartsheet looks and feels like a spreadsheet, so it's easy for beginners to learn. You don’t need coding or IT support to build and customize your inventory tracker — just add columns, formulas, or workflows as needed.

- Built-In Mobile Scanning: With the Smartsheet mobile app, you can scan barcodes using your phone or tablet. It’s ideal for teams that need to update inventory from the stockroom or sales floor, or when they’re on the go.

- Automated Alerts and Workflows: You can create simple automations to track low stock, send restock reminders, or prompt team members to confirm changes. In this way, Smartsheet helps you stay proactive instead of reactive.

- Real-Time Collaboration: Because Smartsheet is cloud-based, everyone has access to real-time inventory data. This eliminates version control issues and minimizes delays. Additionally, team members can scan, update, and access info from anywhere.

- Scalable and Connected: As your business grows, Smartsheet grows with you. You can track thousands of items, build more advanced workflows, or integrate with tools such as your online store or accounting software using built-in connectors or APIs.

- Inventory Insights at a Glance: Dashboards and reports make it easy to monitor key metrics, such as total stock value or items running low, in real time. Your entire team will get visibility without the need for IT-assisted setup.

Create a Reliable Barcode Inventory Tracking System With Real-Time Work Management in Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.