What Are the Basic Principles of Lean?

Originating in Japanese manufacturing, Lean is a methodology that focuses on eliminating waste. Waste can come in many forms — from superfluous motion to wasted raw materials and nonproductive time — and is broadly defined as any aspect of your business process that does not add value for the customer. Within Lean, value means something the customer is willing to pay for.

Lean goes by many names, including Lean manufacturing, Lean production, Lean management, and Lean process improvement. We will touch on the basics of Lean here, and you can learn more about Lean management in this in-depth article.

Lean process improvement looks at the value stream — the series of steps that create value. The stream flows through an organization, with each department or unit (such as manufacturing, distribution, and customer service) adding value.

Traditional management focuses on optimizing each unit in the organization independently and often in isolation from other departments. Lean looks at the value stream as a single, continuous process and strives to make sure it flows smoothly from end to end.

Lean managers understand what customers value and continually strive to minimize the cost (i.e., the effort, space, capital, and time) involved in delivering it. In a true Lean process, all efforts are value adding, and they’re performed with the minimum amount of resources, time, and energy expenditures necessary.

The history of Lean is intertwined with the Toyota Motor Company and Taiichi Ohno, an engineer who was the legendary creator of the Toyota Production System (TPS). In resource-poor postwar Japan, Ohno integrated efficiency theories and practices into the TPS to build the manufacturing paradigm that we now call Lean. The TPS captured the attention of global manufacturers after researchers at MIT’s Sloan School of Management and International Motor Vehicle Program introduced it to the world in the late 1980s.

Ohno described seven wastes (known as muda in Japanese):

- Defects

- Unnecessary motion

- Transportation

- Time spent waiting for processing

- Overprocessing

- Overproduction

- Inventory

Some types of waste are obvious, like excess inventory clogging your warehouses, but others, such as overprocessing, can sometimes be difficult to spot.

MIT’s James P. Womack and Dan Jones wrote the international bestselling book The Machine that Changed the World, which examined the history and future of Lean production. The authors would later become thought leaders in Lean’s spread to the West — Womack founded the Lean Enterprise Institute and Jones founded the Lean Enterprise Academy.

Interestingly, their work was in some ways a reintroduction of Lean to the West, since Ohno gave some credit for TPS to U.S. auto pioneer Henry Ford. The term “lean” was actually coined by the two MIT researchers to describe what they saw at Toyota; the term itself was not used at Toyota.

Many companies that embrace Lean, such as Toyota and Danaher, have their own names for their Lean programs. In creating their own terminology, they make an important point that Lean is a core part of their culture and identity. Lean isn’t a campaign or short-term cost reduction program; it’s a distinct style of production that is undergirded by a philosophy. Lean works best when you commit to it for the long haul.

Project Management Guide

Your one-stop shop for everything project management

Ready to get more out of your project management efforts? Visit our comprehensive project management guide for tips, best practices, and free resources to manage your work more effectively.

What Is Lean Process Improvement?

Lean process improvement is an ongoing campaign to whittle away waste and inefficiency, an effort most famously encapsulated as continuous improvement, or kaizen in Japanese.

Always seeking to move closer to a perfect state of zero waste, Lean process improvement consists of the following:

- Defining value by the product or service

- Identifying the value stream

- Making production or service delivery flow as smoothly as possible

- Progressing at a tempo determined by customer demand

To engage in Lean process improvement, you need a clear understanding of the value of your product and your value stream. Implementing Lean will continually improve your workflow, yielding a seamless delivery of your products and services over time.

In most modern operations, waste can only be eliminated a little bit at a time. Through incremental improvement, your process becomes markedly more efficient. You can’t actually eradicate waste entirely and achieve a perfect value creation process, but you can keep trying to get as close as you can.

Data collection drives a lot of Lean process improvement. You measure a process, such as how long it takes to paint one car. Then, you implement a refinement and time the process again to see if a Lean fix has worked. The new figures become your baseline; you try another tweak to see if you can get the process working even better, and the feedback loop continues.

Continuous improvement underlies much of Japan’s success within manufacturing and has been applied both inside and outside Japan in diverse industries, such as healthcare and software.

Creating a culture that commits to ongoing improvement — rather than allowing complacency set in — involves an organization-wide change in thinking called a Lean transformation.

The cumulative effect of these efforts can be significant. Following are the benefits of Lean process improvement:

- Less waste

- Lower inventory

- Higher productivity

- Improved quality

- Increased customer satisfaction

- Lower costs

- Greater profitability

- Higher levels of responsiveness to changes in market conditions and customer tastes

Don’t let these productivity killers go unchecked.

Uncover the top three factors that are killing your productivity and 10 tips to help you overcome them.

Download the free e-book to overcome my productivity killers

The Evolution of Lean Process Improvement Methodologies

Before The Machine that Changed the World brought Lean into the spotlight, other experts realized in the 1970s that Western industry had lost its competitive manufacturing advantage to Japan. These manufacturing pros concluded that Western companies needed to adopt successful Japanese practices.

Following is a discussion regarding the evolution of various process improvement methodologies:

- Total Quality Management: Manufacturers turned to the work of W. Edwards Deming, who, 30 years earlier, with other quality theorists, had taught Japanese companies how to improve their processes. Deming’s work in Japan centered on statistical product quality management and especially on the uniformity of manufactured parts.

Deming’s work took much longer to catch on in the United States, but it eventually reached American industry in the 1980s as a system called Total quality management (TQM), which was inspired by a 1982 Deming book entitled Out of the Crisis. The book posited that a high quality of manufactured parts was the result of an organization-wide alignment with quality management. - Six Sigma: The U.S. Navy adopted the TQM name for their Deming-inspired statistical process control methodologies in 1985, and, from there, the process spread to other branches of the federal government. TQM is considered the predecessor of process improvement methodologies that followed, especially Six Sigma.

Six Sigma is a statistics and measurement-driven attempt to reduce manufacturing defects. The methodology takes its name from the Greek letter sigma, which in statistics is the unit for variation from the mean. Six Sigma aims to reduce defects to an infinitesimal proportion of total manufacturing output.

Six Sigma, which was born at Motorola and Allied Signal, was refined at General Electric in the 1990s and spread from there. This approach is a Lean methodology because it emphasizes the incremental improvement of processes and reduction of variation through initiatives. The core tool of Six Sigma is the DMAIC, a data-driven process improvement cycle of defining, measuring, analyzing, improving, and controlling manufacturing processes. We will discuss that concept in more depth later.

Six Sigma projects are led by practitioners with different levels of Six Sigma process improvement expertise. They are identified by belts of various colors. - Lean Six Sigma: Six Sigma zeroes in on one of the seven wastes: defects. There’s a hybrid Six Sigma approach called Lean Six Sigma, which targets the other six wastes. As part of a hybrid approach, Lean Six Sigma seeks to reduce manufacturing defects while making manufacturing processes more efficient. In tandem, the two approaches are meant to improve quality while cutting production costs and production times.

- Theory of Constraints: Moving away from the emphasis on quality, another methodology for Lean improvements comes from the theory of constraints (TOC). TOC holds that any suboptimal process is held back from higher performance by a single constraint, which is the weakest link in the chain or a bottleneck.

The constraint is the prime target for a Lean intervention. Once that constraint is addressed, another previously hidden constraint will be revealed. The TOC approach uses a tool called process flow analysis, which helps identify the constraints in a process. - Just in Time: Lastly, there’s the just-in-time approach, made famous by Toyota. Just-in-time (JIT) is an inventory management methodology that aims to have products in assembly and materials arrive at processing stations at the moment workers are ready for them — no earlier or later. Technically, that means zero inventory costs, because items in progress keep moving.

JIT isn’t an alternative to quality management processes like Six Sigma, but rather a supplement to them. So, just like Lean Six Sigma, JIT is typically employed in tandem with a quality control method.

How to Create a Culture of Lean Process Improvement

To begin implementing Lean process improvement, your organization first needs to make sure everyone understands the mission. This shared vision is critical for the success of your Lean initiatives, since Lean only works if it touches every part of your operation and has investment from all staff members.

Here are some key steps to lay the groundwork for Lean process improvement:

- Make Lean Improvement a Mindset, Not a Fad: True Lean process improvement is a long game — if organizations treat it as a one-off, their Lean gains quickly stop accruing. This isn’t to say that an individual Lean intervention is useless. A single initiative can generate a lot of benefits if it addresses an important process. But an isolated intervention does not deliver sustained improvement. In Lean, incremental improvements compound, and sustained effort will yield greater gains.

- Lean Thinking Needs to Permeate an Organization from Top to Bottom: Get every part of your organization on board with Lean process improvement. By definition, Lean works to optimize an entire value stream, and value streams run across departments in an organization. If some departments buy into Lean while others don’t, Lean’s benefits will not materialize. The net result of that scenario tends to be disruption, cross-departmental conflict, and rifts. Even if some departments achieve improvements, the organization ends up in silos that operate in isolation, and the value stream doesn’t necessarily become any leaner.

- Give People the Power They Need to Go Lean: One of the foundational ideas in Lean process improvement is that nobody understands a process better than the people who use it most often. The methodology calls for these staff members to propose, design, and implement Lean initiatives.

In manufacturing, this means production staff. In retail, the front-line people are cashiers and sales clerks. For many executives, investing power in people who might be low in the organizational hierarchy runs counter to instinct. But, if Lean improvements are left exclusively to managers, the program will lack adequate insight into current processes and challenges. - Engage Purpose, Process, and People: Lean process improvement rests on three foundations: purpose, processes, and people.

- Purpose: The purpose is usually simple enough, since organizations and customers both stand to profit from leaner processing. When considering the foundation of purpose, there’s a direct relationship to the bottom line.

- Process: The processes are the ways in which value streams are mapped, assessed, and engineered. We’ll delve into the specifics later on.

- People: Most significantly, you need Lean-minded people to oversee the value streams and take ownership of them.

How to Get Going with a Lean Improvement Process

The nuances of Lean can appear overwhelming to the point that you may hesitate to dive in. But because the method only brings benefits if you put it into action, don’t get stuck on trying to do it perfectly. Lean is all about getting better bit by bit.

Use these quick-start instructions to get going:

- Pick a process or problem to focus on. Lean improvements get underway for one of two reasons: Either there’s a specific waste-related problem that needs fixing or there’s a process that appears wasteful. Whatever the case, hone in on a specific process or problem.

- Build a team that includes not just managers, but also front-line people who actually work with the process or problem. Assuming they’ve been trained to think Lean, workers who are closest to the process or problem are an invaluable part of the Lean team. Their knowledge of the process in real-world conditions, including its strengths, weaknesses, and redundancies, forms the basis of the Lean improvement process.

- Appoint a team leader. A Lean team needs a champion. Often, this is a person with training in Lean or quality management, such as a Six Sigma green or black belt holder. Of course, there’s a wide array of Lean qualifications available besides Six Sigma (we offer a list of training opportunities and certifications at the end of this article).

- Make communication a priority. Since Lean teams are usually cross-functional, a lack of communication will handicap the group. But, intra-team communication is not the only kind that’s important. Cross-organizational communication is also critical.

- Take a big-picture view. With a problem-solving effort, it’s tempting to assume you know the cause or solution. But, Lean teams need to perform due diligence by working through a disciplined value-stream process, or they may miss the real root cause of a problem. And, even if there’s not a specific problem to solve, Lean teams should examine the overall flow of products or services, looking across departments and technologies. Doing so enables them to cut waste across the entire value stream, not just at specific points.

- Make use of Lean improvement tools. There’s a whole toolbox for Lean — making use of these techniques gives you the best chances of success.

A Model for Lean Process Improvement

What does Lean process improvement look like in action? Here’s a simple model for identifying potential improvements and implementing them:

1. Map the Value Stream: The first step is identifying the activities that create value and determining the sequence in which they occur. This sequence of activities that creates value constitutes the value stream we talked about earlier.

2. Identify and Eliminate Waste: Next, look for any activities that do not add value. Brainstorm with staff at every point of the value stream concerning ideas for using less material, reducing motion, cutting duplicated effort, and decreasing waiting or processing. One useful practice for identifying and eliminating waste is the Kata method. Kata is a four-step approach:

- Begin by envisioning where you want to end up and defining what a perfect process would look like.

- Next, assess the current state and cause of the waste or bottleneck. This is an important step because the true issue may sometimes be hidden. You want to target the underlying problem, just as a doctor wants to treat the root illness, not just the symptom.

- After that, map out what your next state should look like. This step will probably be incremental and lead to your ideal state, and will help you determine how — and whether — performance will improve.

- Lastly, conduct experiments to determine the best fix for the process. Which of the proposed solutions will take the process closest to its hypothesized ideal state? You may find yourself implementing many small fixes. Then, begin the cycle all over again.

3. Move to a Pull System: Once you’ve identified and eliminated waste, make customer demand (rather than a condition such as when a supplier delivers materials) the trigger for production. The act of basing production on demand is called a pull system. Pull systems avoid manufacturing more product than is easily sellable to ensure that you don’t accrue extra costs for warehousing inventory. Pacing production to demand also smooths the flow of work, decreasing stress on workers, equipment, and systems.Improve 4. Continuously: Now, you are ready to begin a new cycle of incremental Lean improvement, which means looking for further waste to cut. Typically, the theory of constraints will help you identify the waste that represents the biggest burden.

Problem-Solving Frameworks in Lean Process Improvement

There are a variety of problem-solving approaches that you can call upon during different stages of the Lean model we just described. Let’s look at the most popular ones and when they are most appropriate. As you’ll see, each of these frameworks offers a different way of identifying and dealing with the causes of waste.

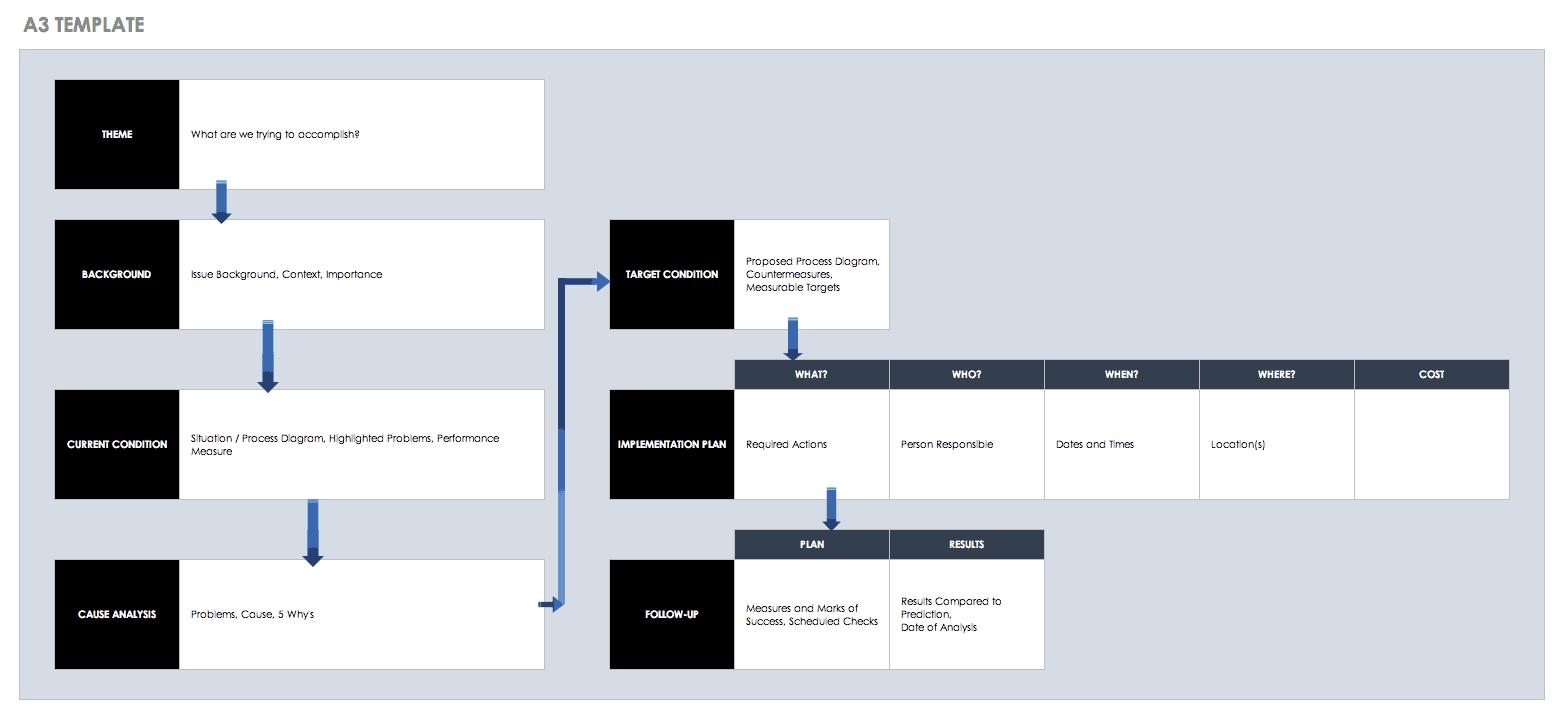

Toyota’s A3 Method

Named for the standardized size of paper on which it fits, Toyota’s A3 method is a problem-solving framework that is remarkable for its versatility in dealing with simple problems. (See the A3 template below.) Using straightforward steps, you can apply the method to any small-scale problem in both production and non-production contexts. You can also use this approach for solving some large-scale problems. There are seven steps involved in the A3 method:

-

Clarify the Problem: Define the problem, the harm it causes, and the value of solving it. What is the discrepancy between the problem state and the ideal state?

-

Break Down the Problem: Study the full scope of the problem. Is it limited to the initial warning sign? Or, is there more going on behind the scenes?

-

Set a Target: What is the goal? The ideal state? Or, will you settle for something less?

-

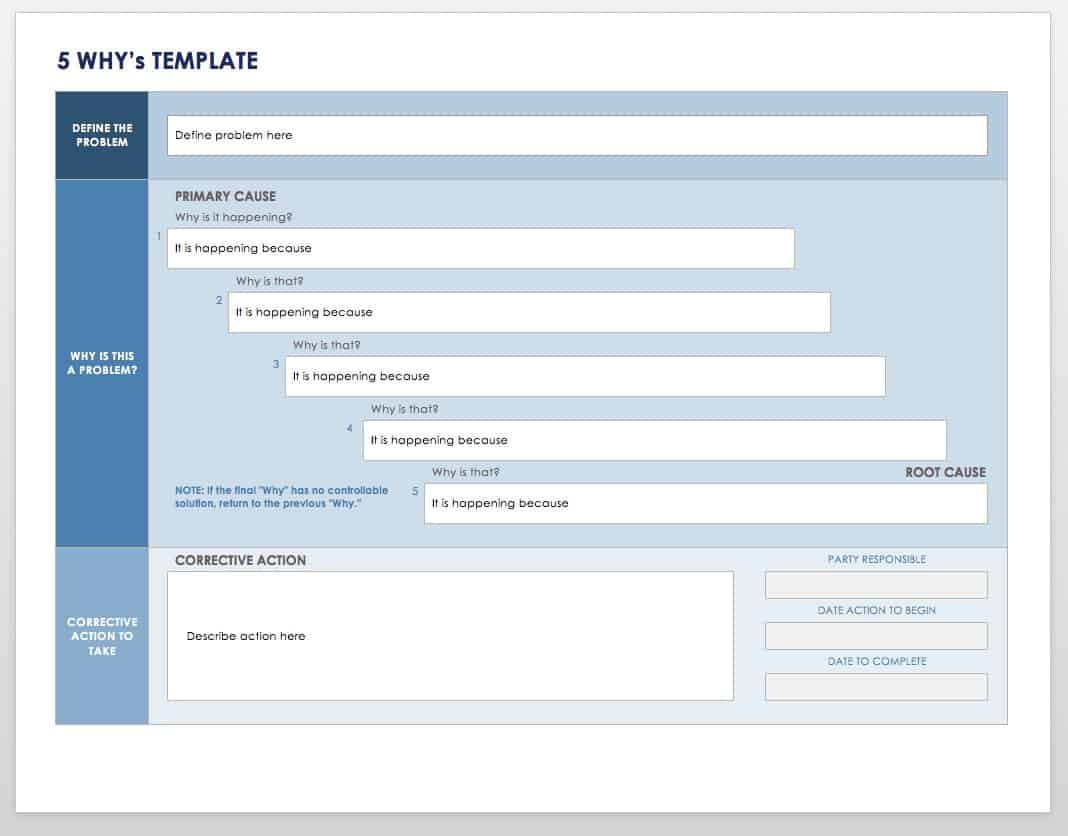

Analyze the Root Cause: This is a meaty step, and Toyota uses 5 whys to tackle it. Starting with the problem itself, you ask five times why something went wrong, which should suffice to get you to the root cause. You can use the template below for the 5 whys process. It includes sections for defining the problem, exploring its root cause and primary cause, and determining corrective action.

Download 5 Whys Template

Excel | Word | PDF | Smartsheet

-

Think of Corrective Actions: Propose and execute countermeasures to fix the root cause of the problem.

-

Monitor the Results: Are the countermeasures working as hoped? If yes, move on to the next step. If no, repeat steps 3–5.

-

Standardize the Solution: Can lessons learned from solving this problem help to preempt similar problems elsewhere? If not, do you know what to do if a similar problem turns up again? Standardizing turns problem solving into a learning experience.

Download this template to conduct your own A3 process. The template walks you through each of A3’s seven key steps.

Download A3 Template - Excel

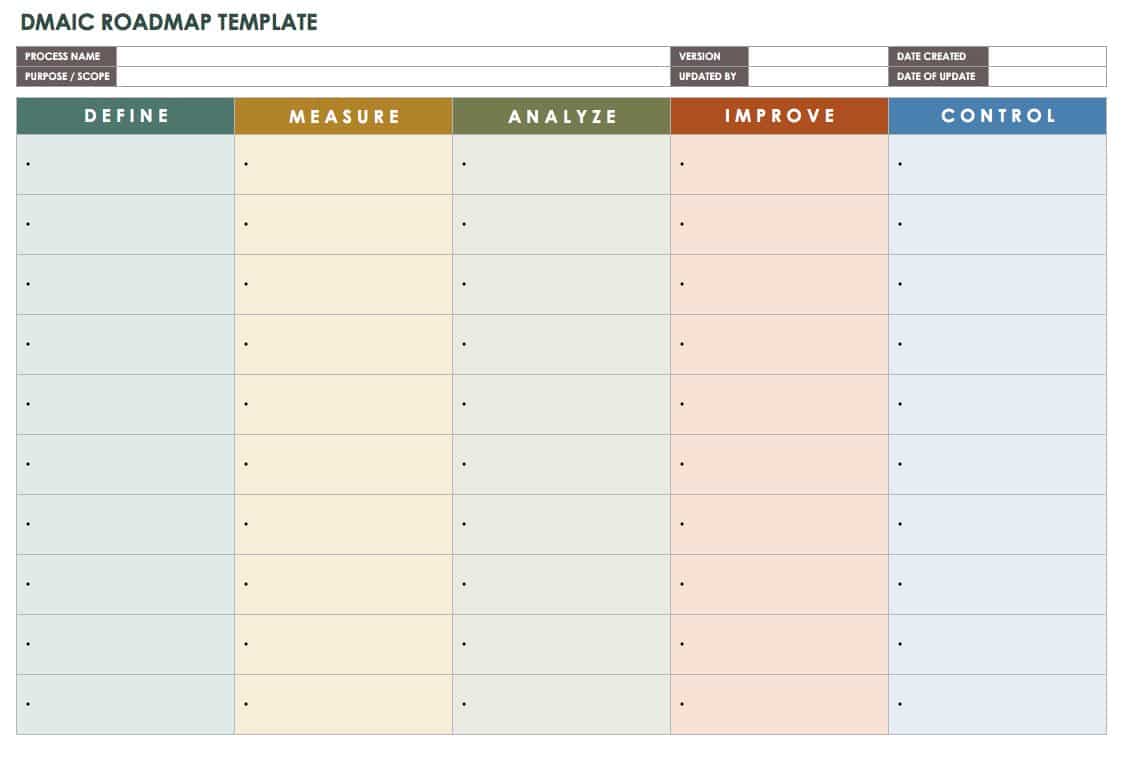

Six Sigma DMAIC

Best for process quality maintenance and improvement, DMAIC comes from Six Sigma, which explains why it has a heavy bent toward data, performance metrics, and measurement. The DMAIC process comprises five stages:

- Define the Problem or Opportunity for Improvement: What is the problem, what resources are available to solve it, and when does it need to be fixed?

- Measure Current Performance and the Deviation from Ideal Performance: You need performance baselines — such as component specifications and variances — to determine if there has been actual improvement by the end of the process.

- Analyze the Process to Determine What Is Causing the Variation in Quality: There are a number of tools to determine the root cause. Most of them involve root cause analyses, such as fishbone diagrams and consensus building tools, like multi-voting.

- Improve the Process by Addressing the Root Causes Identified in the Previous Step: When necessary, brainstorming and testing are also a part of this step.

- Control the New Process: If you have achieved improvement, you need to make the gains sustainable.

As the core problem-solving framework for Six Sigma, DMAIC works best as part of a Six Sigma project. However, it can also be applied to quality problems on its own.

You can use this DMAIC roadmap template and the DMAIC method to organize your own improvement initiative. It includes plenty of space under each of the five DMAIC columns (define, measure, analyze, improve, and control).

Download DMAIC Roadmap Template

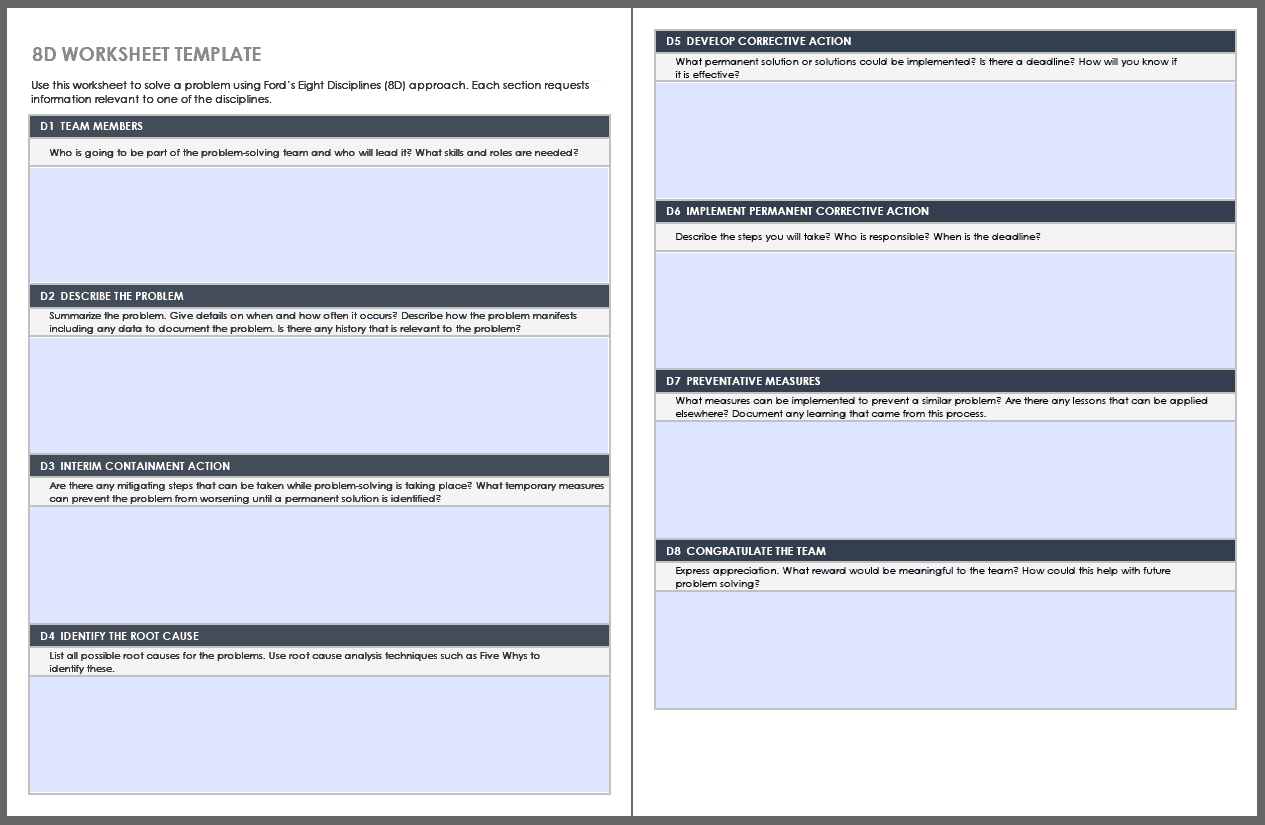

Ford’s Eight Disciplines of Problem Solving (8D)

Best for problems of product quality or safety in manufacturing, Ford’s 8D methodology is another technique that dates back to the 1980s. This method is a team-oriented approach to solving production problems. 8D is easy to learn and straightforward to document.

Here are the 8Ds:

- Form a Team to Tackle the Problem: Usually, this means a cross-functional team.

- Describe the Problem: This combines researching and documenting the problem and sometimes extends to trying to isolate its root cause.

- Take Interim Containment Action: Like plugging a leak with your finger until you find a permanent fix, this step is meant to protect the customer.

- Conduct a Root Cause Analysis: Verify the root cause by collecting data. There are a wide range of tools that can be used here, including fishbone diagrams, Pareto charts, and 5 whys.

- Plan a Permanent Corrective Action: Design a solution and assess it for risk and effectiveness.

- Implement the Permanent Corrective Action: Hopefully, this addresses the root cause and makes the problem go away.

- Prevent Recurrence: Any problem solved is a chance to learn to preempt and address similar problems in the future. Gather lessons learned.

- Close and Celebrate: This makes problem solving rewarding and motivates the team.

The 8D framework, with its emphasis on cross-functional teams and customer protection, is a favorite in assembly processes, such as auto manufacturing.

This report template guides you through the 8D approach with sections for each step, from describing the problem and root causes to identifying the corrective actions and ways to prevent recurrence.

Download 8D Report Template

Deming Cycle (aka the Shewhart Cycle, PDCA, or PDSA)

The Deming Cycle was pioneered by its namesake, W. Edwards Deming — though he himself called it the Shewhart cycle. The approach is also known as the PDCA (plan, do, check, act) and the PDSA (plan, do, study, act) and shares some similarities with the Kata method. Whichever name you choose, the framework serves to drive iterative improvement of processes. It often works best for process engineering.

The Deming cycle has four stages:

- Plan: Decide on a course of action to improve a process.

- Do: Implement said course of action.

- Check: Evaluate of the action. (Deming later replaced “check” with “study,” as he felt that the former implied inspection rather than the objective analysis he intended.)

- Act: Depending on the effectiveness of the action, either implement a new norm for operations going forward or go back to the drawing board.

The Deming cycle brings scientific discipline to problem solving. The cycle represents a sequence of hypothesizing solutions, experimenting with them, and evaluating their effectiveness. As a true Lean methodology designed for continuous incremental improvement, this technique is meant to be employed repeatedly and painlessly.

Techniques and Tools for Lean Process Improvement

On a Lean process improvement project, you will typically employ a primary problem-solving framework and then many tools or techniques to execute the steps. We describe the most commonly used tools below. Often, their value or relevance to your initiative will be evident.

If you are unsure where to start, here are a couple of general guidelines regarding choosing the right technique for your Lean project:

- If you are working in manufacturing or dealing with a tangible good, you will generally use Lean techniques. You can use Six Sigma and Lean Six Sigma with both production and service organizations.

- If your problem lies with process flow and waste, Lean is your best match. If the issue relates to quality, customer satisfaction, and product defects, Six Sigma focuses on these dimensions.

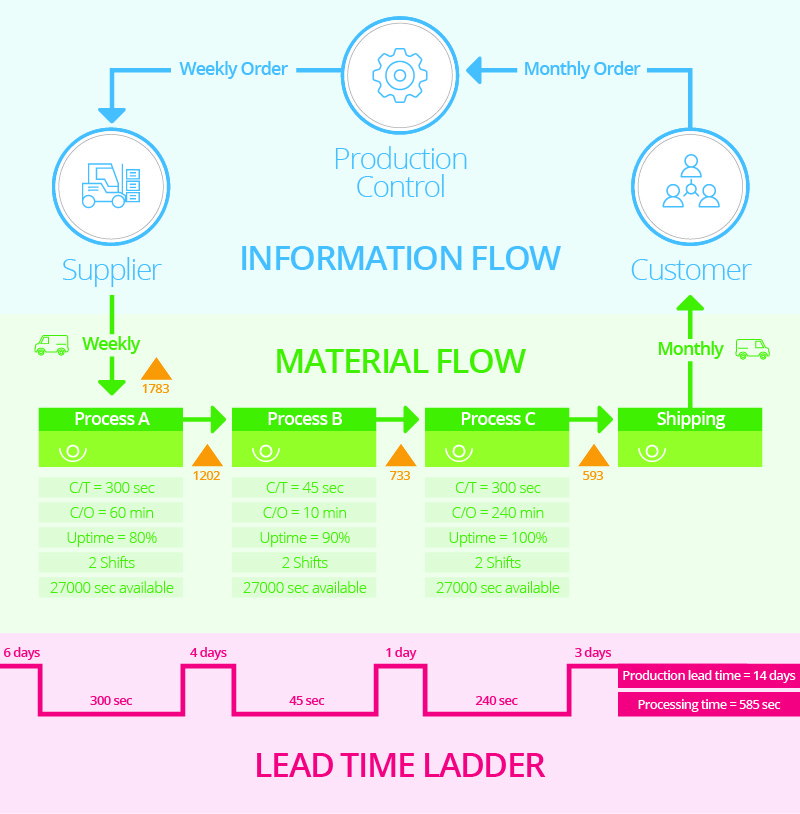

Value Stream Mapping

Value stream mapping is a critical technique for the Lean improvement process, because Lean focuses on optimizing the value stream. As value streams are usually complex, a diagram is quite helpful. To create one, engage in value stream or business process mapping.

The value stream map looks like a highly complex flowchart with multiple inputs. A common practice is to draw two versions of the map: one for the current state and one for the ideal future state.

An associated tool is process mapping, in which you map a single process instead of an entire value stream. Process mapping implies a more granular view than value stream mapping, but it serves the same purpose.

Analysis of Variance (ANOVA)

Analysis of Variance (ANOVA) is a statistical technique that tests whether a difference in the mathematical average (mean) of multiple groups of variables is significant. The analysis is used to compare the outcomes of different interventions.

The advantage of conducting an analysis of variance is that it can tell you whether one change to your process produces more meaningful results than another.

We won’t go into the intricacies of calculating ANOVA here, but you can learn more with these instructions for how to calculate an ANOVA table and a simple ANOVA online calculator.

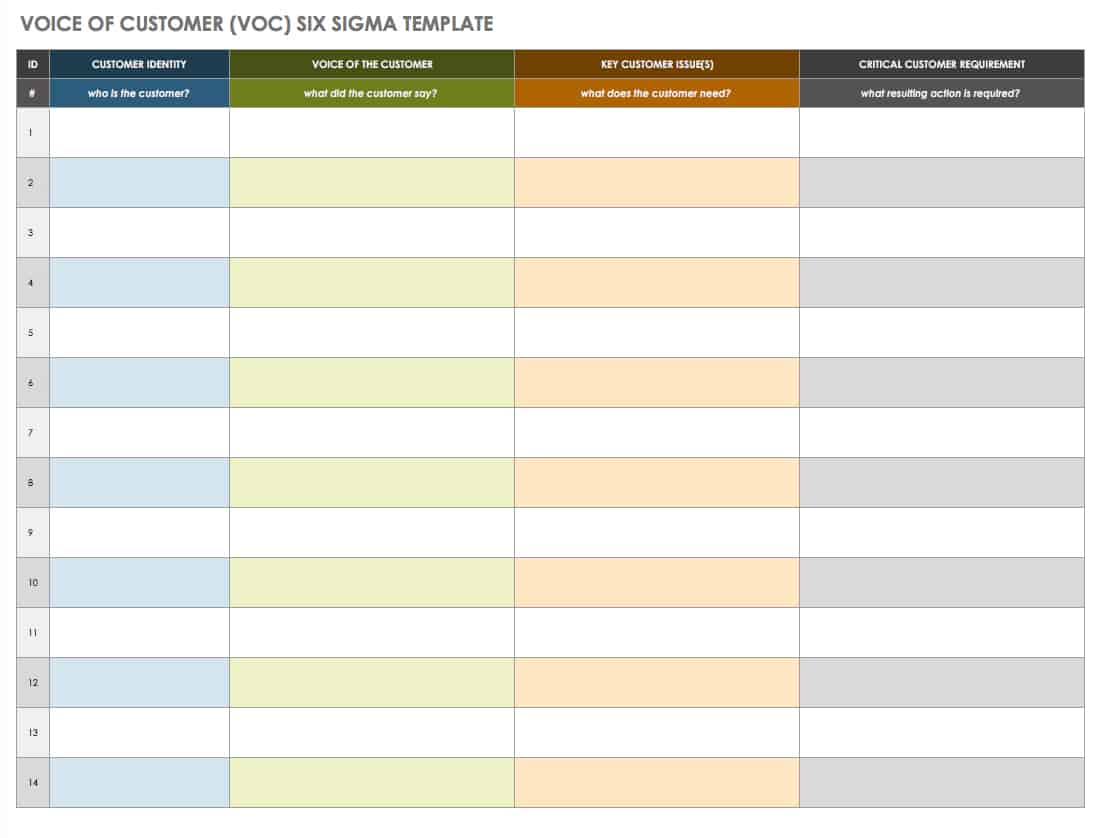

Voice of the Customer Analysis

Lean seeks to maximize value, which is defined as doing something that the customer is willing to pay for. But how do you know what that is? The answer is a voice of the customer analysis (VOC), which is a process of documenting customer requirements and collecting customer feedback.

As a Lean tool, voice of the customer is proactive, which means that you don’t wait for things to go wrong before you seek input from customers. Lean organizations engage with customers all the time. They continuously use their findings to tailor their offerings, so they can offer better value to their customers.

To conduct a VOC process, compile a list of customers for a particular product or service or in a particular region, depending on what information you aim to glean. You want to get feedback from a representative sample.

Then, draw up questions that you will ask each customer in an individual interview. You can also try a round table or focus group, but the most reliable information will probably come from a setting where respondents are not influenced by one another and where you have latitude to delve deeply into an individual customer’s problems or experiences.

Record the findings. Use this template to collect customer expectations and needs, and document required actions. This insight will help you pinpoint where your process can deliver more customer value and where you should address your Lean improvement process.

Download Voice of Customer (VOC) Six Sigma Template - Excel

Kaizen Events

As we mentioned, the word kaizen means “improvement” in Japanese — it’s not so much a tool as an orientation or commitment to continuous improvement. For business purposes, “kaizen” is synonymous with Lean and derives from the idea that incremental changes add up over time to create significant improvements.

One Kaizen tool is the Kaizen blitz or Kaizen event, a short sprint (one that takes place over the course of a few days) to re-engineer a process using Lean principles. A Kaizen blitz typically involves cross-functional teams who scrutinize a process, cut waste from it, and rebuild it.

A Kaizen blitz that is not part of a continuous effort is at odds with the spirit of Kaizen, which is about sustained improvement. But the focused push of a Kaizen blitz that is part of a continuous process can make it a powerful technique in your Lean management arsenal.

5S

5S is a simple methodology for organizing workspaces to maximize efficiency. While this may sound too simple to have much impact, 5S can be highly effective because it deals with foundational issues. 5S has been used to optimize all sorts of workspaces, from mechanic’s benches to kitchen counters.

The name 5S comes from five Japanese words that, phonetically, begin with the roman letter “s:” seiri, seiton, seiso, seiketsu, and shitsuke. In English, the words roughly translate to sort, straighten, shine, standardize, and sustain. Here’s a description of each of the 5S steps:

- Sort: Regularly used items are placed within reach so that rarely used ones don’t take up valuable real estate.

- Straighten: The items are organized so that even a person who’s new to the workspace can quickly find everything.

- Shine: The items and workspace are kept clean and ready for use.

- Standardize: Make it easy for everyone to follow the first three s’s by communicating responsibilities and using pictures of the default state.

- Sustain: Turn 5S into a habit, so people follow it without being told to.

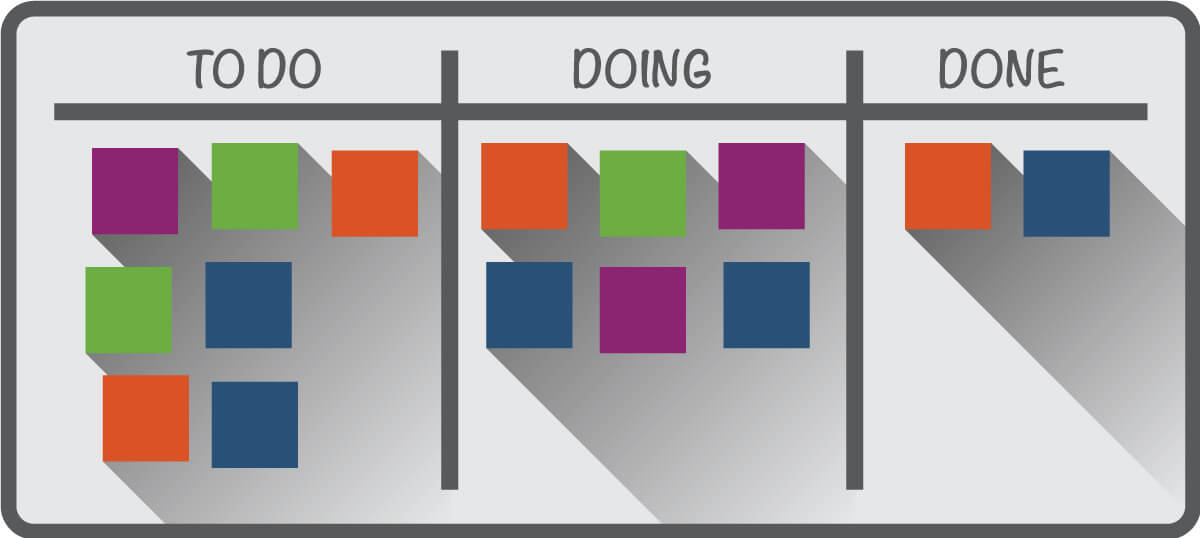

Kanban

Another Japanese invention, Kanban started out as an order coordination system for Lean manufacturing, but it turned out to be such a valuable tool for handing off work that service providers and software engineers now use it too.

The Kanban system embodies the principles of Lean and JIT production, emphasizing minimal wait times in processing and zero inventory. It gets its name from the kanban card, which represents a single unit of work. You can download free kanban card templates customized for different applications here.

Kanban cards are a visual signal of demand and pull work into the value stream. So, a new customer order triggers production of a good, and workers on the assembly line communicate a need for more parts by sending a kanban card to inventory. As processes and systems grow more complex, kanban cards are organized on boards with columns for different stages in the process.

The Kanban system of visual cues allows work items to move forward when capacity opens up, minimizing miscommunication and allowing managers to quickly identify constraints, such as bottlenecks.

Jidoka

Jidoka is a quality control technique that comes from Toyota founder Sakichi Toyoda. In English, Jidoka means autonomation, or automation with a human touch. Jidoka allows manufacturers to harness the increased efficiency of automation while still permitting processes to be interrupted by a person when there is a problem or defect.

Developing this sort of automation is not a quick or inexpensive fix. If you require technology that is not currently in use, your Lean process improvement initiative may lead to a decision to pass this challenge on to your engineering department or outside experts. Still, implementing Jidoka can be transformative for a business process.

For example, In Toyoda’s textile business, automatic looms worked faster and more economically than human workers in order to create cloth from thread. However, if there was a defect in the fabric due to some problem with automation, the machines didn’t stop like human workers did in order to fix the problem. Instead, they kept churning out more defective product until someone noticed what was going on and turned them off to fix the problem. That problem called for a huge number of quality inspectors who had to keep an eye on the product. So, the gains from employing fewer human weavers were offset by the cost of having to hire quality inspectors.

Toyoda equipped the looms with a simple device that could tell when the thread broke and could shut down the machine instantly. Now, when the thread would break, a human operator would check the loom, fix the problem, and manually restart the machine. This new advancement now enabled a single operator to oversee multiple machines. The improvements in quality and reduction in labor were significant.

Toyoda’s Jidoka device proved so useful that a UK company bought the patent for it; Toyoda used the proceeds to create Toyota Motor Company.

Takt Time

Takt time is incredibly useful, as it can help you establish continuous flow for your process. The Japanese “takt,” which is inspired by the German word taktzeit, signifies rhythm or cadence and represents the average time between the start of processing one item and the start of processing another.

Takt time requirements help you determine the average production rate needed to meet demand. Having that knowledge helps you avoid producing too much (creating inventory waste) or too little (wasting sales opportunities and hurting value for customers).

Say your customers buy 50 units per eight-hour shift. Eight hours is 480 minutes, but you need to allow time for breaks and downtime. So, you reduce your total time to 420 minutes. Now, you have the information you need to calculate the Takt time: 420 ÷ 50 = 8.4 minutes per unit. This means your customers need one unit every 8.4 minutes or 504 seconds.

Your Lean process improvement can strive to match that pace by timing your production to a Takt time of 504 seconds per unit or, perhaps, a little faster in order to give you a small buffer. (If you can’t produce at this pace, you need to look for ways to speed up production, like reducing time waste or adding capacity.) This pace of one unit per 504 seconds would be the ideal for a continuous flow of production. To achieve this pace, your processes (including workers, machinery, and quality) must be highly uniform and reliable.

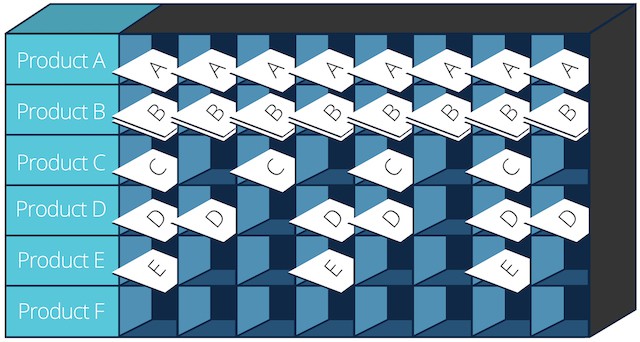

Heijunka

Heijunka means production leveling, which is an effort to reduce both overburdening and underutilization in a production process by keeping the production rate steady. As we saw with Takt time, this means that product is manufactured according to demand, so it doesn’t sit in inventory.

There are a couple of ways to implement Heijunka. One method attempts to level by volume: In any span of time, there’s a range in order quantity, and the shorter the timespan, the greater the variance you can expect in the number of orders. As you increase the span of time, though, the quantities should average out.

Compare this to a highway tollbooth. It handles a large number of vehicles between 7 and 10 a.m., a smaller number between 10 a.m. and 3 p.m., a large number again between 4 and 7 p.m., and then a steadily dwindling number through the evening and early morning, when it begins to pick up again. If you were to look at the number of cars served by the tollbooth per hour, it would vary widely throughout the day. But, if you looked at the number per day, there would be much less variance; and, there’d be fewer still if you looked at the number per week or per month.

Orders work the same way; they come in fits and starts. But, the smart way to deal with this fluctuation isn’t to kick into overdrive when an order arrives and pause when it’s complete, because that method is inefficient and unsustainable for long periods. You would be starting and stopping machinery and struggling to have the right number of staff people at any given time.

Instead, if you looked at order history and knew that during this time of year customers order an average of 50 units per week, you could make 10 a day and optimize all your variables of staff, machinery, and materials for this pace. You might incur a small inventory cost on the days when demand is less than 10, but the trade-off is having far less waste overall.

You need a more advanced form of Heijunka when you’re manufacturing different types of products. This more advanced process is called leveling by type, and Toyota developed a tool called the Heijunka box to facilitate it. The box breaks up total anticipated order sizes for each type of product ordered to level them by volume across a span of time.

Acting as a visual scheduling tool, the Heijunka box typically consists of rows of pigeon holes, with each hole representing production shifts. Kanban cards representing individual jobs are placed in each shift slot to illustrate what will be produced during that particular production period.

Poka-Yoke

Poka-Yoke, which means error proofing, is a quality control measure for human workers. Poka-Yoke is a simple system of (usually) physical measurement that quickly checks the quality of each unit of a product before it moves downstream. The technique arrests errors at the source and prevents them from causing waste downstream.

Imagine cars on an assembly line. A robotic arm installs rear suspensions incorrectly. If someone doesn’t catch the mistake right away, many units could move on to the next step. When someone finally discovers the mistake, teams downstream are unable to perform their work and, therefore, sit idly. Now, the company may have to discard the semi-assembled cars. Both the discarded product and the underutilized employees are forms of waste.

A Poka-Yoke system would rapidly check the rear suspensions on each unit before it moves along. (Fun fact: The Poka-Yoke system was initially known as Baka-Yoke, or idiot proofing, until someone decided that the term sent the wrong message.)

Gemba Walk

In a Gemba walk, high-level supervisors walk to the shop floor to observe and talk to the people closest to the work.

This process prevents managers from being out of touch with actual working conditions and production flows. The higher up an executive is, the greater the risk that they are disconnected from the front line. Gemba walks improve communication, motivate workers, strengthen cooperation, and help senior managers stay grounded.

Ishikawa or Fishbone Diagram

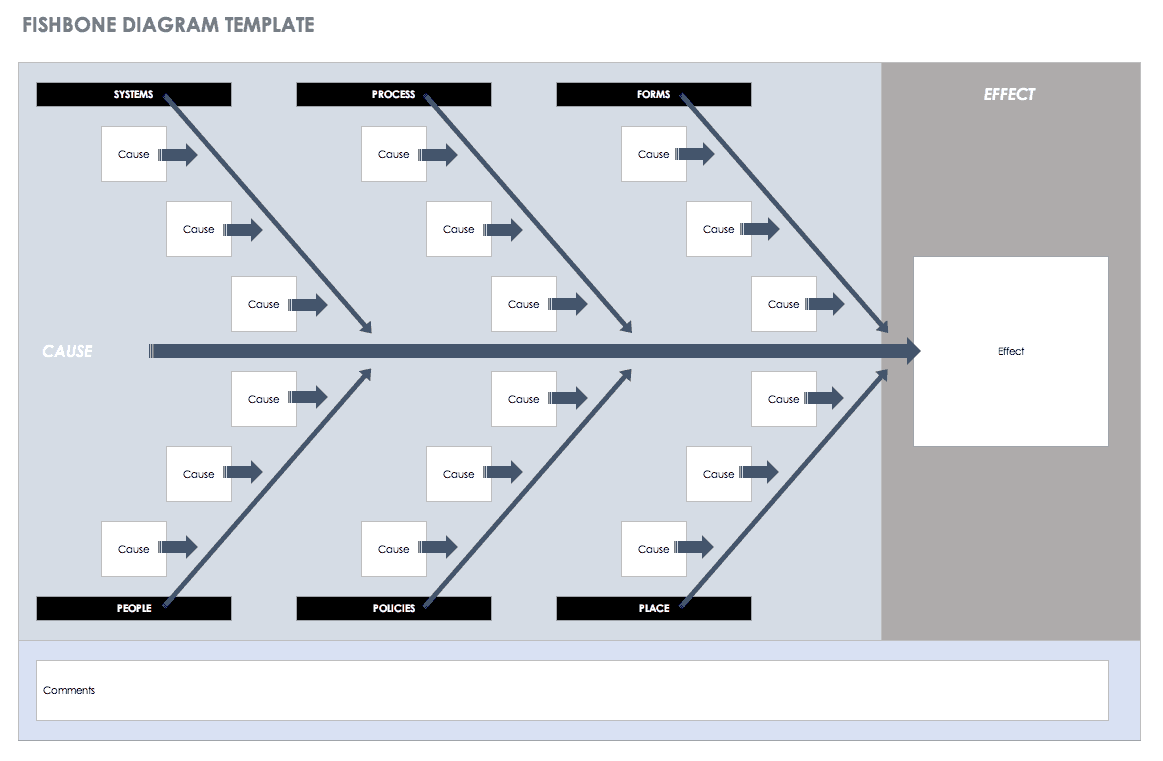

Another simple yet effective diagramming technique is the Ishikawa or fishbone diagram, which is used for root cause analyses. The diagram looks like the skeleton of a fish, with the problem at the head and possible causes branching off from the spine in categories, such as people related and systems related. Gather your team to brainstorm and then analyze the causes through discussion, statistical analyses, and experiments to see which factors contribute the most to the problem.

This fishbone diagram template gives you spaces to write down causes by category. You can change the category names to suit your situation.

Download Fishbone Diagram Template - Excel

Fault Tree Analysis

Fault tree analysis was introduced by Bell Labs and uses deductive reasoning to determine the hardware, software, and human error causes of system failures and problems (called top events).

Using a top-down approach, the diagram starts with the conclusion and works back to identify the specific causes of the final problem. The fault tree looks a little like a family tree. At the top of the tree is the problem state, and branching downward are its immediate causes. Branching downward from those immediate causes are preceding causes and so on, until it’s possible to isolate a root cause.

Pareto Priority Index (PPI)

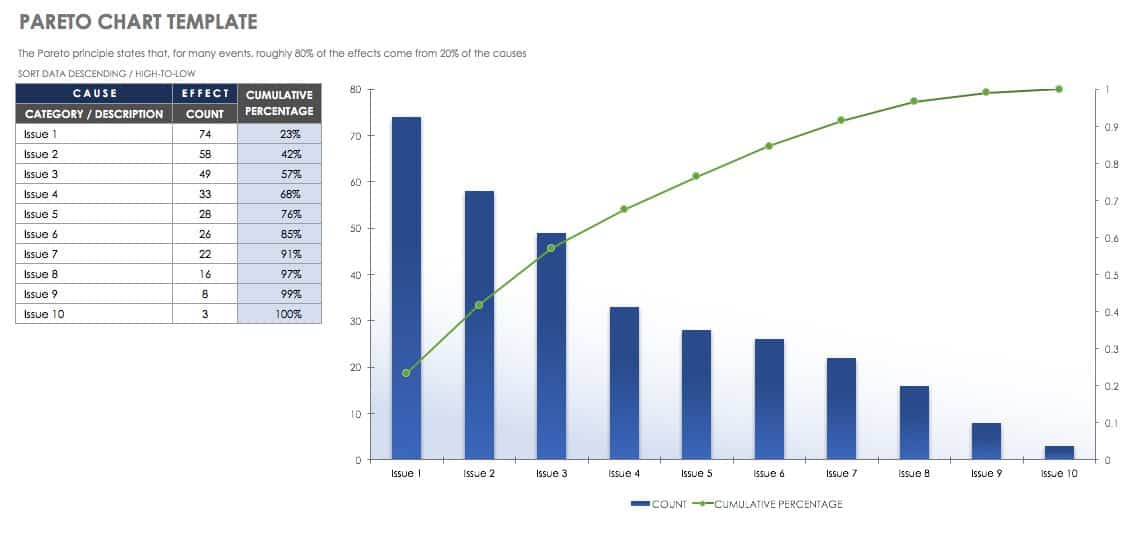

The Pareto Priority Index (PPI) comes from the Pareto principle, named for economist Vilfredo Pareto. The Pareto principle is more commonly known as the 80/20 rule: 80 percent of effects come from 20 percent of causes. The PPI is derived from the Pareto principle, and it’s used to prioritize projects using the formula below.

PPI = Savings x Probability of Success

Cost x Completion Time

A high PPI indicates that a project is high priority.

Use this template to perform a Pareto analysis of the relevant causes, so you can easily identify which changes will have the biggest impact. The template provides a typical Pareto diagram, with a bar chart representing whatever issues you want to analyze and a line graph showing the cumulative percentage of occurrences.

Download Pareto Chart Template - Excel

A Few Other Lean Process Improvement Tools

Below, we define a few other key Lean techniques.

- Standardized Work: This entails defining best practices for work, including pace, sequence, inventory, machinery, and other variables. Doing this creates a baseline for improvement, reduces output variability, and makes training new staff easier.

- Total Productive Maintenance (TPM): This refers to the active commitment to keep systems and resources — human and non-human — in optimal working order. The primary goal of TPM is maximum overall equipment effectiveness (OEE), which includes machine performance, availability, and output quality.

- Setup Time Reduction: This technique attempts to minimize the time taken to transition from producing the last item of one order to producing the first item of the next. It also enables lot-size reduction, which is important for matching production to demand, because the shortening of transition times means people can make transitions more frequently and with smaller lots. A related concept is single-minute exchange of dies, which is a system for drastically cutting the amount of time it takes to change over equipment; it seeks to streamline the steps as well as work as many steps as possible while the equipment is running.

Use the Right Lean Process Improvement Metrics

Metrics are an important part of Lean process improvement. These numbers establish a baseline for the current state and give you a means to measure the impact of any changes. Metrics also provide motivation, as seeing the positive effects of change is inspiring. As you continue to make incremental improvements, you’ll be able to place changes in the context of historical trends.

A huge number of metrics are in use, and you do not want to become so focused on the numbers that they become an end unto themselves. Large companies with dedicated analysts may have the resources to track a lot of them. Smaller organizations simply pick a few metrics that align most closely with their goals.

How do you know which metrics align with your goals? The following list is categorized by various Lean process improvement objectives. Remember that the categories aren’t mutually exclusive; some metrics are useful for multiple goals.

Once you have identified a few critical metrics, create a dashboard to keep your finger on the pulse of these measures.

Flow

Flow is the smoothness of production and the ease with which items of work in progress move from one processing station to the next. Here are some common metrics people use to evaluate flow:

- Work in Progress (WIP): This metric tells you how many items of work are in progress at a given time. Some Lean systems, such as Kanban, put great emphasis on limiting this number.

- Cycle Time: This is the average length of time it takes to process an item.

- Lead Time: This refers to the length of time between a customer placing an order and the product being delivered.

- Processing Time: This is the length of time that a work in progress spends at a particular workstation, not including wait time.

- Best and Worst Completion Times: For projects or untested processes, this metric refers to the longest and shortest estimated durations.

- Non-Value-Added Time: This is the length of time that elapses without value being added to an offering.

- Length of Queues: How long are backlogs? This could refer to the time that a semi-finished product waits to move on through the process, the duration of backorders, or the wait times for raw materials.

- Blockers: This is the number and duration of structural process shortcomings that prevent a work in progress from moving forward, e.g., the loss of a skilled employee.

Quality

These metrics address defects and the frequency of errors:

- Defect Rate: This is the proportion of defective products out of all products manufactured.

- Defects per Million Opportunities: A Six Sigma metric, this rate makes it easier to compare quality among processes with varying complexity, because a complex process like assembling a computer will have much more opportunity for error than a simple process such as milling grain. Defects are defined as a failure to achieve a characteristic that is critical to quality, and, while the process is subjective, opportunities should be determined based on this concept. A process reaches Six Sigma when there are three defects or less per million opportunities.

- Customer Complaints: This is the number and severity of customer complaints.

- Customer Returns: This is the percentage of products returned by the customer due to company error or defect.

- Satisfaction Ratings: This is the numerical rating of how pleased customers are with your product and the service they receive.

- Percentage of Shipments Completed on Time: This is a calculation of how many orders are shipped when promised.

- Rework: This refers to the proportion of products that require reworking because of mistakes or defects.

- Percent of Orders Complete and Accurate: This is the proportion of work in progress that does not require the customer to provide additional information during the processing cycle. Typically, you measure this metric at each step of the processing cycle.

- First Pass Yield: This refers to the proportion of products that do not need any reworking.

- Warranty Claims: This is the amount of money spent on warranty claims or the number of warranty claims received as a ratio of units sold.

- Billing Accuracy: This is the percentage of customer invoices that have errors.

Efficiency

Use these metrics to evaluate how effectively you use resources:

- Labor Productivity: This is the ratio of the value of output compared to the hours of human work needed to produce that output or the number of workers needed to produce it.

- Number of Steps in a Process: How many actions or stations does your product move through as it is produced? This number evaluates process complexity.

- Number of Handoffs in a Process: This is the number of times work is passed from one staff member to another. A handoff disrupts the flow. For example, after one staff member signs a form, it moves to someone else’s inbox and waits for another approval. In a factory, these speed bumps can occur between receiving and inspecting and between other departments.

- Number of Delays: This refers to the quantity and duration of delays when one wastes time by waiting for something to happen.

- Schedule Attainment: This is the percentage of time that manufacturing achieves targeted production levels within a specific period.

- Number of Human Decisions to be Made in a Process: Every time a person has to make a decision, it adds complexity to your process.

- Number of Loops: This is the number of steps that are repeated. Your goal is to eliminate this repetition whenever possible.

- Number of Black Holes: This refers to the number of instances when loops, delays, decisions, and handoffs occur in combination, and the process stalls, sometimes indefinitely.

Maintenance

These indicators convey how well you are taking care of equipment and avoiding or minimizing unplanned outages:

- Mean Time to Repair: This is the average length of time it takes to repair equipment, including wait time.

- Mean Time between Failures: This is how long equipment runs between breakdowns.

- Overall Equipment Effectiveness (OEE): This is a formula that takes into account equipment availability, performance, and quality.

- Uptime: To determine this metric, start at 100 percent; then deduct lost equipment time for all causes, including breakdowns and warm-up and set-up time.

- Preventive Maintenance: This is the percentage of total maintenance time that is spent on preventive activity as compared to unplanned work. This indicates whether you are doing a good job with maintenance or spending more time fixing breakdowns.

Strategic

Senior management executives often use these metrics to evaluate system-wide performance and compare value streams:

- Revenue: This represents the dollar value of sales.

- Cash Flow: This is the amount of money that moves through your business. You aim to maximize money coming in from customers and minimize money going out for expenses. Positive cash flow is when more money comes in than goes out, and net cash flow is the difference between the two.

- Economic Value Added: This is the value a company creates in excess of that required to be paid out as shareholder returns.

- Return on Invested Capital: This is calculated as profits minus payouts to shareholders, divided by total capital. This number measures how profitably you use your money to generate returns.

- Market Share: This is the percentage of sold product that a company controls. A company that has the largest market share of an industry’s total shares is usually excelling at a combination of things, including customer service, product design, pricing, and manufacturing efficiency.

- Return on Investment (ROI): To calculate the ROI, you divide the profits generated from a product by the cost invested in it. This calculation could include all costs or a specific component, such as equipment.

Tactical

These indicators assess the actions you take in the near term to execute long-range planning:

- Budget: How you allocate your spending and trends in expenses.

- Cost of Compliance with Regulations: The amount spent on complying with regulations including fines for violations or cost of remediation.

- Cost of Quality: The total cost of quality-related activities.

- Supply Chain Excellence: There are several metrics to evaluate your supply chain. These include the perfect order index (the percentage of your supply orders placed without errors), cash-to-cash cycle (how much time elapses from when you pay your suppliers and you receive payment from your customers), supply chain cycle time (the time it would take to fulfil a customer order if all your inventories were at zero when the order was placed), and inventory turnover (how many times in a year your entire inventory is sold; in Lean, since you want to minimize inventory, you aim to have high turnover relative to your industry average).

Safety, Regulatory, and Staff

Use these numbers to monitor your human resources management as well as compliance with best safety and environmental practices:

- Recordable Incident Rate: The number of safety failures or accidents in a specified length of time.

- Non-Compliance Events: The number of times a plant operated outside compliance standards over a year.

- Environmental Incidents: The number of environmental violations that occurred over a given period.

- Cost per Recordable Incident: The dollar value of medical costs, lost worker time, delayed orders, or other consequences of an accident.

- Lost Workday Incidents or Number of Lost Workdays: The number of injuries that prevent workers from being on the job or restrict the work they can perform and the amount of time that a staff member cannot perform his or her regular job.

- Time to Hire: The length of time from when you first interact with a potential new staff person and he or she accepts a job offer. This measures the efficiency of your recruiting and hiring.

- Turnover Rate: The number of employees who leave divided by the average headcount over the period. High turnover is a sign of trouble.

- Staff Qualification Levels: How you measure this will depend on your organization and the skills required. A good metric could be the percentage of people who have Lean process improvement certifications or advanced safety qualifications. Another measure might be average hours of continuing education per year per employee.

Value Delivery

These metrics provide indications of how successful you are at delivering value under Lean’s definition of value as something the customer is willing to pay for:

- Value-Added Cycle Time: The percentage of your business process in which value is added to the product rather than waiting or transit times.

- Stock Price: This only applies to publicly held companies, and it’s a lagging, indirect indicator. But in the long run, your success at providing customer value will surely be reflected in your share price.

- Net Promoter Score: This metric asks your customer to rate your brand on a scale of one to 10 on the question, “How likely are you to recommend this product or company to a friend or colleague?” Responses are grouped into three categories with promoters being those who score you a nine or 10 and detractors those who rate you zero to six. The net promoter score is the number of promoters minus the detractors.

- Delivered Value Score: Regularly survey your team and ask how much value they feel they delivered to customers on a scale of one to 10. This metric is not entirely scientific, but your staff probably has better insight into the answer than you imagine. This score also helps establish trends.

- Customer Acquisition and Retention: The rate at which you gain new customers and the proportion of repeat and ongoing customers you have. While these are indirect measures of value delivery, if you are consistently improving value to customers through your Lean efforts, the metrics will reflect that trend.

- Rate of New Product Introduction: How frequently new products are introduced demonstrates your level of innovation and customer focus.

- Time to Market: The length of time from a product concept being created to the product becoming available for sale.

Cost Metrics

These numbers will illuminate where your expenses occur in production and where you might find waste to trim:

- Average Cost per Unit: The average cost of all labor, materials, overhead, and other inputs needed to make one unit of product.

- Labor Costs per Unit: Units or revenue divided by labor hours or labor costs, including overtime.

- Cost of Goods Sold: Aggregate costs to produce goods including fixed and variable costs.

- Total Manufacturing Costs per Unit Excluding Materials: This measures all the costs under your control.

- Break-Even Analysis: Similar to unit cost, this is the amount of money per unit of product that you must receive in order not to incur a loss. This number differs from unit cost when, for example, you incur disposal or transport costs on unsold inventory. Break-even analysis might show you that it would be preferable to sell an item at a small loss from the unit cost if you would suffer a greater loss from having to transport or dispose of unsold product.

- Manufacturing Cost Compared to Revenue: The ratio of manufacturing costs compared to the sales revenue for the goods produced.

- Sales per Employee: Annual sales divided by the total number of employees.

- Asset Productivity: Units produced compared to book value of plant and equipment plus inventory.

- Energy Cost per Unit: How much fuel costs to produce a unit.

- Freight Cost: How much you spend per pound on average delivering your product.

Output Metrics

These types of data relate to how much you are producing and the efficiency of production:

- Throughput: Average number of units produced in a value stream over a period of time.

- Capacity Utilization: A percentage measure of how much of total output capacity is utilized at a particular time

- Inventory: The volume or value of stored raw materials or completed products

- Production Rate: The number of units manufactured per unit time

- Backlog: The number of orders awaiting processing

Tackling Misconceptions about Lean Process Improvement

As you tackle Lean process improvement, you may struggle with some common misconceptions. By being aware of these myths early in the process, you will be less likely to get derailed:

- Myth 1: Lean Should Be Thought of Like Any Other Cost-Cutting Measure: Lean is not just a cost-cutting measure. Rather, Lean fosters a way of thinking with benefits that far exceed cost-cutting. Lean benefits not only an organization’s bottom line but also its value stream and everyone who touches it by making work more streamlined and purposeful.

- Myth 2: Lean Can Be a Quick Fix: This one is partly true because the right initiative can have immediate and dramatic results. But using Lean for a quick fix is like cramming for a test the night before: Doing so may help you pass a class, but six months later, you won’t remember the material or be able to apply it. Lean is a long-term approach that calls for discipline to sustain improvements and to keep improving. Without this discipline, your Lean improvement efforts will plateau quickly.

- Myth 3: Lean Is a Manufacturing Methodology: Lean originated in manufacturing, but the approach is popular in services, healthcare, education, and government.

Lean Process Improvement in Action: Case Studies

Let’s look at some specific examples of Lean process improvement at work:

- Manufacturing: Danaher Corp, based in Washington, DC, is a global conglomerate that designs and manufactures consumer, health, and industrial products. The firm is renowned for the Danaher Business System (DBS), which is an approach based on Lean.

Danaher has built a name for acquiring poor performing companies and turning them around with Lean. The company has been highly successful with an annualized return of 21 percent over the 20 years.

In the 1980s, Danaher’s Jacobs Manufacturing unit, which builds truck brakes, launched a Lean transformation. Managers discovered that machines in a key stage of manufacturing were laid out clockwise, requiring workers to use their left arms. The right arm is three percent stronger on average, so the company redesigned the work area by laying out the machinery counter-clockwise. The move triggered a major productivity boost. - Government: Results Washington, a 2013 initiative by the State of Washington, set five statewide development goals in education, healthcare, environment and other areas. These split into nearly 200 sub-goals. The state created a public dashboard to measure progress against these goals, and it challenged agencies and departments governments to use Lean methods to meet them.

The results from Lean process improvements were dramatic. For example, the public disclosure team at Washington State Department of Transportation's headquarters cut the average time to fulfill a records request by 54 percent, and the state custodial division used Lean to improve safety for its staff members that led to a 44 percent decrease in injuries on the job. - Environmental Impact: The U.S. Environmental Protection Agency maintains a list of case studies detailing projects where Lean methods improved environmental performance. For example, between 2000 and 2005, conglomerate 3M used Lean Six Sigma to slash volatile organic compound (VOC) emissions by 61 percent, the release of toxins by 64 percent, waste generation by 30 percent, and energy use by 27 percent (when indexed to net sales).

What Is Lean Process Improvement in Healthcare?

When Lean expanded beyond manufacturing, the healthcare sector was one of the first new industries to explore Lean principles. Daniel T. Jones, author of The Machine that Changed the World and Lean Thinking, suggested that a Lean approach could “deliver better quality (and safety) and a better patient experience (less queues and rework).”

Jones said Lean could deliver these advancements “while at the same time making better use of existing resources (to treat more patients) and improving the work experience of staff (less frustration and stress).”

Healthcare provides a unique challenge for Lean management. Healthcare delivery is a tremendously intricate system, with many inputs and waste, and the stakes are high because mistakes can result in deaths. Given the aging global population, the stress on healthcare systems internationally continues to increase, and efficiency and quality become ever more critical.

Over the last couple of decades, Lean in healthcare has evolved into a highly specialized approach to healthcare management. Its goals are the same as Lean management everywhere: maximize efficiency, minimize waste.

Nicklaus Children’s Hospital in Florida, for example, cut crash cart inspection times by a factor of 18 using visual optimization and reducing excess equipment. Virginia Mason Institute in Seattle managed to cut liability claims by three-fourths with a patient safety alert system to expedite patient safety concerns. And St. Mary’s General Hospital in Ontario undertook a training-based Lean transformation to improve the quality of healthcare, lowering its mortality rate.

Applying Lean Process Improvement to Education

At first glance, education doesn’t seem to have much in common with manufacturing. But they share a few make-or-break elements — notably, a desire to improve efficiency and lower expenses.

Lean tools have been successfully applied in many schools. 5S, for example, can keep classrooms organized. Smart placement of shared facilities, such as printers, can save teachers and students long walks. And when it comes to assignments, digital submissions instead of printed or handwritten ones save paper and time.

On a structural level, schools offer suffer from excess inventory, overproduction, over-processing, and wasted time. Many educators complain about time spent navigating school systems’ often complex hierarchies.

A school in Norway, Bærland Skole, in 2012 launched a Lean transformation with two goals in mind: increasing learning output and improving the working environment. To do this, the school adopted three Lean practices: 5S, continuous improvement, and the standardization of best practices. In addition, they used value stream mapping when developing curricula.

The Des Moines, Iowa, school district, undertook a Lean improvement initiative that led to over 150 continuous improvement projects. The effort is led by a Lean Six Sigma black belt, one of very few in the education field, and the district has a dashboard tracking Kaizen initiatives. One of the big successes was the reorganization of printing to route all print jobs to a central operation. After applying Lean principles, the school district cut printing costs, achieved turnaround goals, and was able to go from running its print shop 24/7 to 10 hours a day, six days a week.

Lean Process Improvement Learning and Certifications

Organizations all over the world offer Lean training, and there are lots of options to choose from when it comes to course content and depth. Some offerings are classroom-based, while others are online, either live streamed or self-paced. Upon completion of some programs, you receive a certification that attests to your Lean expertise.

Here’s a sampling.

|

Name |

Offered by |

Duration |

Skill Focus |

|

Lean Process Improvement: Delivering More with Less |

American Management Association |

Two days |

Lean metrics, types of waste, 5S, Poka-Yoke, Kanban, Kaizen, and DMAIC |

|

ASQ Lean Training |

American Society for Quality |

Varies |

All core Lean skills |

|

Lean Kaizen: A Simplified Approach to Process Improvement |

American Society for Quality |

Eight hours |

Kaizen methodology |

|

Kaizen Training and Certification |

Kaizen Institute |

Varies |

Online and classroom courses and three levels of certifications |

|

Certified Lean Professional |

SUNY Buffalo Center for Industrial Effectiveness |

33.5 hours |

Lean tools, including 5S, TPM, standardized work, and Kanban; option for one-on-one coaching sessions |

|

Lean Management Certification Training |

SimpliLearn |

Five hours |

Principles of Lean, Lean metrics, and Lean in manufacturing, service, and office contexts |

|

Process Improvement Certificate Program |

Portland State University Center for Executive and Professional Education |

76 hours |

Seven classes on Lean process improvement |

|

Lean Online Review Program, Lean Review Courses, Lean Certification |

Lean Certification Alliance (Association for Manufacturing Excellence, Shingo Institute, SME) |

Varies |

Certifications at bronze, silver, and gold levels of Lean expertise, all aimed at professionals |

|

Lean Process Improvement Training |

Professional Development Training (Australia) |

Two days |

Lean principles, problem solving, waste reduction, and Lean project planning |

|

Lean Professional Programs |

University of Michigan College of Engineering |

Varies |

Certificates in Six Sigma and Lean for healthcare, manufacturing, administration, and supply chain; Lean leadership; and Lean product development |

|

Lean Healthcare Training |

Virginia Mason Institute |

Varies; advanced Lean is seven days; foundations of Lean in healthcare is three days |

Lean concepts as they relate to healthcare delivery |

|

Lean Certification Courses |

Management and Strategy Institute |

Varies |

Certification courses in Six Sigma belts, Lean, total quality management, TPM, Kaizen, and Lean in healthcare |

|

Lean Training and Certification |

GoLeanSixSigma.com |

16 hours |

Lean principles and developing Lean culture |

|

Lean Continuous Improvement |

Florida Tech |

Six weeks |

Essential and advanced Lean tools and methods |

|

Operations Management: Strategy and Quality Management for the Digital Age |

University of Illinois via Coursera |

Six hours |

Process improvement, Lean Six Sigma,and analysis of variance |

|

The Lean Practitioner Course |

The Lean Six Sigma Company |

Three days |

Lean principles, types of waste, value stream mapping, 5S, Poka-Yoke, and flow and pull |

|

Lean Six Sigma and Kaizen |

Integris Performance Advisors |

Varies |

Lean Six Sigma belts, Lean continuous improvement, and custom training for companies. |

|

Professional Development Courses, Lean Six Sigma Certifications |

Creighton University Center for Professional and Corporate Excellence |

Mostly one or two days |

5S, continuous flow, Lean basics, value stream mapping, and root cause analysis |

|

Lean and Process Improvement Training |

EEF, The Manufacturers’ Organization |

Varies |

Multiple specializations, including Kaizen, 5S, Lean, and Lean Six Sigma |

|

Lean Six Sigma Certificate |

Villanova University |

Varies |

Lean Six Sigma |

|

Improvement Training |

Lean East |

One day |

Variety of courses on Lean in healthcare, Lean for leaders, and continuous improvement coaching |

|

Lean Enterprise Academy Workshops |

The Lean Enterprise Academy |

Varies |

All aspects of Lean and Lean techniques |

|

Lean Enterprise Institute Education |

The Lean Enterprise Institute |

Varies |

All aspects of Lean and Lean techniques |

|

Continuous Process Improvement Certificate |

Missouri Southern State University |

Varies |

Engineering technology, quality control, Lean, and Six Sigma |

|

Continuous Improvement Training |

Kaizen Consulting Group |

Mostly one or two days |

Kaizen, 8D, continuous improvement leadership, and root cause analysis |

|

Lean Business Process Improvement Certificate |

University of Minnesota |

Varies |

Process mapping, improving work processes, and implementing process change |

|

No Cost Lean Certification Course |

Veterans Transition Support |

One day |

Free class for U.S. military personnel, veterans, and family members |

|

Lean Practitioner Certificate, Lean Six Sigma Training and Certification, Professional Development |

Kent State University |

Varies |

5S, Lean Six Sigma, Kaizen, and 8D |

|

Lean Six Sigma and Continuous Improvement Certificate |

Sheridan College |

Varies |

Lean Six Sigma, value stream mapping, and statistical process control |

Improve Lean Process Improvement with Smartsheet for Project Management

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.