What Is Product Life Cycle Management (PLM)?

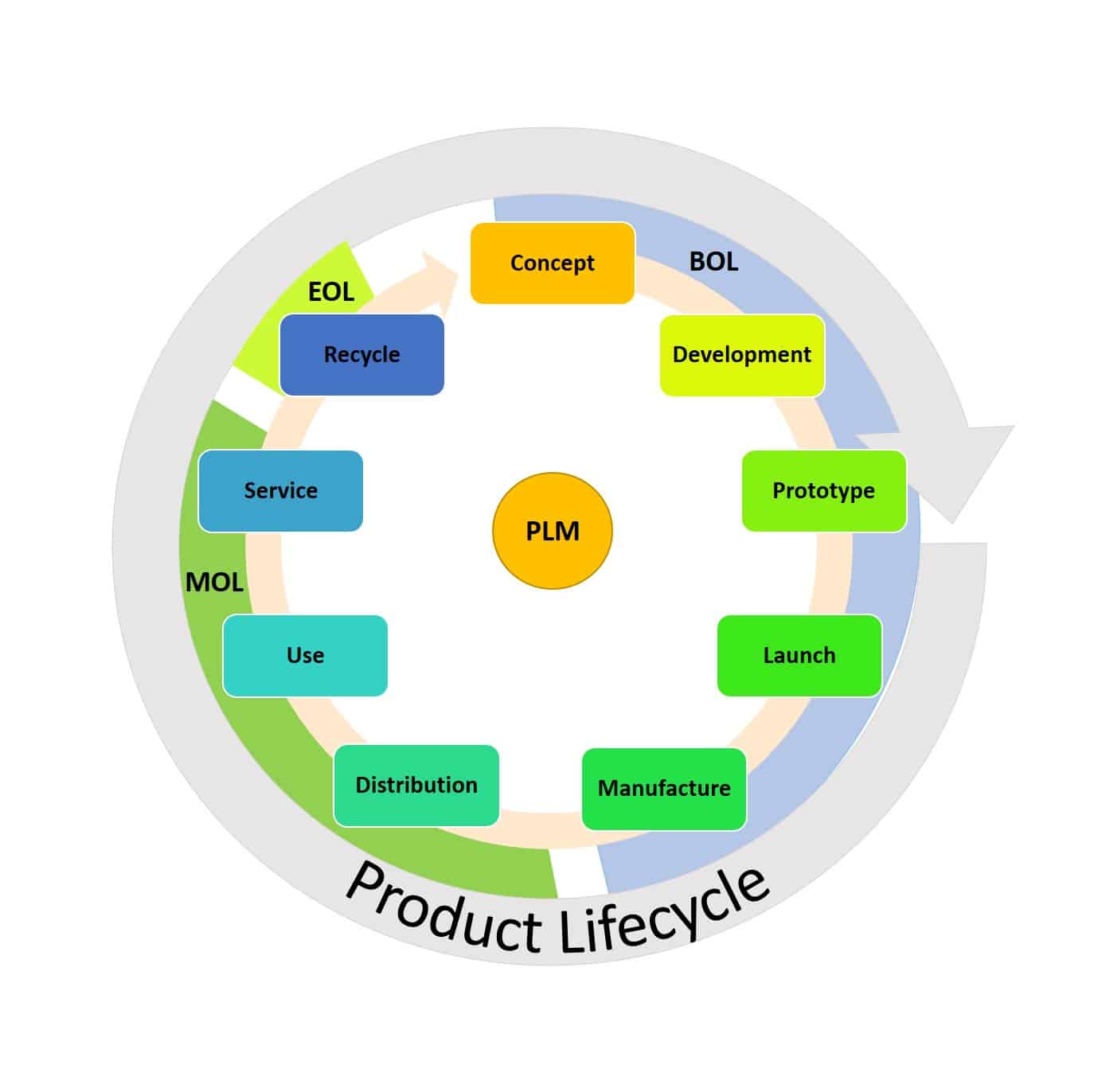

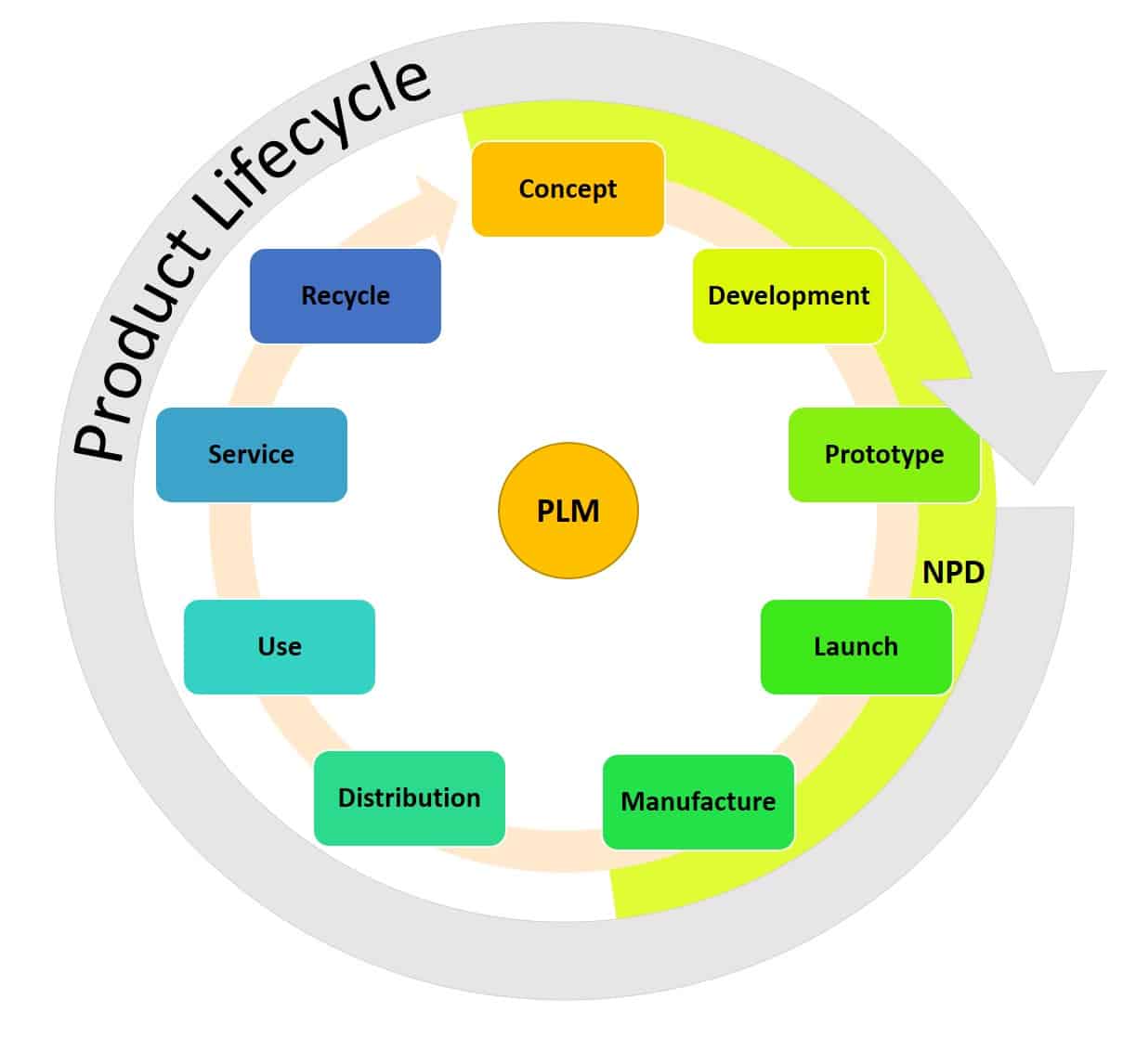

Product lifecycle management (PLM) refers to the cyclical phases of a product, from conception, development, and launch to retirement. PLM merges the organization’s vision for managing and executing the overall plans for the product.

PLM lowers the cost and speeds the time to market for new product development (NPD). Whether the new products consists of incremental or derivative changes to old products, groundbreaking new items, or the next generation of platform, there need to be a process for each organization to manage them. This new product development process (PDP) uses the PLC to determine what the general shape and sequence of the process will look. A good PLM is holistic, manages and secures the product information, and ensures that business processes use and build upon the information.

The three main elements of PLM are:

- The Information and Communication Technology (ICT): This is all about the necessary unified platforms and systems, including the architecture, tools, and standards.

- The Processes: This includes all of the people, skills, and organizations involved.

- The Methods: This is the procedures, rules, and practices.

PLM is proliferating because the economy has gone global. Outsourcing and new supply chain initiatives, along with shorter production runs require that companies have reliable and up-to-the-minute information for manufacturing. And because the internet makes it feasible to share information quickly with far away partners. Now, PLM allows for the adjustment of manufacturing specifications during production. This process would typically take days or weeks with siloed engineering and production departments, especially if the production facility were in another country.

PLM increases your speed to market in several different ways:

- Managing your changes over time

- Keeping your organization up-to-date with the product knowledge

- Integrating the enterprise systems

- Logging the raw materials and parts

- Tracking the manufacturing procedures

- Managing product intent and customer expectations

- Cataloging the chemical and physical properties

- Maintaining version history and control

- Keeping record of past, present, and future concepts and products

- Recording changes in customer demands, regulations, improvements, and costs

What Is the Product Life Cycle?

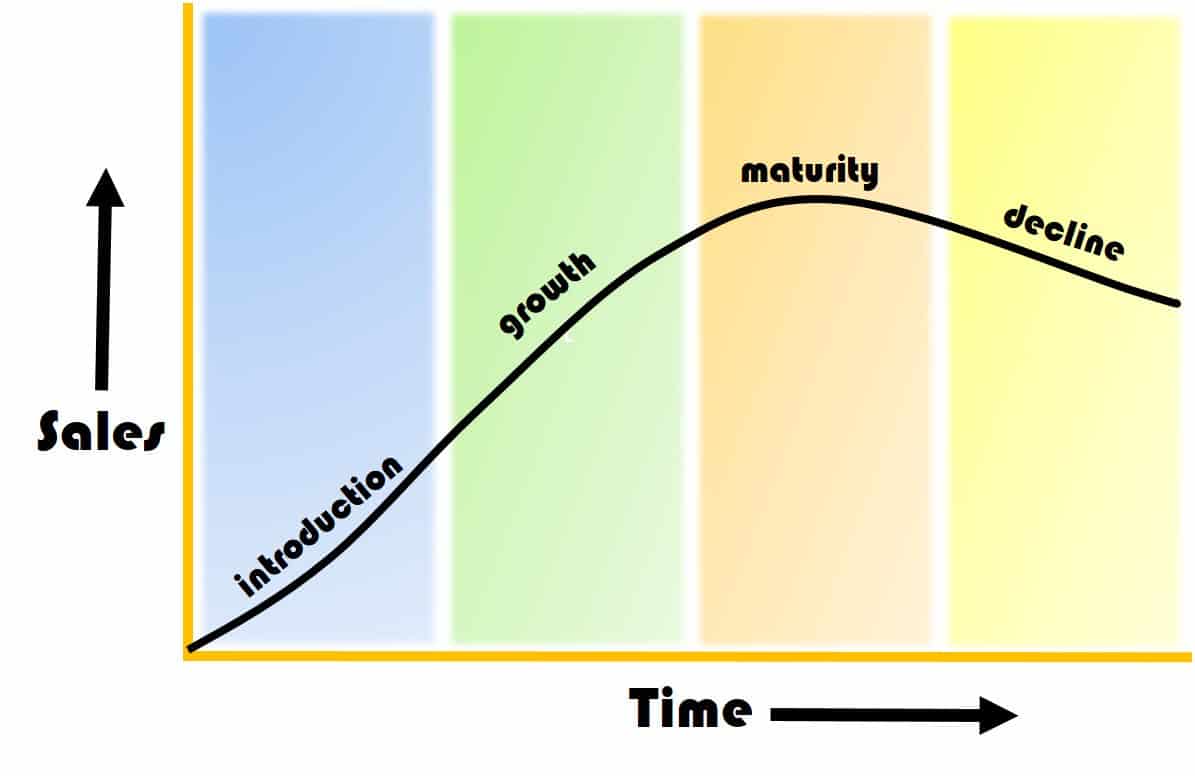

The product lifecycle (PLC) is the repeatable pattern of product development, including introduction into the market, growth, maturity, and decline. Every product’s PLC differs in scope and duration, and is at risk of not surviving the introduction phase.

The PLC, in brief, is as follows:

Stage 1: Product Development: The new product is introduced; this is when all of the research and development happens.

Stage 2: Product Growth: The product is more than an idea or a prototype. At this stage, the product is manufactured, marketed, and released. Distribution increases, demand increases, and competition also increases.

Stage 3: Product Maturity: During this stage, the product is widely available, and there are many competitors in the marketplace. You market the product to different segments, but more spending on advertising will have no impact on its demand.

Stage 4: Product Decline: The product is losing market share, or becoming obsolete. It is well past its point of highest demand, and the demand decreases.

Additionally, the product life cycle affects the average selling price (ASP). The ASP is how much you generally sell your products or services for. When a product has many competitors or it is in the decline stage of its PLC, the ASP will be lower.

Product image also drives the ASP. Products with an image of exclusivity have a higher ASP. For example, Louis Vuitton luggage is considered a luxury brand of products that are made by hand and use the finest materials. There is a limited assortment of products, a long wait time to procure one, and a higher than average price point. The company has even sped up their manufacturing process, but the price point still reflects the exclusivity and time to market of a custom bag. In fact, Louis Vuitton increased its prices in 2013 to attract more high-end consumers because they experienced a decline. This approach is an interesting twist on the PLC since normally the prices would drop with the waning in demand.

Closed-Loop Manufacturing Cycle

So far, we have been discussing the typical PLC. It is linear and at each stage has material, labor, and resource inputs. It also has waste outputs that can negatively affect the environment. Researchers assert that the introduction stage where design takes place determines between 70 percent and 90 percent of the life cycle costs. At this stage, manufacturers can also remove excess waste and continue to develop sustainable manufacturing practices. These practices should include products being reused, recycled, and remanufactured. With this, you are developing a closed-loop manufacturing cycle. Instead of a linear PLC, this represents a circular PLC.

A closed-loop cycle is a natural extension of PLM, and creates a truly full life cycle that takes your obsolete or used products back into raw materials, not just assigning them to waste. Although many of these closed-loop products are down cycled (converted into lesser-quality materials), the products are still recycled and reused repeatedly.

An example of this is Dell’s take-back program, which takes the computers that it manufacturers and turns a majority of them into new computers. Other companies separate out product components and sell them to their partners on the commodities market, as raw materials, who then make them into new products. The benefits of a closed-loop system include:

- Better for the environment

- Does not affect performance or price

- Fewer carbon emissions in manufacturing

- As programs scale, they become cheaper and more effective

The History of Product Life Cycle Management

First used in the aviation and automotive industries, PLM branched out to other trades including packaged goods, electronics, pharmaceuticals, and fashion. PLM evolved out of technological advances in the area of computer-aided design (CAD), computer-aided engineering (CAE), and product data management (PDM). These advances allowed manufacturers to link design and manufacturing, shortening production cycles and lead-time. Because manufacturing is complex and has many steps, speeding up the process by making all of the information centralized allowed increased competition. However, PLM is more about the integration of these tools with the processes, people, and theory along the stages of a product’s life.

Additionally, PLM caused mass customization to be within reach, and instead of just buying products, the market is capable of providing products as services, called servitization. The model of servitization evolved from services supporting products, to services differentiating products, to services as the product. Examples of servitization include leasing a car instead of buying it, companies that pay for document management services instead of buying copy machines, or airlines paying for the number of engine hours instead of buying engines. These are advanced services that include maintenance and repair, which means that the products only make money when they are reliable. Further, the vendor-customer relationship becomes more intimate, and feedback about the product’s performance is critical so that the manufacturer can turn out better products and the company can deliver more efficient services. However, PDM must have the necessary information at the necessary time to achieve this goal.

The Product Life Cycle Management Stages

Since many companies need to coordinate their resources and people in different places, the processes need to be cohesive if there is a chance at minimizing waste. Cohesiveness also keeps the process product-centric and gives it a better chance of success in the marketplace. Many industry models of PLM are in use today. The one featured below is a compilation of the best and most widespread methods used with the necessary steps annotated. To start, PLM has three overarching stages:

Beginning of Life (BOL): The beginning of life phase includes all of the design and manufacturing, which consists of the initial conceptualization and development, and any prototypes built. Initial development has multiple sub-actions that identify all the requirements, concepts, and necessary testing. Regardless of the structure of production, the company must maintain the BOL stage. BOL is your product coming to life, along with its specifications, production process, and supply needs.

Middle of Life (MOL): The middle of life phase is post-manufacturing, when your product is distributed, used, and serviced. At this point, your product is in the hands of the end user. You can collect data on any failures, maintenance rates, and user experience to get information for immediate fixes and future development.

End of Life (EOL): The end of life phase is the retiring, recycling, or disposing of your product. At this point, the reverse logistics happen for the company. EOL starts when users no longer have a need for the product. At this stage, companies collect information about what parts and materials are still valuable.

The New Product Development Process and Product Life Cycle Management

When you use the tenets of PLM in new product development (NPD), there are better chances of success for the product. PLM allows for sharing the data with the various processes and actors for quicker reaction time and more collaboration. In turn, this leads to shorter cycles and products that are more successful.

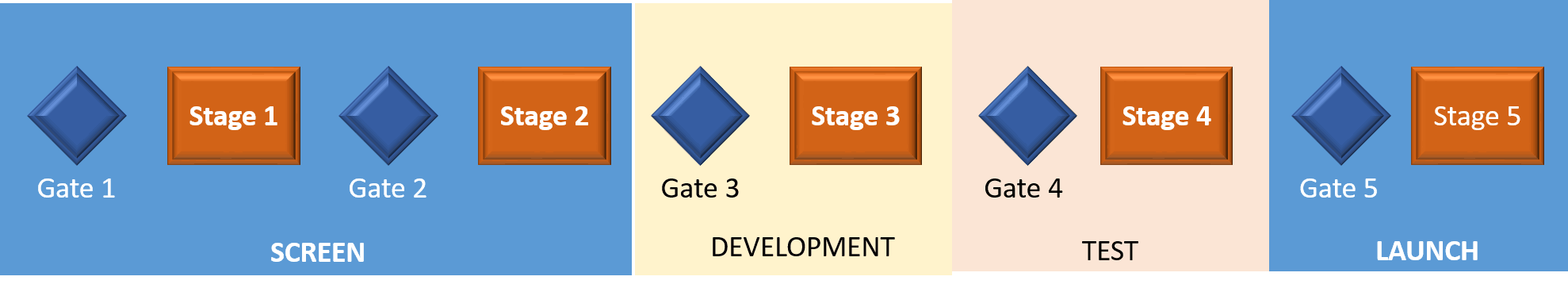

The NPD process follows the stage-gate model, which is the process of developing new products in a funnel system. After each stage of the development process is complete, the product is passed through a management-approved gate before it can go onto the next stage. NPD passes through the four main phases of screen, development, test, and launch. You can repeat a stage multiple times based on the needs of the product in development. Using a PLM overview allows for accelerated innovation and increases the accuracy of these stage-gate decisions because it ensures managers have all of the information available regardless of its point of origin.

NPD goes from the earliest product stages through distribution in PLM.

To set the right price for your new products, you must consider the total costs of your product and what your customers will pay for your product’s level of quality. Companies use a variety of costing methods. You can and should develop profiles on your products with their costs over their life cycles to determine the best prices for your new products. These take into account all the costs associated with:

- Design

- Production

- Distribution

- Service

- Use

- Recycling or disposal

Target costing is another way to set your prices, and helps you set the life cycle cost. You subtract your desirable profit margin from the competitive market price, taking into account all of the possible cost reductions. These selling prices and the profit needs are set during the development stage, giving you the target cost. From this target cost, you develop your product around it. According to many experts, companies today still struggle with target costing.

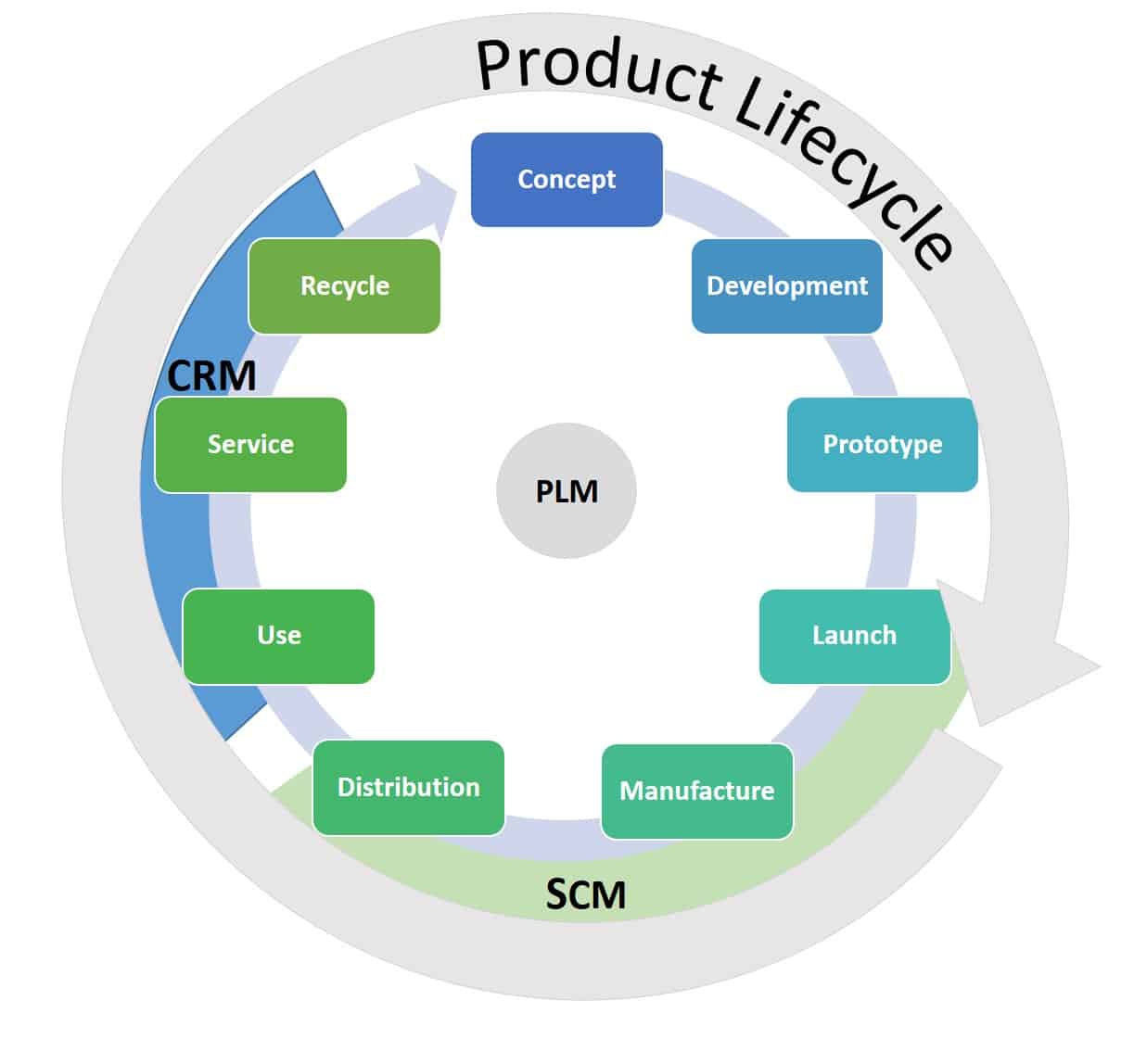

Supply Chain Management, Customer Relationship Management, and Product Life Cycle Management

Supply chain management (SCM) is the administration of the workflow that takes raw materials and parts from the supplier to the manufacturer, then to the wholesaler, onto to the retailer, and finally to the customer. All of the materials, information, and monetary resources are part of SCM. In PLM, SCM is everything from the launch through the distribution, which includes manufacturing.

Customer relationship management (CRM) is the oversight of current and prospective customers, their interactions with your company, and data about them and their purchases. CRM helps you look at the big picture between customer and product. In PLM, CRM is everything after the customer buys the product through the retiring or recycling of that product. There is also a life cycle associated with customers, called the customer life cycle, that enables you to identify critical points in the PLC where there are opportunities to supply your known customers’ needs. This lifecycle is the steps that a customer goes through with your company: considering a purchase, purchasing, using the product, and maintaining loyalty to your product or service.

All three systems of SCM, CRM, and PLM have overlap. In theory, running SCM and CRM through PLM should drive up profits and drive down extraneous costs because the enterprise becomes cohesive. This is enterprise management, not just processes management. Businesses that manage all of their processes cohesively and have access to all of the information regarding a product, who is buying it, and what happens to the product once produced have the advantage of agility over the competition. Further, with increasing requirements for regulation and sustainability, having all the information allows your company to have a clear picture of the “cradle to grave” for their products.

Lean Business Process Management for Product Life Cycle Management

Many businesses use a combination of Lean and business process management (BPM) for the analysis and improvement of their business processes. BPM defines how to use Lean when they are combined. Lean principles address the root causes of business problems, looking for efficiencies while BPM addresses the business processes. Together, they bridge the gap between the overarching strategies and the day-to-day operations. Lean BPM works in every stage of the PLM process, putting continuous improvement in the forefront of every stage. However, Lean BPM is best used in the manufacturing and delivery of the products because the process helps management see the risks, timelines, and progress regardless of where they are in the world.

Integrating with Product Life Cycle Management

Five main areas integrate into PLM. Depending on the field that you fall into, PLM can be a regular part of your workflow, or an unknown entity that you are discovering can help with your current work. These five areas include:

- Systems Engineering (SE): SE is the overall view and management of a system from the design through its use, management, and retirement. SE can include people, hardware, software, and information. This area also includes reliability engineering that is specifically focused on the reliability within the life cycle of a product.

- Product Portfolio Management (PPM): PPM is the overall management of the portfolio of products, and ensures that you align your product strategies with your business strategies, and that you allocate your resources properly based on project progress.

- Product Design (Cax): This uses computer-aided technologies to create new products for your customer base.

- Manufacturing Process Management (MPM): This defines how you make your products so that you can develop your production processes to be more agile and efficient.

- Product Data Management (PDM): Mostly within PLM, PDM is the management of product data. Version control of documents is one function of PDM.

The Best Practices, Benefits, and Challenges of Product Life Cycle Management

Following best practice when you implement PLM can save you time during deployment and ensure that your company is following a standard practice for the best possible outcome. Since PLM is a business process transformation, it is critical to understand your company. The following are best practices recommended by experts to keep in mind while implementing PLM.

- Focus on your customer

- Define what success in PLM looks like for your company

- Use tried and true methodologies

- Define roadmaps to follow

- Perform risk assessment and management

- Execute exception management

- Integrate your software systems

- Take on new products that have clear targets

- Focus on product quality

- Concentrate on lowering your product costs

- Create an enterprise-wide framework

- Link your framework to your priorities

- Use PLM as an investment-planning tool

- Assign a group who owns your PLM

- Establish annual revenue standards

- Establish product packaging and structure taxonomy standards

- Develop an end-of-life process for your products

The critical benefits of PLM center on your time, costs, and product quality. The benefits will differ for each company, so you should understand what benefits PLM has for your organization. The following are a list of possible benefits:

- Increased revenue

- Reduced costs

- Speed time to market

- Improved product quality

- Maximized product value over product’s life cycle

- Decreased compliance risks

- Driving innovation

- Single source of alignment and accountability

However, anytime you implement a new system, set of theories, or software package there are bound to be problems. These challenges may include:

- Product specification changes are difficult to keep records up to date

- Disconnect between manufacturing and operations joining in the PLM process

- Supply chain is mismanaged

- Difficulty tracking metrics for PLM

- Training takes too much time

- Different sources for specifications and vendor information

- Poor product portfolio management

- Obstacles to sustainable packaging

How to Measure and Evaluate Your Product Life Cycle Management Program

If you are uncertain whether your PLM implementation is going successfully, you should look for the following signs. These mean that you need to slow your implementation down, reevaluate, and take more care with it:

- There are too many non-value add tasks

- Your staff resumes some of their old practices

- Not all of the decisions are unanimous

- Everything seems like it is urgent

- Everyone is making decisions - there are no gates

- You have bad data

You can measure and evaluate the effectiveness of your PLM program by looking at the following metrics and the relative changes after implementation:

- Innovation: The total sales or revenue coming from new products.

- Lead Time: The time from order to delivery.

- Cycle Time: The time from production start to completion (including any testing).

- Product Life: The length of time the product is usable by the customer.

- Product Waste: The amount of waste per product produced.

- Product Reliability: The amount of your product found to be flawed or faulty within a period.

- Warranty Claims: The number of warranty claims per products sold.

- The Accuracy of Provisioning: How accurately you determine the need for parts.

- Customer Feedback: The amount of customer input given in the development process.

The Product Life Cycle Management Industry

Depending on which expert you ask, the PLM market is between 25 and 30 billion dollars per year, with about a 10 percent growth rate. Many companies are making huge investments in the PLM business process, at times five to 25 percent of their revenue. According to some analysts though, almost half of this spending within PLM ends up squandered on products that miss the market trends.

Many people, particularly vendors, define PLM strictly as a software package that guides your company’s products. Most vendors and consultants say that PLM is best to implement while also implementing a PLM software package. The reasoning behind this is that the quality of your data is assured with the software, so that you can implement efficiencies and better product quality.

Right now, vendors of PLM software are focusing on several things. These include:

- Integrating their platforms to include CAD, CAM, CAE tools so that you can truly go from concept through the PLM cycle. This process of integration is accelerating with the availability of the tools in the software.

- Industry 4.0 is reshaping manufacturing technologies. Industry 4.0 includes cyber-physical systems, IoT, and the transition to cloud computing.

- Vendors are specializing in specific industries.

- Systems engineering approaches are pushing for better integration between enterprise-level applications such as PLM, CRM, and SCM.

There are many vendors of PLM software in the marketplace right now. The biggest ones (and the rankings change regularly) are Autodesk, Dassault Systèmes, PTC, and Siemens. Siemens offers Teamcenter, a suite of PLM software that was originally made by the UGS Corporation. It is one of the leading products on the market; it has received many awards and has communities devoted to it.

Experts recommend, however, that if you are choosing a vendor that you start with your business strategy, and leverage best practices and decision-making frameworks. Before you get the vendors into your business for product demos, you need to figure out what you want from your software, and what role it will play in your organization now and in the future. You will have a better return on investment (ROI) if you consider current projects and future projects. The ROI on PLM software increases with each successive project because your company learns how to leverage it. You should be evaluating the software, the servicing of the software, the vendor, any specialized industry needs that you have, and lastly the size of your company.

After you consider your company needs, you need to determine how the vendors work with their customers and if their approach is right for you. Some vendors stress implementation with your current software, while others stress the full adoption of their software without regard to existing packages you may use. Some vendors train your staff, and some just send you the software or give you the access code to download it. Your choice in vendor may vary based upon your service requirements, and if you have the technical resources and PLM experience in-house. Further, this varies based upon whether you need the infrastructure such as servers and operating systems provided as well. Be sure to consider your support requirements. Some vendors can support a migration and some cannot. It is critical to your success that you know the vendor that you choose can assist your company in the areas that you need.

Lastly, you need to determine if your vendor is financially sound and ingrained in the market. Some vendors do not specialize in PLM but offer PLM products. Their main investments may be other products, which does not bode well for future support and possible upgrades to your expensive investment.

PLM consultants are another matter entirely. PLM consultants analyze your business strategy, its current processes, and any industry-benchmarked processes to develop a roadmap for you. This roadmap helps you choose a software system and implement it. Some PLM consultants only work with specific software systems and implementation methodologies, and some are more innovative.

Some experts say that the future of PLM consultancy is crowdsourcing, that your future PLM consultant is hundreds or even thousands of PLM specialists and data analysis of what works for them. However, until this disruptive technology has a stronger foothold, you should consider if you need to hire a consultant. To start your thinking, ask the following questions:

- Are there other documented use cases that are similar to yours?

- What software environment do you use? Do you need to integrate multiple platforms?

- How long has the software that you are considering been available?

- Is cloud PLM a realistic option for your company, or do you need to have onsite storage?

- How much software training will your staff realistically need?

What Is Product Life Cycle Management Software?

Product lifecycle management software is a solution that businesses use to manage all aspects and processes involved in the PLC. While you don’t necessarily need PLM software, having one centralized tool can improve efficiency in managing concepts, workflows, and processes.

PLM software is the information management system that allows you to assimilate all the data, systems, processes, workflows, and people using it in your company. PLM software specializes in the life cycle of your products, from conception to retirement. PLM software can also consolidate your disparate systems, taking your global company to a single team. Further, the software provides all of the information available to make decisions based on real-time information at every stage of your products’ lifecycles. Some of the technology that a PLM software system can integrate includes:

- Manufacturing operations

- CAD

- CAE

- PDM

- Predictive engineering analytics

- Testing and analysis

- Computer-aided manufacturing

- Finite element analysis

The tools needed to accomplish PLM objectives can be diverse. Many software packages, however, have user-specific roles that you can set for different interfaces. Some of the designs that the software systems may be set up for include:

Concurrent Engineering Workflow Design: This performs tasks in parallel instead of sequentially, which cuts down on lead-time and improves your speed to market. It also improves the communication between your departments and acts to prevent rather than solve problems.

Bottom-Up Design: This is CAD-centric design, and starts with the individual parts of the product. These parts are brought together to show you what your product will look like at the different levels of development, and helps you generate and maintain the bill of materials for each product. Bottom-up design is best at coming up with real solutions with current technology and materials.

Top-Down Design: This type of design focuses on the high-level requirements of your products. It looks for the most valuable thing your product can do. It is not very focused on the current technology to implement this design. Sometimes with top-down design, you get a decreased performance and too much abstraction as a trade for the best solution.

Both Ends Against the Middle Design: This type of design refers to combining the best of both worlds of top-down and bottom-up design. The focus here is starting at both ends of the design process: from the solution requirements and from the available technology. This design is considered the best of both worlds, and very powerful for development.

Front Loading Design and Workflow: This is top-down design further on down the line, often called pre-project planning. You gather all of your downstream design and data before you define your product or get management approval. Front loading design and workflow is a strategic way to perform design, and typically has a stage-gate process associated with it.

Design in Context: This is designing while not being in isolation but in the middle of the situation. This method uses assembly modeling techniques, interactive systems, and designs concurrently with other parts and products. Design in Context may be done in the circumstances or setting that the product or part may be in, too.

Which software features are important to you? When choosing software for PLM, consider not only how your business runs today, but also how you want your business to run in the future. Here, you can find some of the PLM software features and functions to look for in your software.

- Documentation management

- Bill of material records

- Electronic file repository

- Part and document metadata

- Environmental compliance tracking

- Task assignment to team members

- Workflow and process management

- Secure multi-user access controls

- Integrated, web-based platform

- Increased management oversight

- Services beyond software

- Integration with training programs

- Infrastructure

- Migration capacity

- Configurable for any size

- Available upgrades

- First mover advantage

- Collaboration, version control

- Cloud-based, multi-tenant

- Internal audit planning and reporting

- Visibility into CAPA

- Access to design history files (DHFS)

- Access to device master records (DMRS)

- Environmental compliance assurances

- Non-conforming materials reporting

- Supplier quality management

- Supply chain collaboration

- Product structure and reuse

- Engineering changes

- Stage-gate approvals

- Software configuration

- Quality testing for defects

- Product costing

- Project status reporting

- SKU count reduction

Other Life Cycles Related to Product Life Cycle Management

The following are other lifecycles and concepts that you may encounter in the literature, blogs, and possibly in conversation with other professionals. Some are intimately related to PLM, and some are more distant.

Product and Process Lifecycle Management

Product and Process Life Cycle Management (PPLM) is a part of regular PLM, but for regulated fields such as chemical and pharmaceutical manufacturing. In these industries, the agencies such as the Food and Drug Administration (FDA) tightly regulates the process for manufacturing using either industry specifications or product-specific specifications. These specifications are essentially a “recipe” for manufacturing and are documented each time at production. These requirements and documentation are in place to protect the public and to ensure the same results each time you manufacture the product.

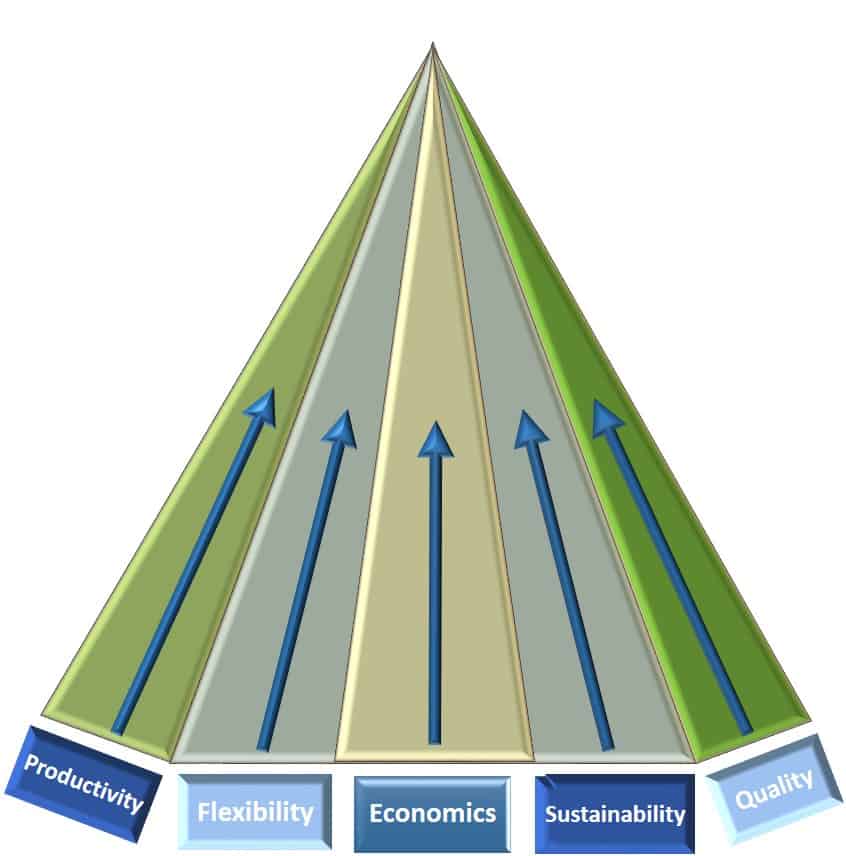

The Pyramid of Production Systems

According to Behnam Malakooti, there are five main objectives for production. These include productivity, cost, quality, flexibility, and sustainability. The best of all of these concepts gives the pinnacle of manufacturing. These are represented as a pyramid, with different combinations of objectives moving up the pyramid, the apex of the pyramid as the very best of these five, and the lowest of these five as the base. He says that the tip of this pyramid is not realistic.

Source: Behnam Malakooti

Industry Life Cycle Analysis

The industry life cycle analysis is a much higher-level PLC that is specific to each industry, though it looks a lot like the PLC. There are four similar stages: introduction, growth, maturity, and decline. However, the industry life cycle analysis has a stage before decline that is stability. Strategic planners use the industry life cycle analysis when they are considering investing in certain industries in the market to determine risk.

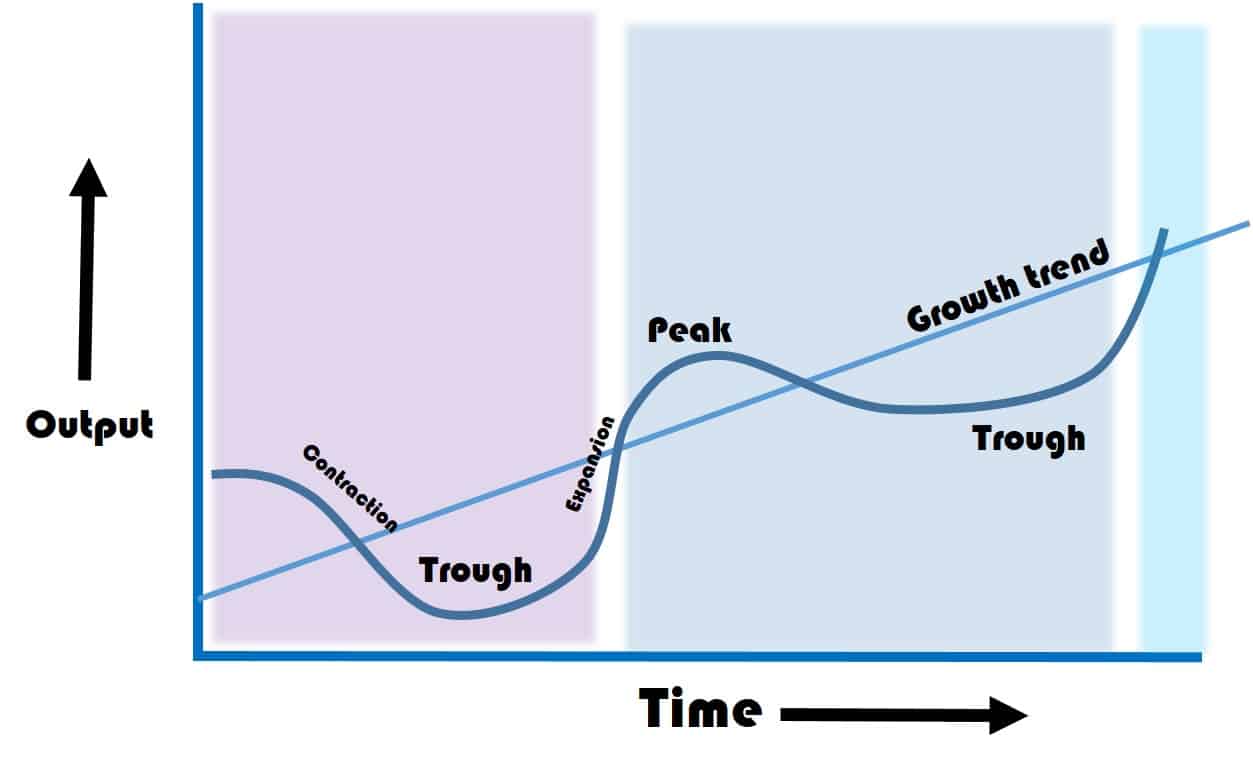

The Economic Cycle

The economic or business cycle is the up and down movement that an economy experiences over a period. One cycle is an expansion, peak, contraction, and trough. The peak is the top of the cycle, and the trough is the bottom. You measure the cycle from the peak to the trough. These cycles are not at regular intervals, but have identifiable signs. Economic cycles are similar to a product life cycle, but they are for the full economy and represent all of the products on the market.

The Accounting Cycle

The accounting cycle is internal to each company and starts when a transaction occurs in a time period. This cycle includes all the transactions in your financial statement for your period, and happen monthly, quarterly, and annually. The transactions include all your received invoices and sales. You start with your journal entries, and enter them into your general ledgers, which compiles your unadjusted trial ledger. At the end of the period, you adjust your entries. These corrections are normal and occur because of the progress of your business. Then, you prepare a trial balance and financial statements. You then close your period. Your closing entries put your company’s net income into retained earnings. Lastly, you prepare a closing trial balance to ensure that everything matches.

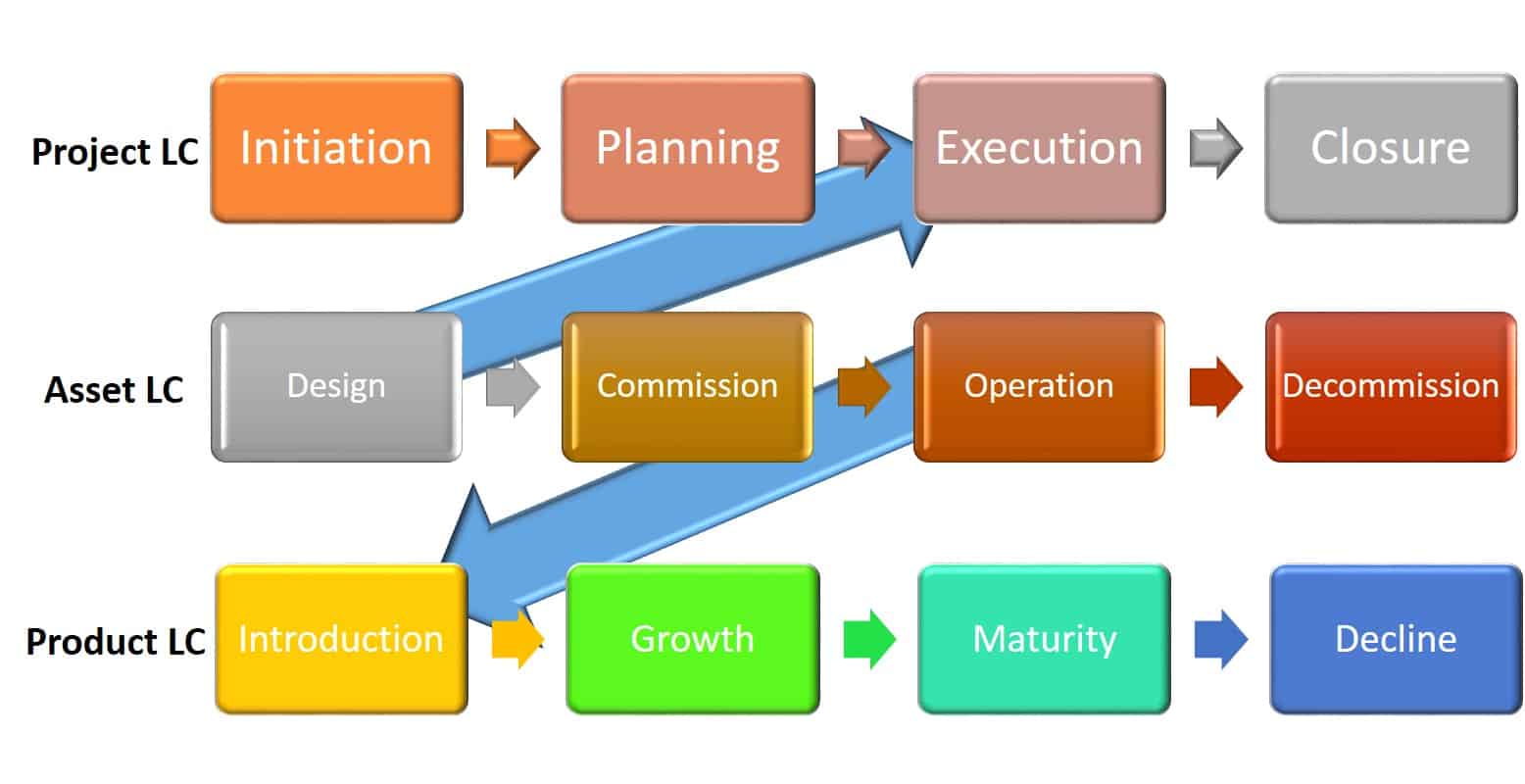

Manufacturing Industry Life Cycles

The manufacturing industry has several life cycles. These include the product life cycles that we have stressed in this guide, the asset life cycles, and the project life cycles.

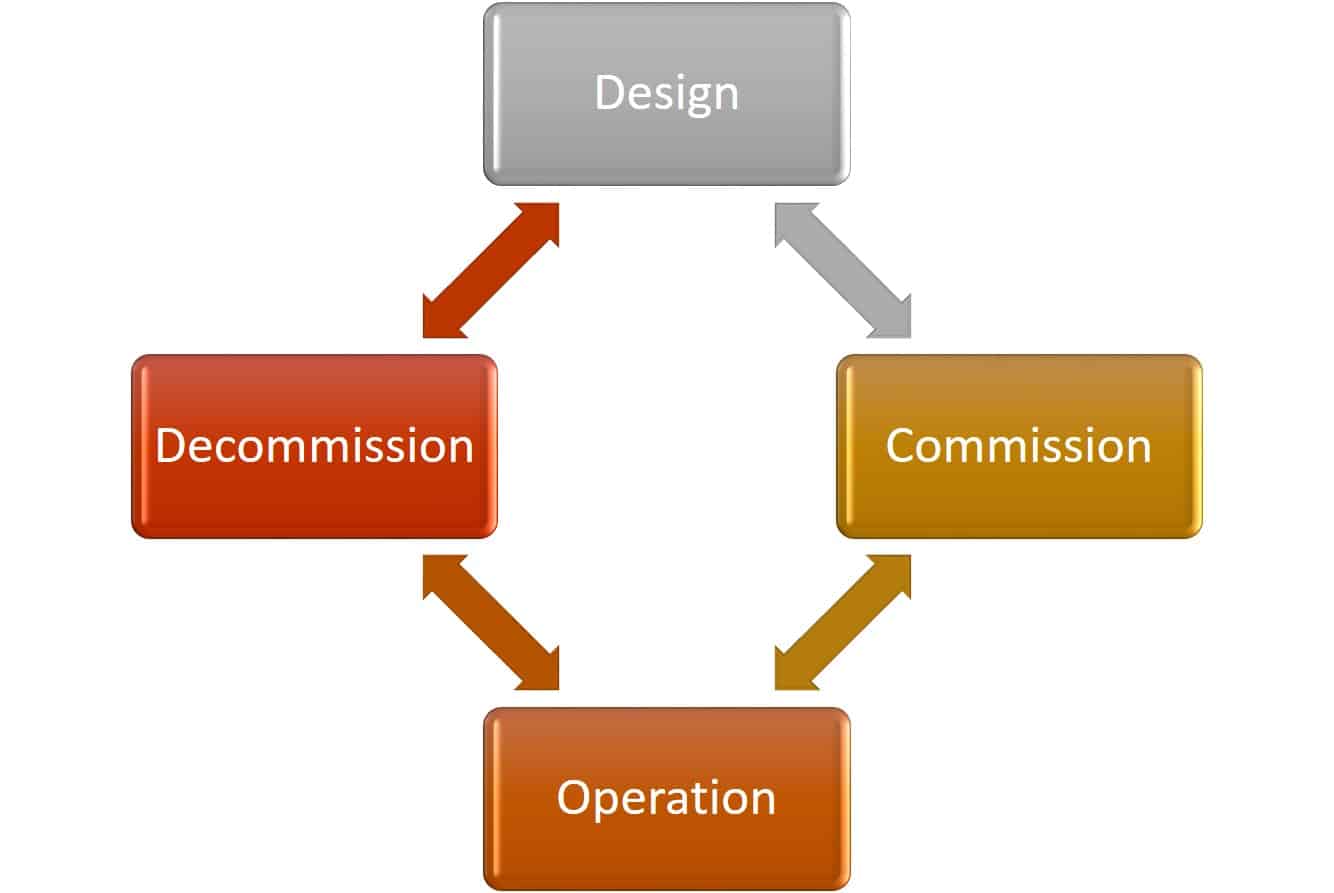

The Asset Lifecycle

Life cycle asset management is a part of the manufacturing environment because it takes into account the manufacturing infrastructure such as facilities and equipment. The main phases are design, commissioning of the designs, operation and maintenance, and decommissioning.

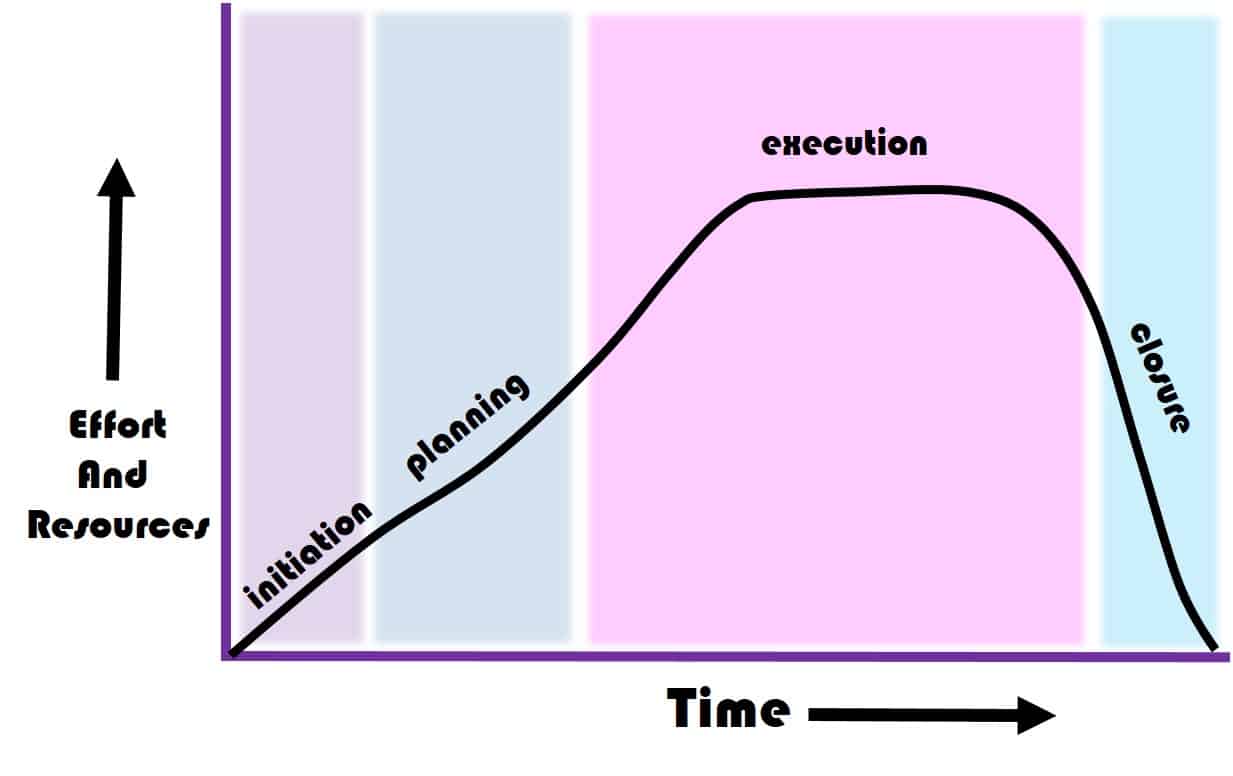

The Project Life Cycle

The project life cycle in a manufacturing environment is also more about the products you’re manufacturing, although you can apply it to any project. These are the drivers of internal change. The stages are initiation (which includes whether a product is feasible), planning (which includes development), execution (which includes testing), and closure (which is the launch and production illustration request (PIR)).

Integrating the Manufacturing Life Cycles

It is important to know where these life cycles integrate. Their successful integration is critical for success in manufacturing. For the project life cycle and the asset life cycle, the integration point is during the project execution and during the asset design. For the asset life cycle and the PLC, the integration point is during the asset operation and the PLC cycle’s beginning. These integration points are important to getting your company used to addressing the other cycles concurrently.

How Can You use Product Life Cycle Management to Improve Your Business?

PLM is most effective when all team members use it consistently. Your PLM system should allow you to manage multiple product phases and gain visibility into your workflows, so you can identify areas for improvement.

The PLM process is most efficient when you have it centrally coordinated across your systems. Because most businesses have many highly skilled people, too many processes may not add value or may even be redundant. PLM gives you countless opportunities to work together to improve this substantially.

Experts in Product Life Cycle Management

Here our experts weigh in on PLM: its current status, how they see it developing in this world with IoT front and center, and any tips that they have.

The future of PLM is to bring the post-sale operational details into the fold. Especially with the introduction of IoT, baselines of operating standards have to be included in order to understand the performance of the product. PLM would finally close the loop between design, development, and operational maintenance. This analysis of the usage of the products would help in improving features and redesigning systems that customers use the most. There are three main use cases that will extend PLM beyond what it is today are:

- Product Monitoring

- Product Performance

- Product Maintenance (Proactive and Reactive)

PLM benefits tremendously with the advent of IoT. PLM should include the additional software, electrical, and mechanical components of an IoT system. PLM technologies also need to integrate with the big data analytics and IoT platforms to consume data returning from sensors. PLM software should also look into extending it to the post-sale process where maintenance and service of products are key to bringing in additional revenue both in terms of service contracts as well as to create better products based on feedback.

In the future, total connectivity will involve sensors and a variety of data-capturing features integrated into the products. I predict smarter software, and disruption in the spheres of product design, engineering, and manufacturing cycles. Lastly, I see the future incorporation of Agile, Lean methodologies that are currently employed by modern software developers.

My tips for other professionals are that you should ensure technology compatibility before moving forward with PLM. From my experience, this is the most important step. With complex enterprise deployments, a company must manage a multitude of components in the technology stack: servers, firewalls, operating systems, databases, and various PLM software modules. Technology incompatibilities and complexities among any of these elements can turn an implementation into a nightmare.

Efficiently Manage and Monitor the Product Life Cycle with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.